Coke quenching device for coking production

A technology of coke quenching and balancing water tower, which is used in the cooling of coke, coke oven, petroleum industry, etc., can solve the problems of affecting the pumping effect of the water pump, affecting the service life of the water pump, increasing the labor intensity of workers, etc., to achieve convenient installation and maintenance, and reasonable design. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

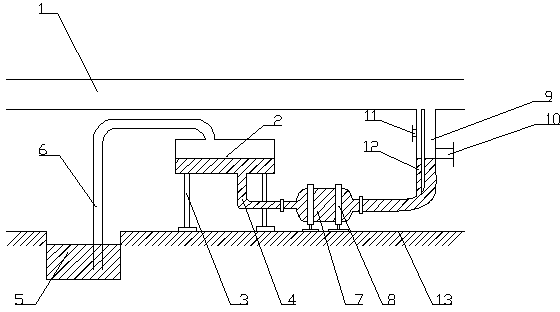

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. As shown in the figure: a coke quenching device for coking production, including a balance water tower 2, a pool 5, a water pump 7 and a coke quenching water pipeline 1, the water pump 7 is fixed on the ground 13, the bottom of the balance water tower 2 is higher than the top of the water pump 7, Because the water level of the balance water tower 2 is higher than the water level in the water pump 7, it is prevented that when the water pump 7 stops working, the water in the coke quenching water pipeline 1 instantly flows back to the water pump 7, causing damage to the water pump 7; the coke quenching water pipeline 1 is horizontally erected on the The water storage in the balance water tower 2 is still supplied to the coke quenching water pipeline 1 due to the high potential when the top of the balance water tower 2 prevents coke quenching from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com