Electronic expansion valve

An electronic expansion valve, valve seat technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of electronic expansion valve noise, liquid medium easily mixed with air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

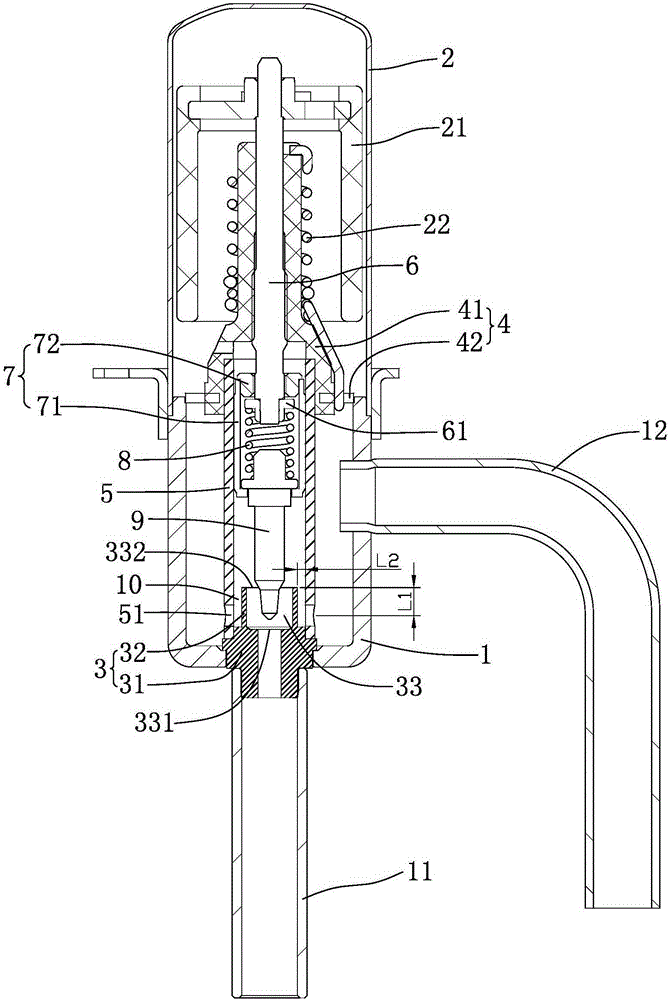

Embodiment 1

[0025] refer to figure 1 , an electronic expansion valve, comprising a valve body, a valve needle 9, a valve seat 3 and a driving mechanism, the valve seat 3 is arranged at the lower end of the valve body, the valve seat 3 is provided with a valve port 331, the driving mechanism is arranged at the upper end of the valve body, and the valve The needle 9 is connected to the driving mechanism and is driven by the driving mechanism to open or close the valve port 331. The valve body is also provided with a guide sleeve 5 for guiding the axial movement of the valve needle 9. The guide sleeve 5 is provided with a number of side wall through holes 51. , considering the manufacturing cost, the side wall through holes 51 are substantially evenly distributed on the guide sleeve 5 .

[0026] refer to figure 1 Specifically, the electronic expansion valve further includes a nut assembly 4 , the nut assembly 4 includes a nut 41 and a connecting piece 42 , the nut 41 is covered with a limit...

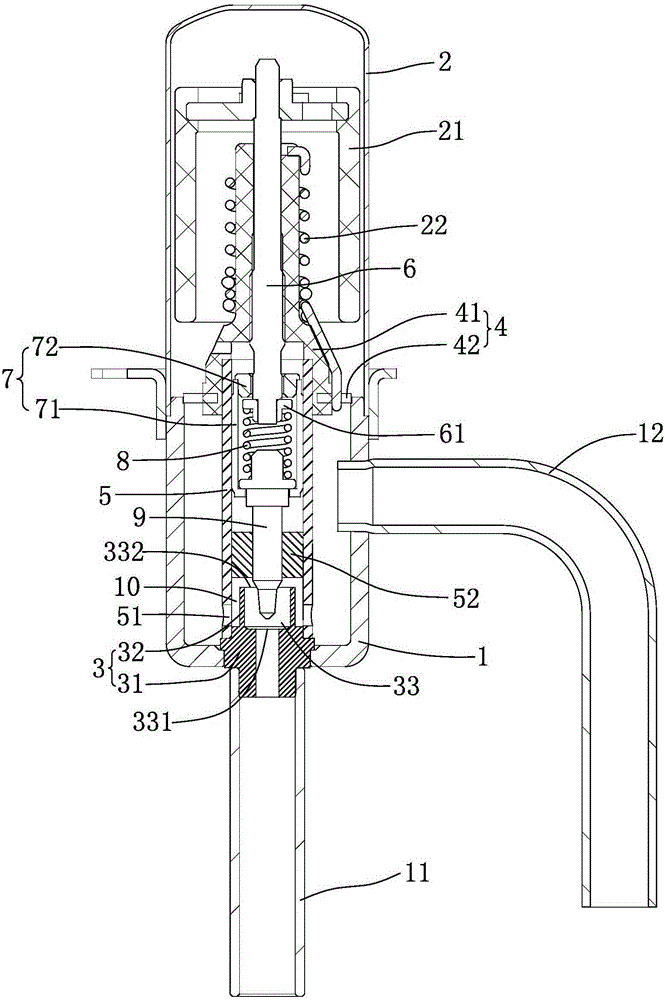

Embodiment 2

[0035] refer to figure 2 , an electronic expansion valve, comprising a valve body, a valve needle 9, a valve seat 3 and a driving mechanism, the valve seat 3 is arranged at the lower end of the valve body, the valve seat 3 is provided with a valve port 331, the driving mechanism is arranged at the upper end of the valve body, and the valve The needle 9 is connected to the driving mechanism and is driven by the driving mechanism to open or close the valve port 331. The valve body is also provided with a guide sleeve 5 for guiding the axial movement of the valve needle 9. The guide sleeve 5 is provided with a number of side wall through holes 51. , considering the manufacturing cost, the side wall through holes 51 are substantially evenly distributed on the guide sleeve 5 .

[0036] refer to figure 2 Specifically, the electronic expansion valve further includes a nut assembly 4 , the nut assembly 4 includes a nut 41 and a connecting piece 42 , the nut 41 is covered with a lim...

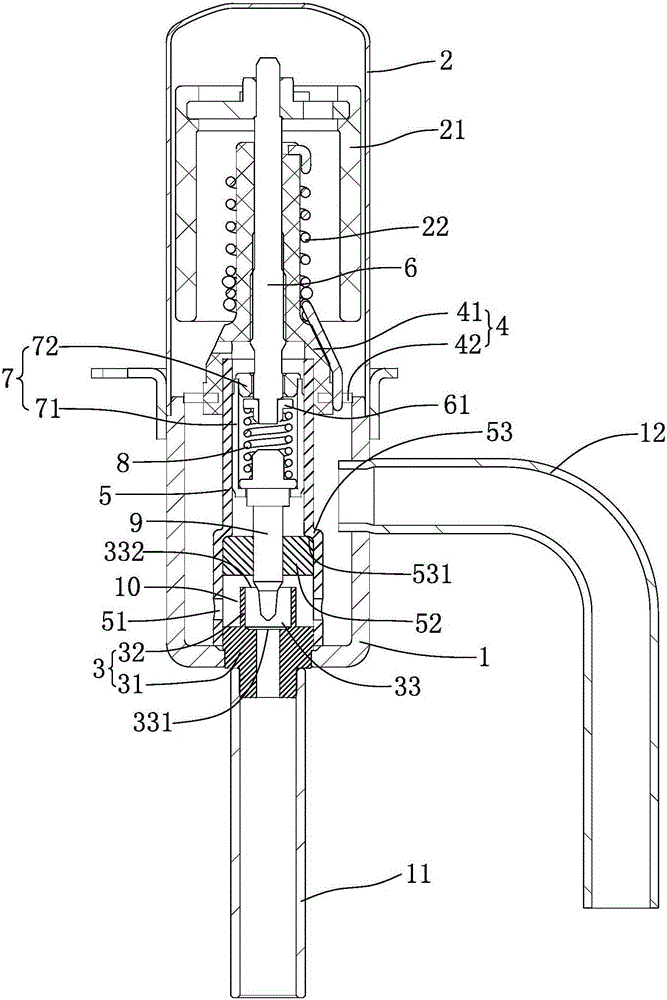

Embodiment 3

[0041] refer to image 3 , an electronic expansion valve, comprising a valve body, a valve needle 9, a valve seat 3 and a driving mechanism, the valve seat 3 is arranged at the lower end of the valve body, the valve seat 3 is provided with a valve port 331, the driving mechanism is arranged at the upper end of the valve body, and the valve The needle 9 is connected to the driving mechanism and is driven by the driving mechanism to open or close the valve port 331. The valve body is also provided with a guide sleeve 5 for guiding the axial movement of the valve needle 9. The guide sleeve 5 is provided with a number of side wall through holes 51. , considering the manufacturing cost, the side wall through holes 51 are substantially evenly distributed on the guide sleeve 5 .

[0042] refer to image 3 Specifically, the electronic expansion valve further includes a nut assembly 4 , the nut assembly 4 includes a nut 41 and a connecting piece 42 , the nut 41 is covered with a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com