A two-stage propeller for ships

A technology for propellers and ships, applied in the direction of ship propulsion, propulsion components, ship components, etc., can solve the problems of low thrust, poor stability, and large resistance, and achieve the effect of strong propulsion, good stability, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

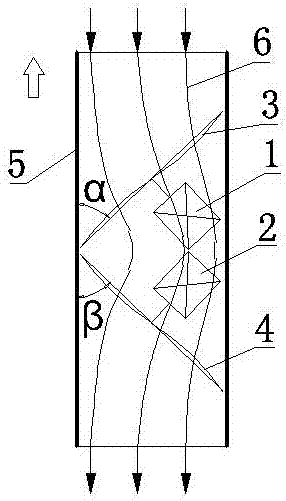

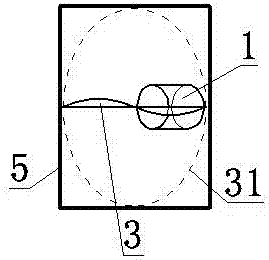

[0008] The present invention is described below in conjunction with accompanying drawing: with reference to accompanying drawing, a kind of two-stage thruster for ships comprises front engine 1, rear engine 2, front propeller 3, rear propeller 4 and square tubular shell 5. Square tubular shell 5 is surrounded by left plate, top plate, right plate and bottom plate. Front propeller 3 is installed on the output shaft of front engine 1, and rear propeller 4 is installed on the output shaft of rear engine 2. The diameters of the front propeller 3 and the rear propeller 4 are equal, and they are arranged in the inside of the square tube shell one after the other. The front engine 1 and the rear engine 2 adopt electric motors with the same parameters, and they are installed in the inside of the square tubular shell 5 by brackets. The forward angle α between the rotation plane of the front propeller 3 and the left plate of the square tubular housing 5 is 45°; the rear angle β between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com