A kind of method that utilizes high-concentration starch milk to continuously produce starch saccharification product

A starch milk and starch sugar technology, applied in biochemical equipment and methods, glycosylases, glycosyltransferases, etc., can solve the problems of glucose compound reaction, complex processing, increased viscosity, etc., to achieve continuous production, inhibit Compound reaction, fast filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 4

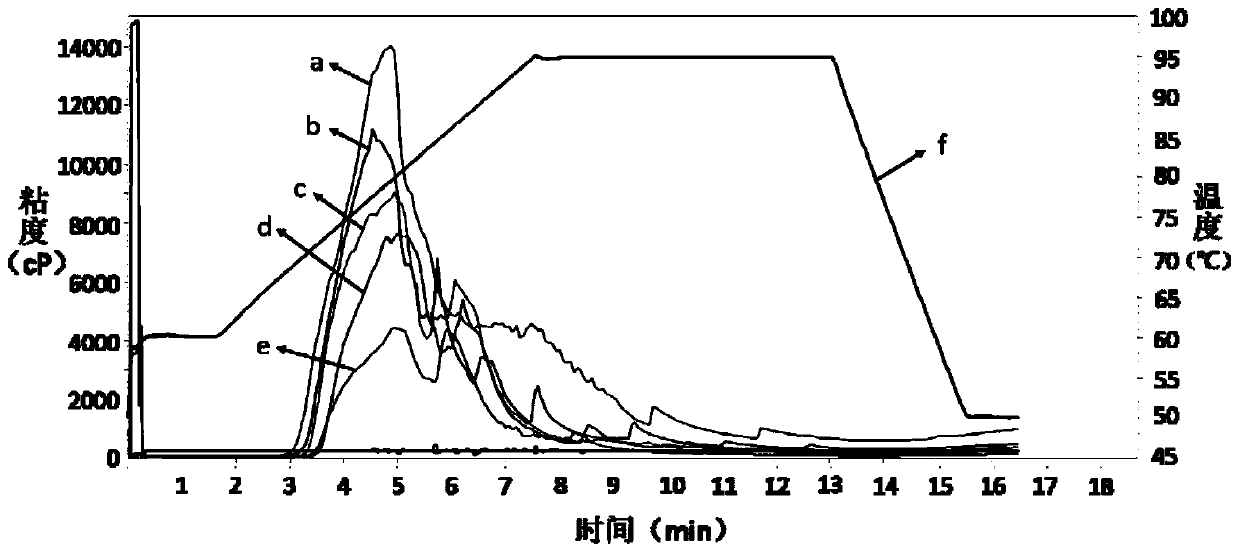

[0097] Embodiment 1-Example 4: Utilize high-concentration starch milk to produce starch saccharification product

Embodiment 1

[0099] (1) Pre-liquefaction step: using commercially available cornstarch as a raw material, prepare starch milk with a dry basis mass fraction of 45wt% in a mixing tank at 50°C, adjust the pH to 6.0 with 8M hydrochloric acid, dry the starch milk with starch milk Based on the starch milk in the mixing tank, add 0.15wt‰ of medium temperature α-amylase, 0.2wt‰ of high temperature resistant α-amylase, 0.04wt‰ of lipase and 0.07wt‰ of neutral protease, After mixing, heat preservation at 55° C. for 0.5 h to obtain the first starch milk with a brix value of 15%.

[0100] (2) Liquefaction step: at 0.18m 3 The speed of / h causes the first starch milk to be discharged from the mixing tank through the pipeline into the spray gun, sprayed out through the spray gun mouth and contacted with high-pressure steam (the pressure is 0.6MPa) to carry out spray liquefaction, and the temperature of the spray gun mouth is 108 ° C; The sprayed liquefied material is kept in the maintenance tube for 3...

Embodiment 2

[0104] (1) Pre-liquefaction step: using commercially available cornstarch as a raw material, starch milk with a mass fraction of 40 wt% on a dry basis was prepared in a mixing tank at 50°C, and the pH was adjusted to 6.0 with 8M hydrochloric acid. Based on the starch dry basis of starch milk, add 0.2wt‰ of medium temperature α-amylase, 0.2wt‰ of high temperature resistant α-amylase, 0.08wt‰ of lipase and 0.12wt‰ of Protease, mixed and incubated at 55°C for 0.5h to obtain the first starch milk with a brix value of 13%.

[0105] (2) Liquefaction step: at 0.18m 3 The first starch milk is discharged from the mixing tank through the pipeline at a speed of / h into the spray gun, sprayed out through the spray gun mouth and contacted with high-pressure steam (the pressure is 0.6MPa) to carry out jet liquefaction, and the temperature of the spray gun mouth is 108 ° C; The sprayed liquefied material is kept in the maintenance tube for 3 minutes, and then enters the flash tank for flash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com