Water cooling electric machine for vehicle

A water cooling and vehicle technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of large volume and poor heat dissipation effect, and achieve the effect of strengthening cooling effect, small thermal resistance and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

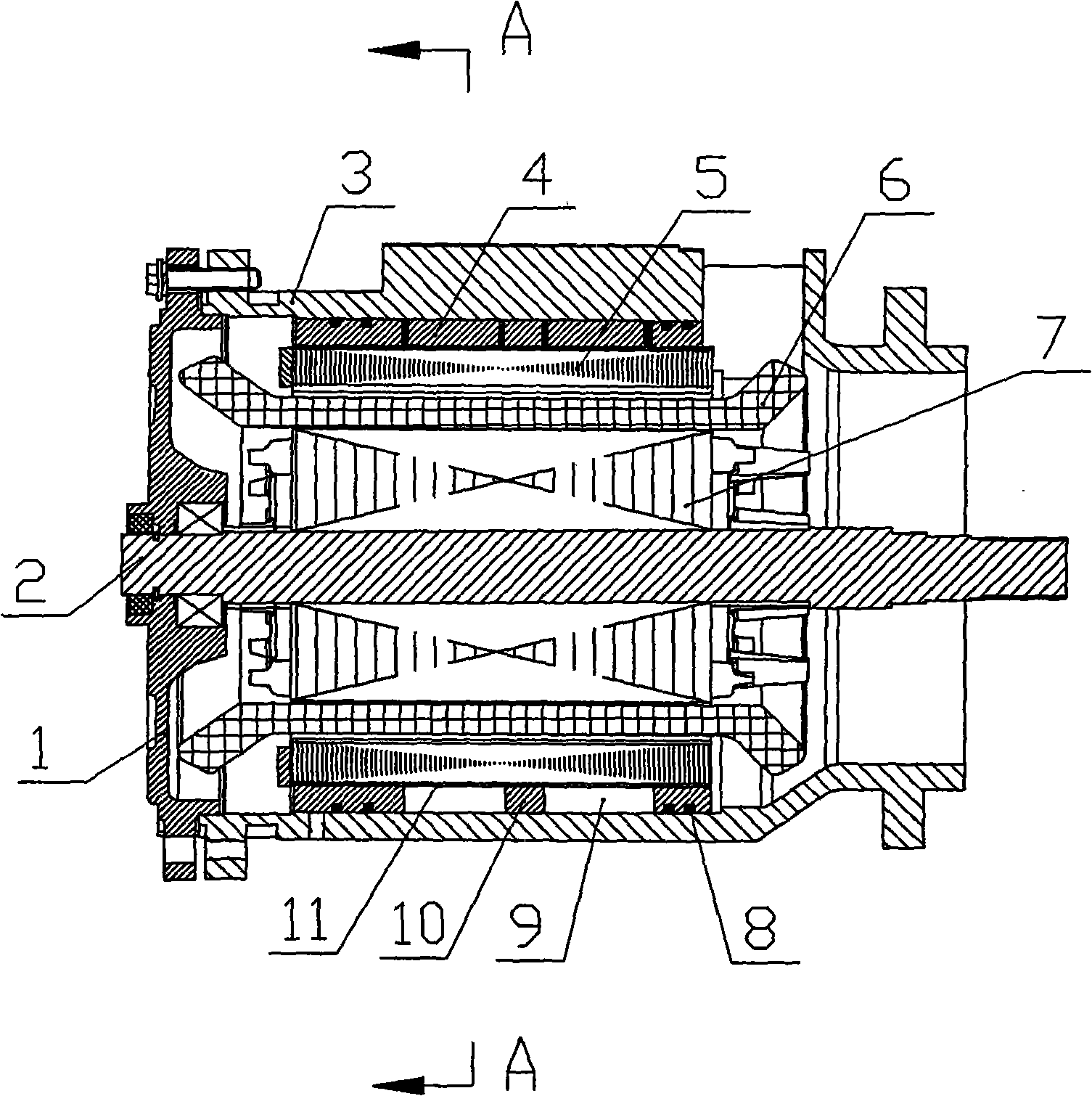

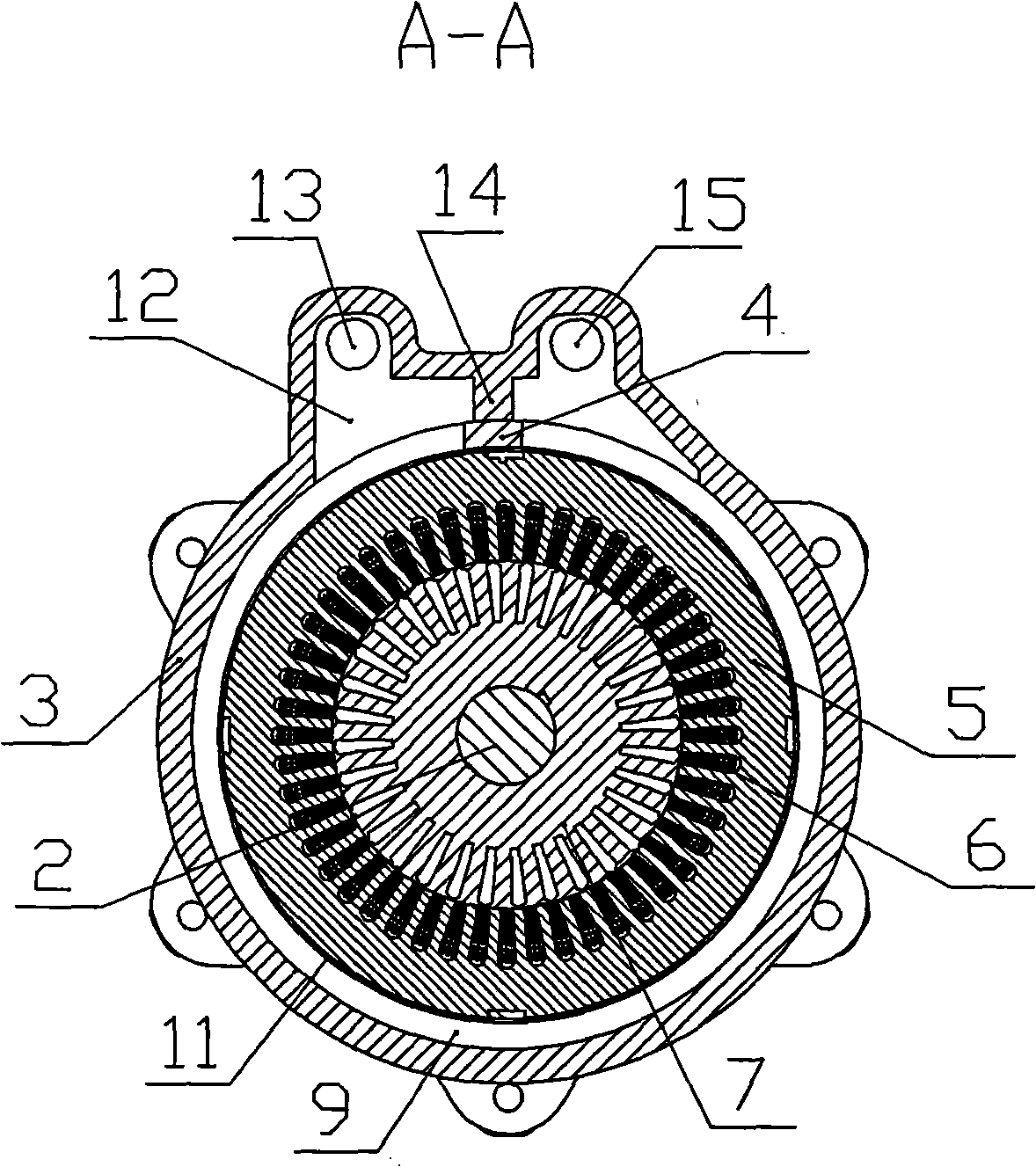

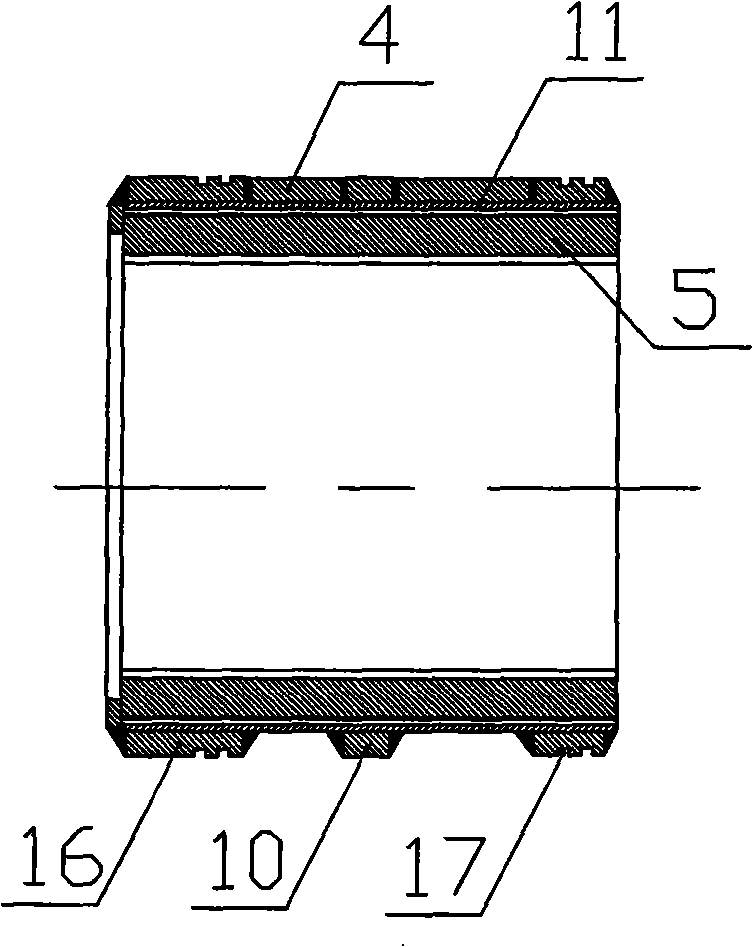

[0023] Such as Figure 1 to Figure 4 Shown is the first embodiment of the present invention. It mainly includes end cover 1, motor shaft 2, motor casing 3, axial partition 4, stator core 5, stator winding 6, rotor 7, sealing ring 8, cooling water cavity 9, circumferential hoop 10, circumferential water tank 11. Water collection cavity 12, water inlet 13, longitudinal rib 14, water outlet 15, side plate 16 and sealing groove 17, etc.

[0024] In the present invention, the motor shaft 2 is arranged in the motor casing 3, and the rotor 7 is installed on the motor shaft 2, and the rotor 7 is composed of a rotor iron core and a rotor winding. The stator composed of stator winding 6 and stator core 5 is installed outside the rotor 7, and the end cover 1 is installed at the end of the motor casing 3, and a cooling water cavity 9 is arranged between the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com