Bidirectional DC-DC circuit topology structure and control method in bidirectional charger

A circuit topology, DC-DC technology, applied in the direction of battery circuit devices, circuit devices, control/regulation systems, etc., can solve the problems of high cost, potential safety hazards, and large power variation range, and achieve the goal of reducing the withstand voltage level Requirements, improve the efficiency of electric energy utilization, and avoid the effect of high-frequency circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific embodiments.

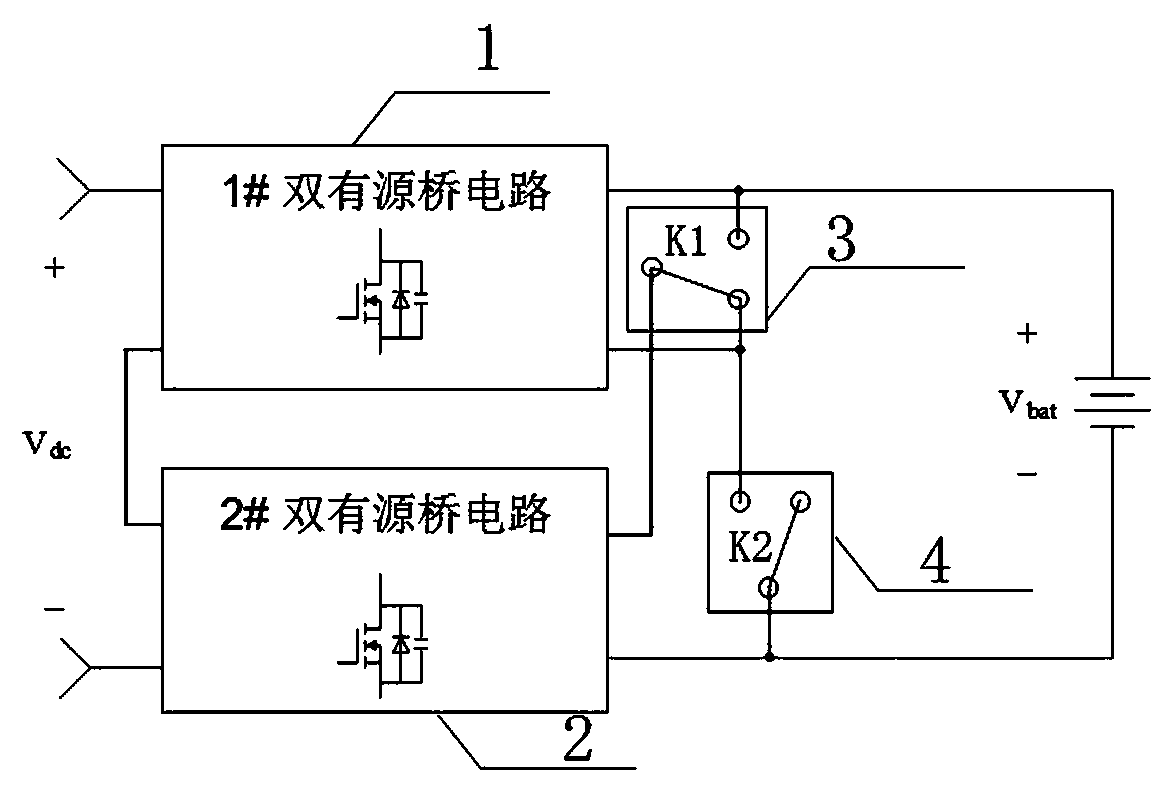

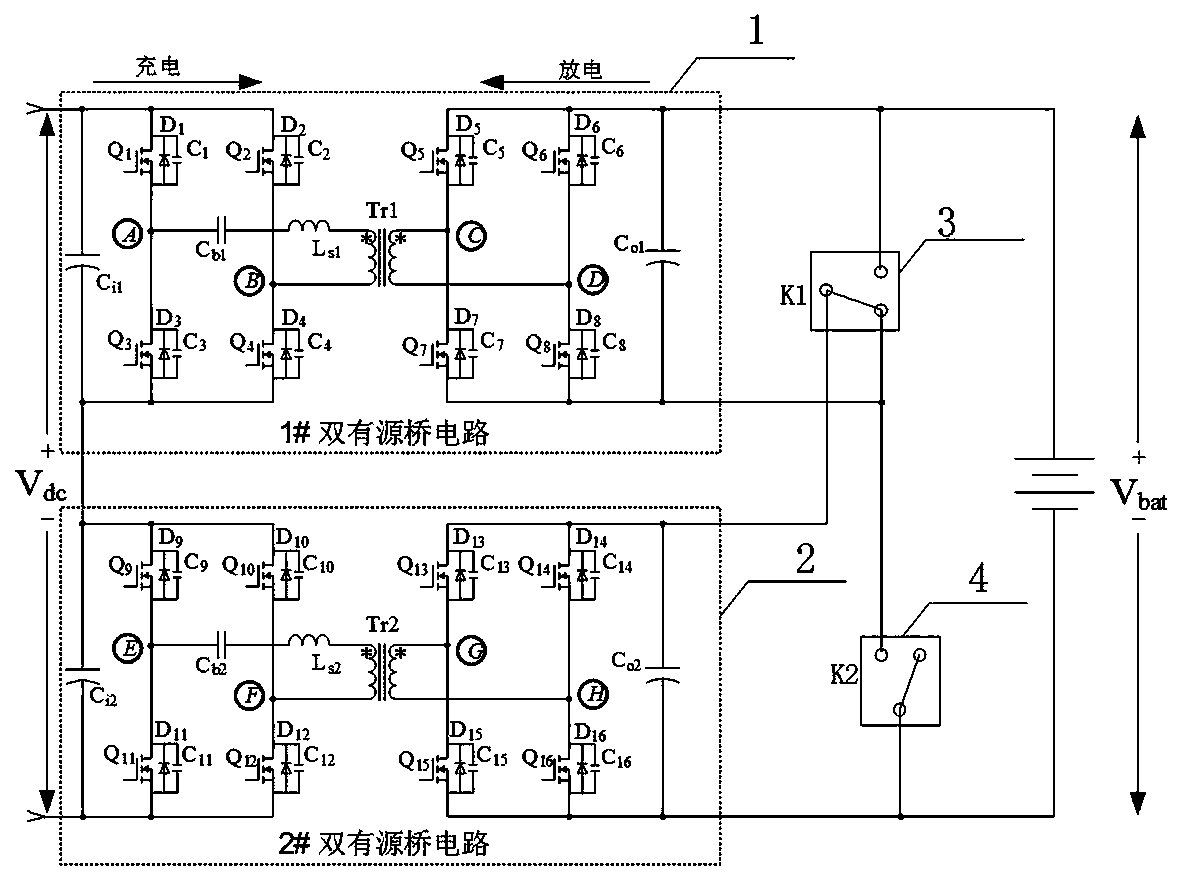

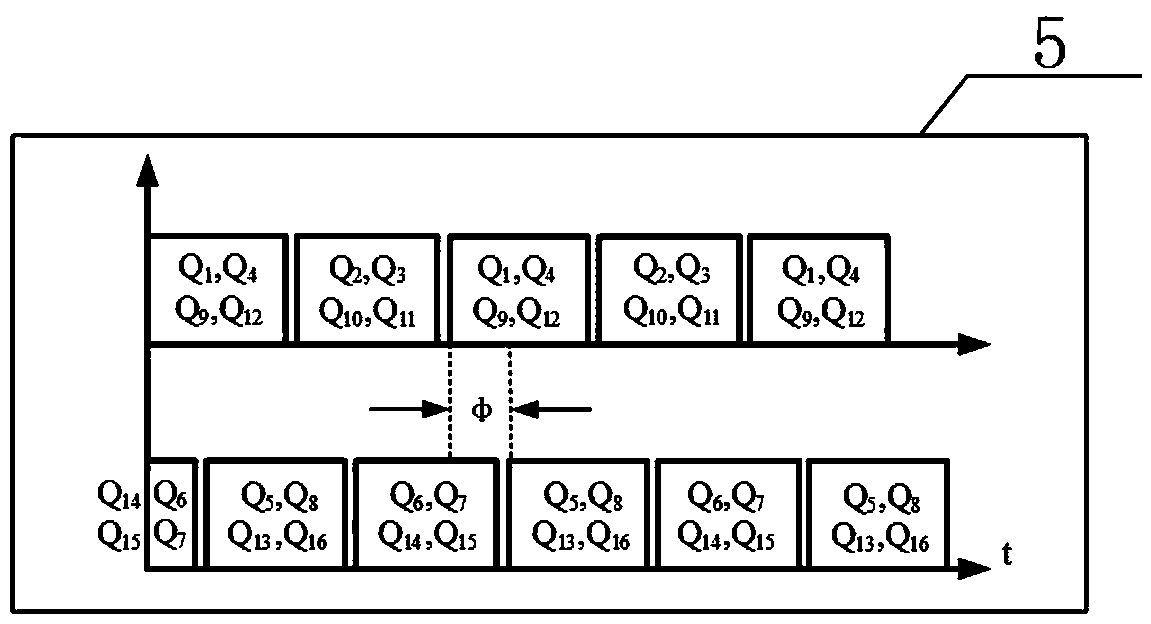

[0052] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown: the system is composed of a first dual active bridge circuit 1, a second dual active bridge circuit 2, a relay 3, a relay 4 and a switching tube driving pulse signal 5.

[0053] Depend on figure 1 and figure 2 Shown: a bidirectional DC-DC circuit topology in a bidirectional charger, including the first dual active bridge circuit 1 and the second dual active bridge circuit 2, the first dual active bridge circuit 1 and the second dual active bridge circuit The bridge circuit 2 is connected to the high-voltage input DC side after being connected in series at the input end, and the first dual active bridge circuit 1 and the second dual active bridge circuit 2 are connected to the battery after being connected in series or in parallel through the relay 3 and the relay 4 at the output end.

[0054] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com