Bobbin connector for spinning spindle or silk throwing spindle

A technology of spinning spindles and couplings, which is applied in textiles and papermaking, conveying filamentous materials, processing thin materials, etc., can solve problems such as complex structure and loss, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

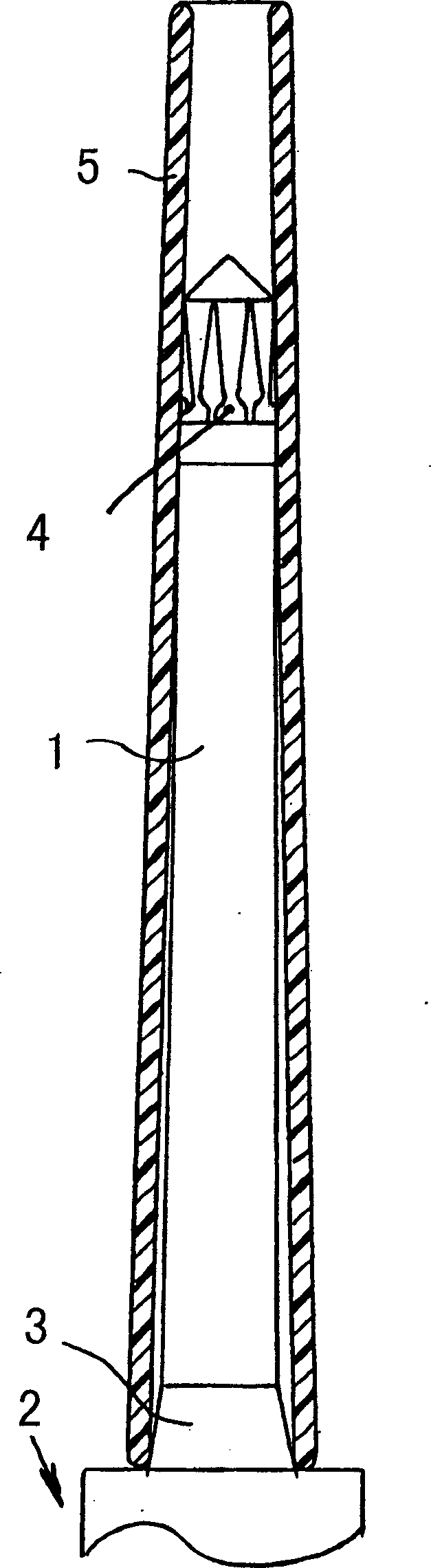

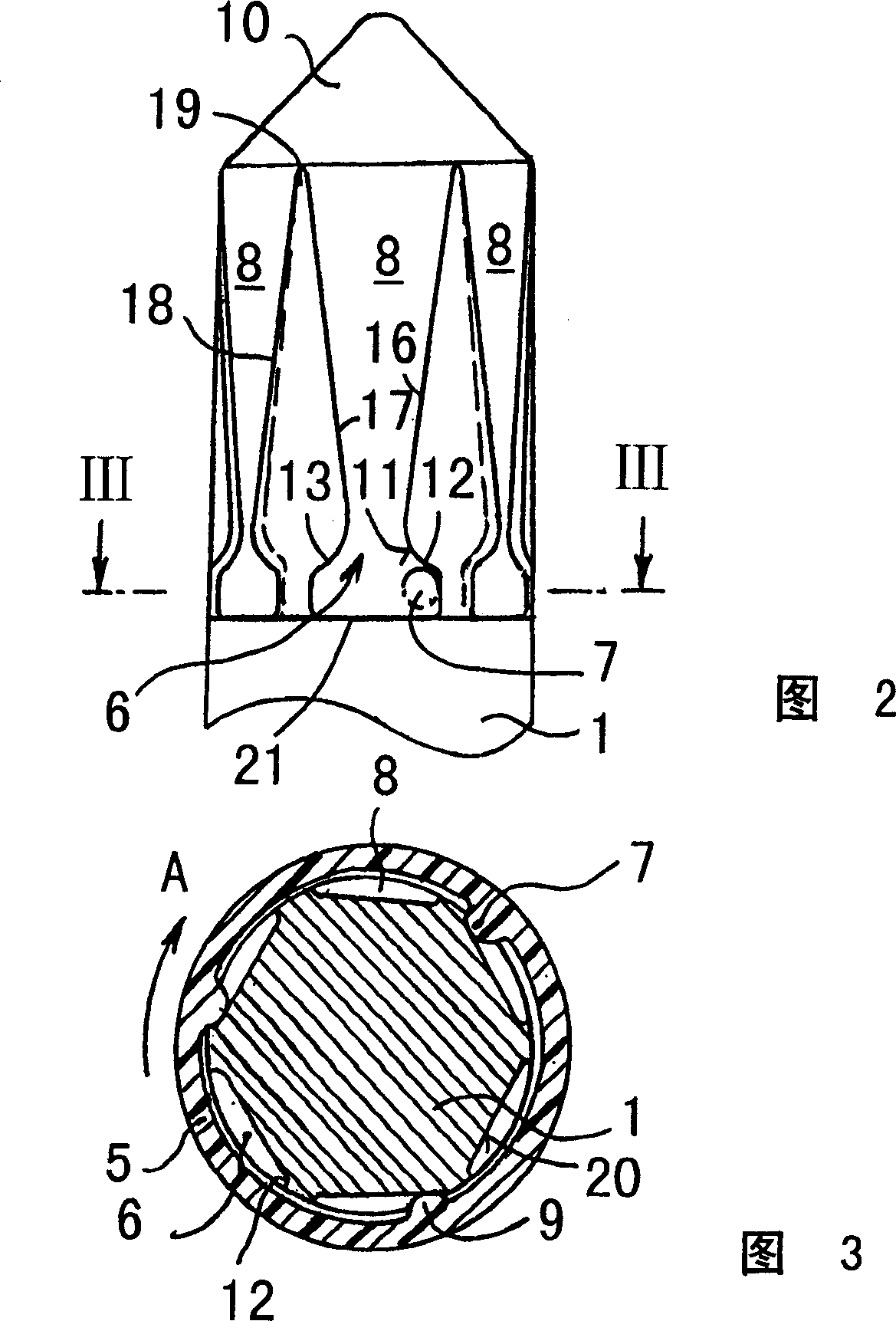

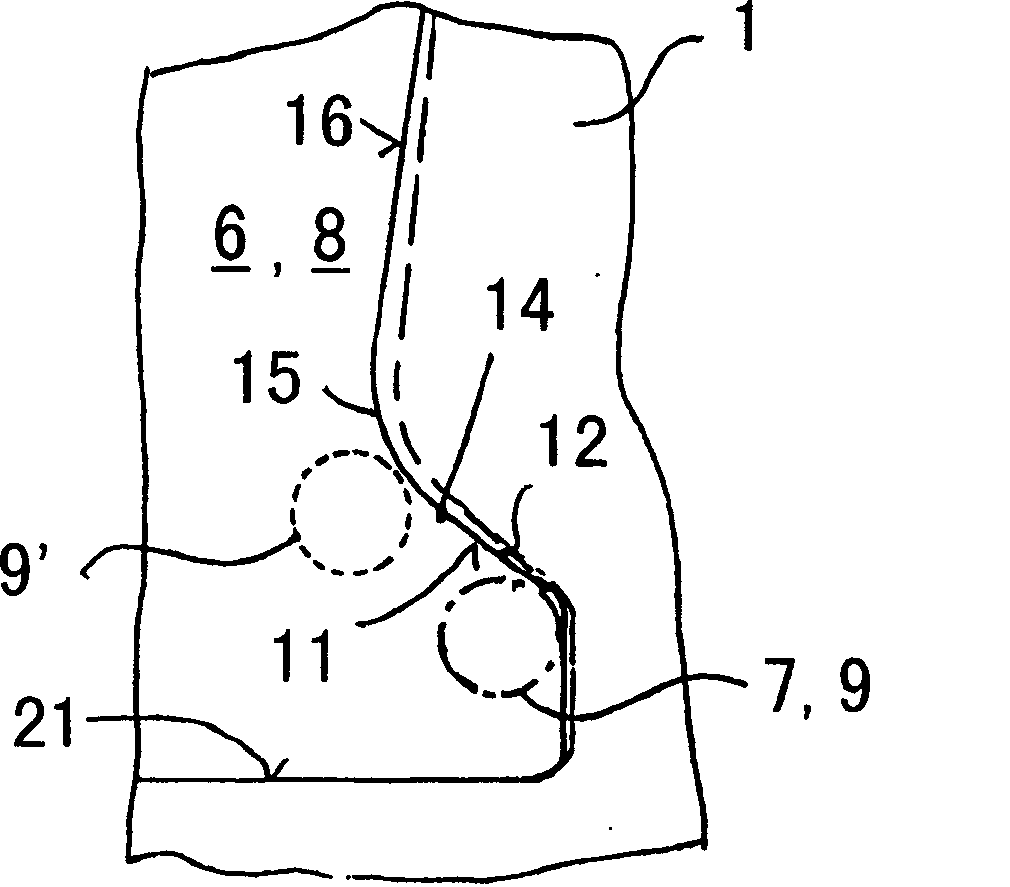

[0029] exist figure 1 A longitudinal view of the spindle top 1 of the spinning or twisting spindle 2 is shown in . In its lower part, the upper spindle part 1 merges into a conical bearing surface 3, on which a drive spindle disk (not shown) and a spindle shaft are connected in a known manner. In the upper region of the spindle upper part 1, a bobbin coupling 4 is arranged, which will be described in detail below.

[0030] A bobbin 5 , which is shown in longitudinal section, is inserted onto the spindle upper part 1 . Its underside rests on the conical bearing surface 3 or rests against a stop and is thus centered on its underside. The bobbin 5 is synchronously driven along the direction of rotation by the rotating spindle upper part 1 during the operation of the spindle 2 .

[0031] When inserting the bobbin 5 into the spindle upper part 1, usually the last 50 mm of the bobbin 5 is exposed downward. This is possible both with manual and automatic doffing. Alternatively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com