Electric car parallel flow condenser core

A technology of parallel flow and condenser, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of inconvenient replacement, core damage, etc., and achieve the effect of improving service life and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

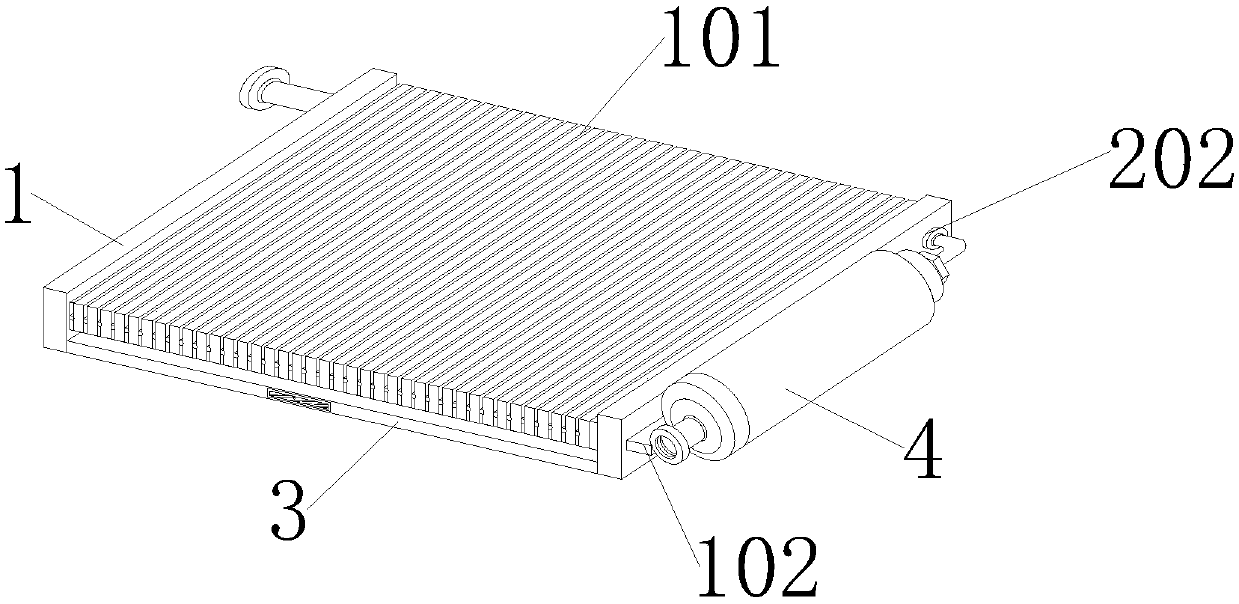

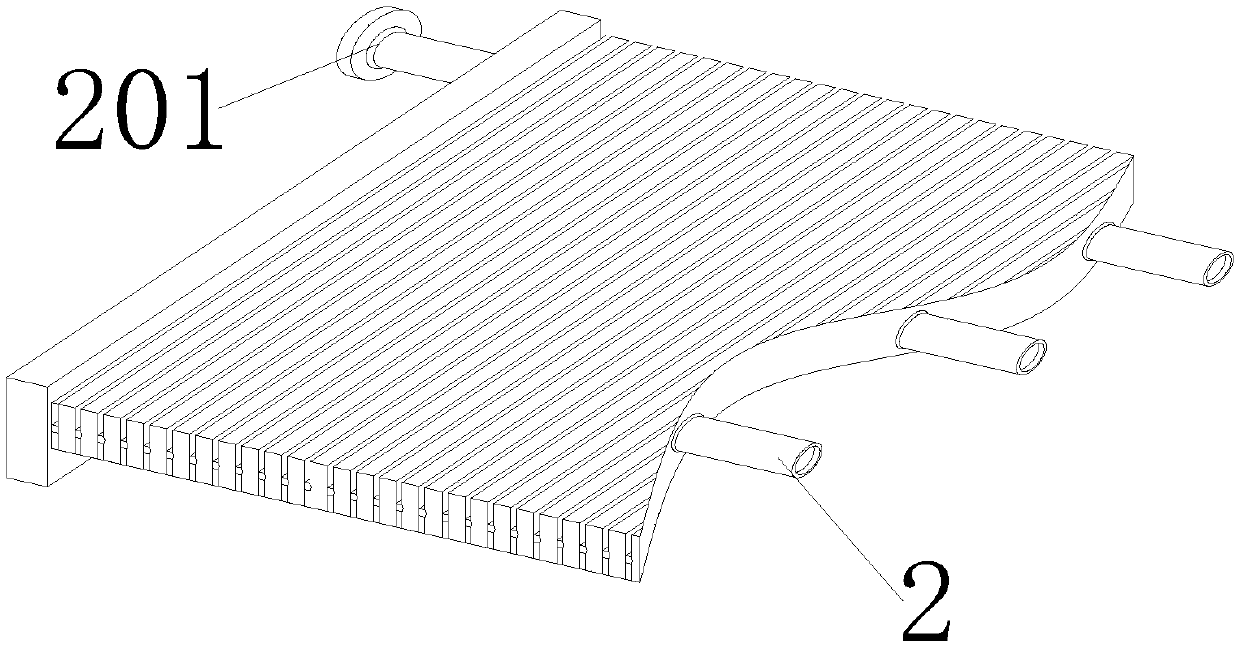

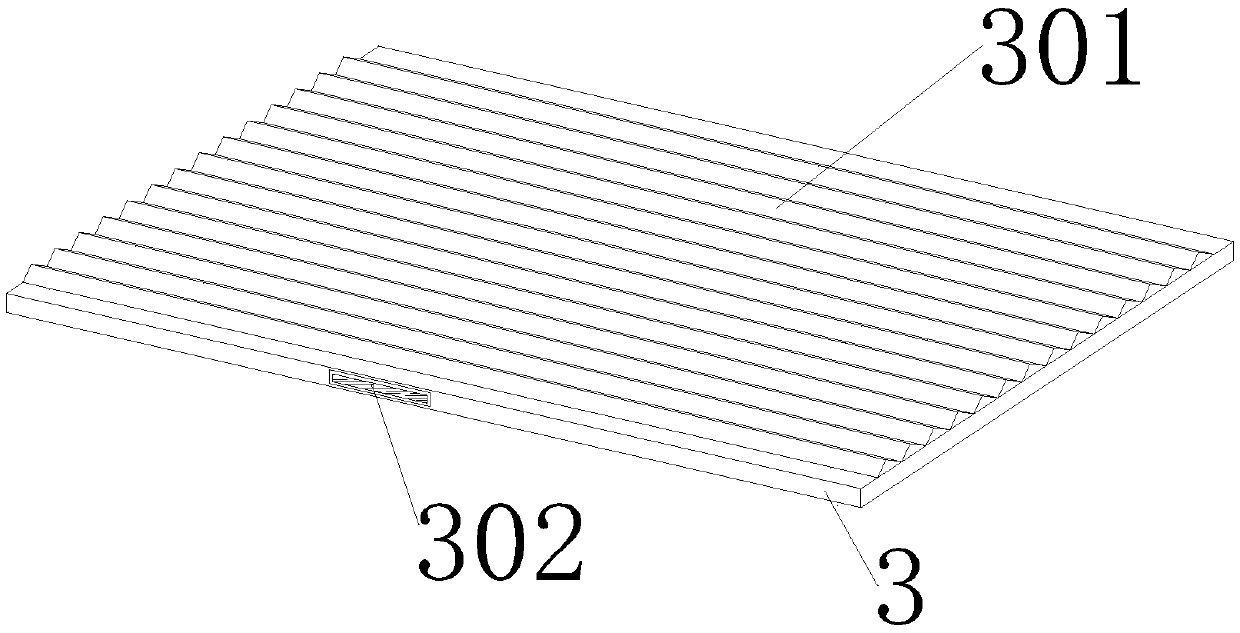

[0021] see Figure 1-5 As shown, a parallel-flow condenser core for an electric vehicle, the parallel-flow condenser core for an electric vehicle includes a support plate 1 and a backing plate 3, the number of support plates 1 is two, and the inner wall of the support plate 1 is between the left and right sides The backing plate 3 is welded below, and several fins 101 are welded between the support plates 1 and above the backing plate 3, and the inner coil 2 is installed inside the fins 101, and the right rear end of the inner coil 2 is set through the The support plate 1 on the right has an interface 202 on the right rear end of the inner coil 2, the left rear end of the inner coil 2 runs through the left support plate 1, and the left rear end of the inner coil 2 has a At the outlet 201, at least ten top blocks 301 are uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com