Lubricating oil reaction kettle

A technology of reaction kettle and lubricating oil, which is applied in the directions of lubricating composition, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of increased pressure of the reaction kettle and cannot be effectively controlled, and achieves accurate pressure control, easy calculation and control, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

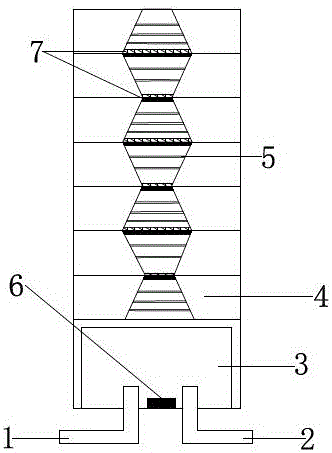

[0026] A lubricating oil reactor, including a reactor, an oil inlet pipe 1 and a hydrogen inlet pipe 2, is characterized in that: the reactor includes a reaction tank 3 and a plurality of unit units 4, and a plurality of unit units 4 overlap above the reaction tank 3, Both the oil inlet pipe 1 and the hydrogen inlet pipe 2 lead into the bottom of the reaction tank 3; the oil inlet pipe 1 and the hydrogen inlet pipe 2 are higher than the bottom of the reaction tank 3; each unit 4 is provided with a plurality of movable baffles 5 The unit element 4 is hollow; the upper end of the unit element 4 located on the uppermost layer is sealed; the inner side of the bottom of the reaction tank 3 is connected with a pressure sensor.

Embodiment 2

[0028] A lubricating oil reactor, including a reactor, an oil inlet pipe 1 and a hydrogen inlet pipe 2, is characterized in that: the reactor includes a reaction tank 3 and a plurality of unit units 4, and a plurality of unit units 4 overlap above the reaction tank 3, Both the oil inlet pipe 1 and the hydrogen inlet pipe 2 lead into the bottom of the reaction tank 3; the oil inlet pipe 1 and the hydrogen inlet pipe 2 are higher than the bottom of the reaction tank 3; each unit 4 is provided with a plurality of movable baffles 5 The unit element 4 is hollow; the upper end of the unit element 4 located on the uppermost layer is sealed; the inner side of the bottom of the reaction tank 3 is connected with a pressure sensor.

[0029] The hollow part of the unit element 4 is in the shape of a truncated cone, and the ends of the truncated cone are connected in sequence.

Embodiment 3

[0031] A lubricating oil reactor, including a reactor, an oil inlet pipe 1 and a hydrogen inlet pipe 2, is characterized in that: the reactor includes a reaction tank 3 and a plurality of unit units 4, and a plurality of unit units 4 overlap above the reaction tank 3, Both the oil inlet pipe 1 and the hydrogen inlet pipe 2 lead into the bottom of the reaction tank 3; the oil inlet pipe 1 and the hydrogen inlet pipe 2 are higher than the bottom of the reaction tank 3; each unit 4 is provided with a plurality of movable baffles 5 The unit element 4 is hollow; the upper end of the unit element 4 located on the uppermost layer is sealed; the inner side of the bottom of the reaction tank 3 is connected with a pressure sensor.

[0032] The hollow part of the unit element 4 is in the shape of a truncated cone, and the ends of the truncated cone are connected in sequence.

[0033] Both the upper end and the lower end of the unit element 4 are connected with sealing rings 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com