Brushless electric steering control unit and method based on functional safety design

A technology of electric steering and functional safety, which is applied in the direction of electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve problems such as insufficient safety and driving danger, and achieve the effect of improving safety reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

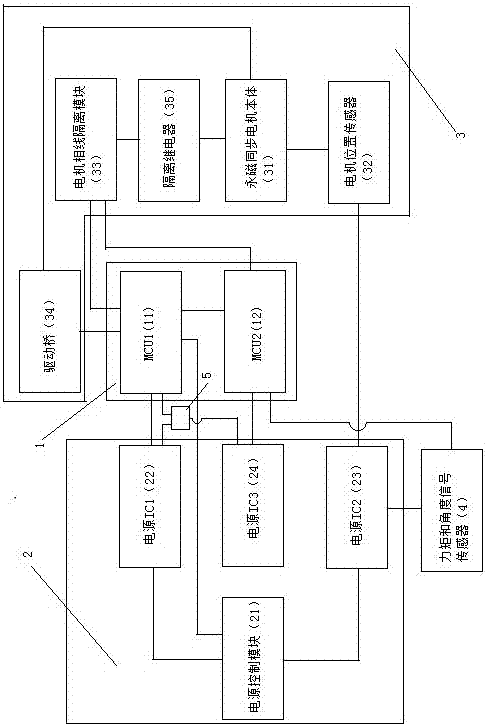

[0035] Embodiment: A brushless electric steering control unit based on functional safety design, such as figure 1 As shown, it includes EPS controller 1, power redundant module 2, torque and angle signal sensor 4 and permanent magnet synchronous motor module 3, and the power redundant module includes power control module 21, power IC1 22, power IC2 23 and power IC3 24 , the EPS controller includes MCU1 11 and MCU212, MCU1 is also connected with MCU2, and MCU1 and MCU2 are also connected with EPS controller memory. The permanent magnet synchronous motor module includes a permanent magnet synchronous motor body 31 and a motor position sensor 32, the permanent magnet synchronous motor body is connected to the motor position sensor, the power control module is connected to the power supply IC1 and the power supply IC2 at the same time, and the power supply IC1 is connected to the MCU1. The power supply IC2 is connected with the torque and angle signal sensor and the motor position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com