Method for punching dovetail groove in front surface of lead frame of semiconductor

A technology of lead frame and dovetail groove, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems such as poor surface flatness of products, achieve improved reliability, good dovetail structural strength, Effect of reducing material stress variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

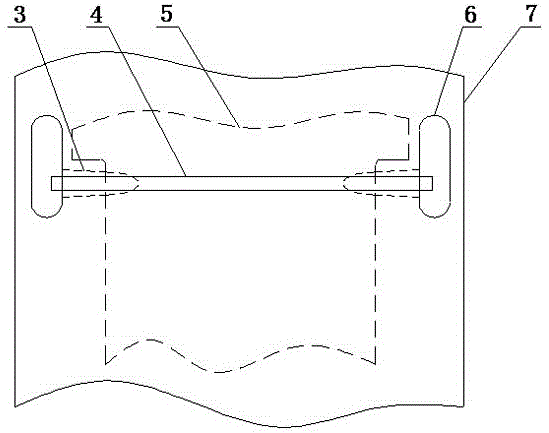

[0021] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0022] A stamping method for dovetail slots on the front of a semiconductor lead frame, including the following:

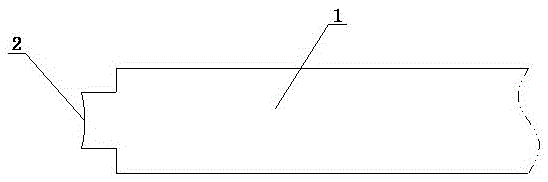

[0023] A. Process the lead frame blank, pre-cut both sides of the lead frame blank at one time, and punch a strip hole on both sides of the lead frame blank;

[0024] B. Press the rectangular groove: press the material through the mold, use the punch I with a rectangular cross-section to vertically extrude the lead frame blank, and obtain a rectangular groove with a rectangular cross-section;

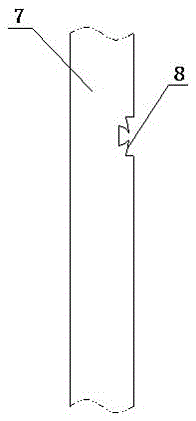

[0025] C. Pressing the dovetail groove: use the convex die II with a concave arc at the top of the section to vertically extrude the center of the rectangular groove formed in the previous step to form the dovetail groove;

[0026] D. Pre-cut dovetail groove: cut off the excess material on both sides of the dovetail gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com