Patents

Literature

31results about How to "Small sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

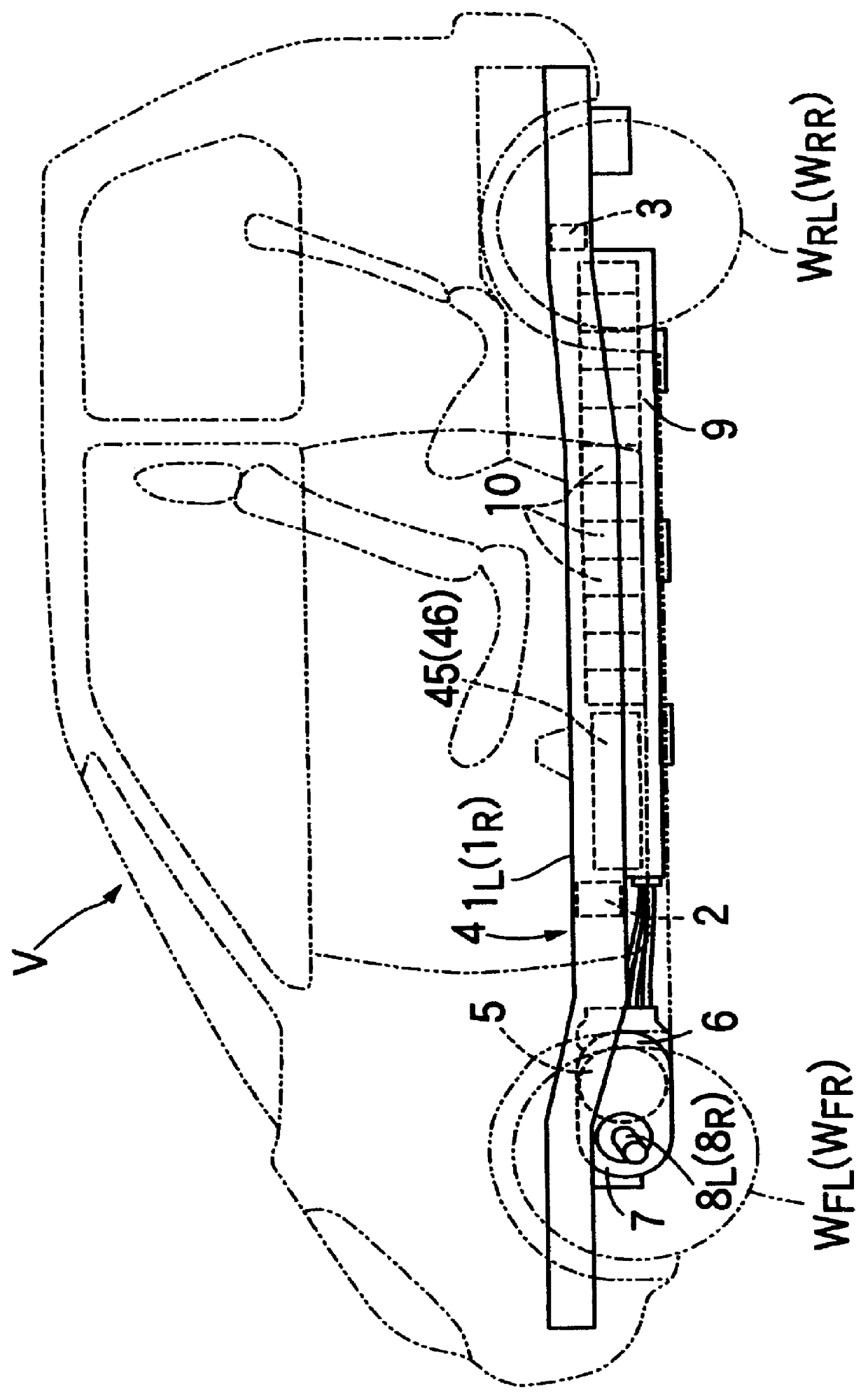

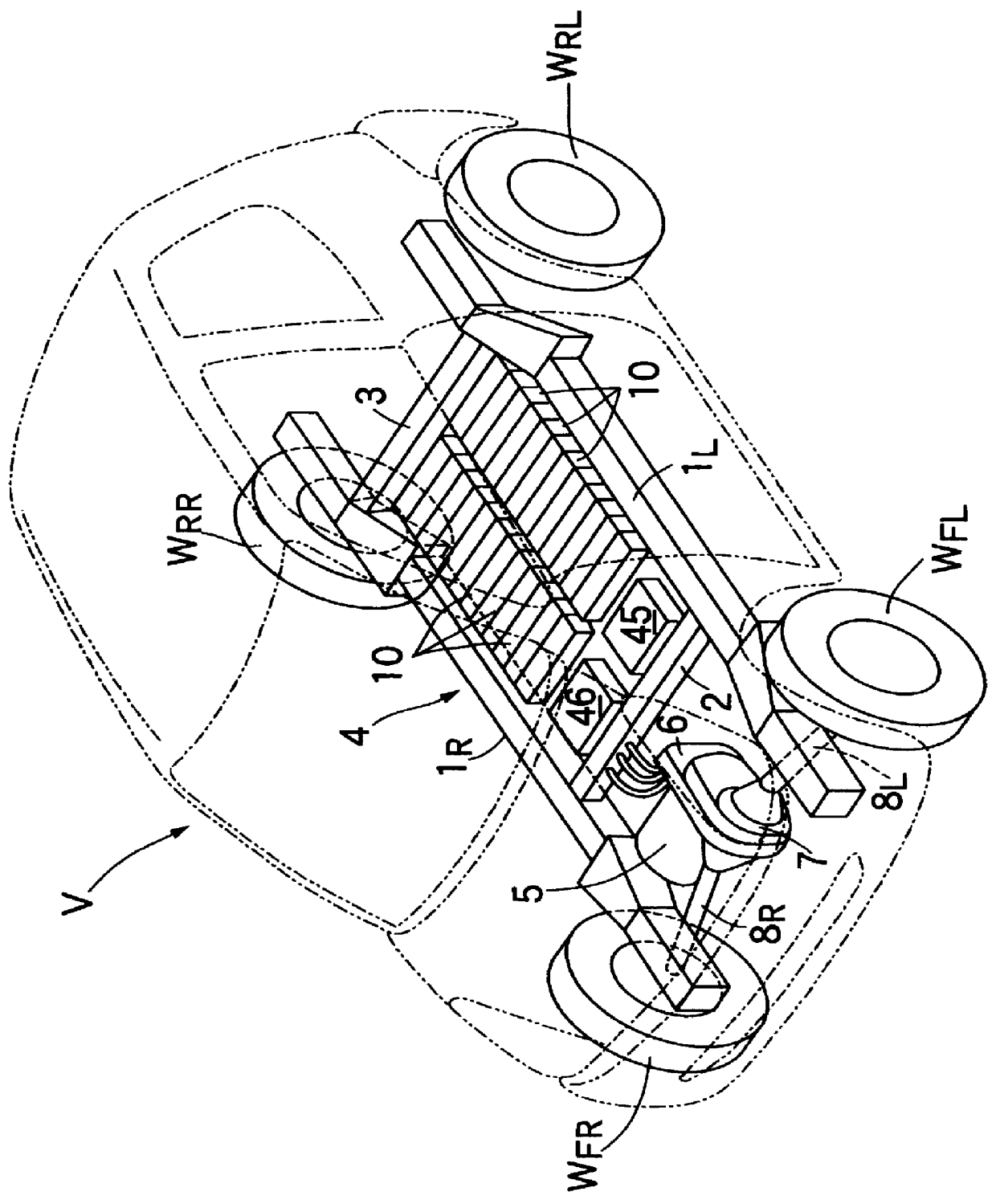

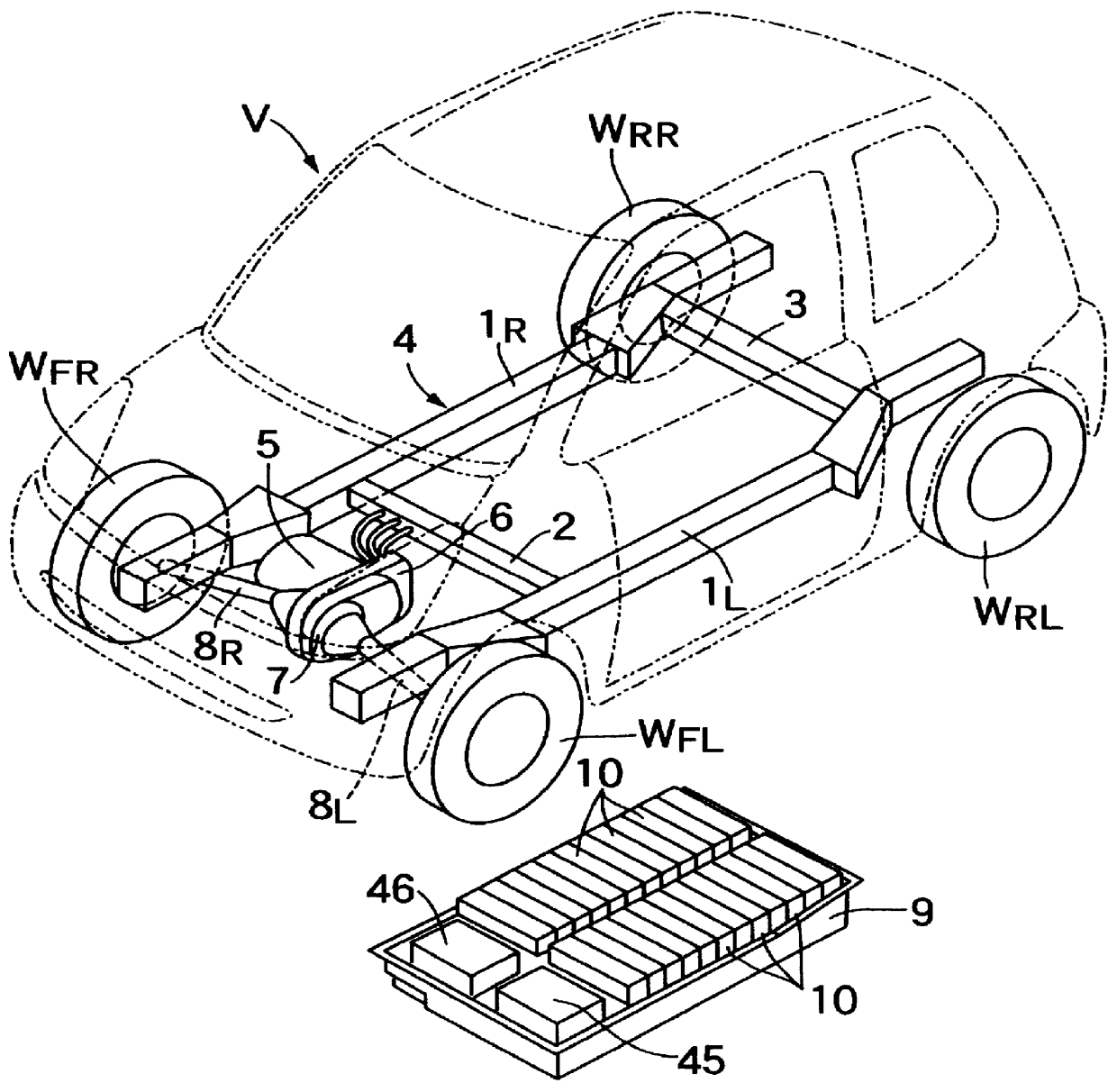

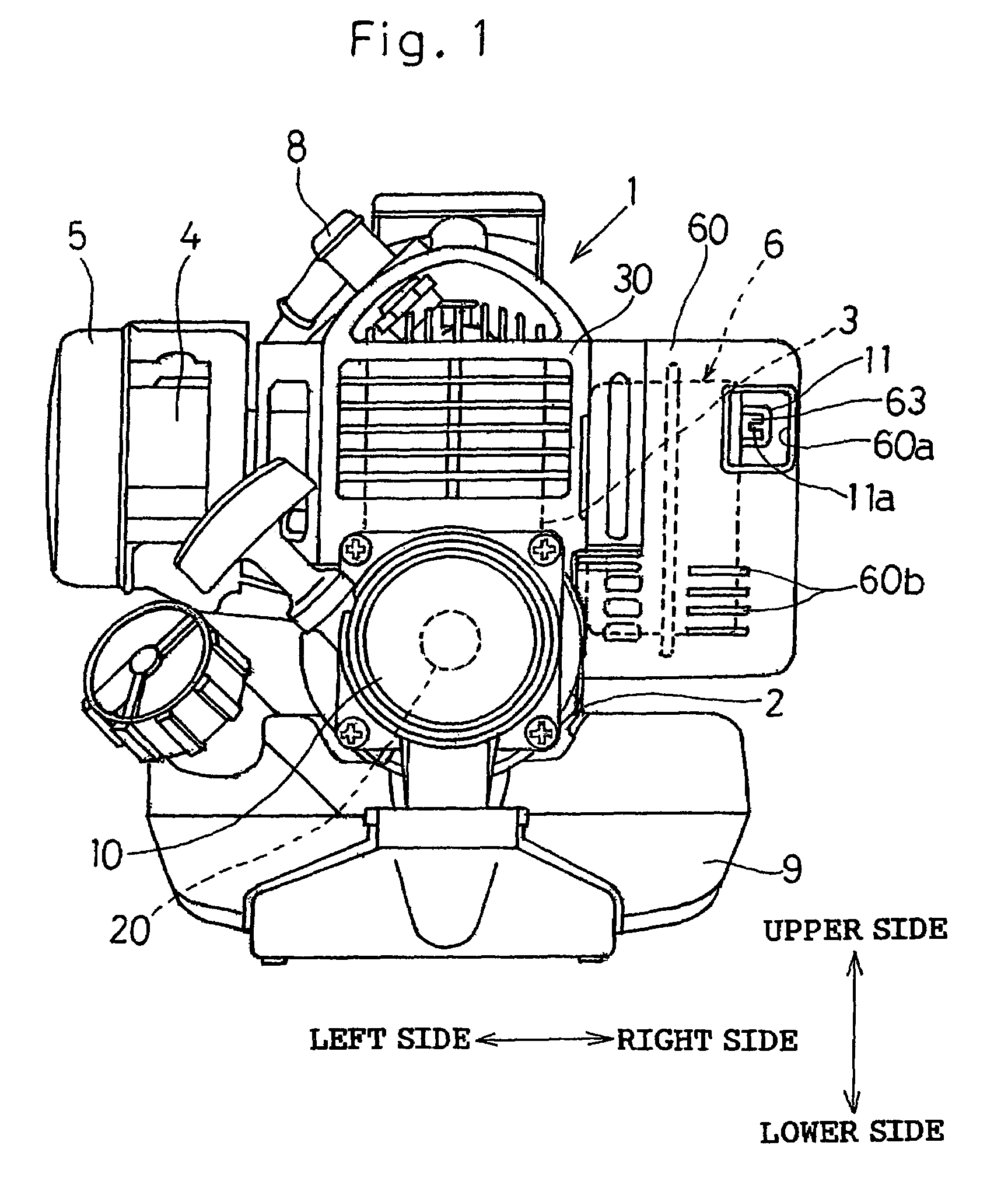

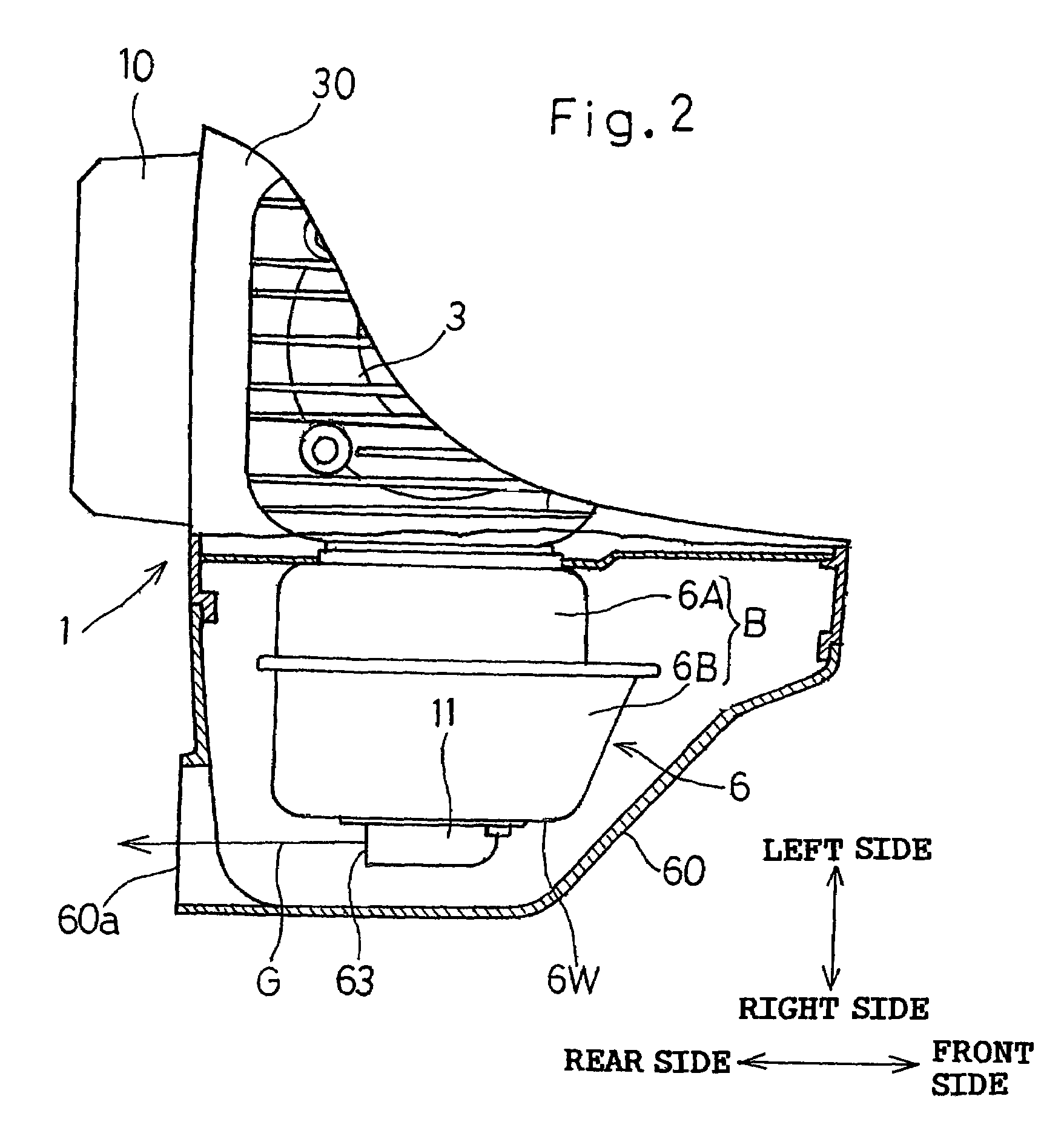

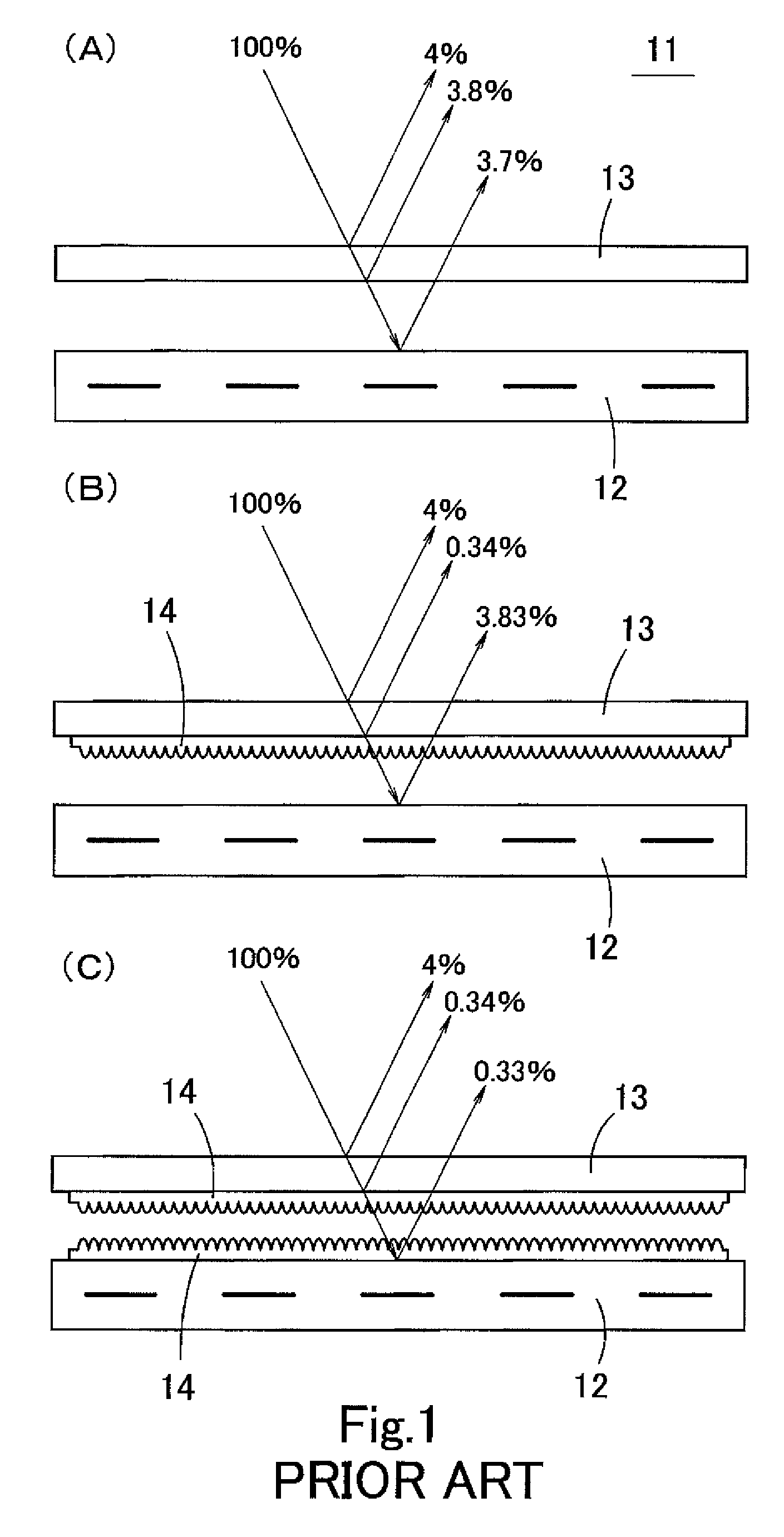

Cooling structure an electric vehicle

InactiveUS6094927AReliable coolingImprove cooling effectDomestic cooling apparatusLighting and heating apparatusAirflowThermal resistance

An electric vehicle includes plurality of batteries accommodated in a rear portion of a battery box, and an electric part is accommodated in an electric part accommodating chamber provided in a front portion of the battery box. Cooling air supplied from a cooling fan to the rear portion of the battery box cools the batteries having a large thermal resistance, while being passed through a first cooling air passage around outer peripheries of the batteries at a low flow rate. A second cooling air passage having a smaller sectional area than that of the first cooling air passage is provided below the electric part accommodating chamber, and cooling fins protruding downwards from the electric part are exposed within the second cooling air passage. The second cooling air passage extends continuously the first cooling air passage in a downstream direction of airflow, so that cooling air which has first cooled the batteries then cools the electric part having a smaller thermal resistance, while being passed through the second cooling air passage at a higher flow rate than that in the first cooling air passage.

Owner:HONDA MOTOR CO LTD

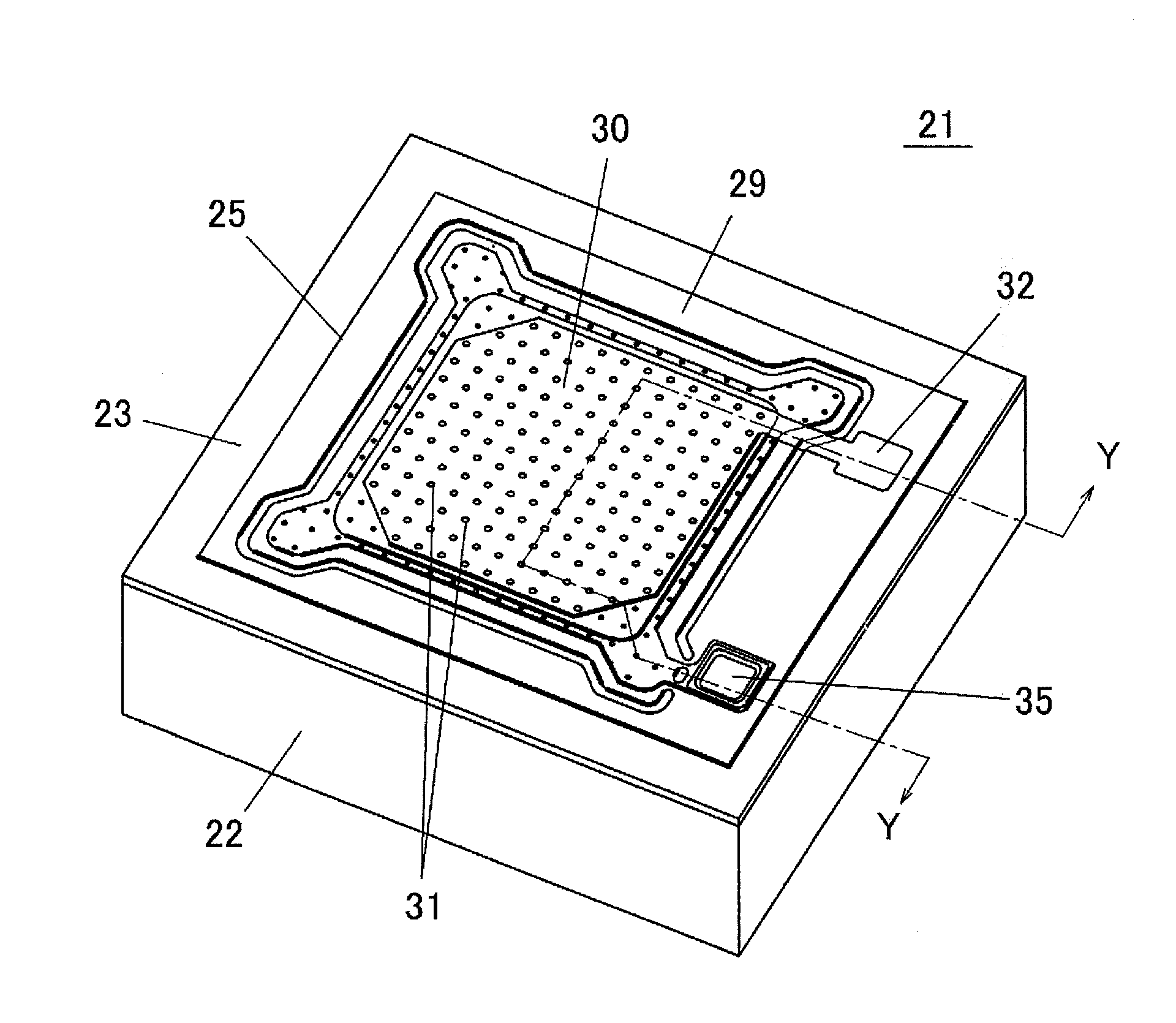

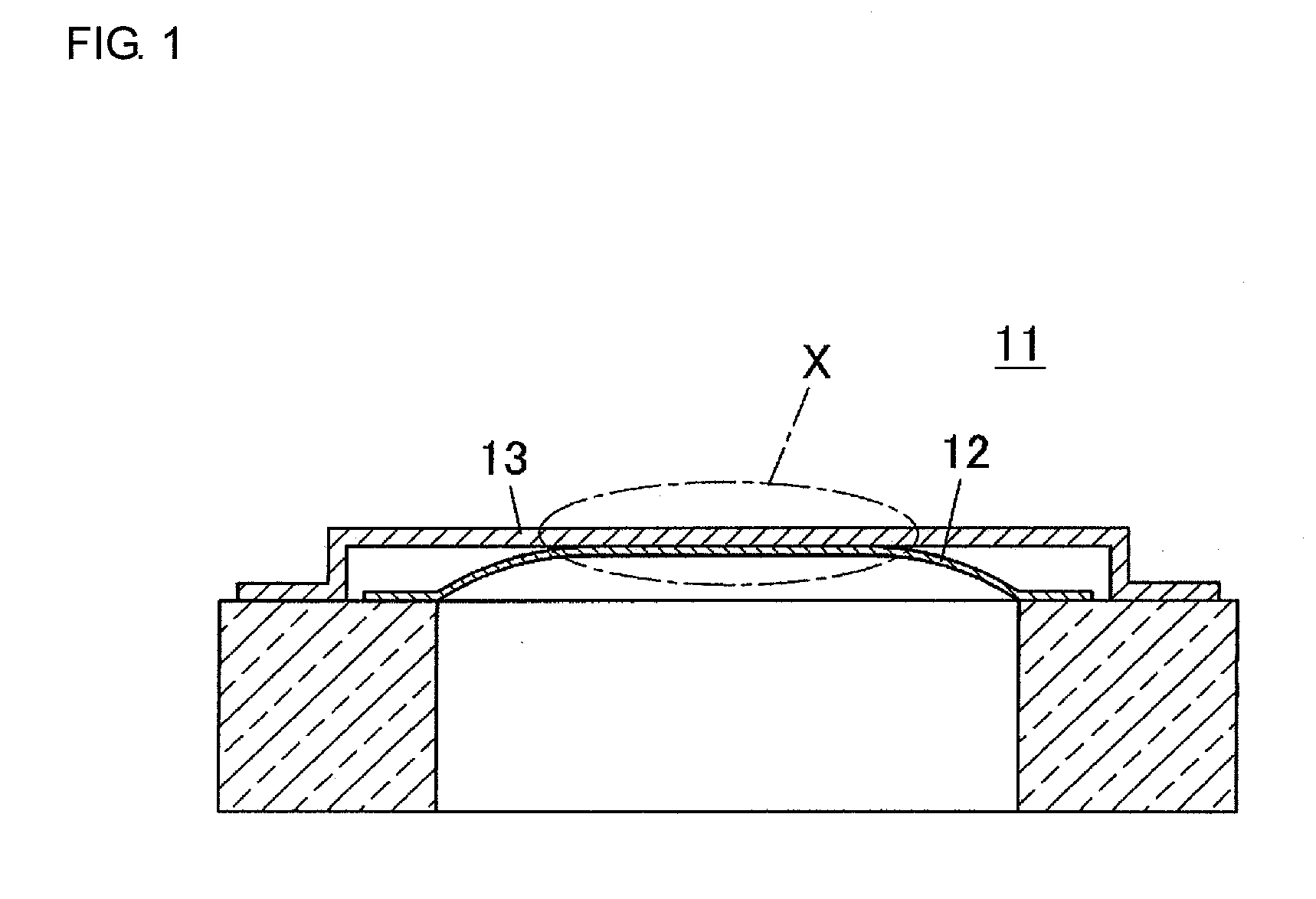

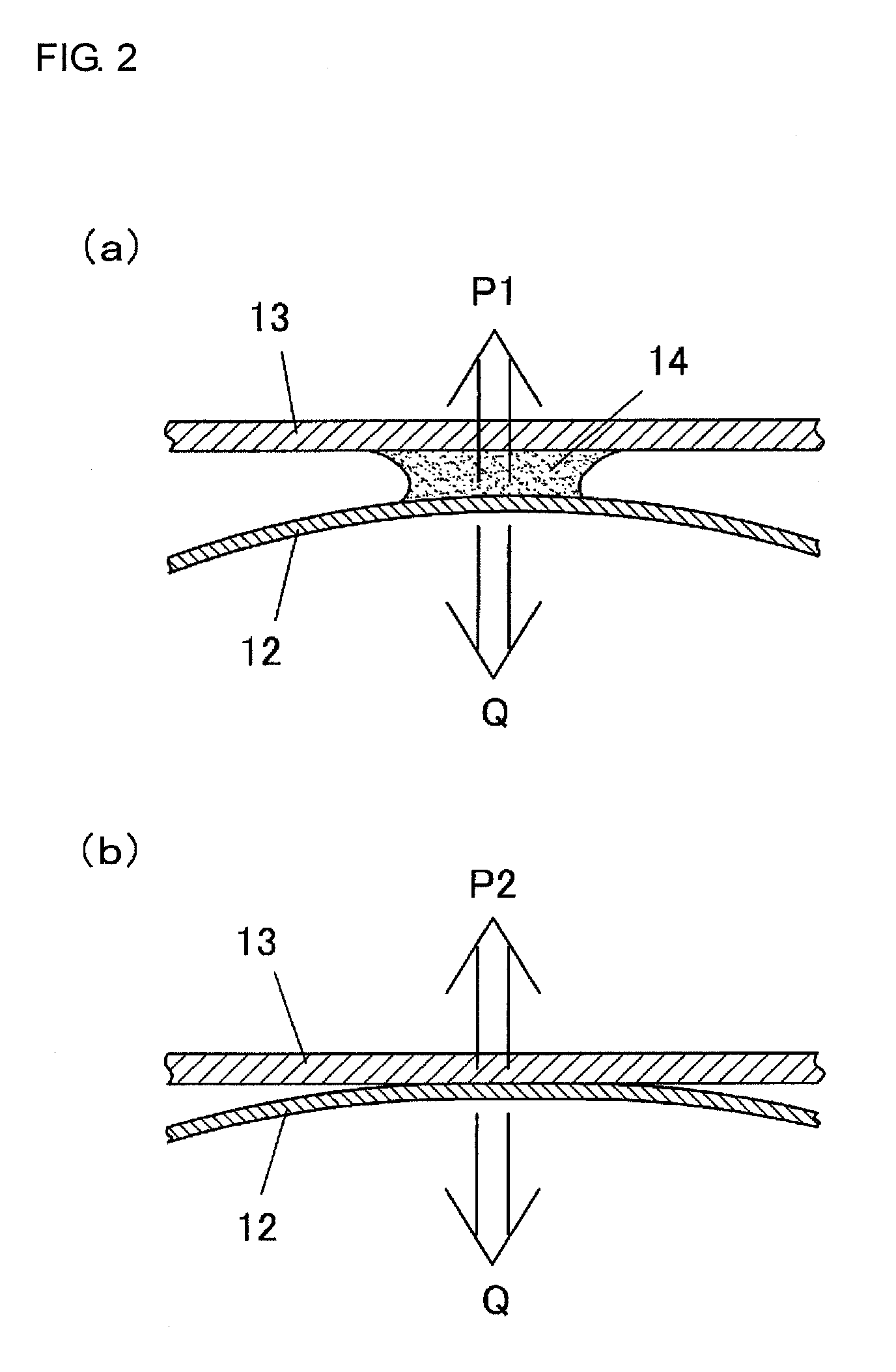

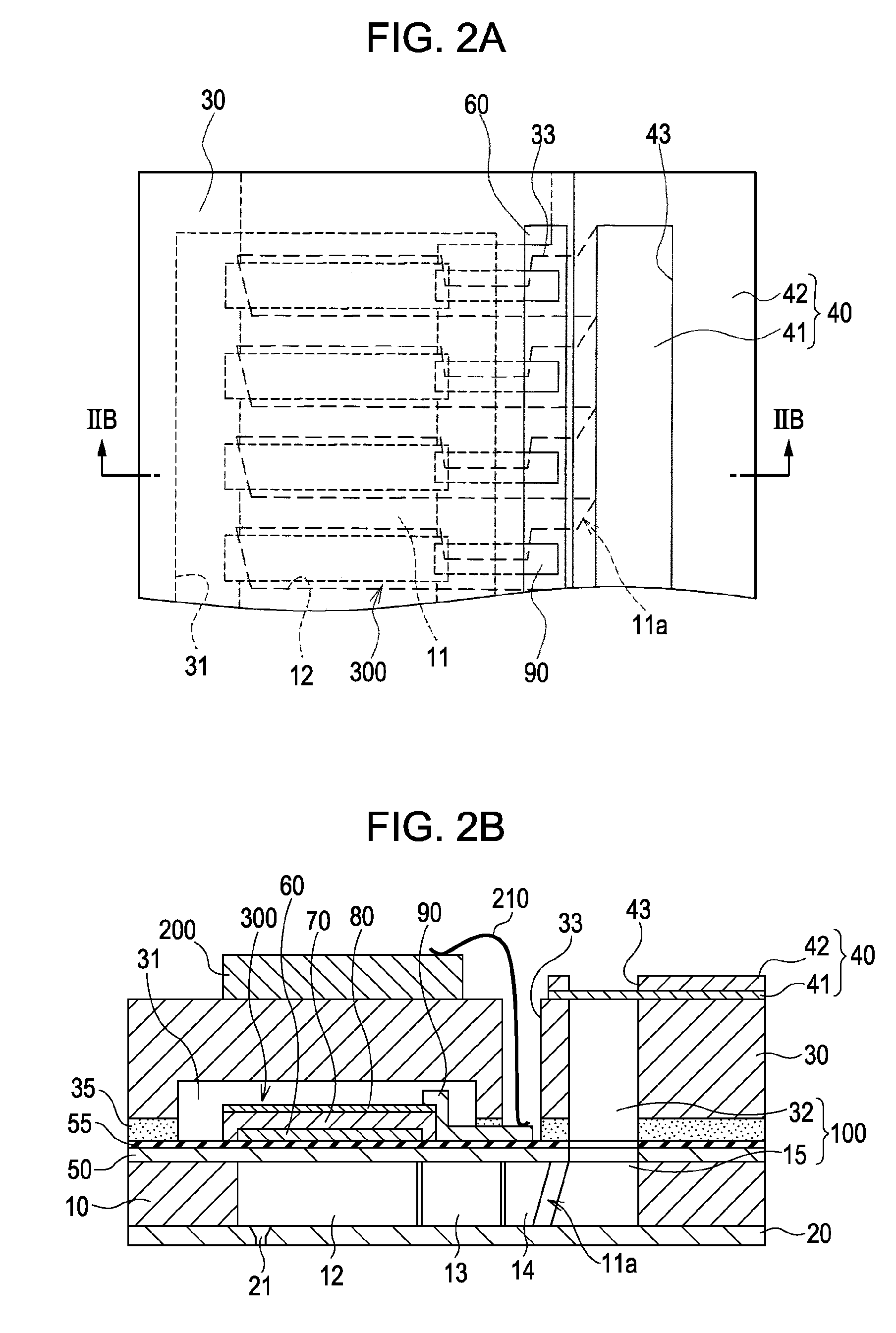

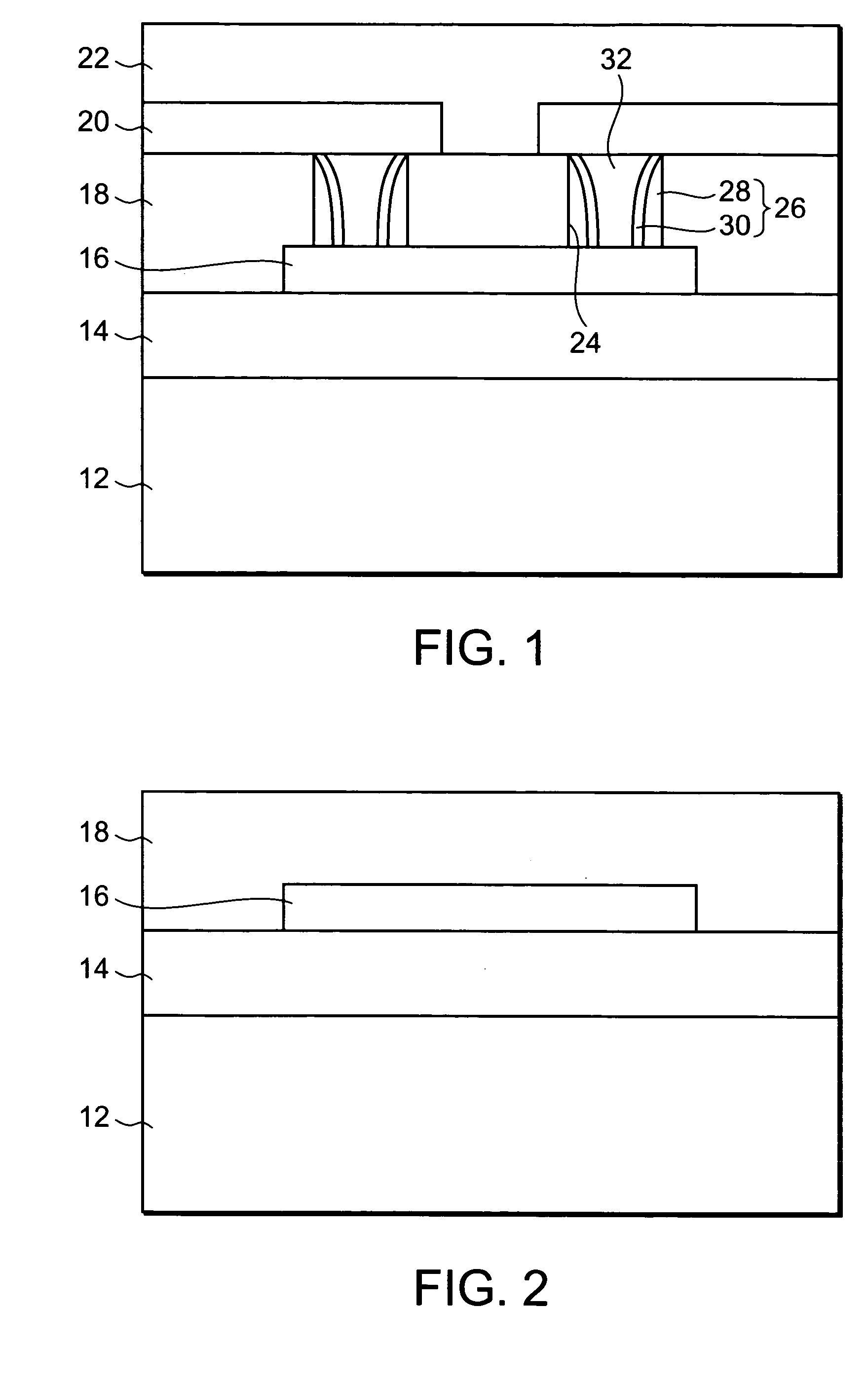

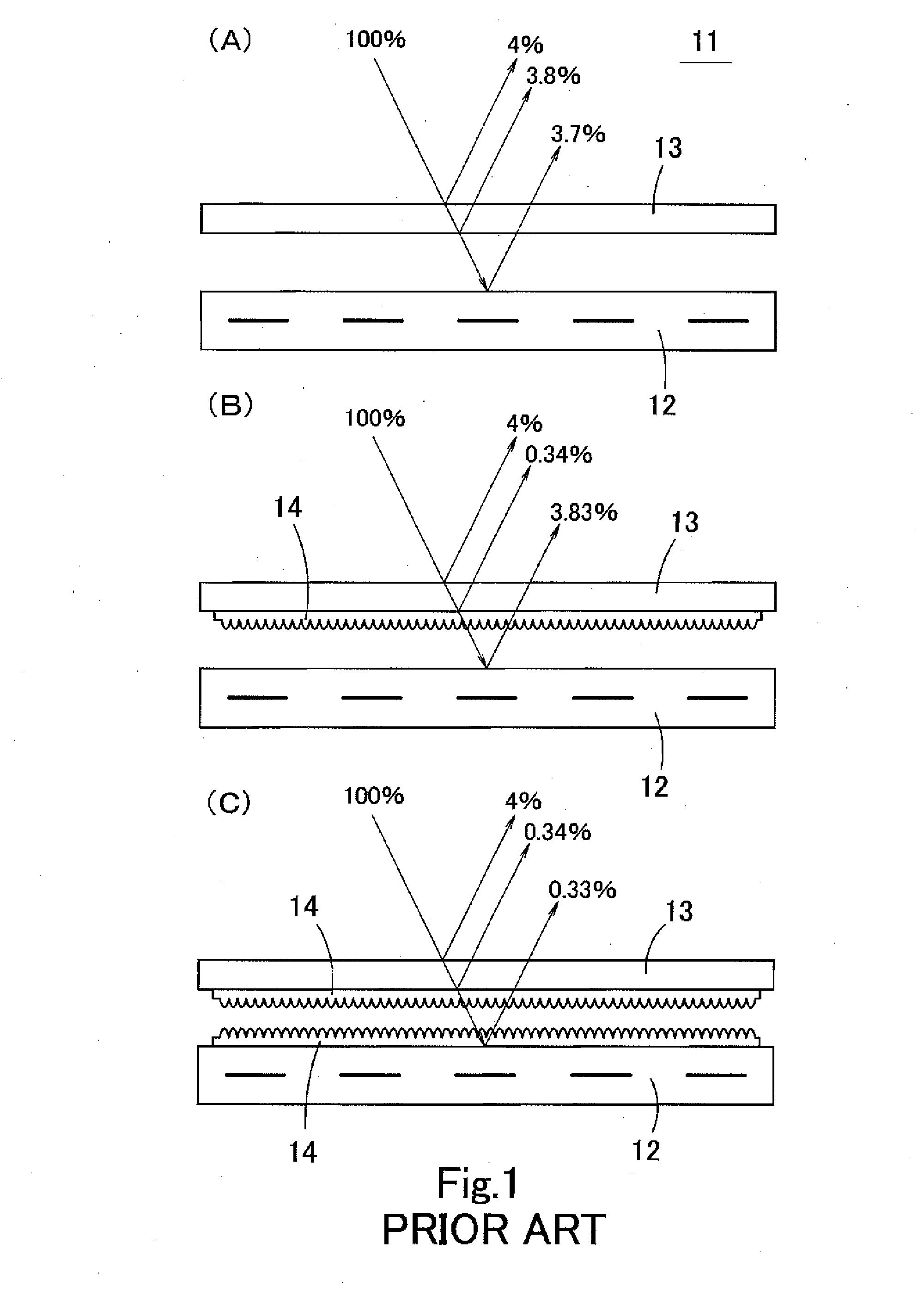

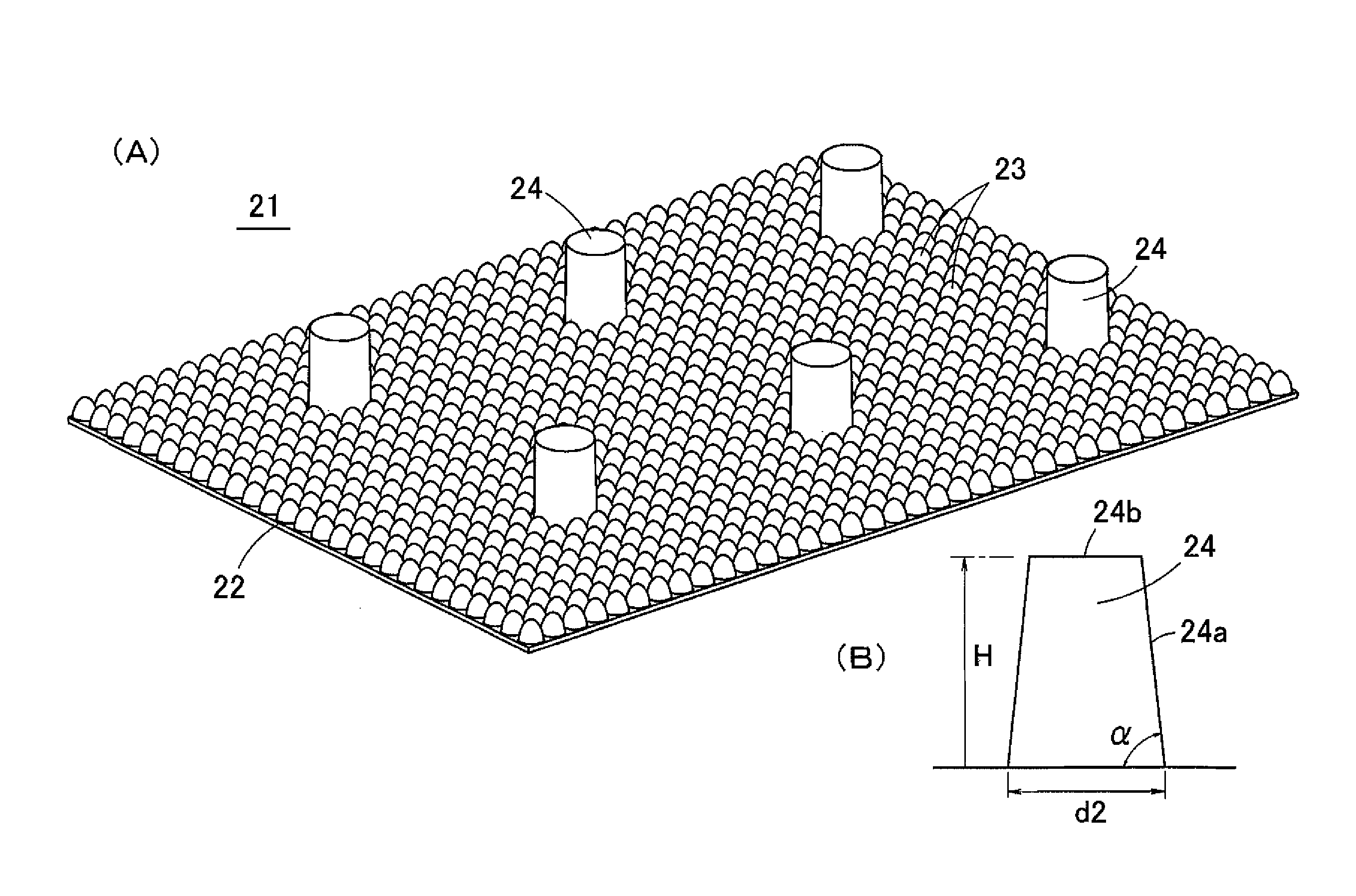

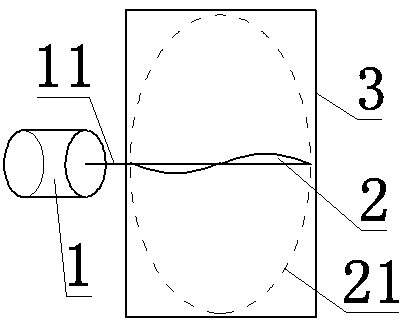

Acoustic sensor

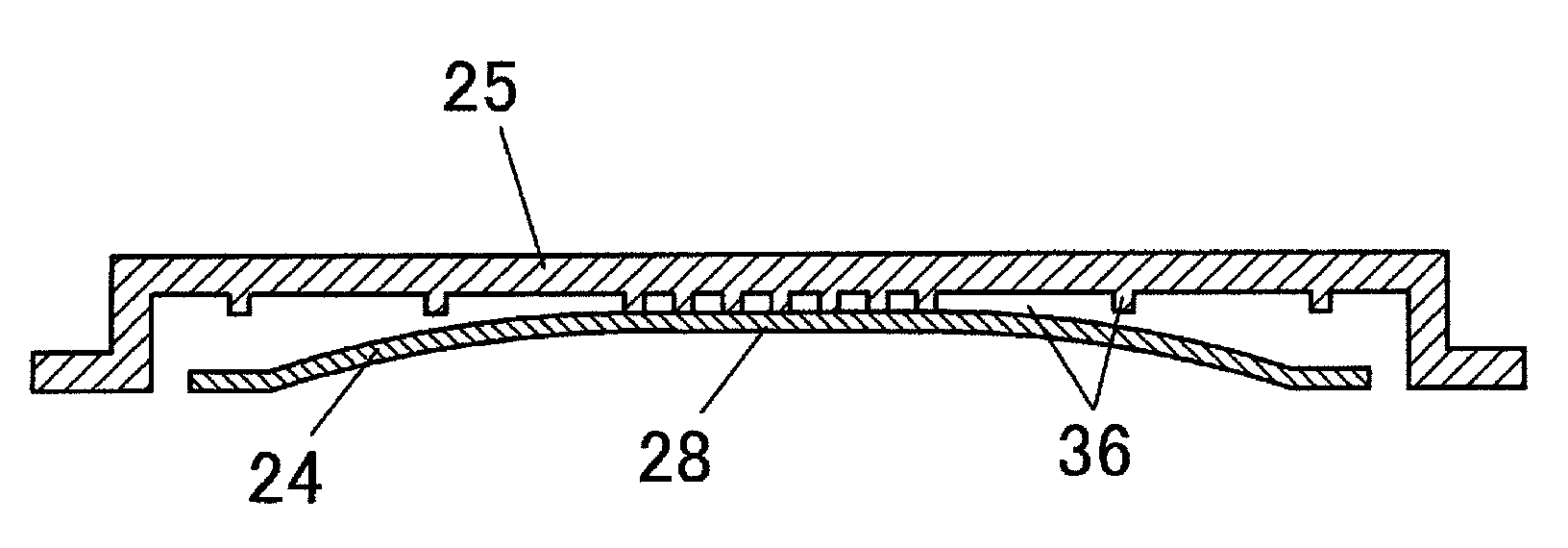

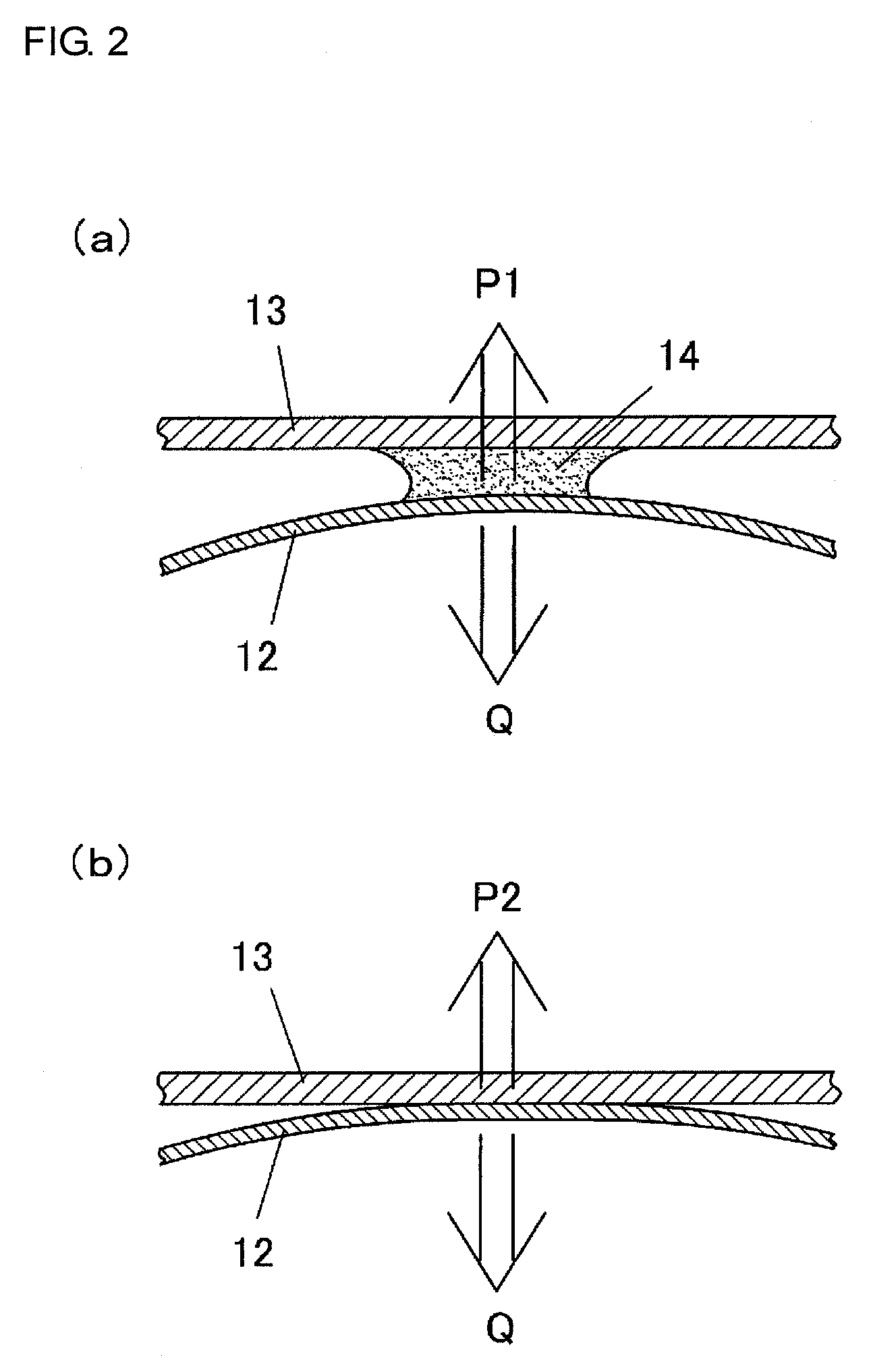

ActiveUS20100175477A1Local sticking be reduceReduce stickMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidCapacitanceMaterial Perforation

A vibrating electrode plate 24 that senses a sound pressure faces a counter electrode plate 25 to constitute a capacitance type acoustic sensor. In the counter electrode plate 25, acoustic perforations 31 are opened in order to pass vibration, and plural projections 36 are provided on a surface facing the vibrating electrode plate 24. An interval between the projections 36 is decreased in a region where the vibrating electrode plate 24 has high flexibility to easily generate local sticking with the counter electrode plate 25. The interval between the projections 36 is increased in a region where the vibrating electrode plate 24 has low flexibility to hardly generate local sticking with the counter electrode plate 25. The projections thus arranged prevent firm fixing of the vibrating electrode plate to the counter electrode plate and interruption of vibration of the vibrating electrode plate.

Owner:MMI SEMICON CO LTD

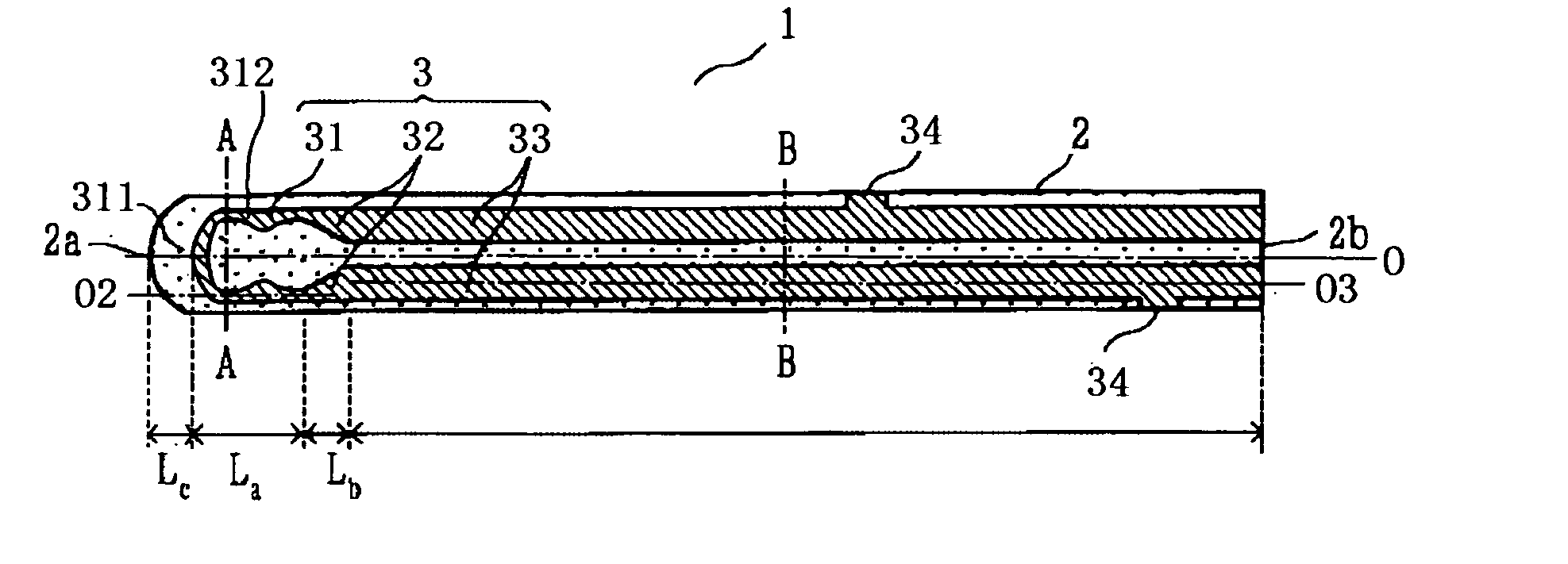

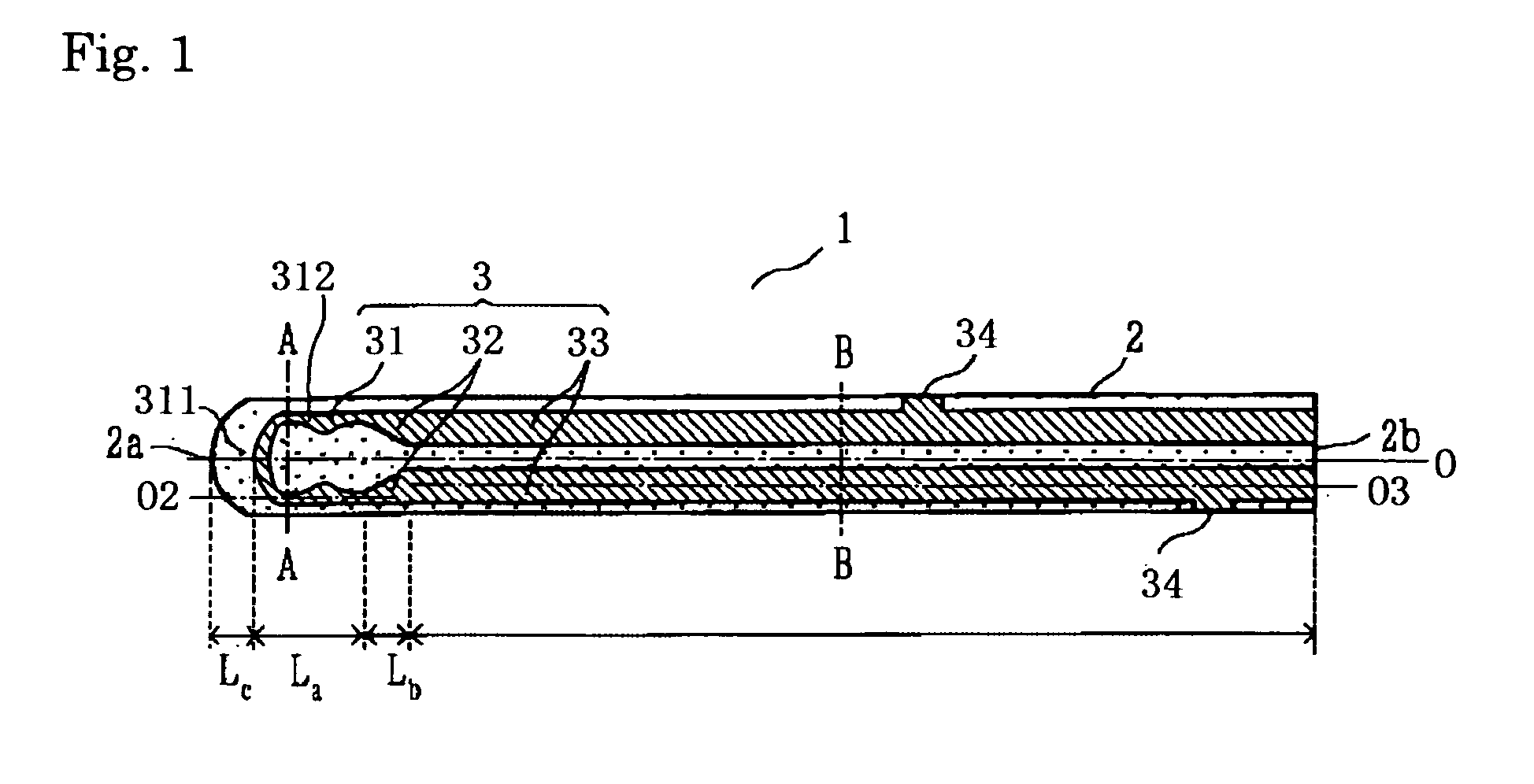

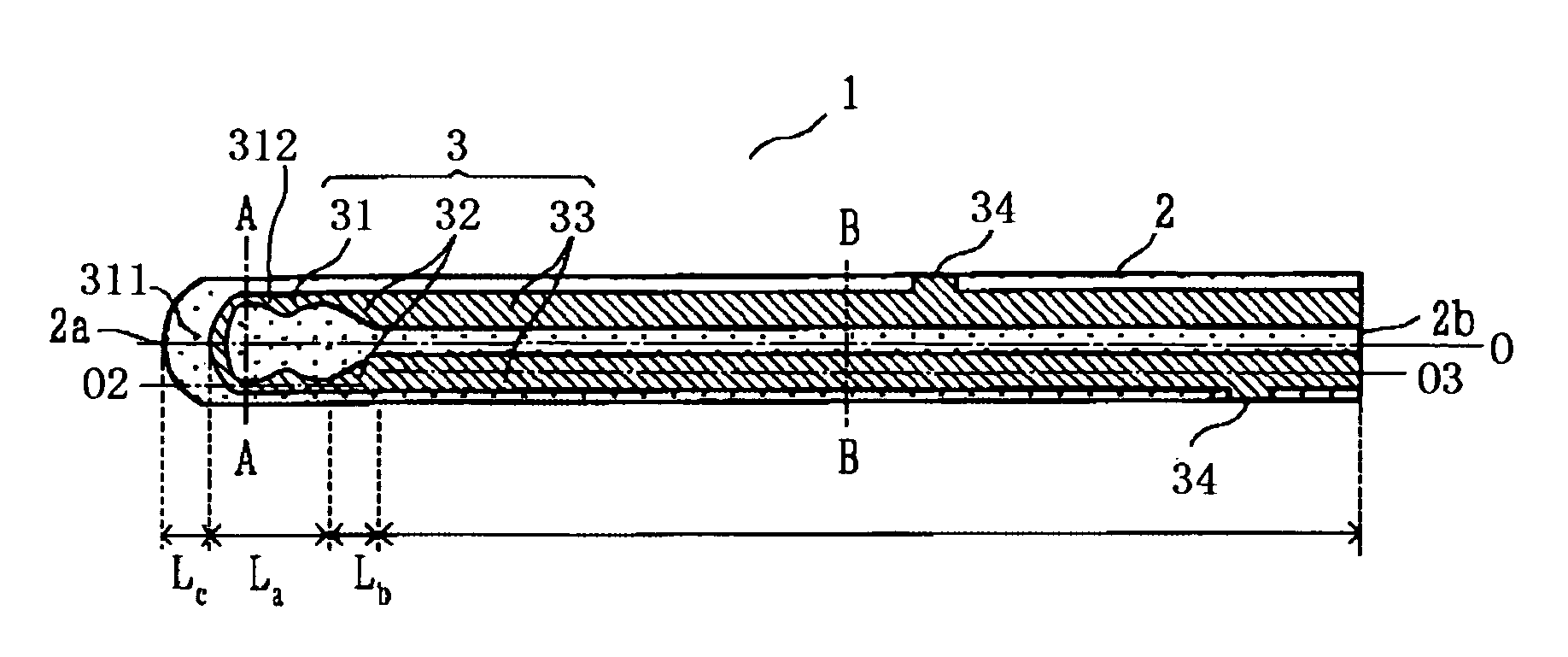

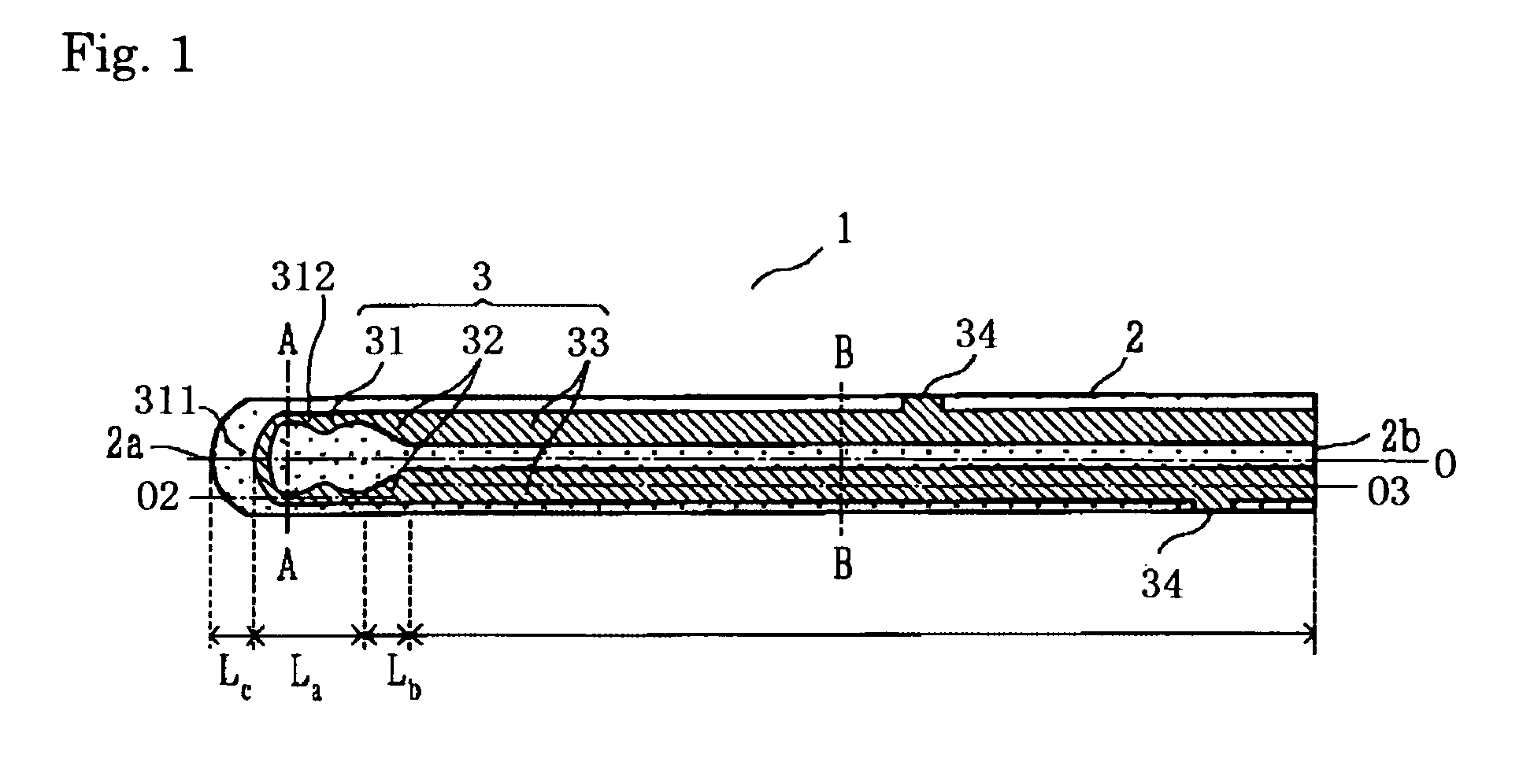

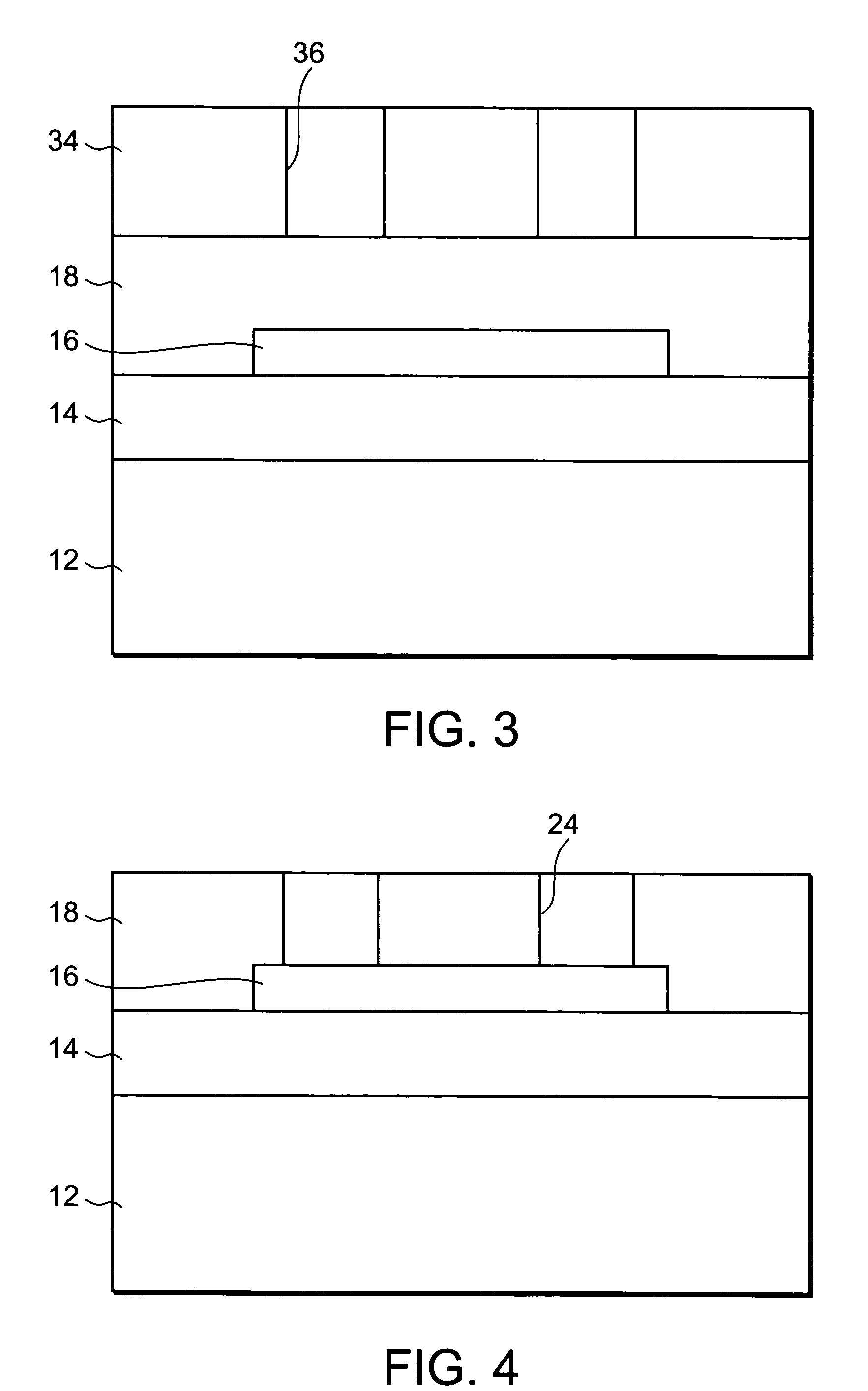

Ceramic Heater, Method of Producing the Same, and Glow Plug Using a Ceramic Heater

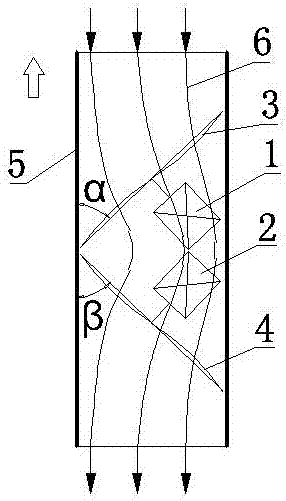

InactiveUS20070210053A1Improve reliabilitySmall sectional areaIncandescent ignitionOhmic-resistance electrodesEngineeringResistor

A ceramic heater in which a damage in a joining portion between a heating portion and a lead portion is suppressed and the reliability is excellent is provided. In a ceramic heater (1) including: a rod-shaped support (2) which is made from an insulative ceramic; and a resistor member (3) including a heating portion (31) embedded in a tip end part of the support (2), and a pair of lead portions (33) which extend from the heating portion (31) toward a rear end side of the support (2), the heating portion (31) and the lead portions (33) are made from the same conductive ceramic.

Owner:NGK SPARK PLUG CO LTD

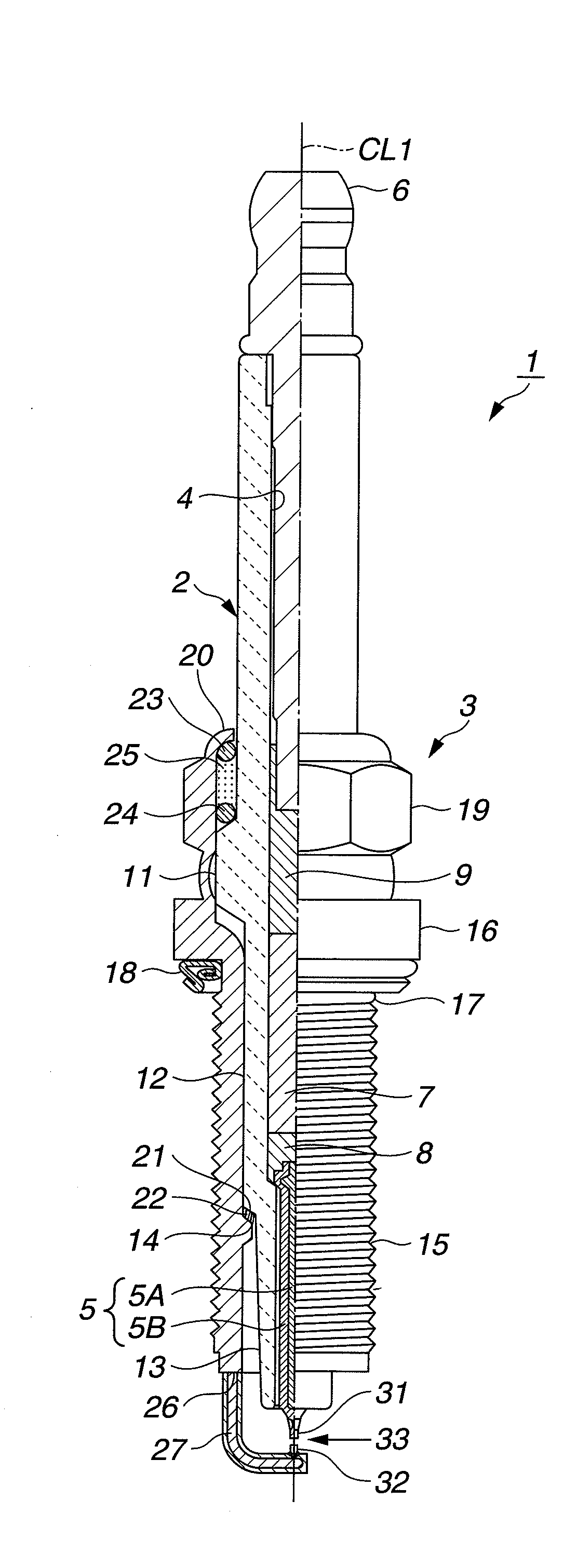

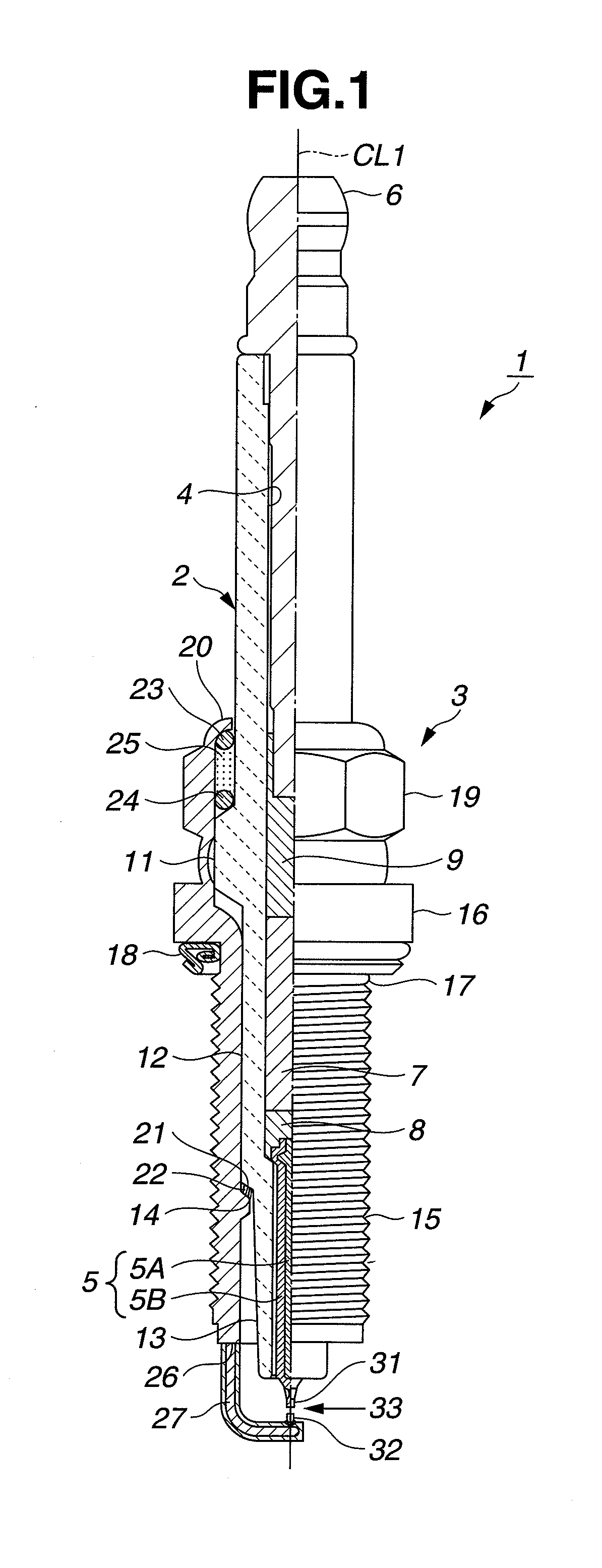

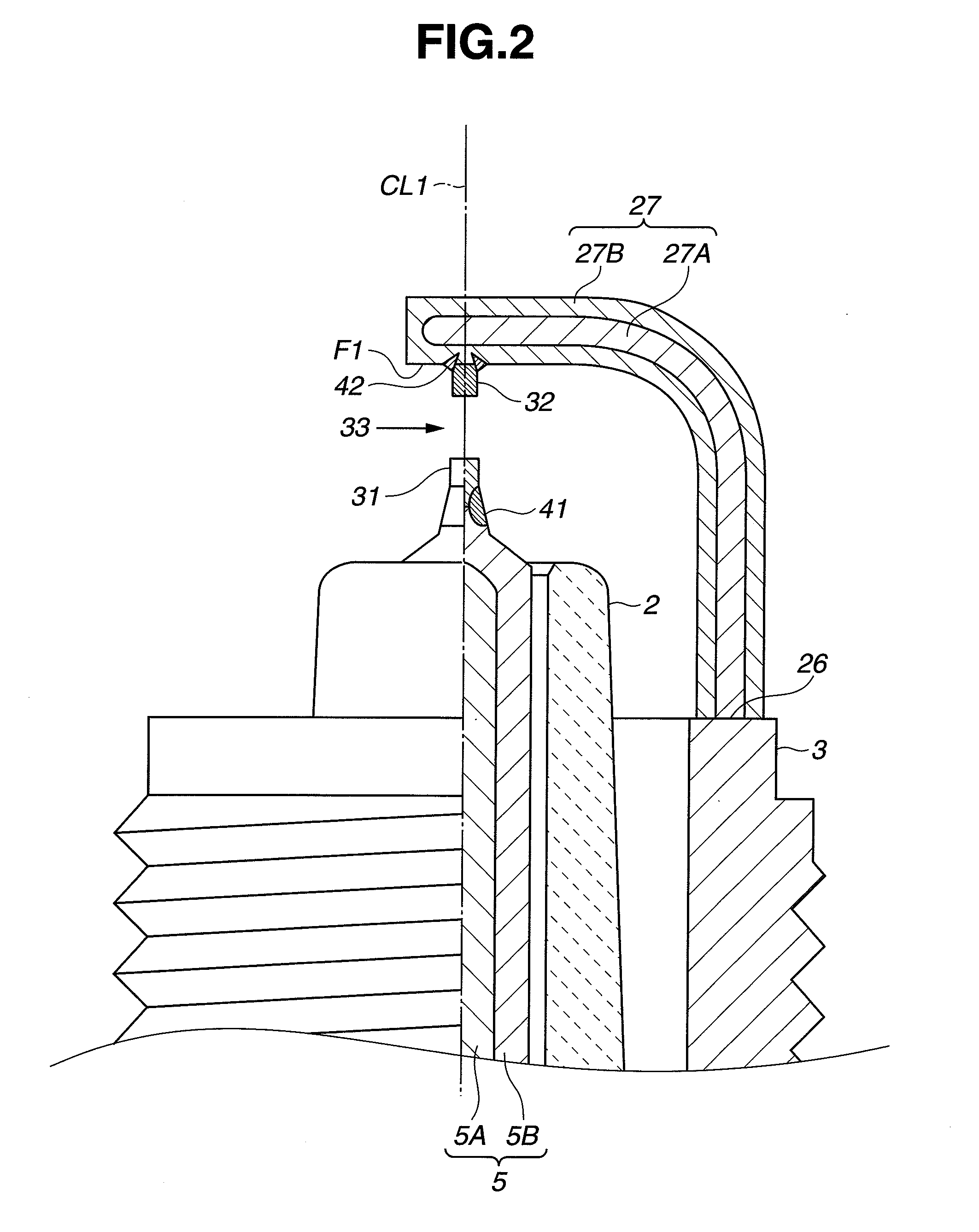

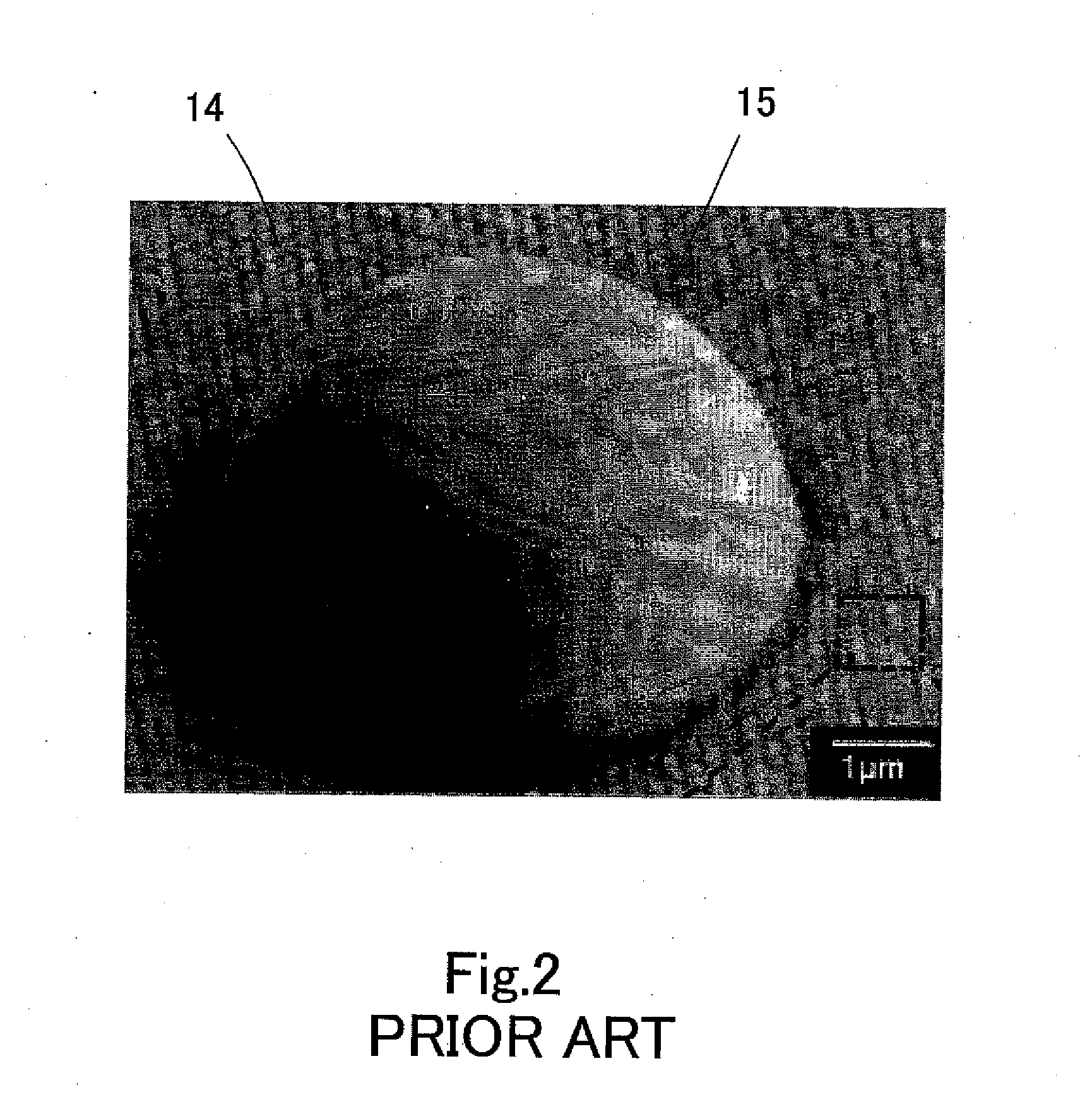

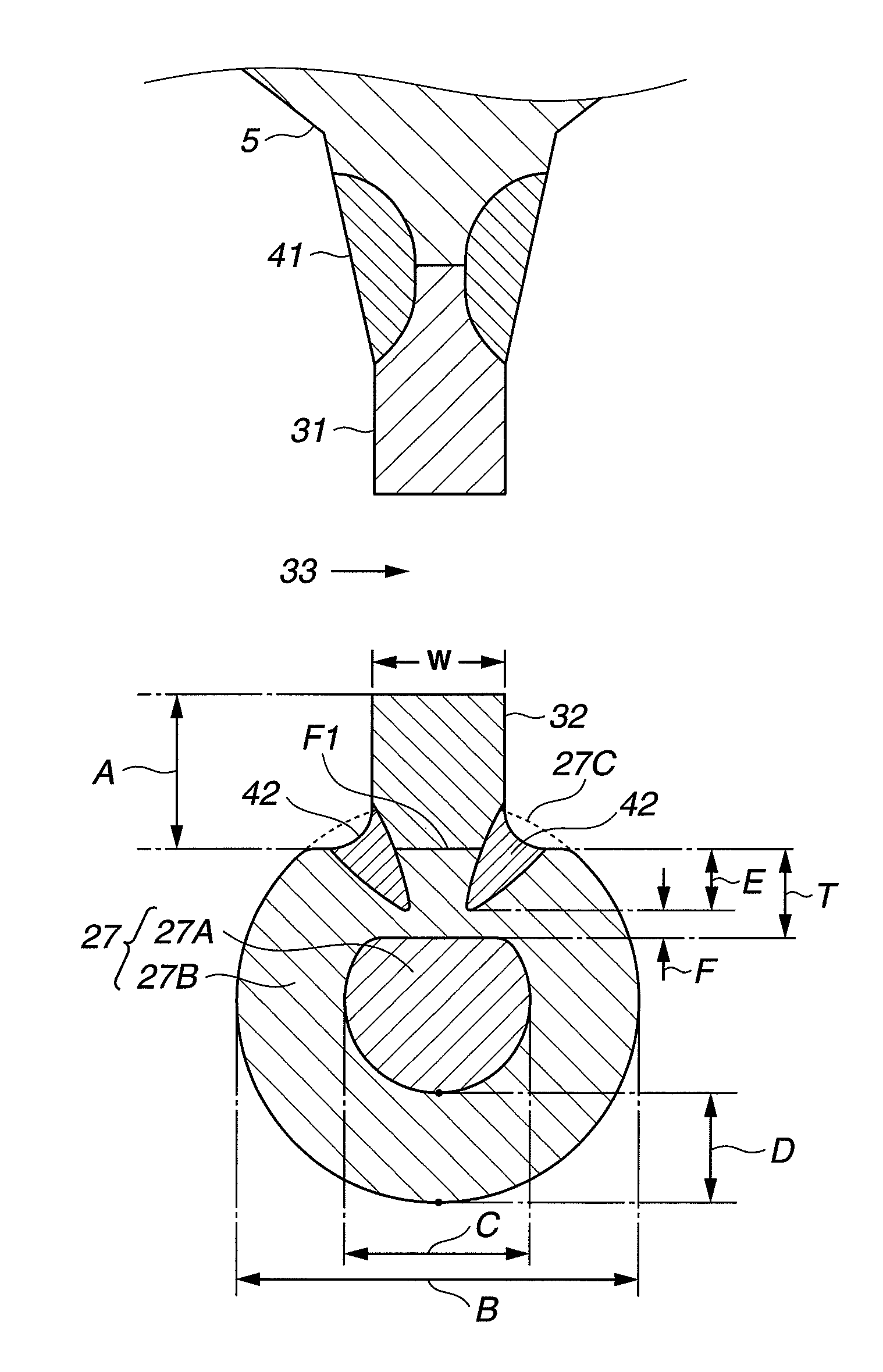

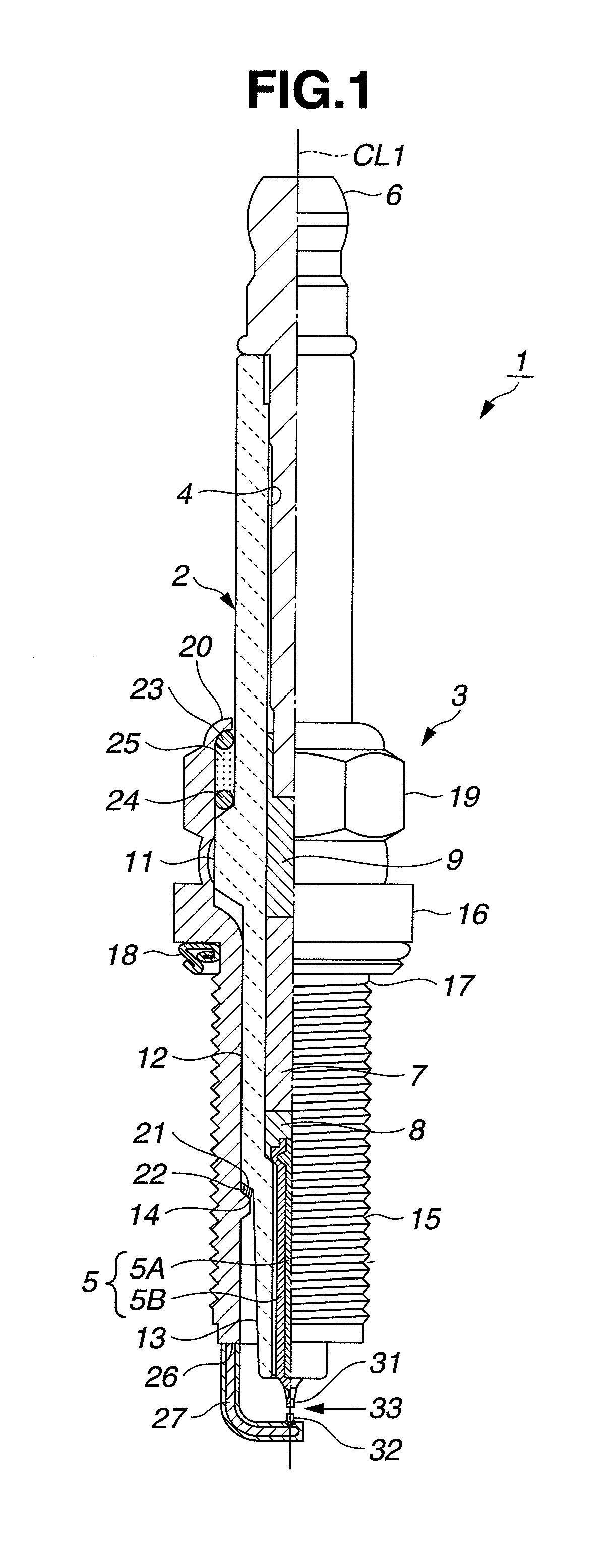

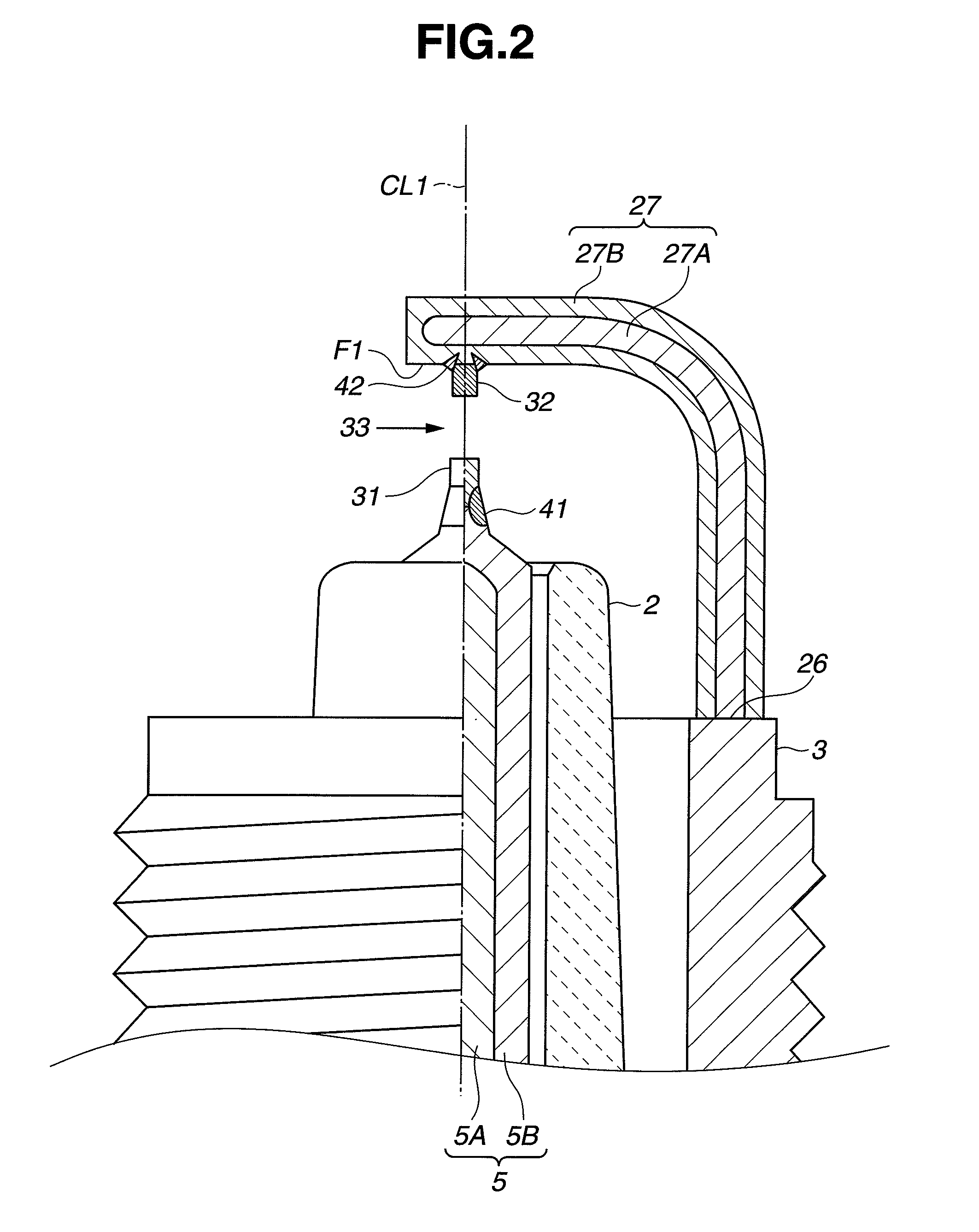

Spark plug

ActiveUS20090289540A1Easy to riseRate of exhaustion of becomes largeSparking plugsGrounding electrodesMinimum distance

A spark plug comprising a center electrode, a first noble metal tip joined to the center electrode, an insulator, a metallic shell, a ground electrode joined to the metallic shell and including an outer layer and an inner layer, and a second noble metal tip joined to the ground electrode by way of a melted portion, wherein in a cross section of the ground electrode, the protrusion height A of the second noble metal tip is 0.4 mm or more, the ground electrode includes a substantially flat joining surface to which the second noble metal tip is joined and an outwardly curved surface, the inner layer has at the joining surface side a substantially flat surface or recessed surface, and the minimum distance F between the melted portion and the inner layer is 0.1 mm or more.

Owner:NGK SPARK PLUG CO LTD

Ceramic heater, method of producing the same, and glow plug using a ceramic heater

InactiveUS7705273B2Small sectional areaReduce intervalIncandescent ignitionOhmic-resistance electrodesElectrical resistance and conductanceEngineering

A ceramic heater in which a damage in a joining portion between a heating portion and a lead portion is suppressed and the reliability is excellent is provided.In a ceramic heater (1) including: a rod-shaped support (2) which is made from an insulative ceramic; and a resistor member (3) including a heating portion (31) embedded in a tip end part of the support (2), and a pair of lead portions (33) which extend from the heating portion (31) toward a rear end side of the support (2), the heating portion (31) and the lead portions (33) are made from the same conductive ceramic.

Owner:NGK SPARK PLUG CO LTD

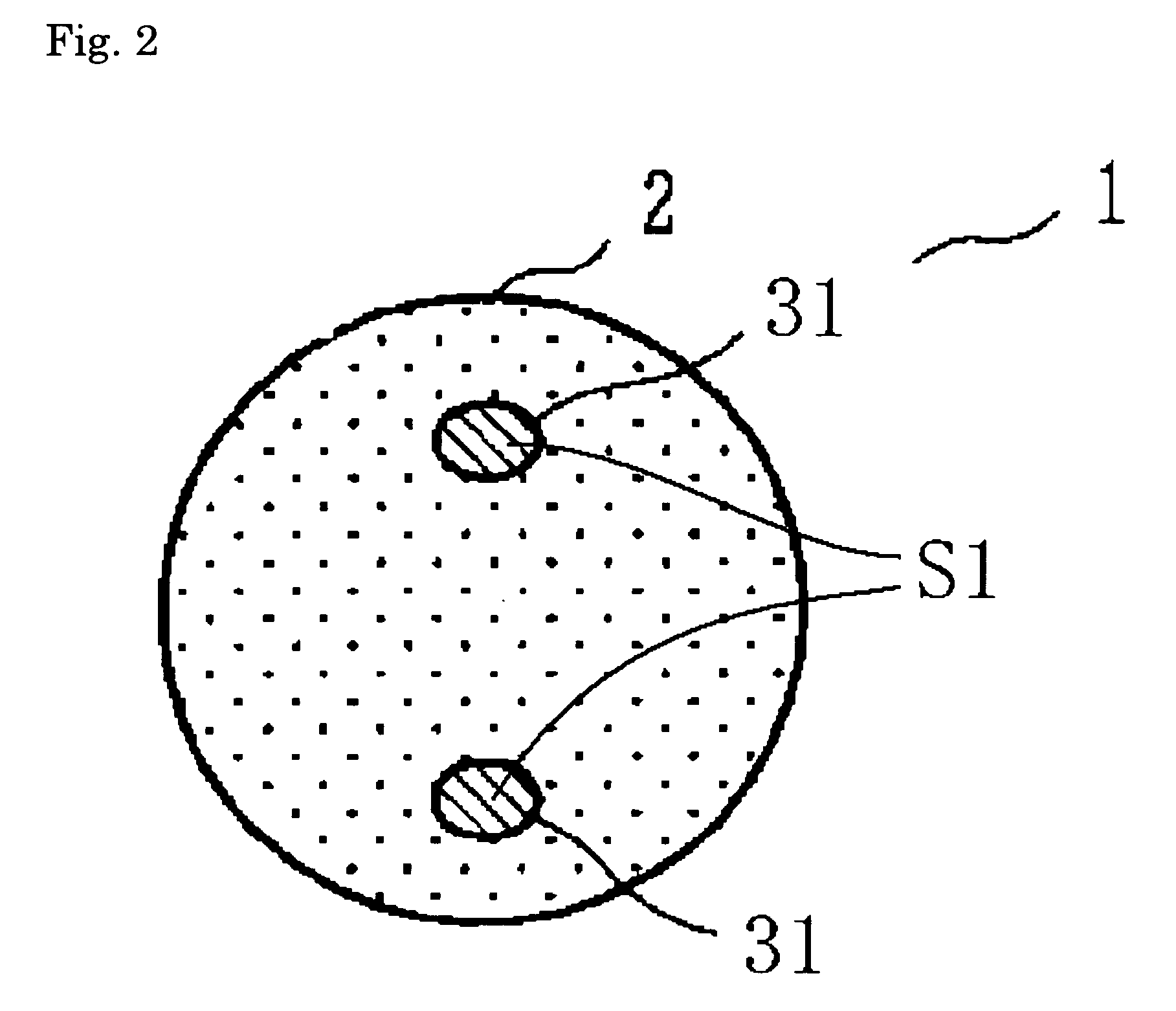

Skateboard assembly and skateboard having the same

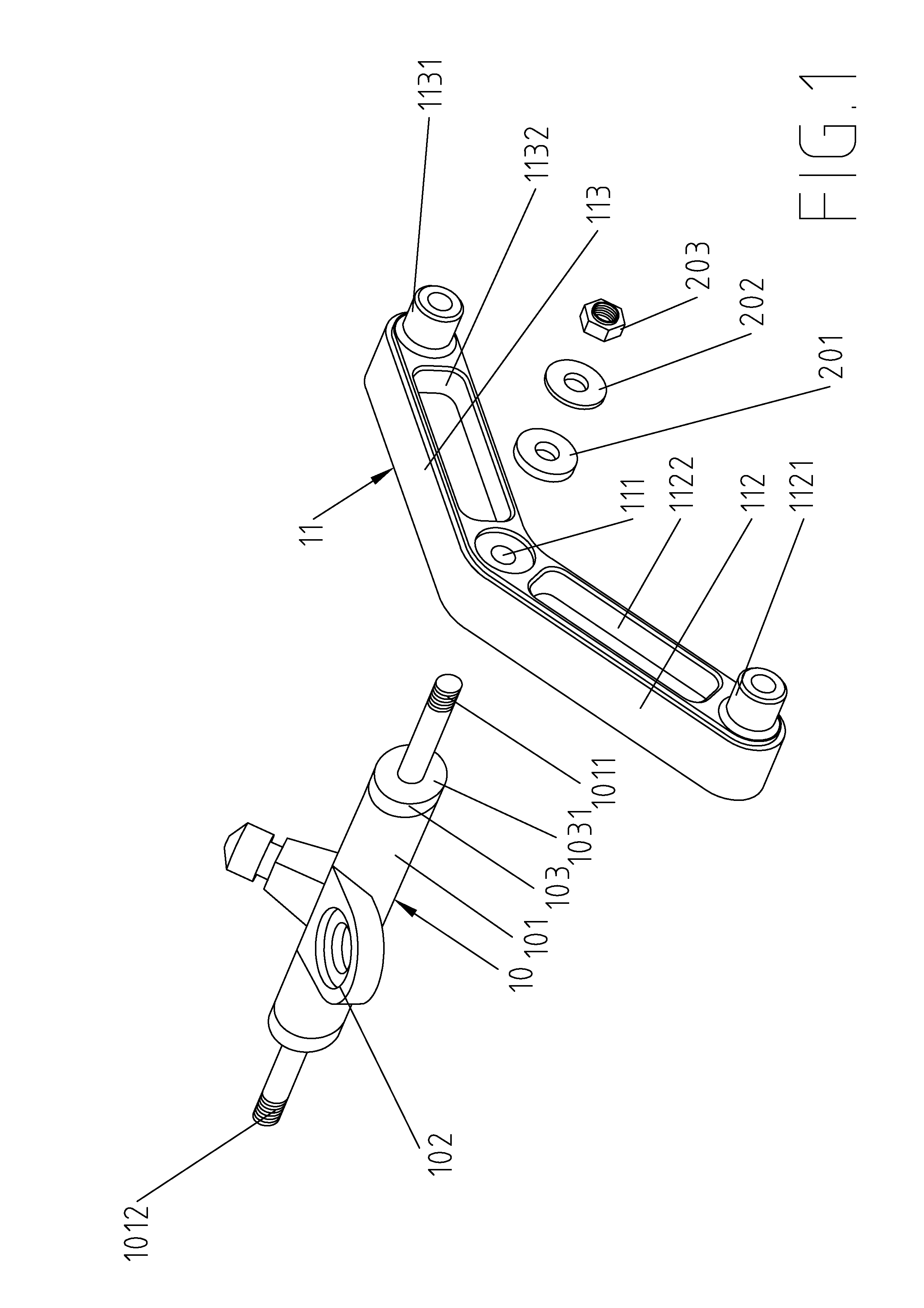

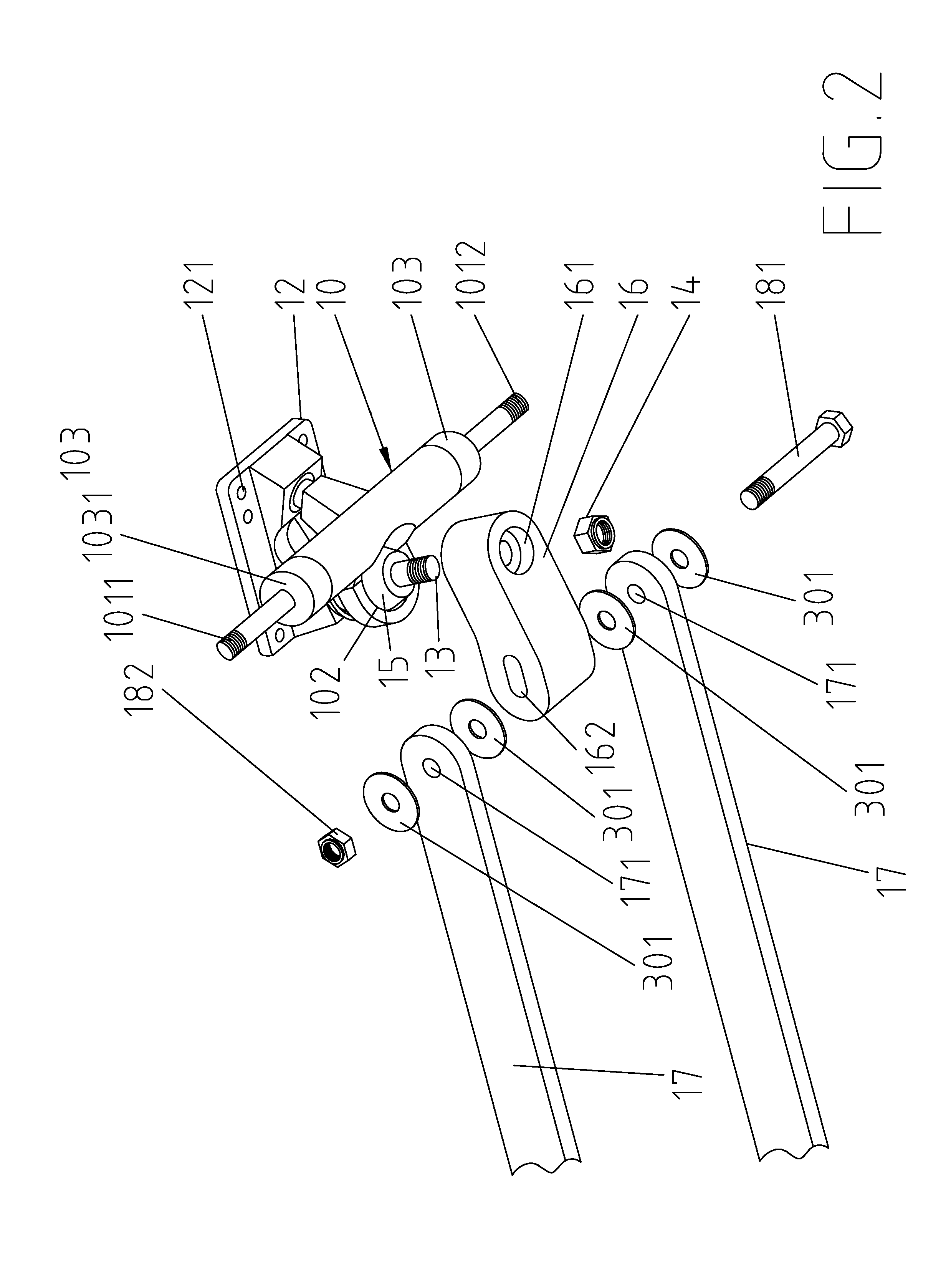

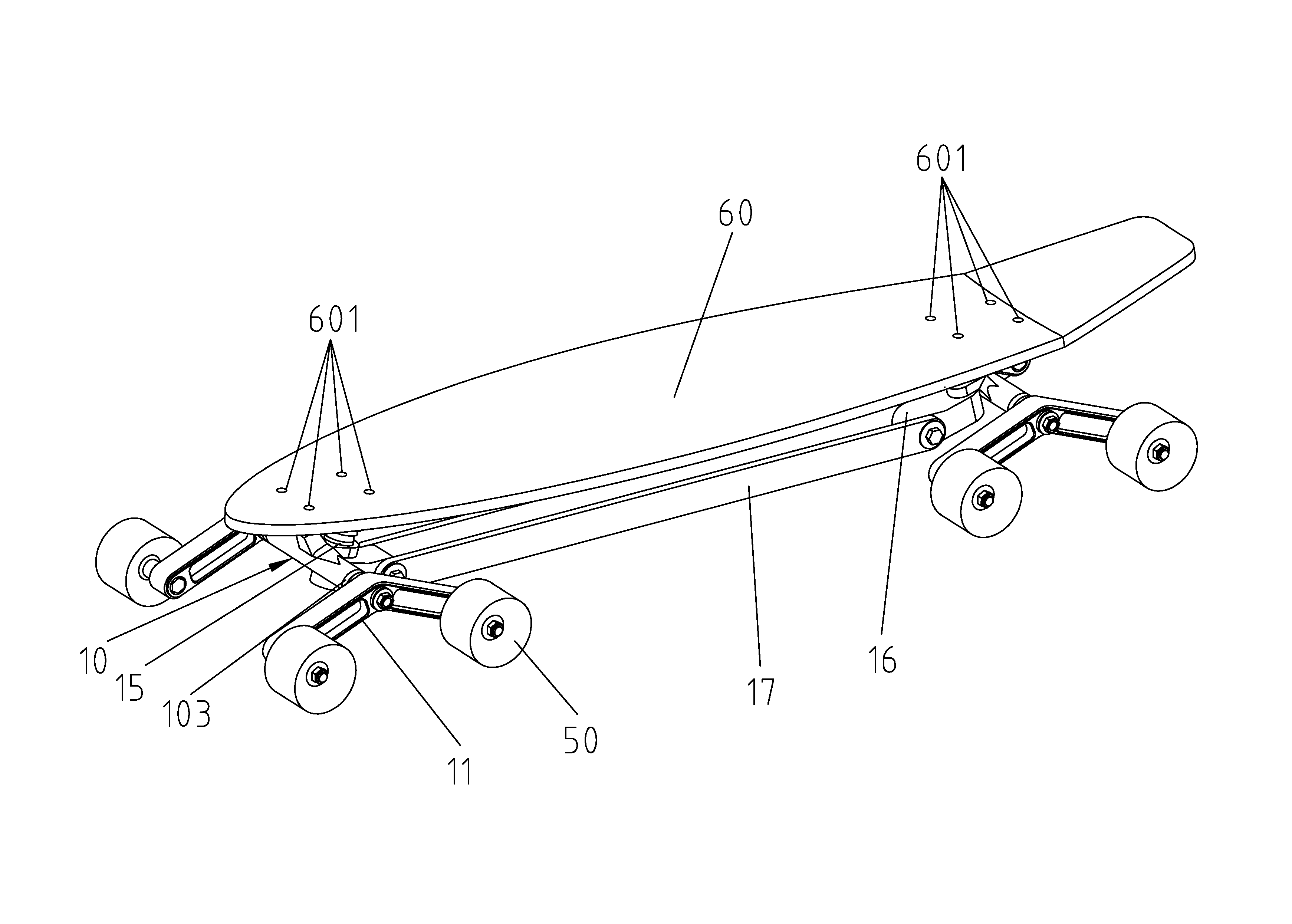

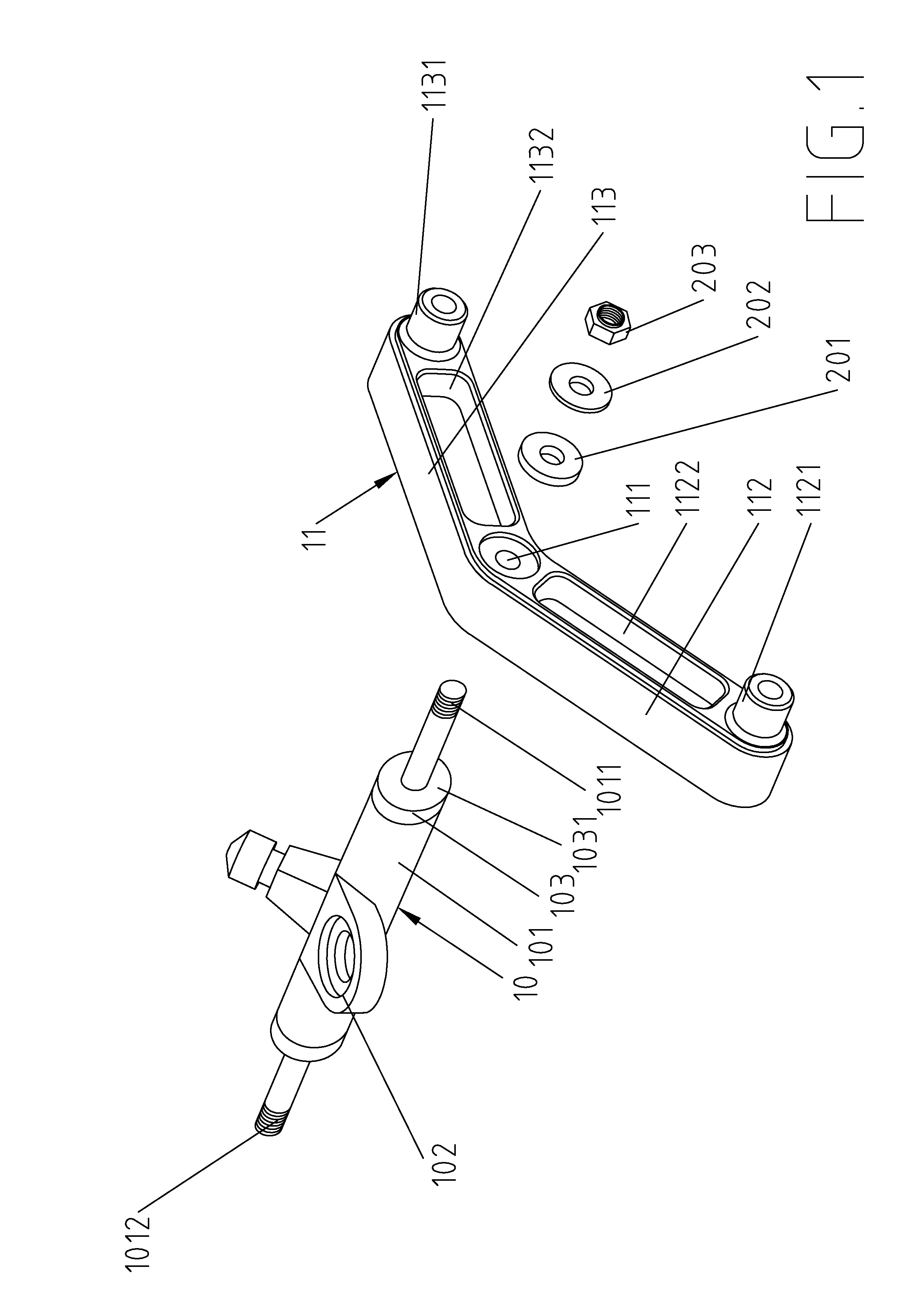

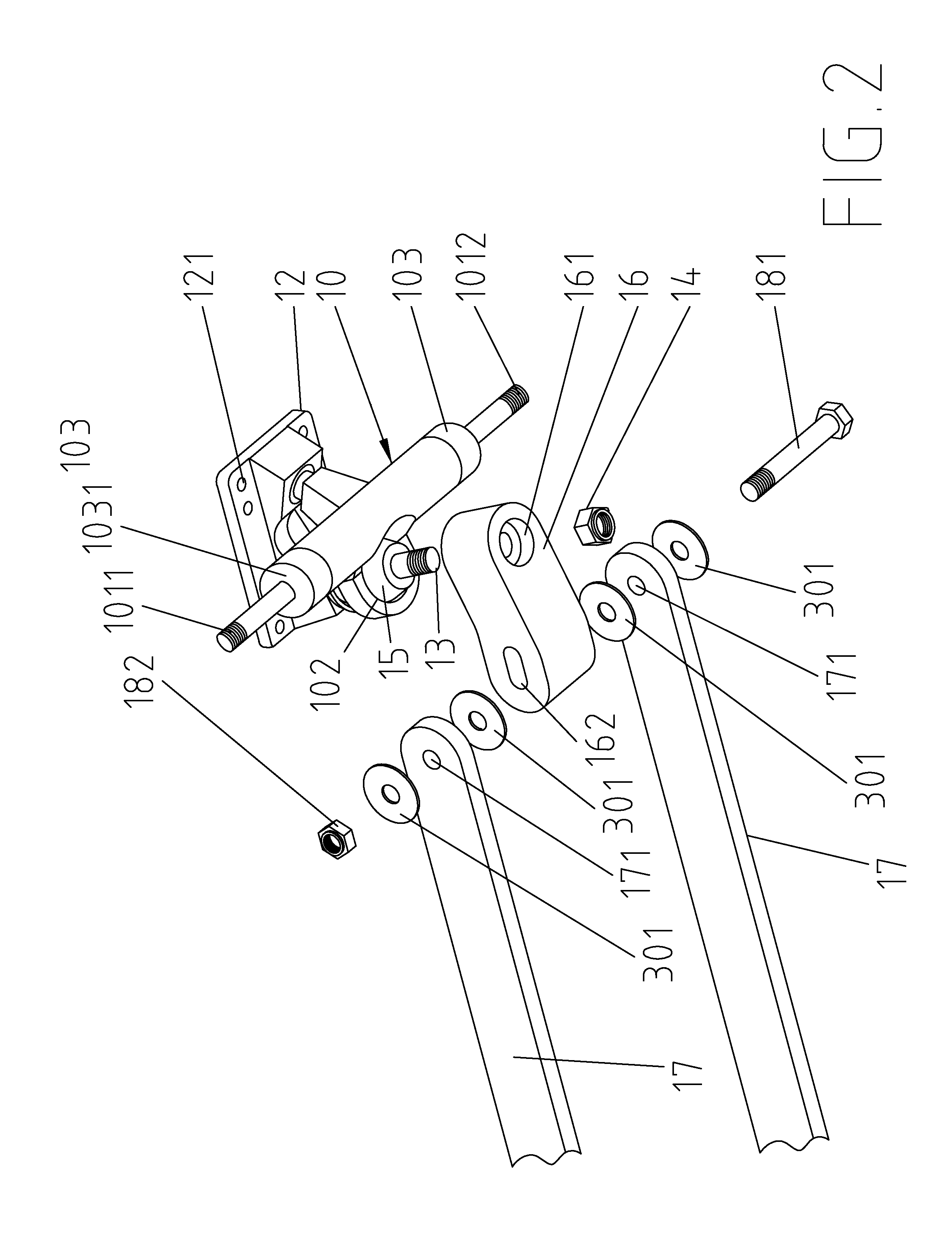

A skateboard assembly and a skateboard having the same are provided. The skateboard assembly includes a truck and a frame. The truck includes a pivot that has two oppositely extending axial sections, and the frame includes a pivot hole, and a first segment and a second segment extending at two sides of the pivot hole, wherein the first segment and the second segment include an angle and each of the first and second segments has an end far from the pivot hole provided with an axle.

Owner:QIANG ZHUANG CO LTD

Skateboard assembly and skateboard having the same

ActiveUS20140197611A1Small sectional areaTractor-trailer combinationsRider propulsionEngineeringSlide plate

A skateboard assembly and a skateboard having the same are provided. The skateboard assembly includes a truck and a frame. The truck includes a pivot that has two oppositely extending axial sections, and the frame includes a pivot hole, and a first segment and a second segment extending at two sides of the pivot hole, wherein the first segment and the second segment include an angle and each of the first and second segments has an end far from the pivot hole provided with an axle.

Owner:QIANG ZHUANG CO LTD

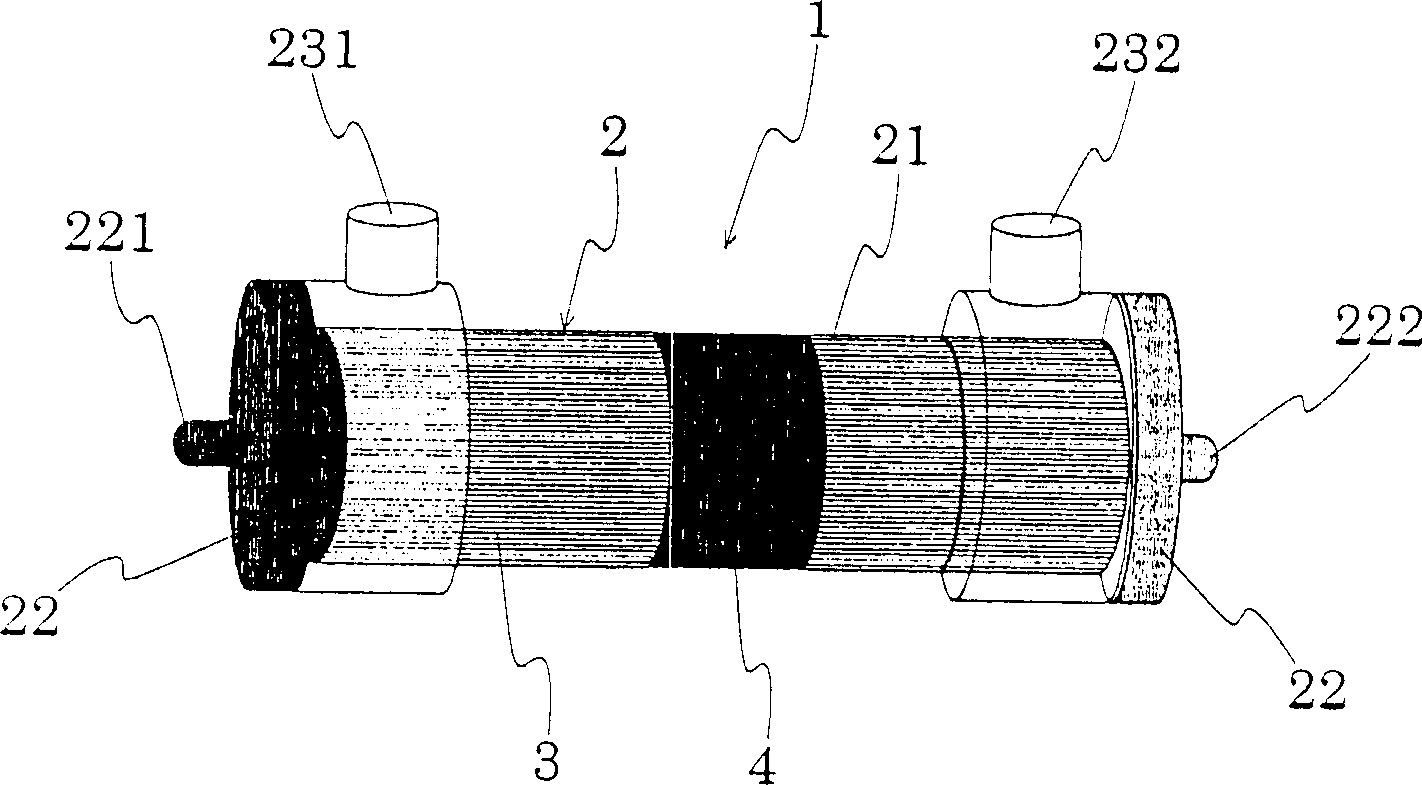

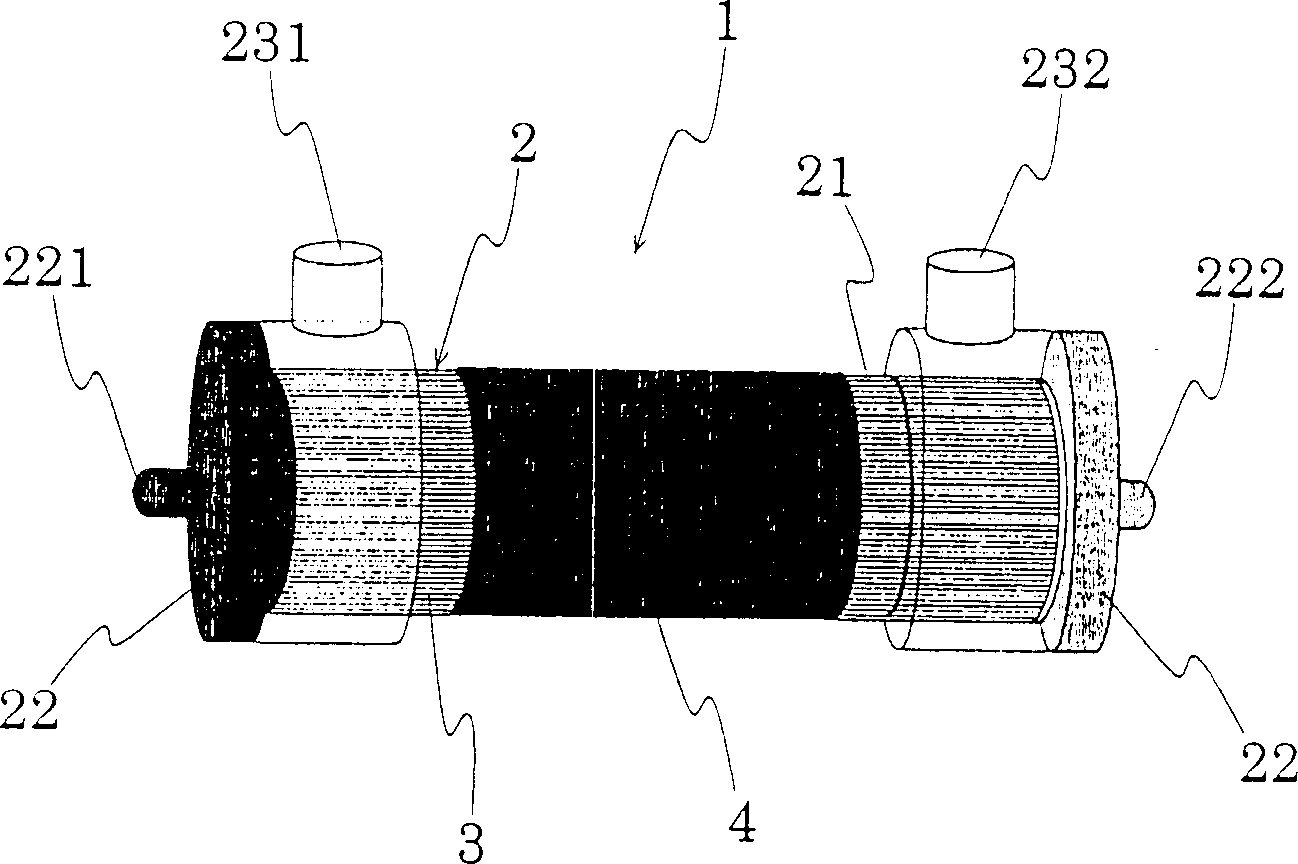

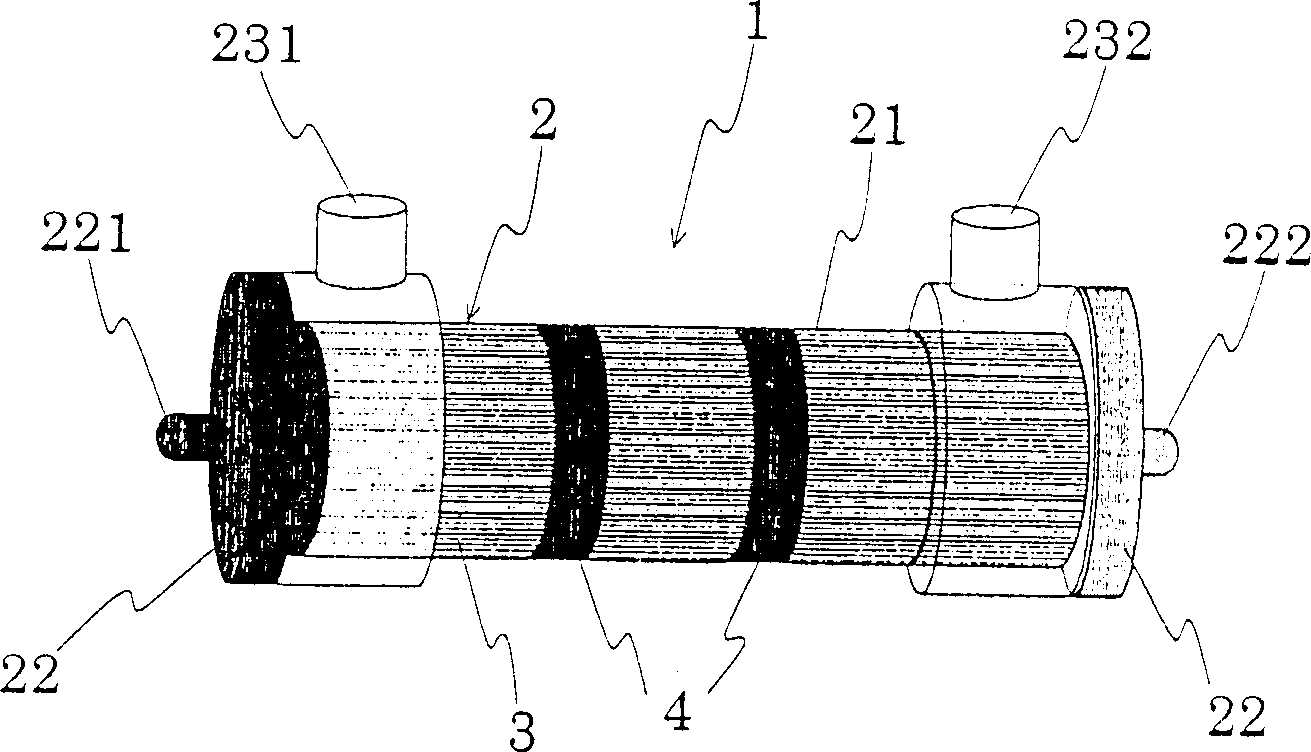

Dialyser and its producing method

ActiveCN1511596ASmall sectional areaDon't worry about damageMembranesHaemofiltrationFiber bundleEngineering

Owner:NIPRO CORP

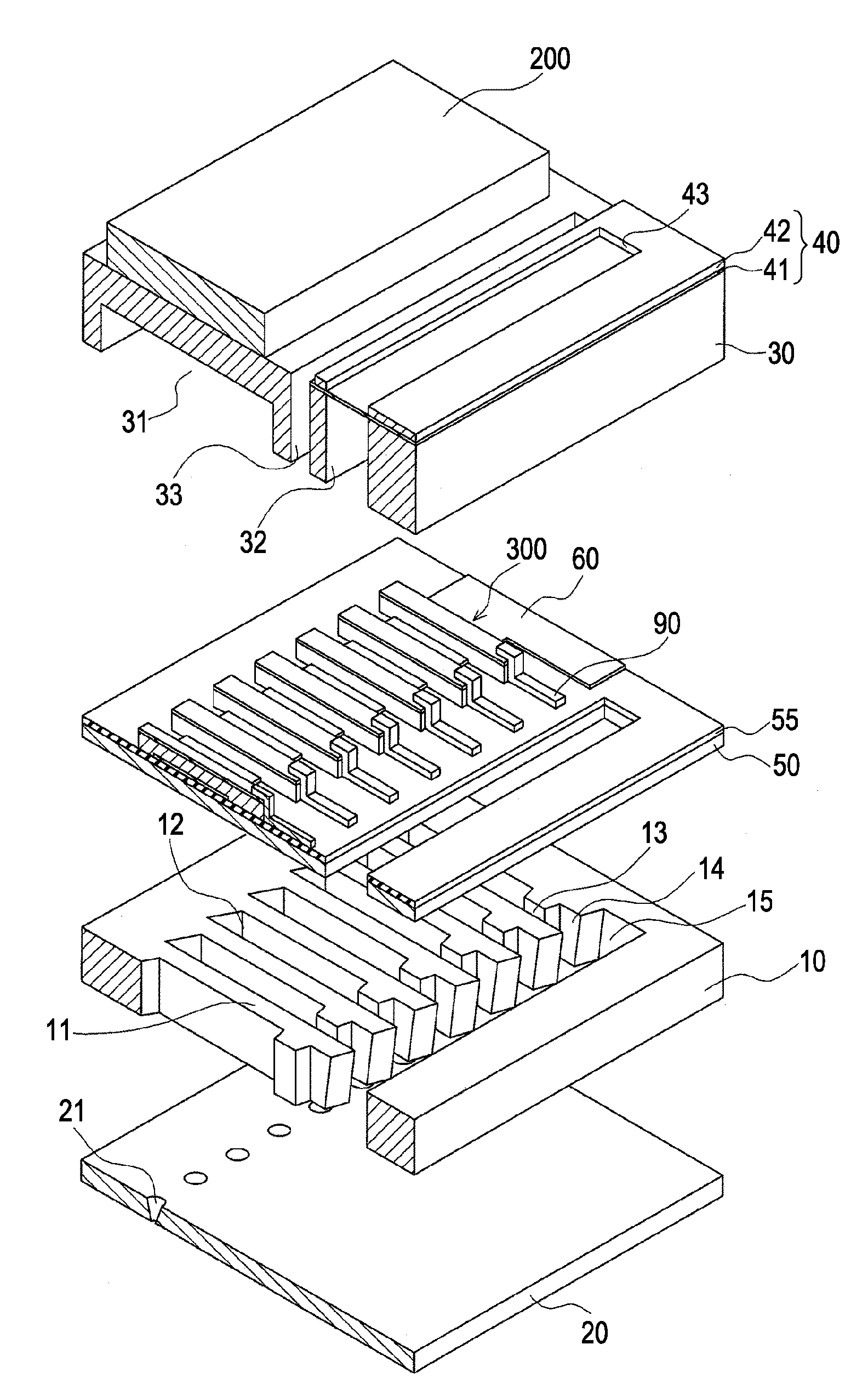

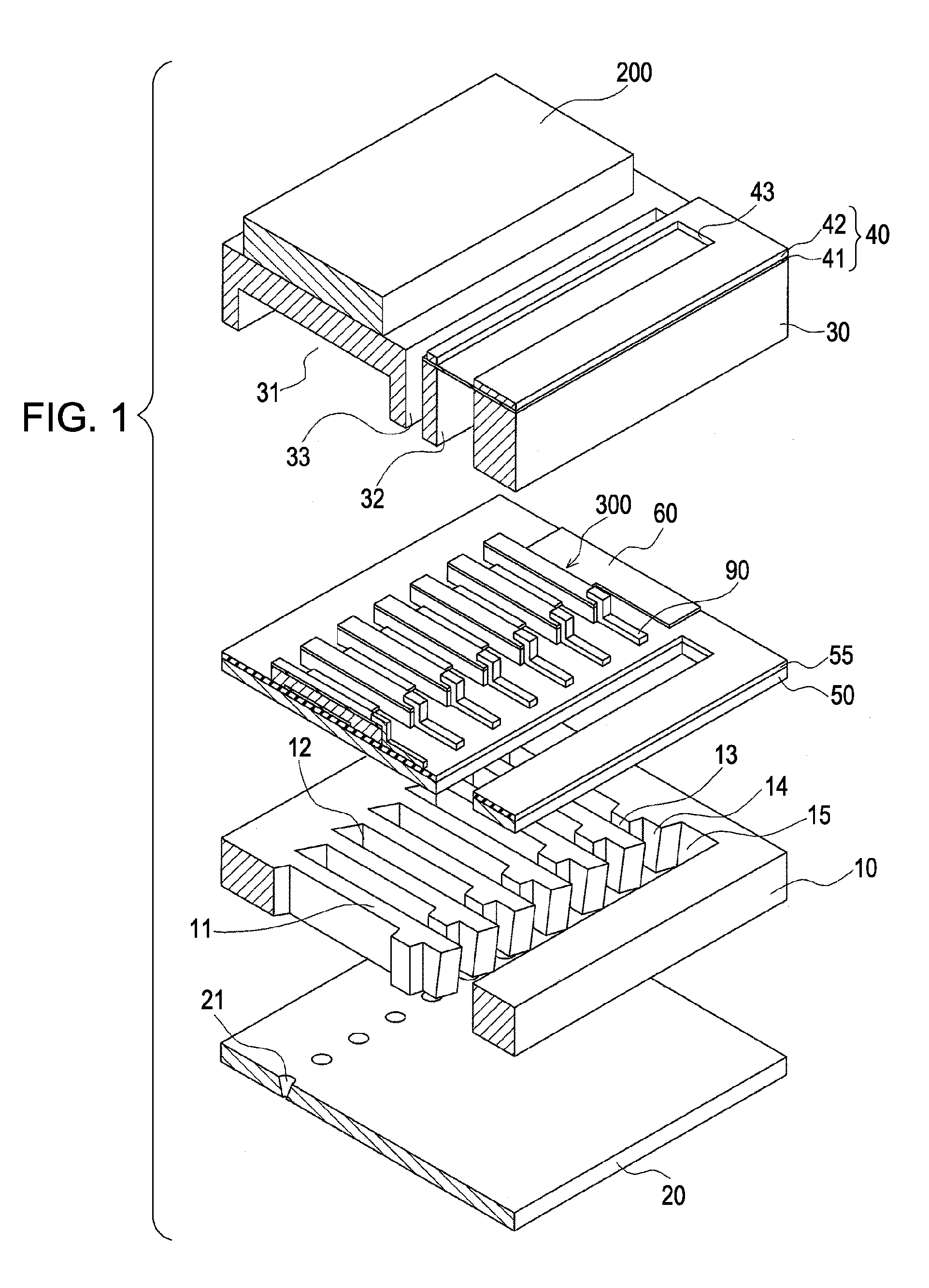

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head that includes a fluid channel formation substrate and pressure generation units. The fluid channel formation substrate is made of a silicon single crystal substrate having a crystal face orientation of. The fluid channel formation substrate has a plurality of separate flow channels that include at least pressure generation chambers demarcated by partition walls, each of the pressure generation chambers being in communication with a nozzle opening that ejects liquid drops. The fluid channel formation substrate further has a communication portion that is in communication with each of the separate flow channels. The pressure generation units are provided so as to correspond to the pressure generation chambers and generate a pressure change in the pressure generation chambers so as to cause ejection of liquid drops.

Owner:SEIKO EPSON CORP

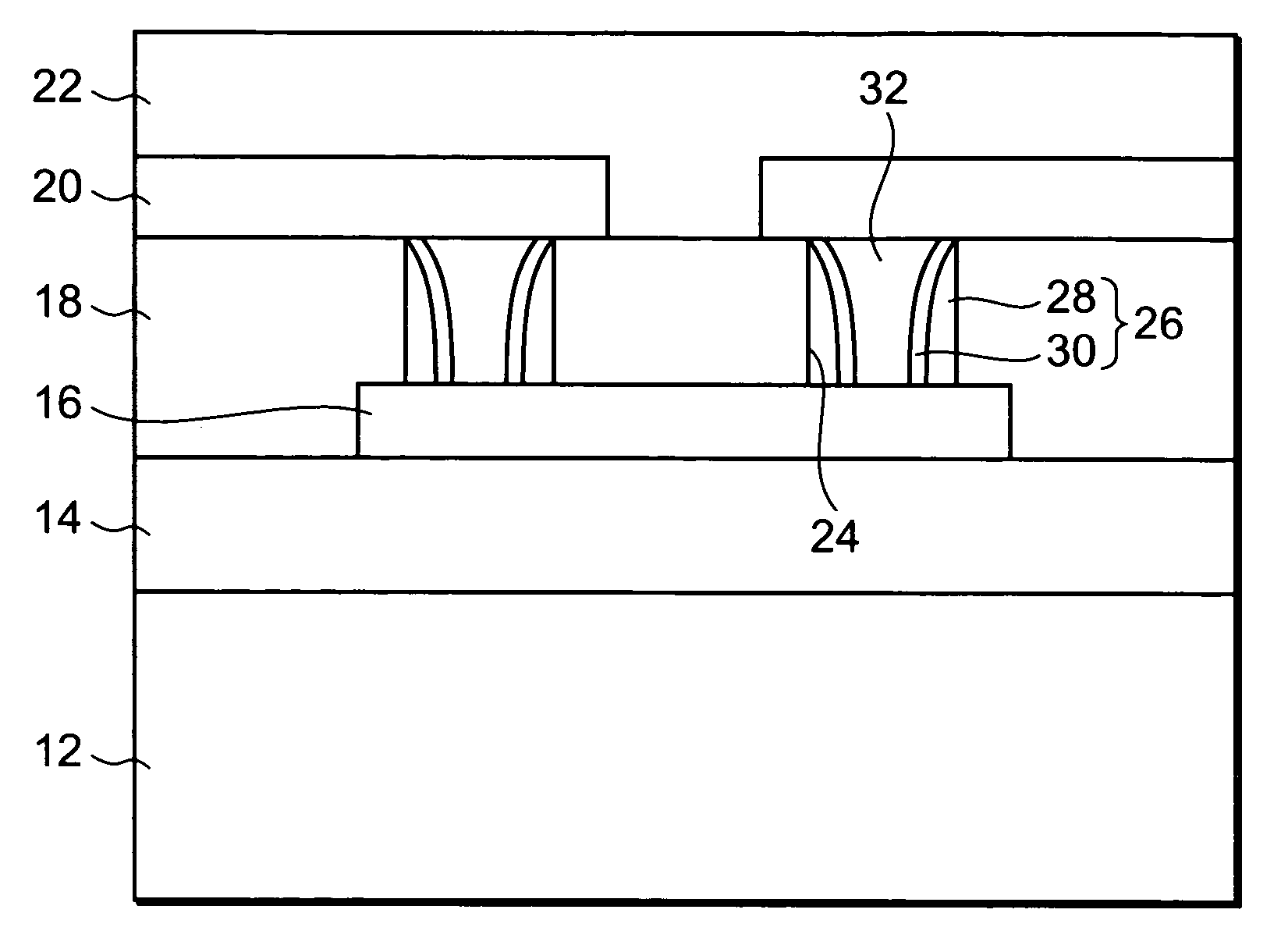

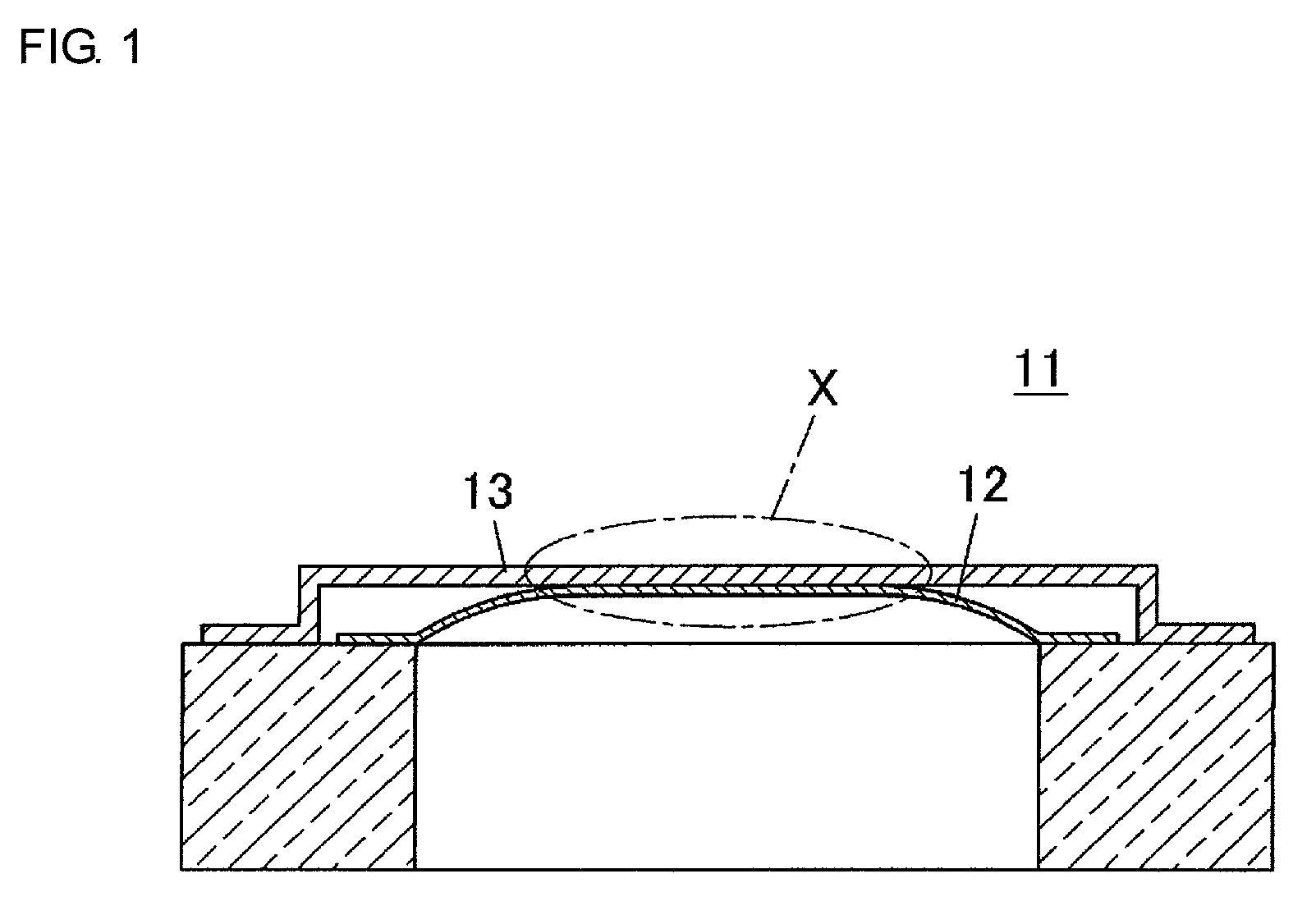

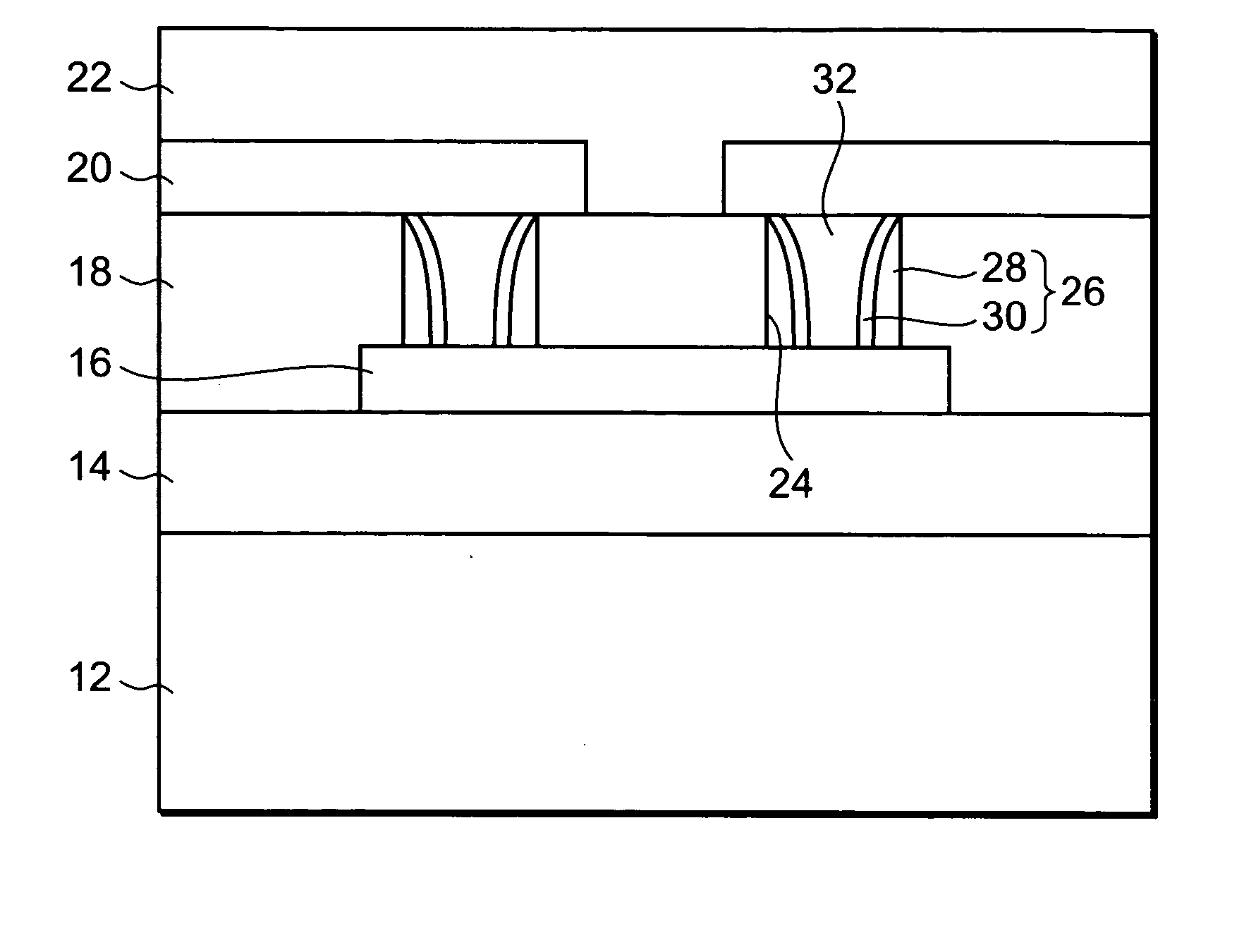

Semiconductor device

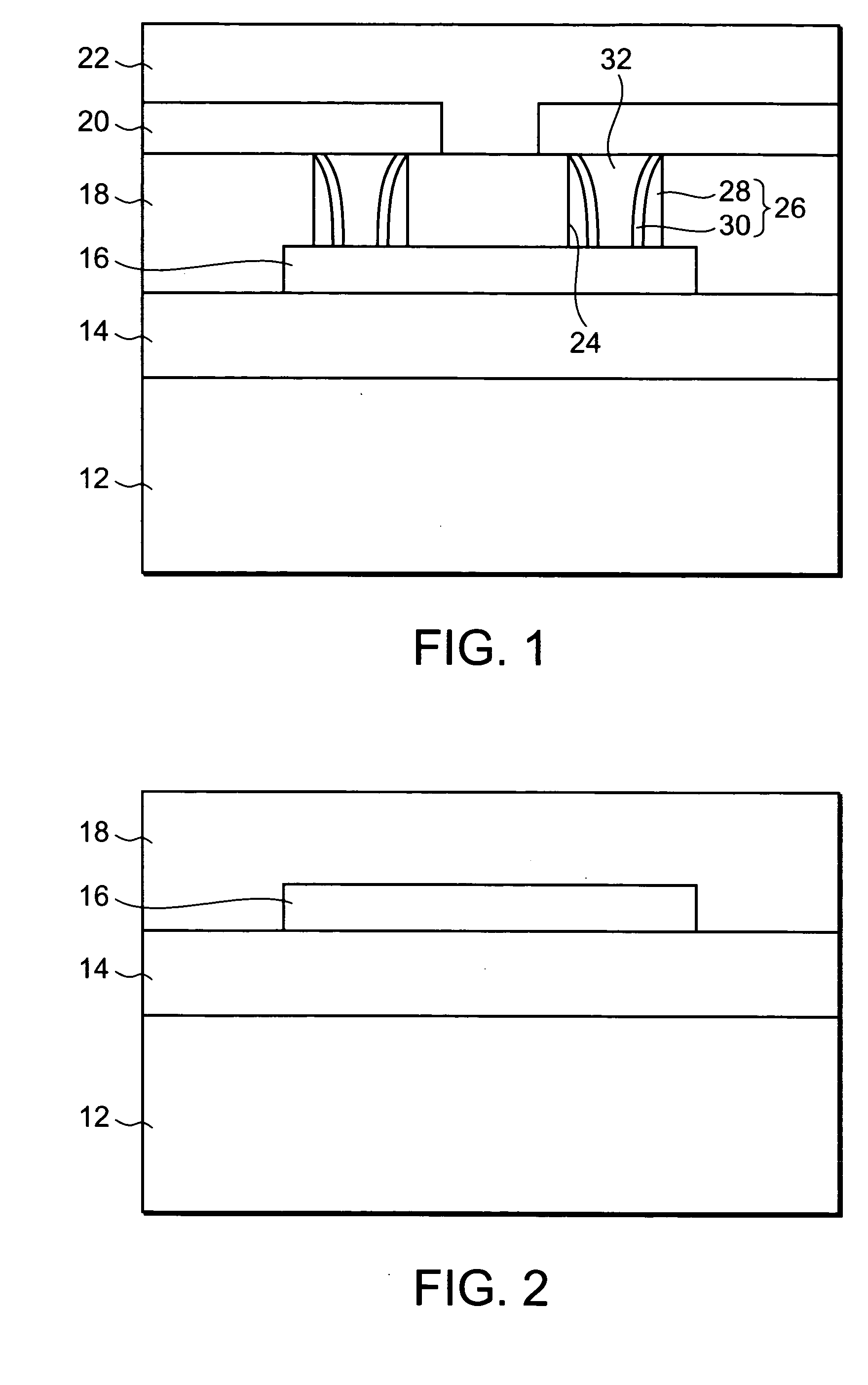

InactiveUS7095119B2Reduce the cross-sectional areaReduce wire connectionsSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

A semiconductor device is equipped with fuses each made of a conductive material vertically extended through an insulator layer employed in the semiconductor device. Holes are formed which vertically penetrate the insulator layer. Sidewalls are formed on their corresponding wall surfaces of the holes. The holes formed with the sidewalls are buried with a conductive material.

Owner:LAPIS SEMICON CO LTD

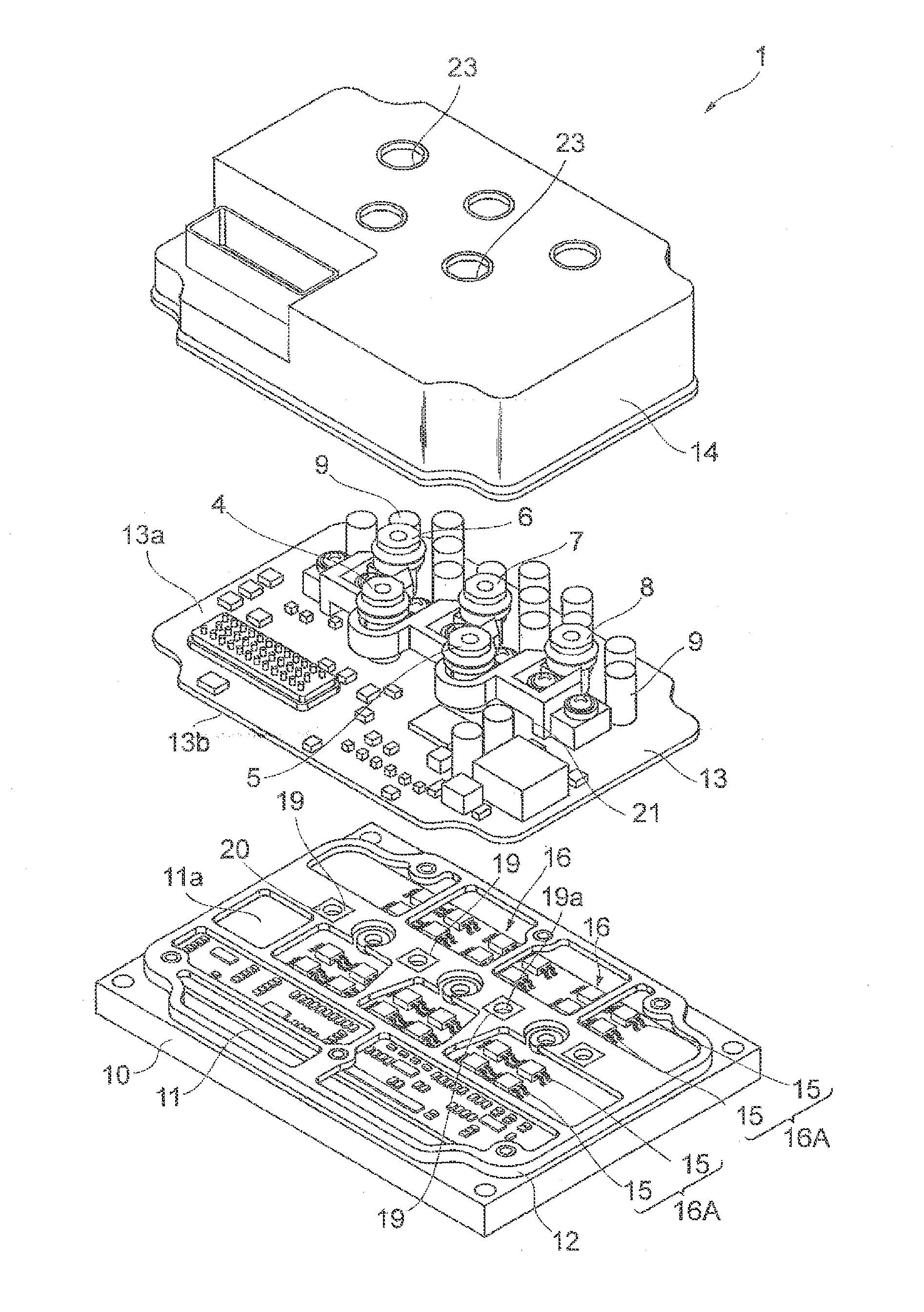

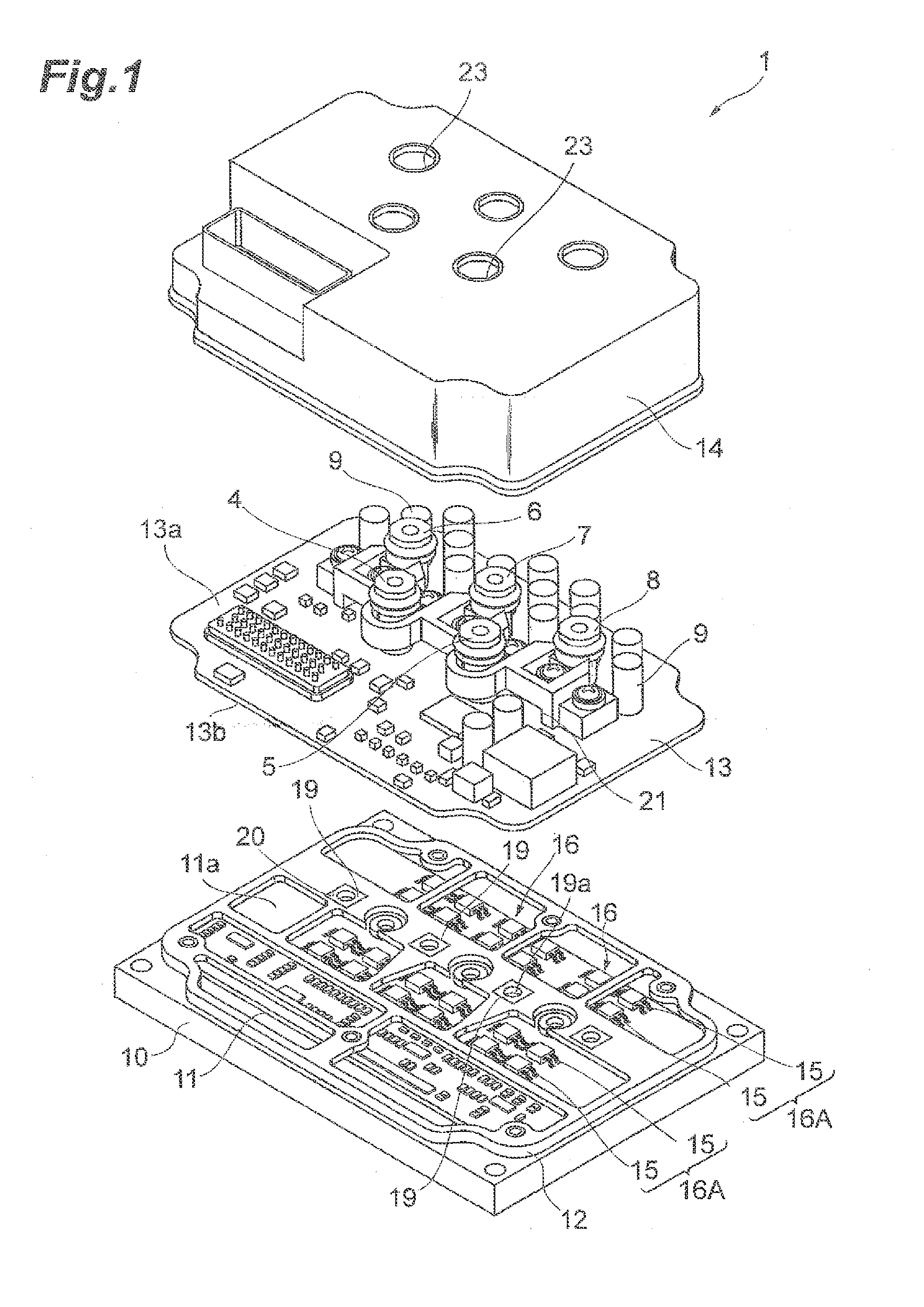

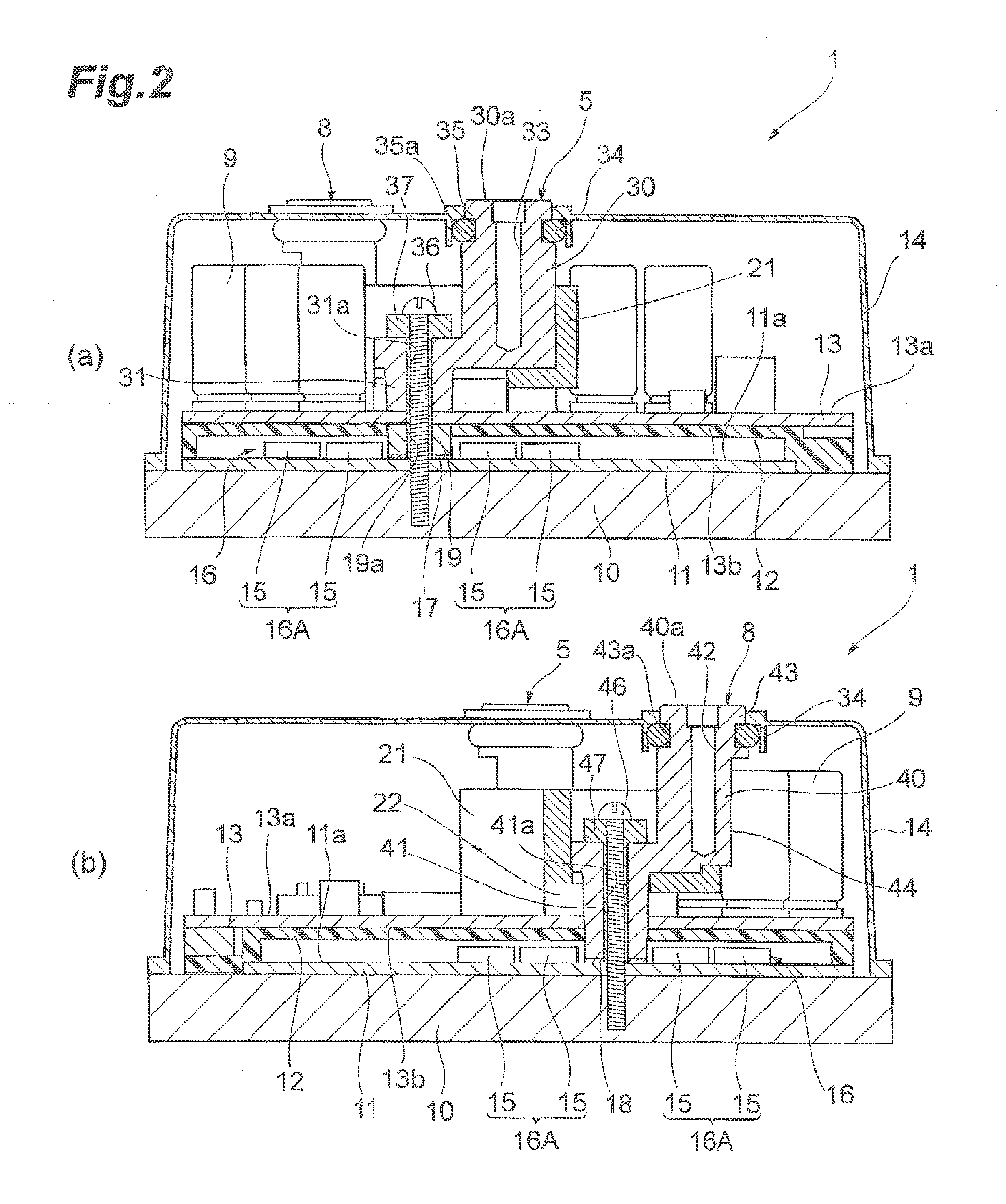

Semiconductor Device

ActiveUS20150208524A1Reduce the cross-sectional areaSmall sectional areaCasings with connectors and PCBConversion constructional detailsPower semiconductor deviceElectronic component

Owner:TOYOTA IND CORP

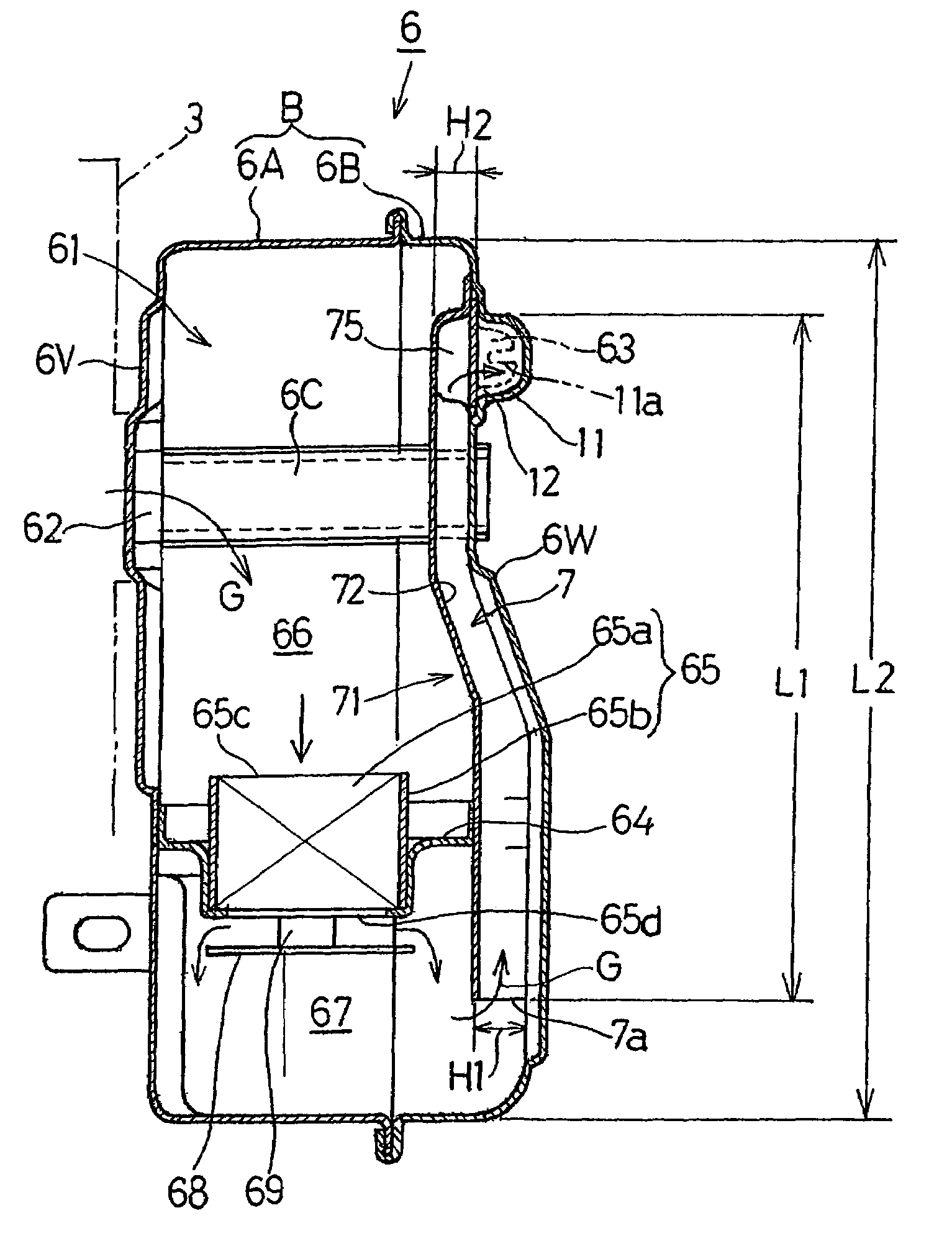

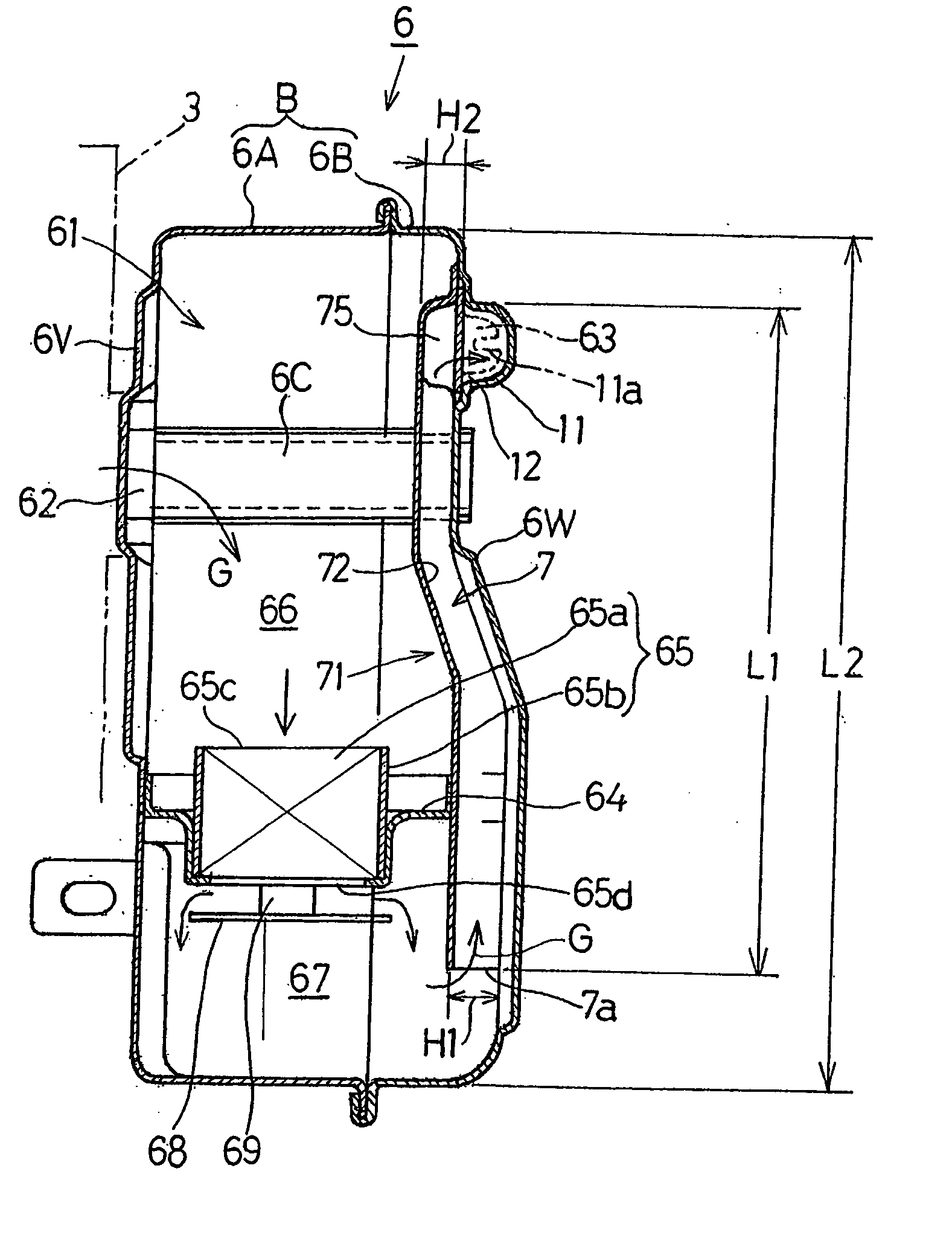

Muffler for compact combustion engines

ActiveUS7407036B2Simple structureReduce the temperatureExhaust apparatusSilencing apparatusCombustionInternal combustion engine

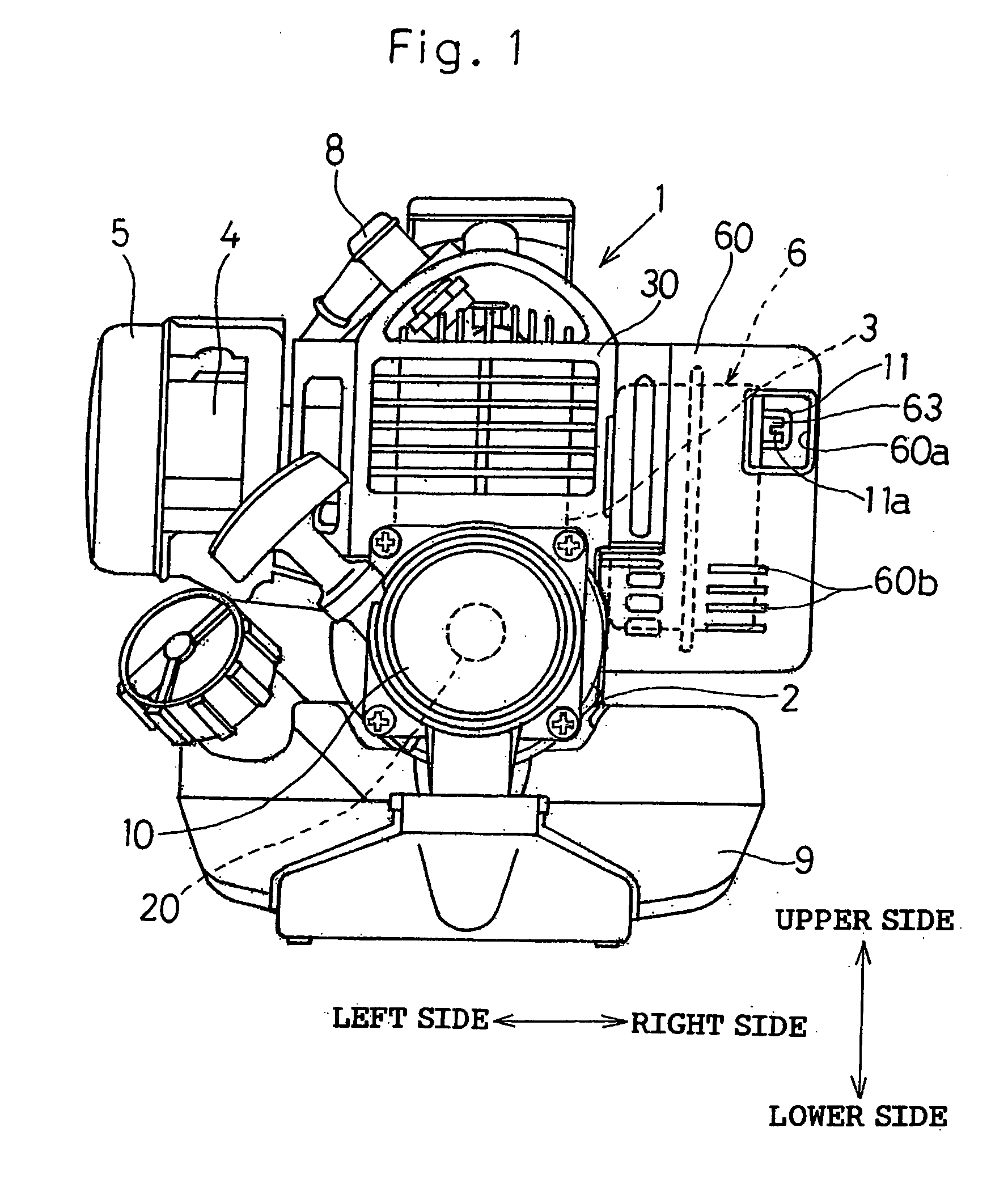

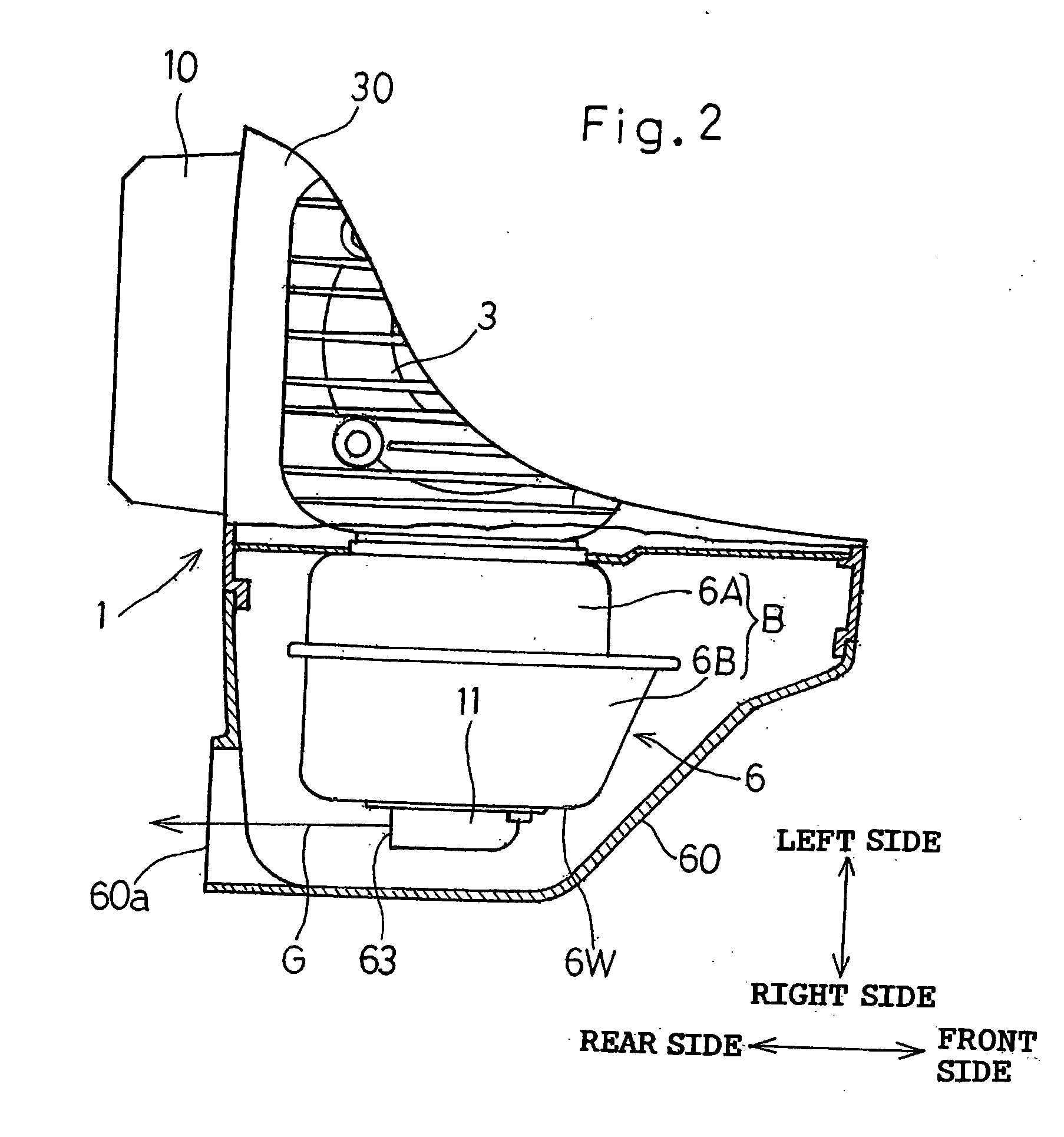

To provide a muffler for a compact combustion engine, which is simple in structure and effective to sufficiently reduce the temperature of exhaust gases while avoiding contact with an external air, an exhaust guide passage 7 for communicating the exhaust gases (G) to a discharge port (63) is provided within an interior hollow of a muffler housing 6 defining an exhaust chamber (61) therein, and a side wall of this exhaust guide passage (7) is constituted by a portion (6W) of the muffler housing (6) and a duct wall (71) jointed to the muffler housing (6).

Owner:KAWASAKI MOTORS LTD

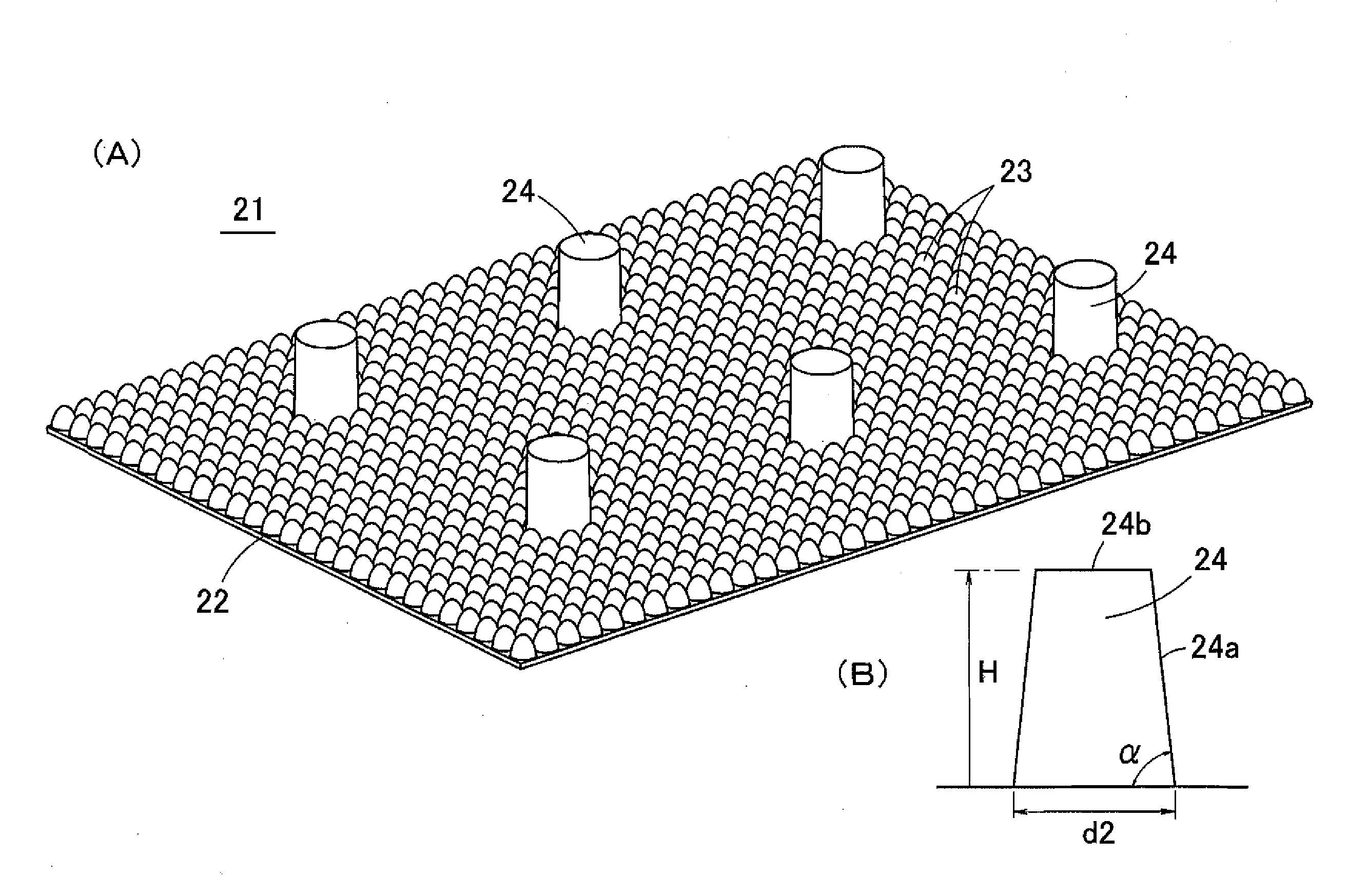

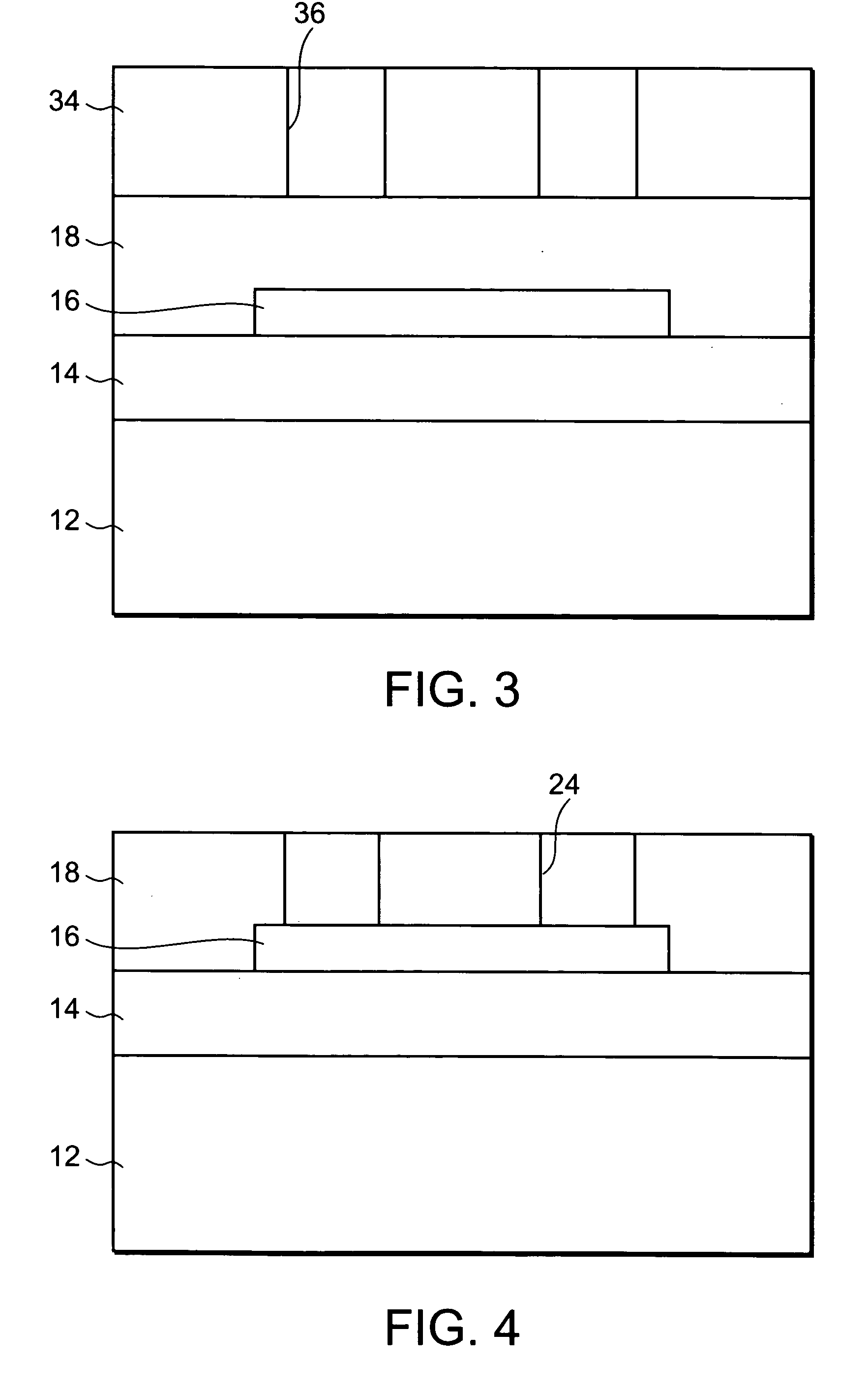

Contact prevention film, touch panel and display device cover panel

InactiveUS20150055032A1Good optical performanceSmall haze valueDetails for portable computersCoatingsDisplay deviceEngineering

Means of solution: Optical protrusions 23 of nano-size for restricting reflection of light and protection columns 24 for preventing crushing of the optical protrusions 23 are provided on a surface of a film substrate 22. The protection columns 24 have a frustum shape. When a ratio of a projection area in which all of lateral surfaces of a single protection column24 are projected on a surface of the film substrate 22 from a direction that is perpendicular to the surface of the film substrate 22 to a divided area on the surface of the film substrate 22 with respect to the single protection column 24 is defined to be a lateral surface projection occupying area rate, the lateral surface projection occupying area rate of the antireflection film is not more than 0.25% and not less than 0.01%.

Owner:SOKEN CHEM & ENG CO LTD

Muffler for compact combustion engines

ActiveUS20050252715A1Improve cooling effectGood effectExhaust apparatusSilencing apparatusCombustionEngineering

To provide a muffler for a compact combustion engine, which is simple in structure and effective to sufficiently reduce the temperature of exhaust gases while avoiding contact with an external air, an exhaust guide passage 7 for communicating the exhaust gases (G) to a discharge port (63) is provided within an interior hollow of a muffler housing 6 defining an exhaust chamber (61) therein, and a side wall of this exhaust guide passage (7) is constituted by a portion (6W) of the muffler housing (6) and a duct wall (71) jointed to the muffler housing (6).

Owner:KAWASAKI MOTORS LTD

Acoustic sensor

ActiveUS8379887B2Easy to pasteIncrease intervalMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidCapacitanceVibrating electrode

A vibrating electrode plate that senses a sound pressure faces a counter electrode plate to constitute a capacitance type acoustic sensor. In the counter electrode plate, acoustic perforations are opened in order to pass vibration, and plural projections are provided on a surface facing the vibrating electrode plate. An interval between the projections is decreased in a region where the vibrating electrode plate has high flexibility to easily generate local sticking with the counter electrode plate. The interval between the projections is increased in a region where the vibrating electrode plate has low flexibility to hardly generate local sticking with the counter electrode plate. The projections thus arranged prevent firm fixing of the vibrating electrode plate to the counter electrode plate and interruption of vibration of the vibrating electrode plate.

Owner:MMI SEMICON CO LTD

Spark plug

ActiveUS8288929B2Easy to riseRate of exhaustion of becomes largeSparking plugsGrounding electrodesMinimum distance

A spark plug comprising a center electrode, a first noble metal tip joined to the center electrode, an insulator, a metallic shell, a ground electrode joined to the metallic shell and including an outer layer and an inner layer, and a second noble metal tip joined to the ground electrode by way of a melted portion, wherein in a cross section of the ground electrode, the protrusion height A of the second noble metal tip is 0.4mm or more, the ground electrode includes a substantially flat joining surface to which the second noble metal tip is joined and an outwardly curved surface, the inner layer has at the joining surface side a substantially flat surface or recessed surface, and the minimum distance F between the melted portion and the inner layer is 0.1mm or more.

Owner:NGK SPARK PLUG CO LTD

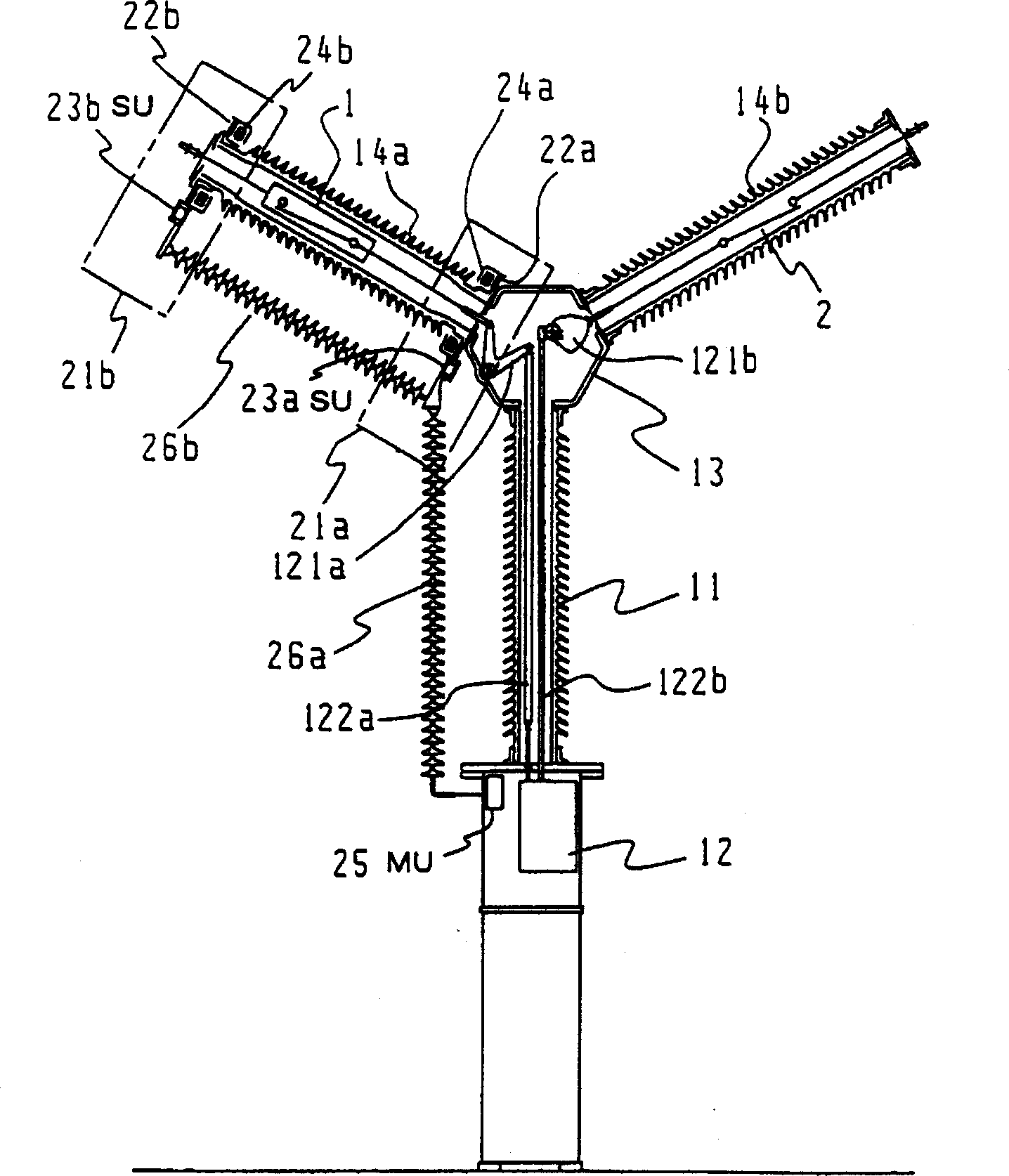

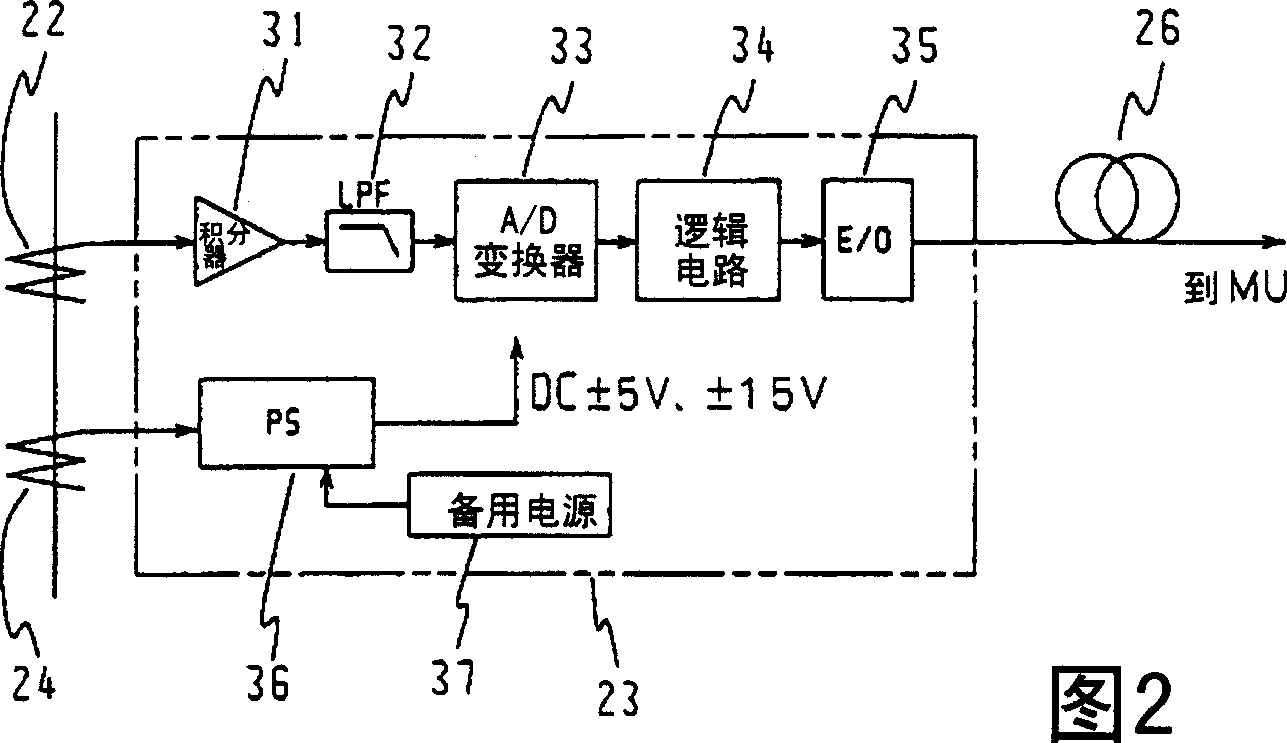

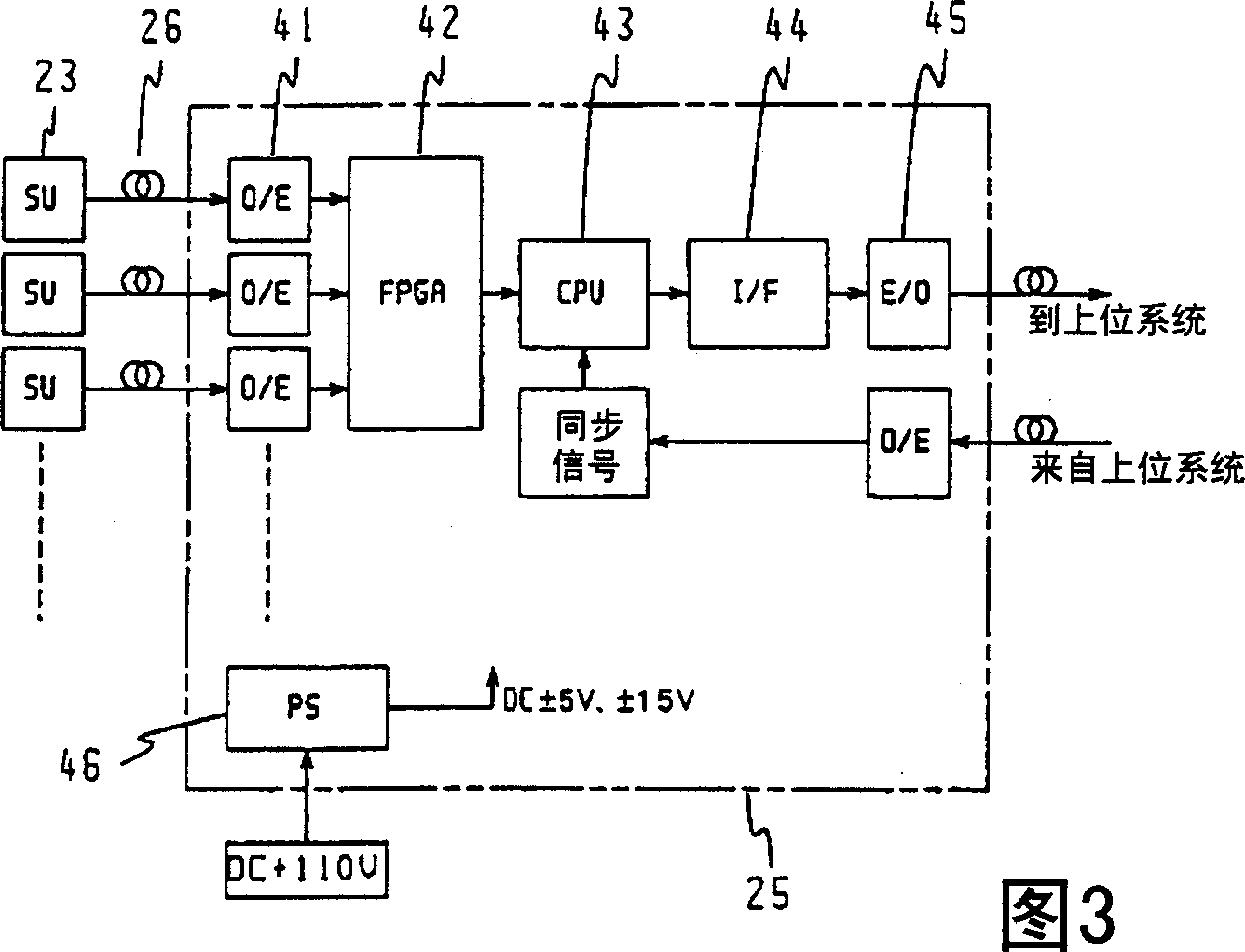

Current transformer used on composite type gas insulation switch

InactiveCN1353487AIncreased Design FreedomSmall output powerElectric signal transmission systemsVoltage/current isolationEngineeringSwitchgear

The present invention provides a current transformer for a compound-type gas-insulated switchgear which can be arranged on either side of a circuit-breaker. To the lower end of an insulating support structure 11, an operating apparatus 12 is connected, and to the upper end a metal container 13 is connected. To the upper part of the metal container 13, a first ceramic bushing 14a, in which a circuit-breaker 1 is housed and a second porcelain bushing 14b in which a disconnector 2 is housed, are connected. The circuit- breaker 1 and the disconnector 2 are opening / closing-operated by the operating apparatus 12. Current transformers 21a, 21b are set at both ends of the ceramic bushing 14a. The current transformers 21a, 21b are composed of current detect means 22a, 22b, sensor units 23a, 23b, power-feeding current transformers 25a, 24b and an integrating unit 25. The integrating unit is set in a housing part for the operating apparatus, and the sensor units 23a, 23b and integrating unit are connected to each other with insulators 26a, 26b which house optical fibers.

Owner:KK TOSHIBA

Semiconductor device

InactiveUS20050067705A1Reduce the cross-sectional areaReduce wire connectionsSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device is equipped with fuses each made of a conductive material vertically extended through an insulator layer employed in the semiconductor device. Holes are formed which vertically penetrate the insulator layer. Sidewalls are formed on their corresponding wall surfaces of the holes. The holes formed with the sidewalls are buried with a conductive material.

Owner:LAPIS SEMICON CO LTD

Contact prevention film, touch panel and display device cover panel

InactiveUS9557448B2Avoid it happening againSmall valueDiffusing elementsDetails for portable computersDisplay deviceEngineering

Owner:SOKEN CHEM & ENG CO LTD

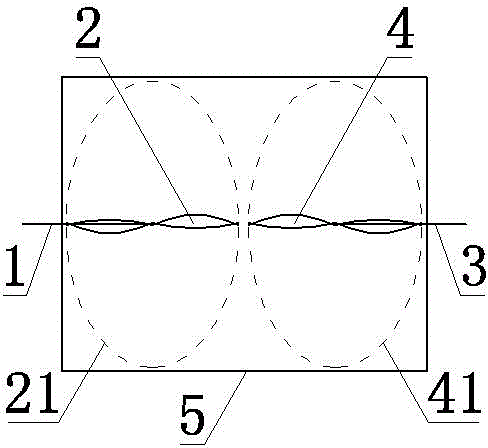

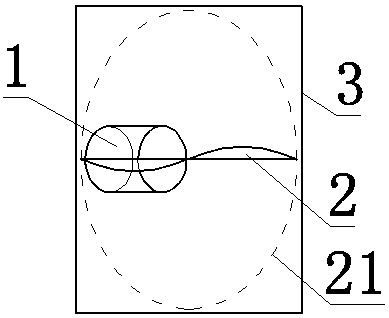

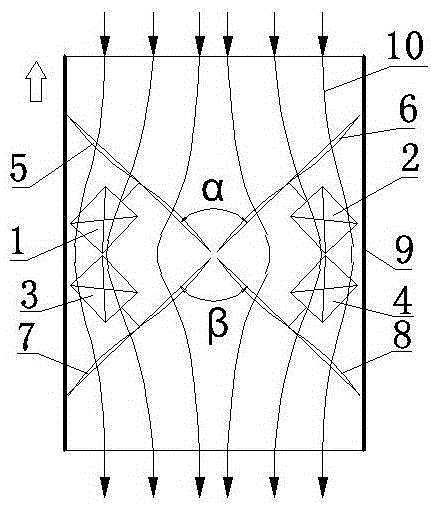

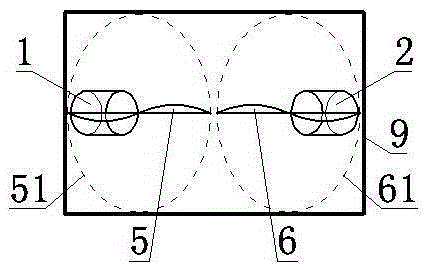

Double-oar square-tube marine propulsor device

A double-oar square-tube marine propulsor device relates to a ship propulsor. The double-oar square-tube marine propulsor device comprises a left main shaft, a left propeller, a right main shaft, a right propeller and a square-tube-shaped housing. The left main shaft is mounted on the left plate of the square-tube-shaped housing through a bearing. The left end of the left main shaft is oriented to the left front direction and is arranged at the left outer side of the square-tube-shaped housing, and the right end is connected with the left propeller in the square-tube-shaped housing. The left propeller and the right propeller are symmetrical in a left-and-right direction. An included angle between the rotating plane of the left propeller and the rotating plane of the right propeller is smaller than 150 DEG. The rotating plane of the left propeller is perpendicular with the top board and the base board of the square-tube-shaped housing. The square-tube-shaped housing is in compact matching with the left propeller and the right propeller. A power is transmitted to the left propeller and the right propeller respectively through the left main shaft and the right main shaft. The rotation directions of the left propeller and the right propeller are opposite. Compared with a traditional marine propulsor, the double-oar square-tube marine propulsor device has advantages of higher efficiency and small resistance when a same flow is realized.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

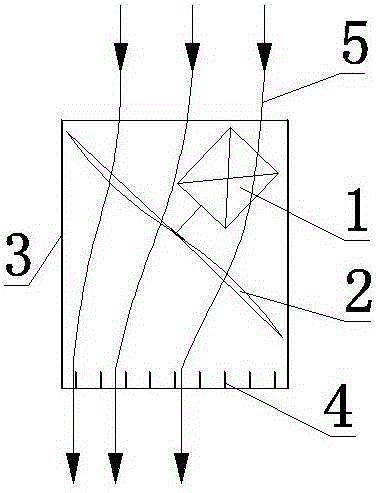

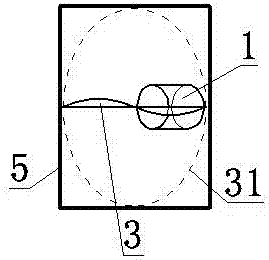

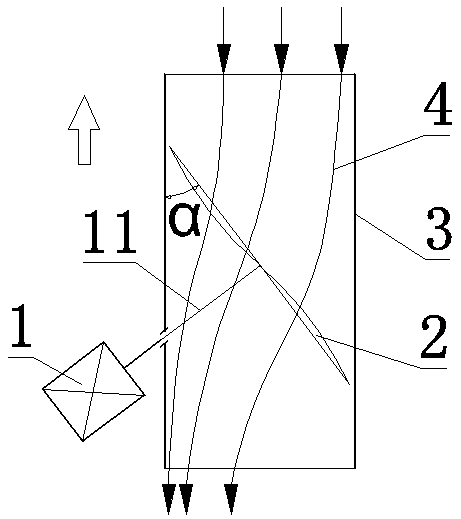

A square tube fan for cooling the engine

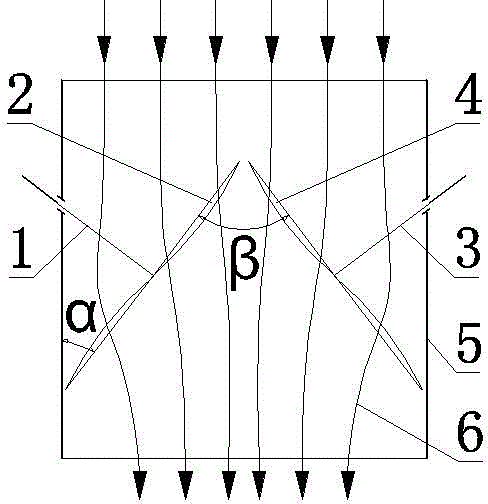

ActiveCN105221448BEasy to installSmall sectional areaPump componentsEngine cooling apparatusAcute angleEngineering

The invention discloses a square pipe fan convenient for engine cooling, and relates to a fan. The square pipe fan comprises an engine, a bracket, a blade and a square pipe type shell. An output shaft of the engine and an opening direction of the square pipe type shell are formed to an acute angle. A rotating plane of the blade is perpendicular to the output shaft of the engine, and is formed to an acute angle with the opening direction of the square pipe type shell. The inner periphery of the cross section of the square pipe type shell is rectangular; the length of the rectangle is slightly greater than the maximal outer diameter of the blade rotating along with the output shaft of the engine; and the width of the rectangle is slightly greater than a product between the maximal outer diameter of the blade rotating along with the output shaft of the engine and the sine of the acute angle formed by the rotating plane of the blade and the opening direction of the square pipe type shell. A rotating center of the blade is positioned on a geometric center line of the opening direction of the square pipe type shell. The engine is positioned at the downstream of an air flow. Compared with a traditional axial flow fan, the square pipe fan is much smaller in section under the condition of equal flow, so that the square pipe fan is convenient to be installed in a narrow space.

Owner:DEZHOU ZHONGWEI AIR CONDITIONING EQUIP

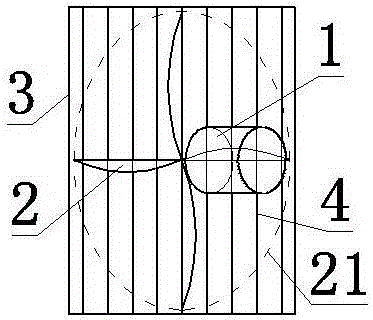

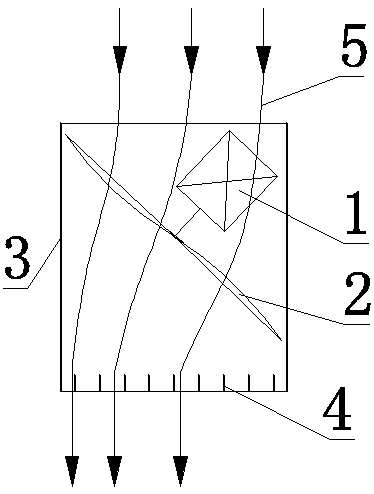

Square tube-shaped fan

ActiveCN105221449ASmall sectional areaEasy to installPump componentsPump installationsAcute angleEngineering

The invention provides a square tube-shaped fan and relates to a fan. The square tube-shaped fan comprises an engine, a support, a fan blade, a square tube-shaped housing and a flow deflector. The engine is mounted inside the square tube-shaped housing through the support. Four flat plates are encircled to form the square-tube-shaped housing. The rotating plane of the fan blade is perpendicular to two parallel flat plates of the square tube-shaped housing and an acute angle is formed between the rotating plane of the fan blade and each of the other two parallel flat plates of the square tube-shaped housing. The engine is located upstream of airflow. The flow deflector is mounted at the outlet of the square tube-shaped housing. Compared with a traditional axial-flow fan, in case of the same flow, the sectional area of the square tube-shaped fan is much smaller, and therefore, the square tube-shaped fan can be mounted in a narrow space conveniently.

Owner:梵帝风机(泰州)有限公司

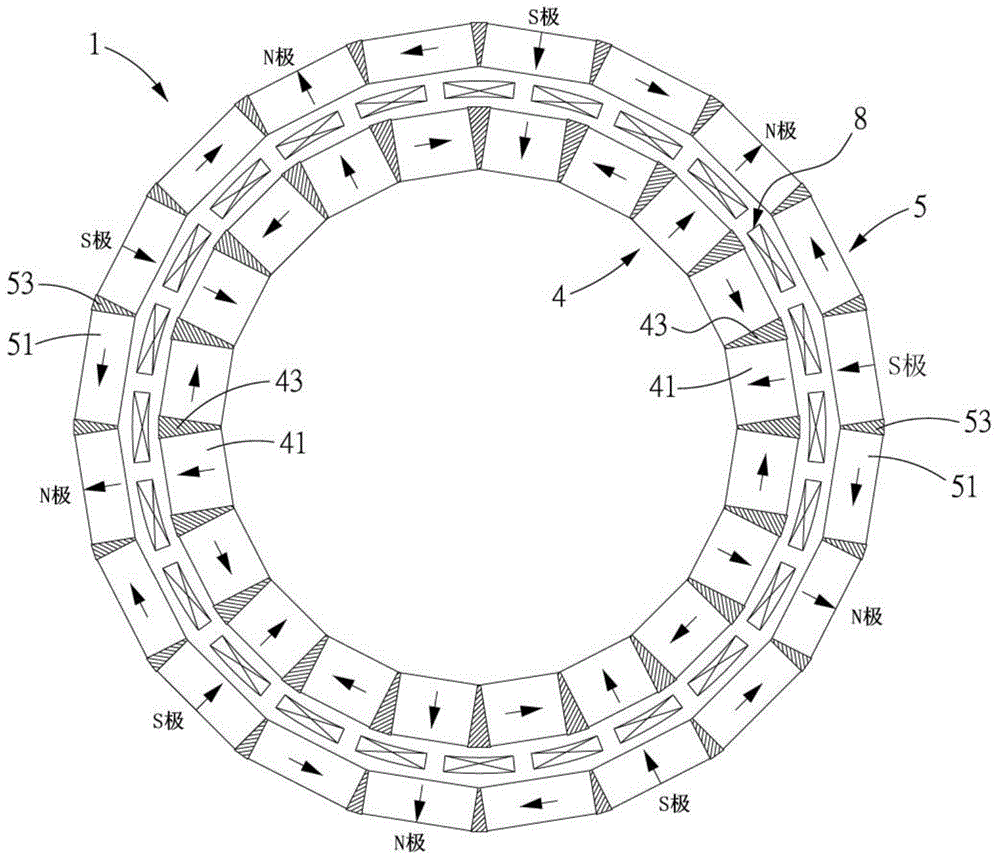

Rotary motor

InactiveCN105207378ALow costSmall sectional areaMagnetic circuit rotating partsFilling materialsPhysics

The invention discloses a rotary motor. The rotary motor is a double-layer Halbach type excitation rotary motor which can assist in decreasing manufacturing cost. The rotary motor comprises permanent magnets of which the sections are rectangle-shaped and are vertical to the rotation shaft; the permanent magnets are distributed annularly; the permanent magnets of which the sections are rectangle-shaped are distributed at intervals and are separated from each other by the same angle so as to form a ring-shaped structure; filling materials are inserted in wedge-shape slots between adjacent magnets; and the filling materials are composed of a non-magnetic material and a non-electric conduction material. With the above technical schemes of the invention adopted, the rotary motor can be manufactured with low cost. The permanent magnets of which the sections are rectangle-shaped and are vertical to the rotation shaft, are adopted, and therefore, cost for manufacturing the rotary motor can be decreased; the permanent magnets are used in such a manner, so that the consumption of magnets can be decreased, and resources can be saved; the filling materials are inserted between the adjacent permanent magnets, and therefore, the positions of the permanent magnets can be determined conveniently, and the permanent magnets can have sections vertical to the rotation shaft.

Owner:NEW SUN OVERSEA +5

A two-stage propeller for ships

ActiveCN105270589BSmall sectional areaImprove cooling effectPropulsive elementsPropellerDouble stage

A two-stage propeller for ships relates to a ship propeller, which comprises a front engine, a rear engine, a front propeller, a rear propeller and a square tube casing. The front propeller is mounted on the output shaft of the front engine, and the rear propeller is mounted on the output shaft of the rear engine. The diameters of the front propeller and the rear propeller are equal, and they are arranged inside the square tube shell one after the other. The forward angle between the rotation plane of the front propeller and the left plate of the square tubular shell is no more than 80°. The rearward angle between the rotation plane of the rear propeller and the left plate of the square tubular shell is no more than 80°. The planes of rotation of both the front and rear propellers are perpendicular to the top and bottom plates of the square tubular housing. Driven by the front engine and the rear engine respectively, the front propeller and the rear propeller rotate in the square tubular shell, sucking the water in the front into the square tubular shell and extruding it from the rear of the square tubular shell. Compared with traditional ship propellers, it has large thrust, low resistance and high efficiency.

Owner:SUZHOU RUIPENGCHENG SCI & TECH CO LTD

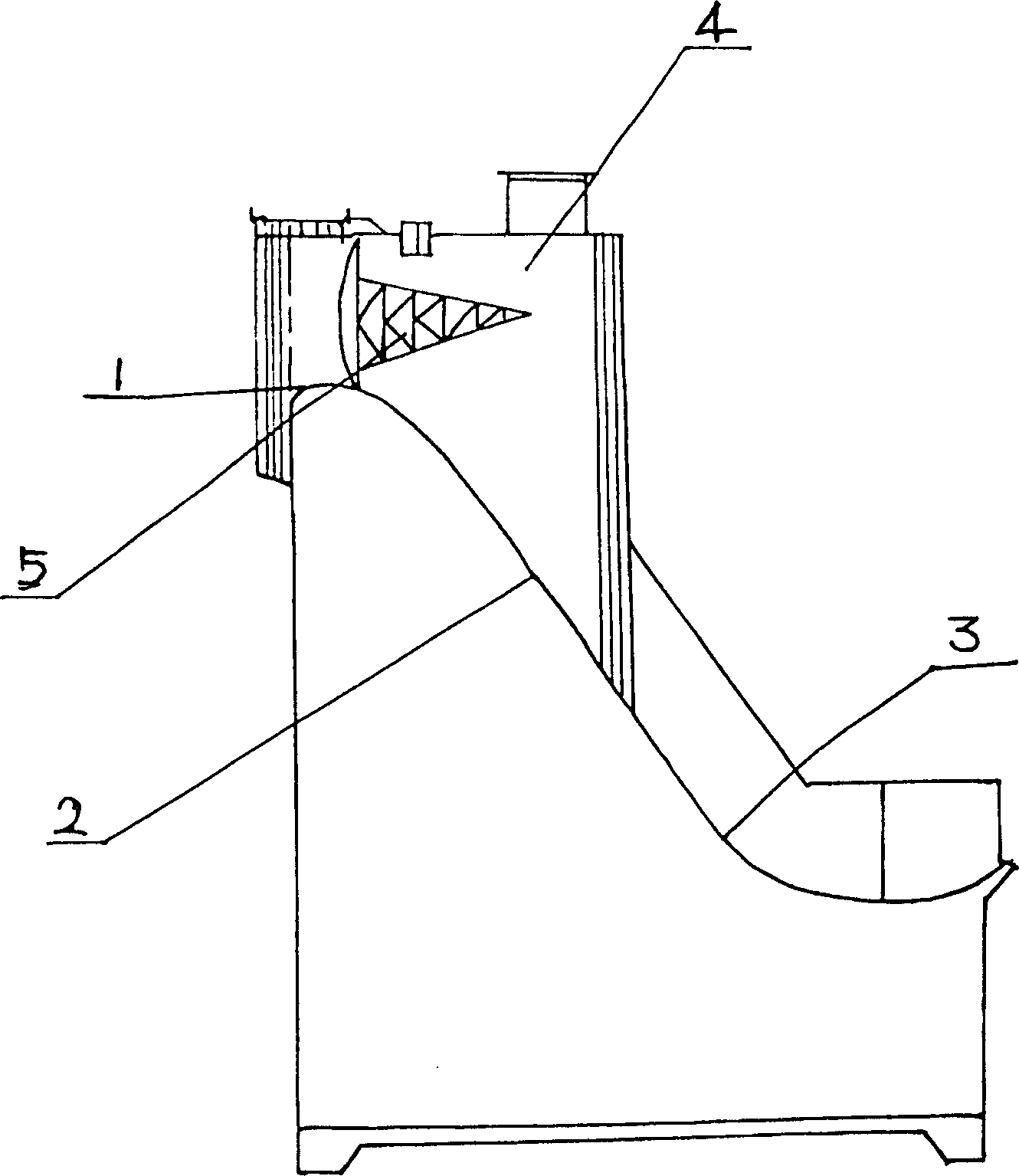

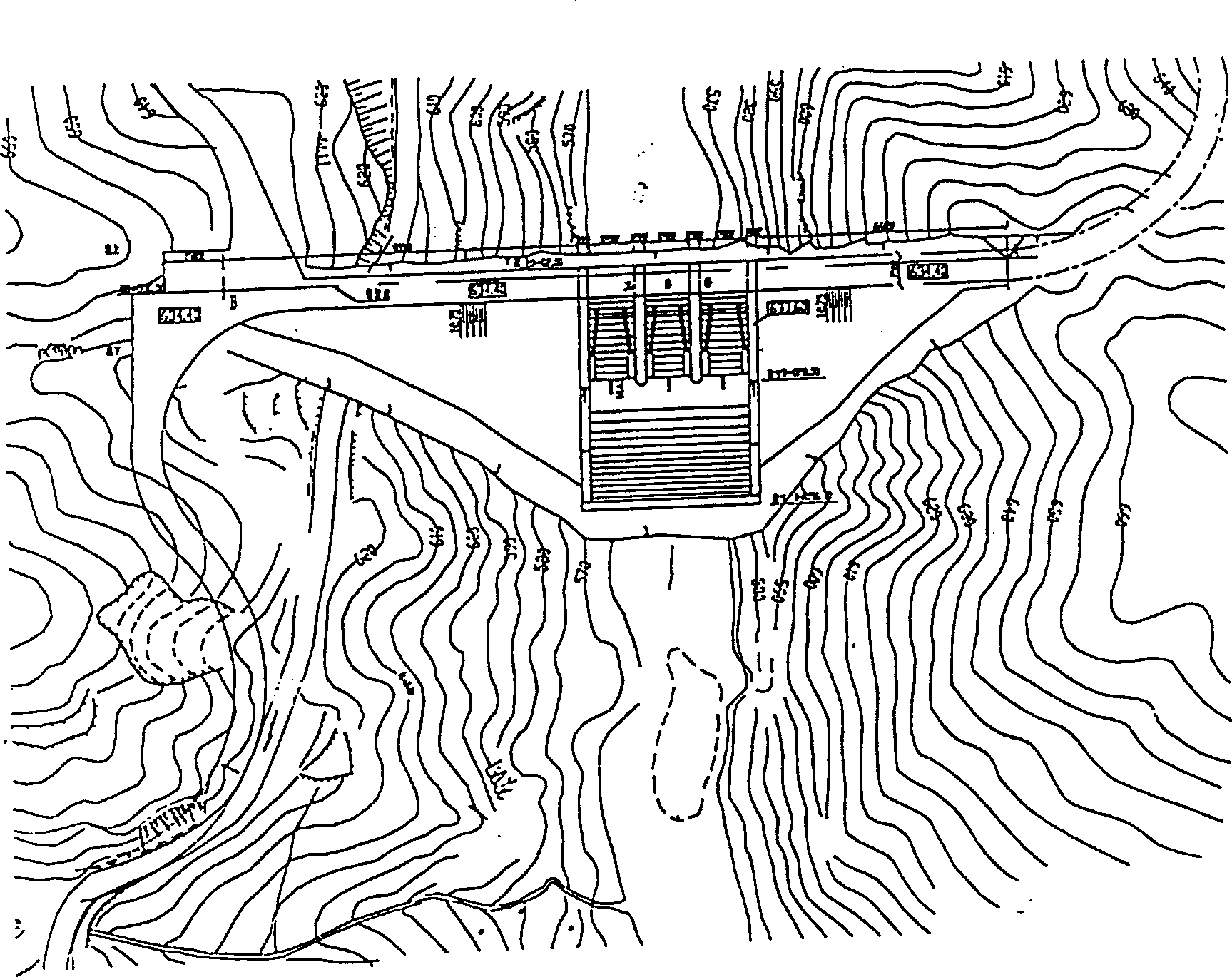

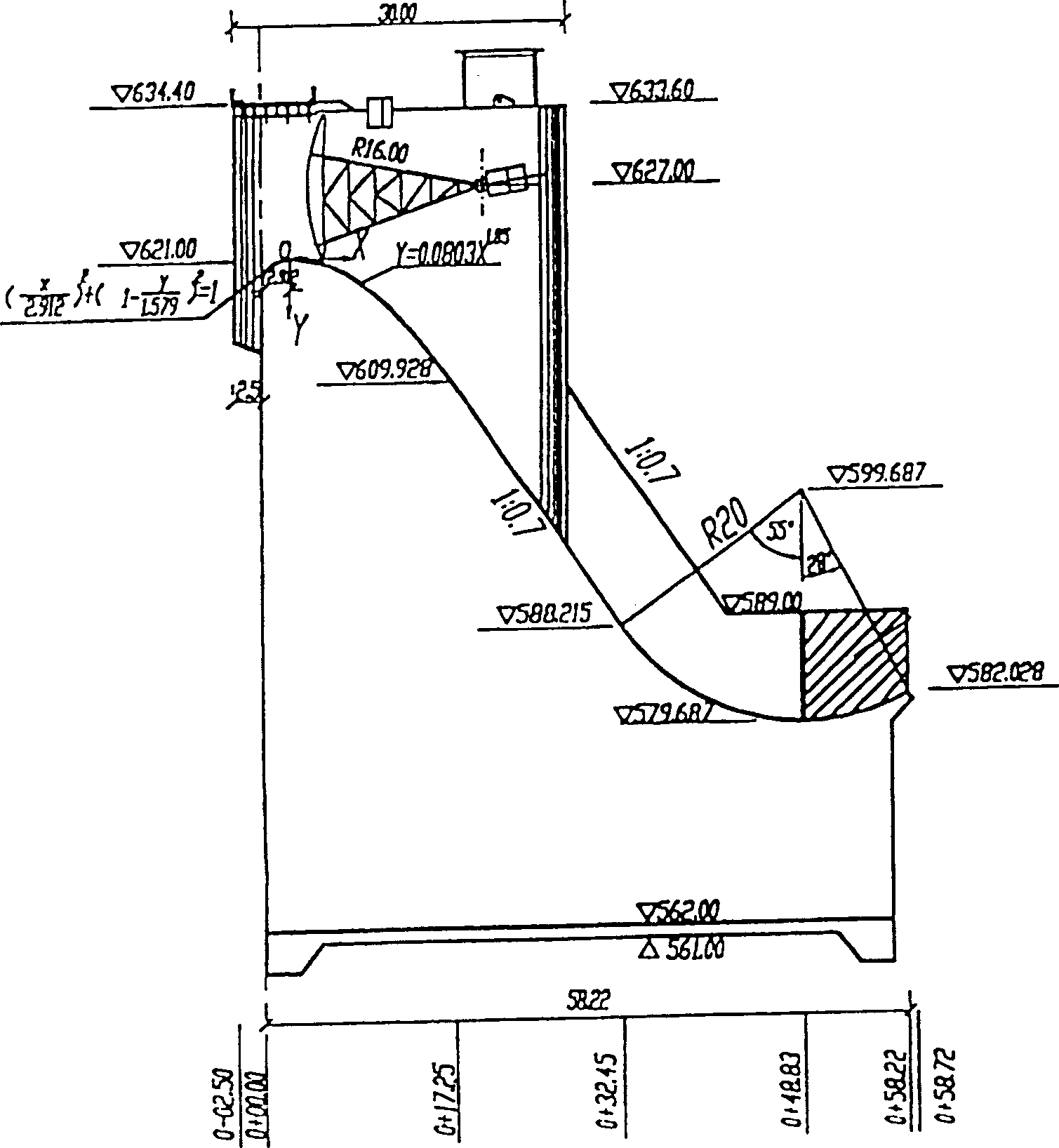

Method for designing practical weir in broadband and coarse vacuum

InactiveCN1277994CLarge flood capacityNo harmful negative pressure occursBarrages/weirsSystems designCarrying capacity

The present invention discloses a design method of broad base low-vacuum practial weir. Said invention includes system design mentality, weir surface curve design, flood carrying capacity calculation method, finite element stress check calculation and technical economic comparison of new weir type and WES weir. The most key of said design includes three factors of flood carrying capacity, weir surface pressure and volume of dam body, and its concrete design calculation method includes two portions of body type designand discharge coefficient definition.

Owner:FUJIAN PROVINCIAL INVESTIGATION DESIGN & RES INST OF WATER CONSERVANCY & HYDROPOWER

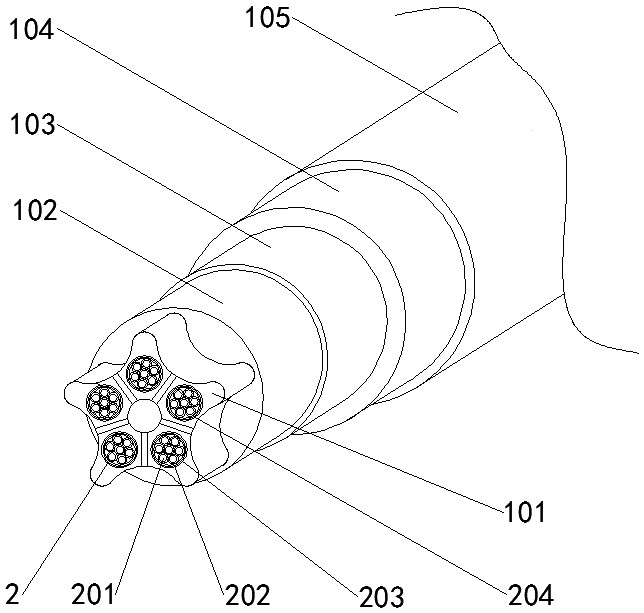

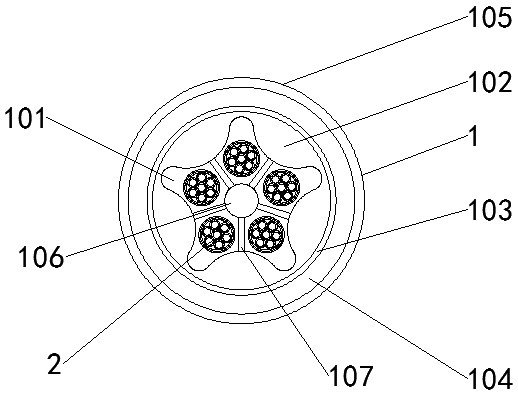

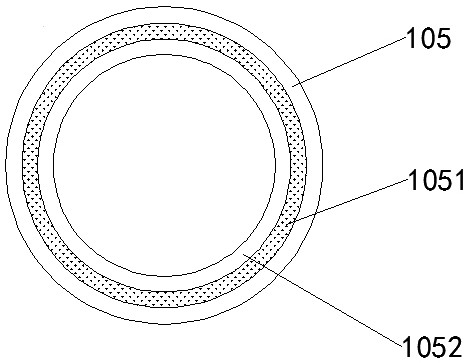

Flame-retardant power cable

PendingCN113012853AImprove flame retardant performanceNot prone to crackingClimate change adaptationInsulated cablesCarbon fibersPower cable

The invention discloses a flame-retardant power cable, and belongs to the technical field of cables. The technical key points are that the flame-retardant power cable comprises a cable main body, a filling layer is arranged in the middle of the cable main body, and a carbon fiber layer, an aerogel felt layer, an ethylene-propylene copolymer and a halogen-free flame-retardant jacket are sequentially arranged on the outer side wall of the filling layer from inside to outside. A polyvinyl chloride column body is arranged in the middle of the filling layer, a plurality of uniformly distributed alumina fiber blocking edges are fixedly connected to the outer side wall of the polyvinyl chloride column body, and conductor main bodies are arranged between every two adjacent alumina fiber blocking edges. An alumina fiber coating and rock wool are sequentially arranged on the inner side wall of the halogen-free flame-retardant outer sleeve from outside to inside. The polyvinyl chloride cylinders reinforce the non-deformability of a power cable, facilitate the protection to the conductors and prevent the conductors from being broken, and the polyvinyl chloride cylinders are made of ultra-light high-temperature heat-insulating materials, so that the flame-retardant performance of the power cable is further enhanced, the flame-retardant effect is achieved inside and outside the power cable, and the safety performance of the power cable is improved.

Owner:康乐

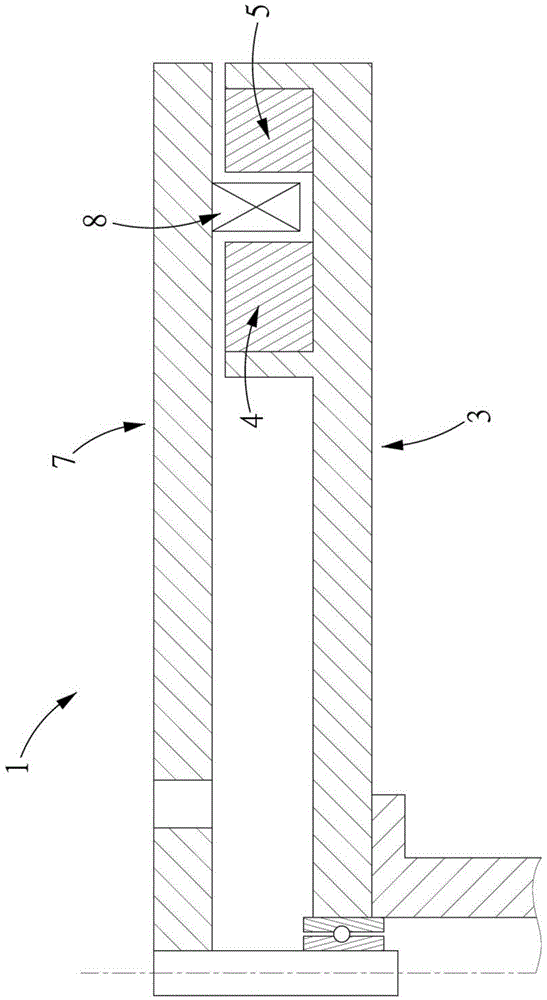

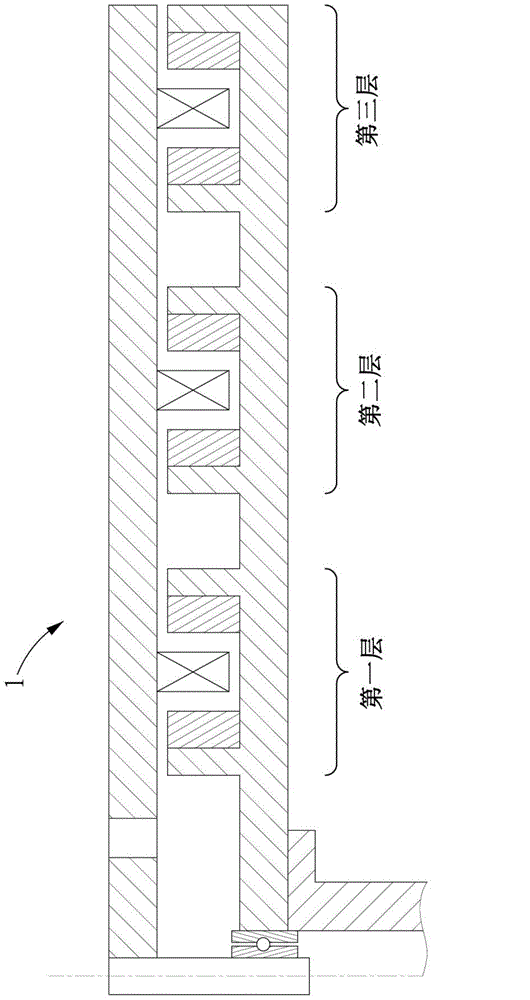

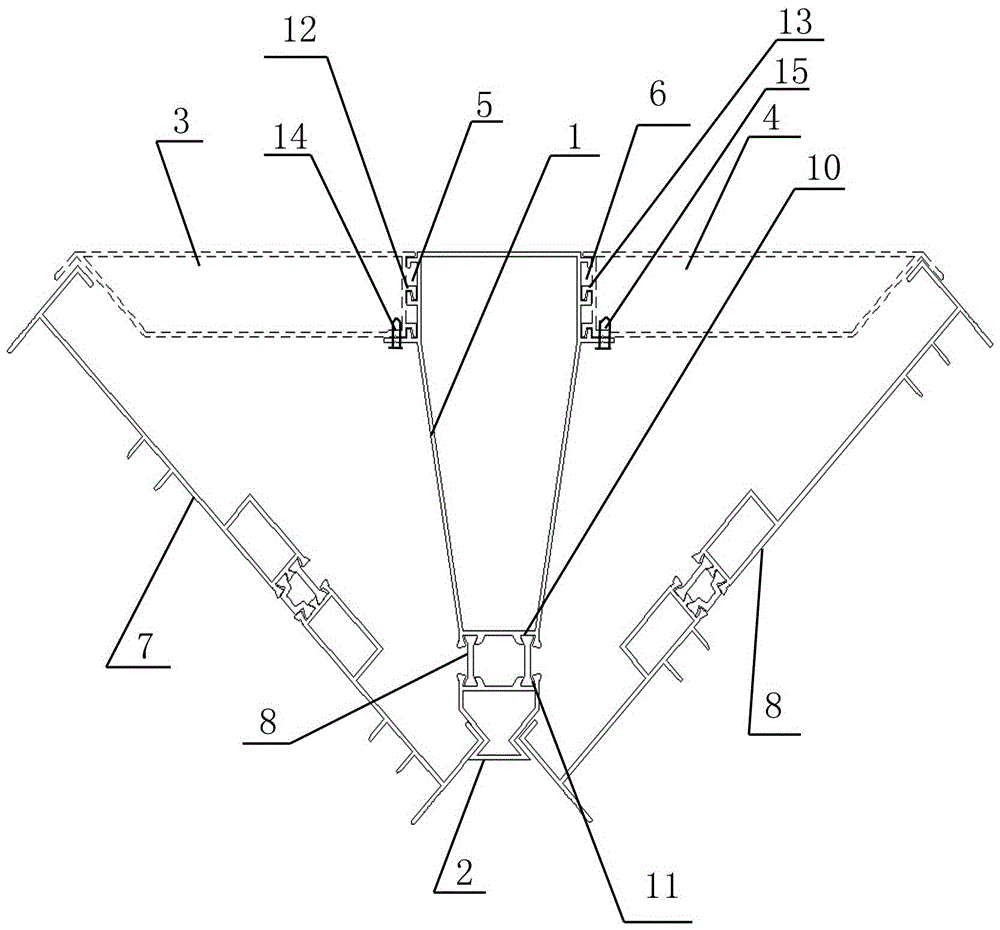

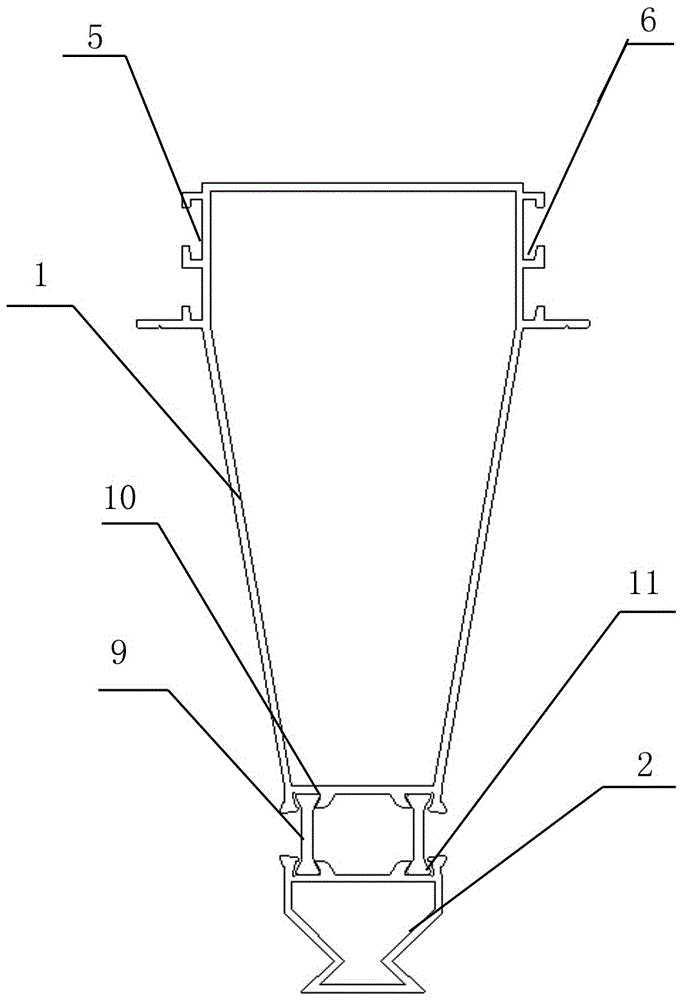

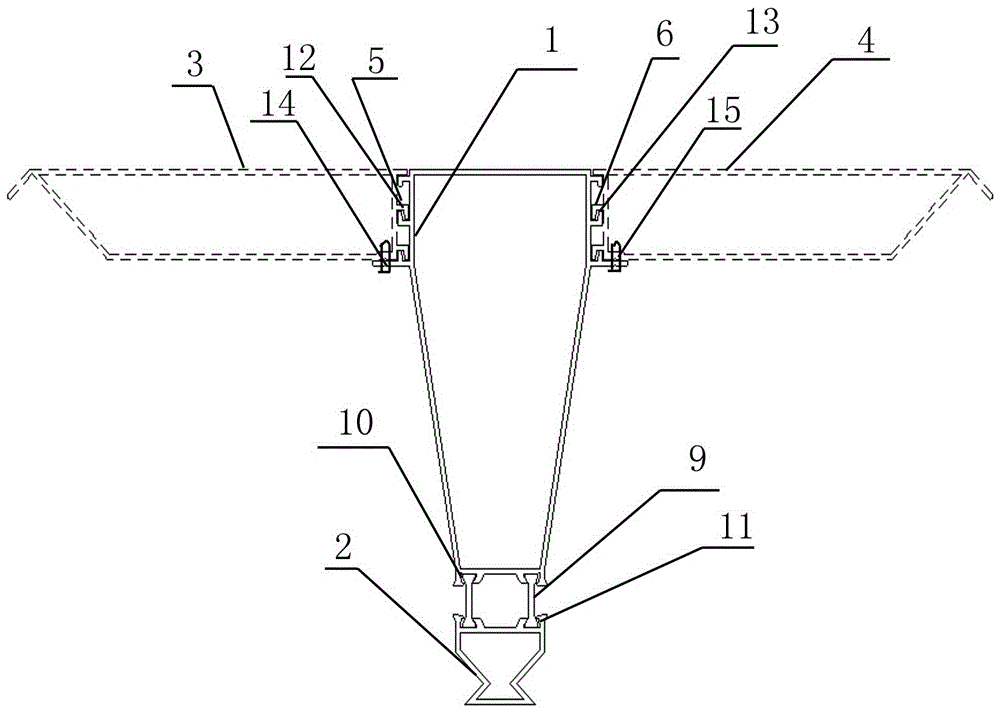

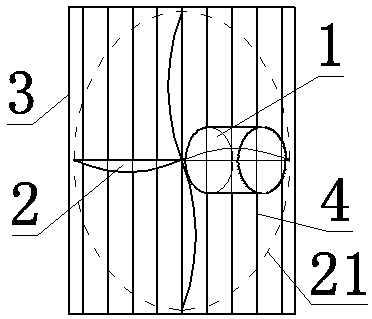

Combined aluminum alloy door window corner structure

The invention discloses a combined aluminum alloy door window corner structure. A left corner auxiliary material (3) and a right corner auxiliary material (4) are connected to the two sides of the upper portion of an upper corner main material (1) respectively, one end of the left corner auxiliary material (3) is inserted into a left insertion groove (5) formed in the left side of the upper portion of the upper corner main material (1) and detachably connected with the upper corner main material (1), and one end of the right corner auxiliary material (4) is inserted into a right insertion groove (6) formed in the right side of the upper portion of the upper corner main material (1) and detachably connected with the upper corner main material (1); a thermal insulation strip combination is arranged between the bottom of the upper corner main material (1) and a lower corner main material (2), a left double-layer window vertical material (7) is arranged between the other end of the left corner auxiliary material (3) and the left side of the lower corner main material (2), and a right double-layer window vertical material (8) is arranged between the other end of the right corner auxiliary material (4) and the right side of the lower corner main material (2). Accordingly, the machining cost is greatly reduced.

Owner:江苏宇马铝业有限公司

A square tube propeller ship propeller

A ship propeller with a square tube propeller relates to a ship propeller, which includes an engine, a propeller and a square tube casing. The engine is mounted on the outside of the square tube casing through brackets. The rotation plane of the propeller is perpendicular to the output shaft of the engine, and the rotation plane of the propeller forms an acute angle with the opening direction of the square tubular shell. The section of the propeller is airfoil. The inner circumference of the cross-section of the square tubular shell is rectangular, the length of the rectangle is slightly greater than the maximum outer diameter of the propeller, and the width of the rectangle is slightly greater than the maximum external diameter of the propeller, the rotation plane of the propeller and the opening direction of the square tubular shell. The product of the sines of the acute angles formed. The propeller is completely inside the square tube housing. The propeller can rotate flexibly in the square tubular casing. Compared with the traditional ship propeller, the cross-sectional area of the propeller of the present invention is much smaller when the flow rate is the same, and the efficiency is high and the resistance is small.

Owner:DUTCH THRUSTLEADER MARINE PROPULSION (JIANGSU) CO LTD

A square tube fan

ActiveCN105221449BSmall sectional areaEasy to installPump componentsPump installationsAcute angleInsertion stent

A square-tube fan relates to a fan, which includes a motor, a bracket, fan blades, a square-tube casing and a guide vane. The engine is mounted inside the square tubular casing with brackets. The square tubular shell is surrounded by four flat plates. The rotation plane of the fan blade is perpendicular to the two parallel flat plates of the square tube-shaped casing, and the rotation plane of the fan blade forms an acute angle with the other two parallel flat plates of the square tube-shaped casing. The engine is upstream in the airflow. The deflector is installed at the outlet of the square tube housing. Compared with the traditional axial flow fan, the cross-sectional area of the fan of the present invention is much smaller when the flow rate is the same, and it is convenient to be installed in a narrow space.

Owner:梵帝风机(泰州)有限公司

Symmetric double-stage propelling device for ship

The invention provides a symmetric double-stage propelling device for a ship, which relates to ship propelling devices. The symmetric double-stage propelling device for the ship comprises a left front engine, a right front engine, a left rear engine, a right rear engine, a left front propeller, a right front propeller, a left rear propeller, a right rear propeller and a square tube-shaped housing. The left front propeller, the right front propeller, the left rear propeller and the right rear propeller are symmetrically mounted within the square tube-shaped housing in pairs. A front angle between the rotating plane of the left front propeller and the rotating plane of the right front propeller is not more than 150 DEG. The rotating planes of the left front propeller, the right front propeller, the left rear propeller and the right rear propeller are all vertical to a top plate and a bottom plate of the square tube-shaped housing. The left front propeller, the right front propeller, the left rear propeller and the right rear propeller rotate under the driving of power so as to suck the water ahead of them into the square tube-shaped housing and then extrude the water from the backside of the square tube-shaped housing. Compared with the traditional ship propeller, the symmetric double-stage propelling device for the ship, provided by the invention, has the advantages of large thrust face, high efficiency and low resistance.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com