Automobile door-window frame sealing strip automatic punching cutting production line

A technology for door and window frames and sealing strips, which is applied in the field of automatic punching and cutting production lines for automobile door and window frame sealing strips, which can solve the problems of low production efficiency and achieve the effects of low equipment cost, high detection accuracy and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

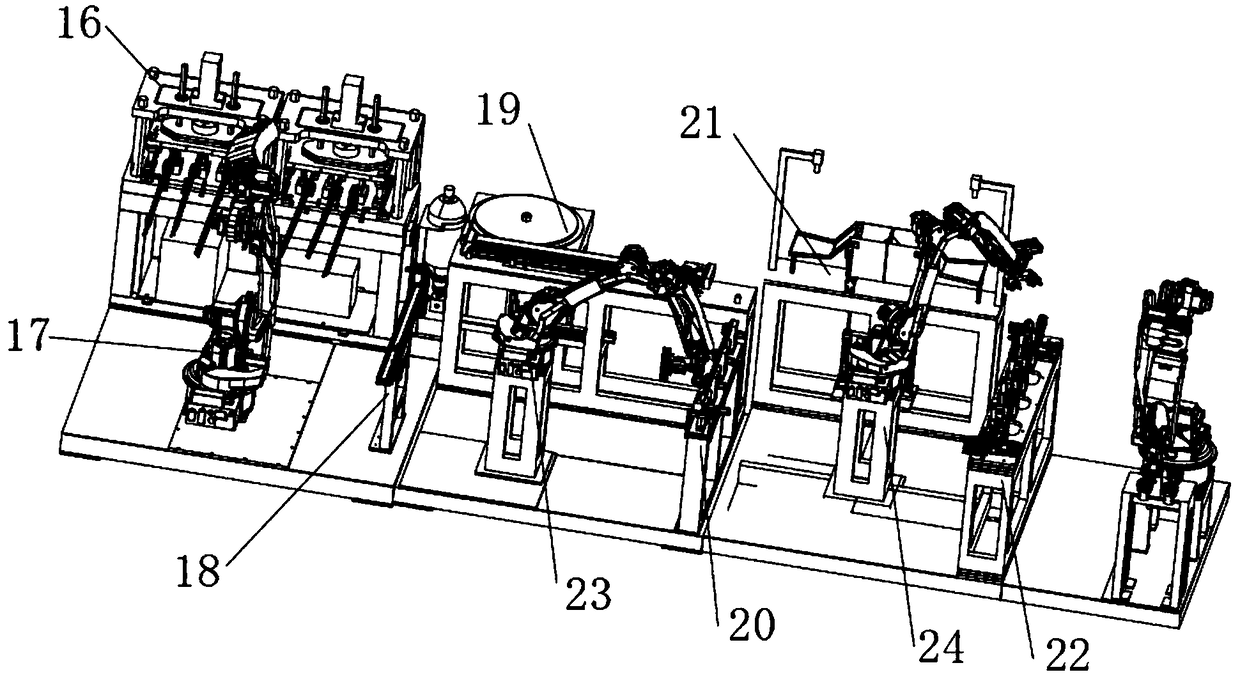

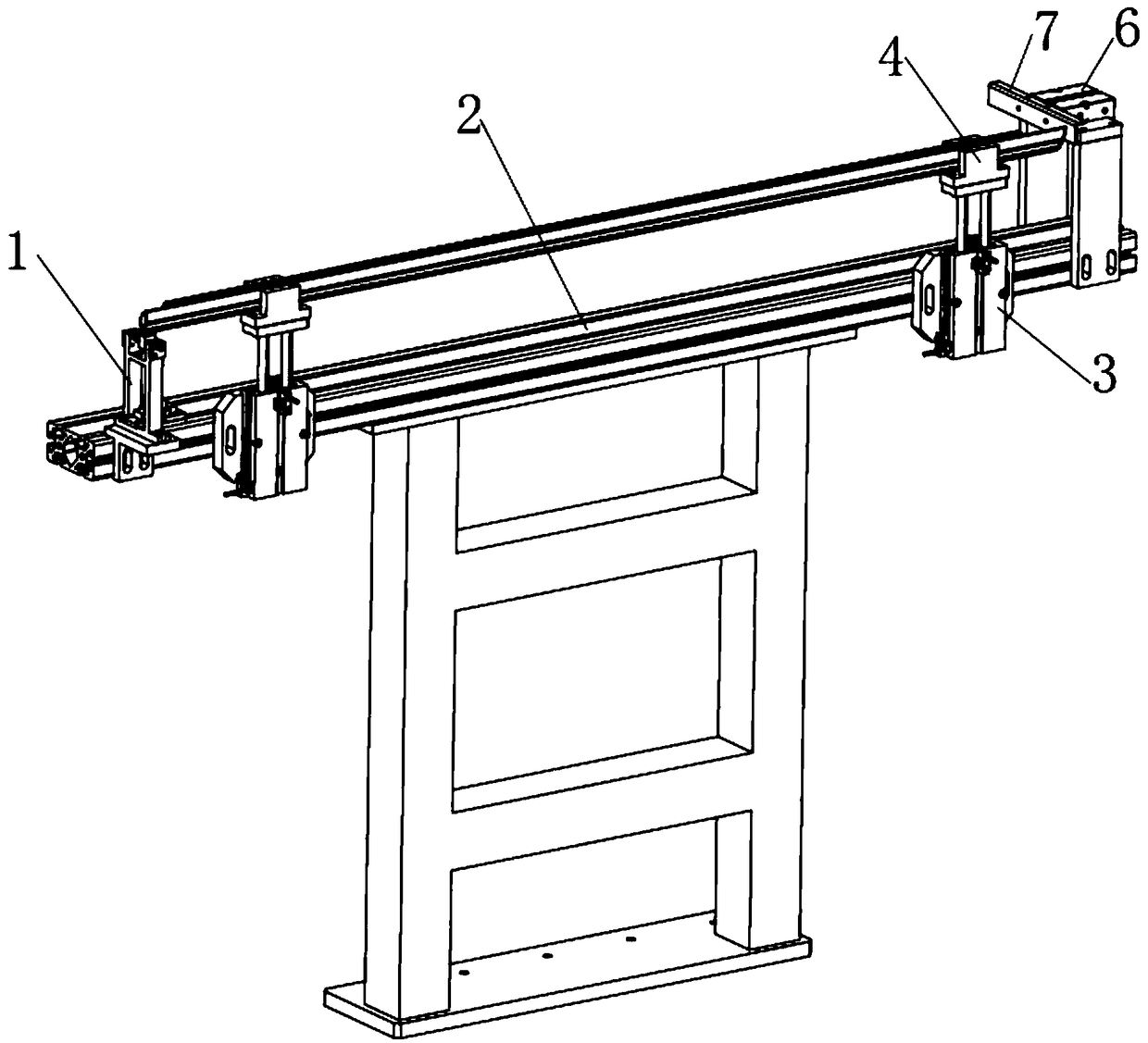

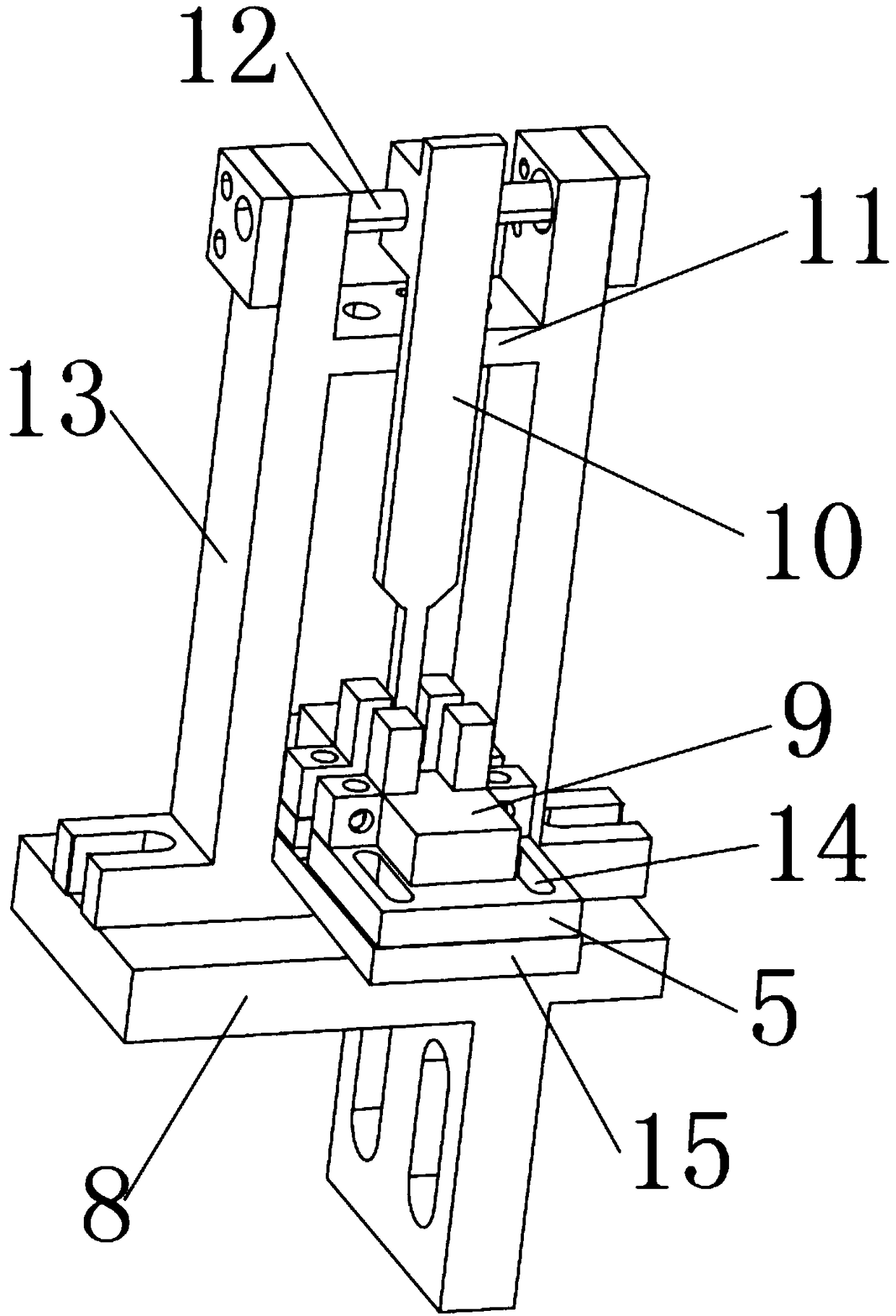

[0049] The sealing strip is punched through the punching die 16, and the first robot 17 puts the punched sealing strip into the length detection device 18 for detection. Put it in the groove, then start the driving cylinder 6, the piston rod of the driving cylinder 6 is extended, the control push plate 7 pushes the sealing strip to slide towards the detection device 1, and one end of the sealing strip bears against the upper end of the seesaw 10, because the lower end of the seesaw 10 and the rotating shaft The distance between 12 is about several times of the distance between the upper end of the seesaw 10 and the rotating shaft 12. The size deviation of the sealing strip can be enlarged, and the lower end of the seesaw 10 swings in a thin strip shape. When the lower end of the seesaw 10 is located between two induction The length of the sealing strip is acceptable between the sensing areas of the device 9, otherwise it is a sealing strip of unqualified length. The positions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com