Energy-saving full-automatic four-axle horizontal tapping machine

A tapping machine, fully automatic technology, used in thread trimmers, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of high labor intensity, large waste of cooling oil, and high hopper, to avoid uneven flow, reduce Production cost, accurate feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

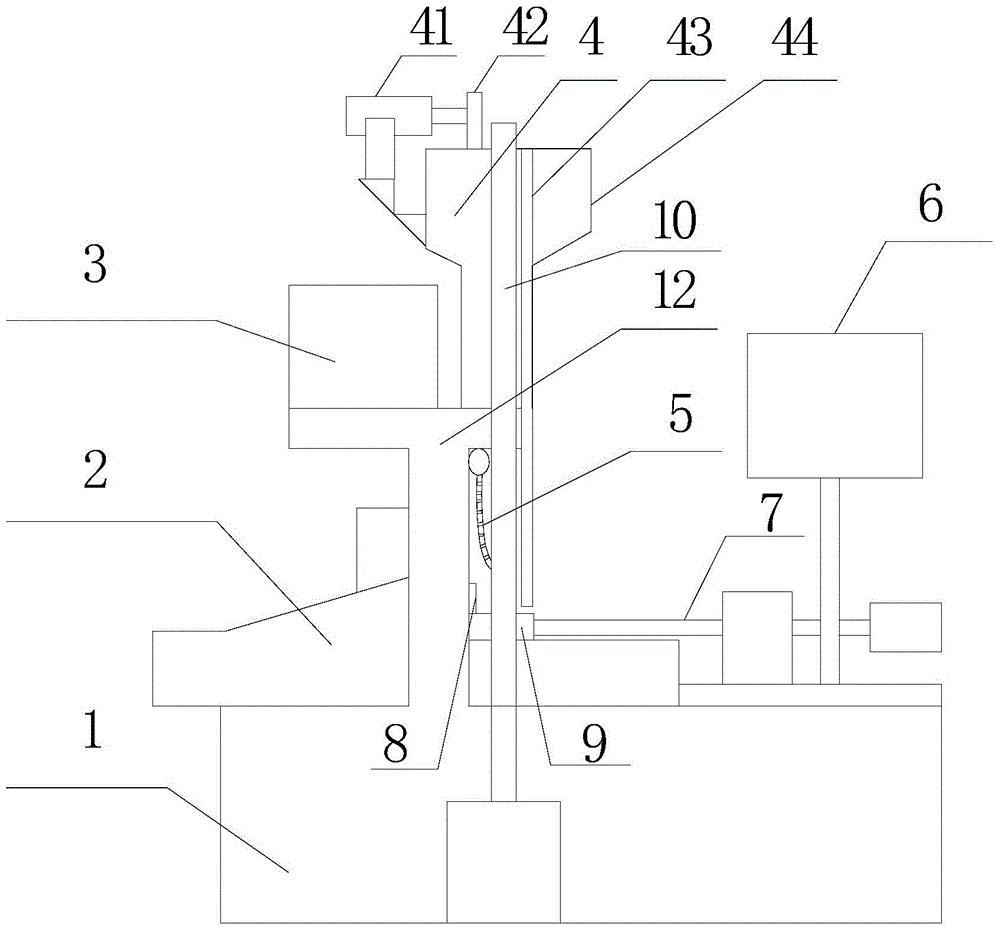

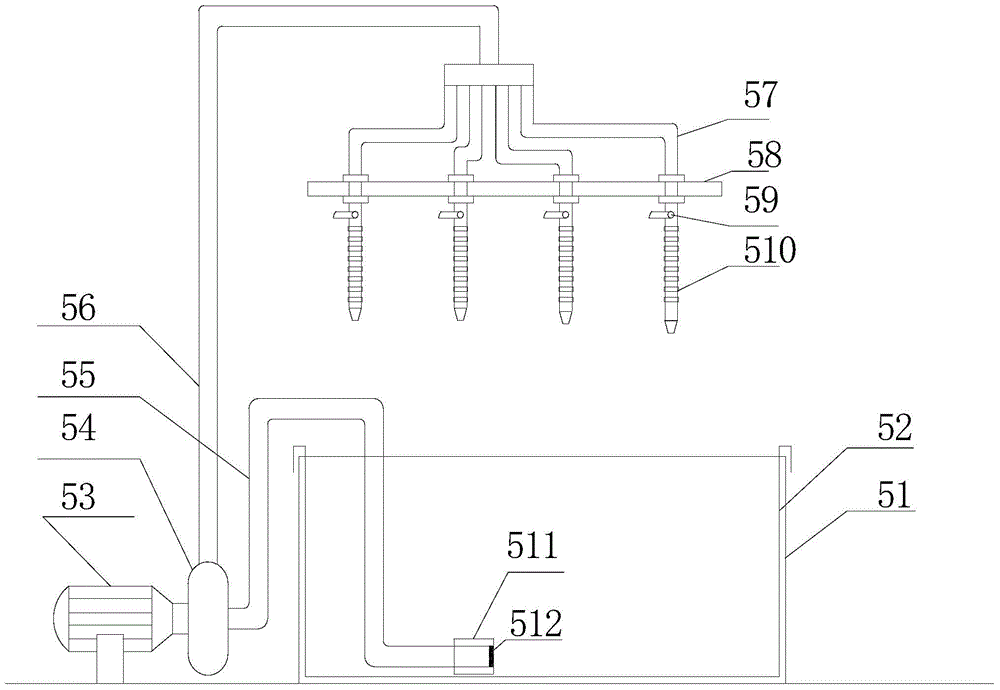

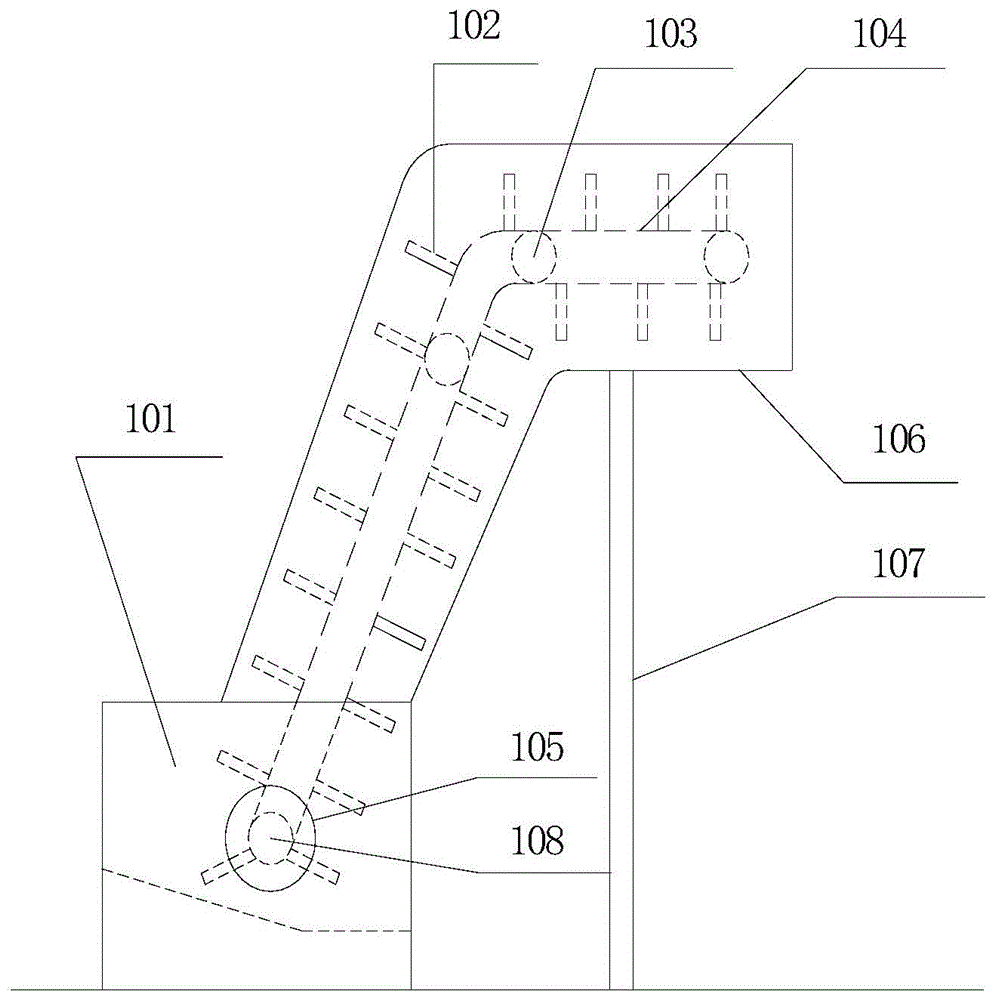

[0017] see figure 1 , figure 2 and image 3, an energy-saving fully automatic four-axis horizontal tapping machine of the present invention, comprising a frame 1, a discharge device 2, a body shield 3, an arrangement device 4, a cooling oil circulation device 5, a control device 6, and a pneumatic pushing device 7. Tapping device 8, material guide device 9, feeding device 10, arrangement device fixed boss 12, stirring rod power motor 41, stirring rod 42, arrangement plate 43, material storage tank 44, stirring rod power motor support base 45 , cooling oil recovery tank 51, filter device 52, water pump power motor 53, water pump 54, oil inlet pipe 55, oil outlet pipe 56, oil distribution pipe 57, oil distribution pipe bracket 58, oil distribution pipe switch 59, metal hose 510, oil inlet pipe Fixing device 511, filter screen 512, storage tank 101, material delivery plate 102, driven shaft 103, conveyor belt 104, feeding device power motor 105, dividing plate 106, support fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com