Hydraulic prop for hydraulic support system

A technology of hydraulic props and hydraulic supports, which is applied in the field of hydraulic props, can solve problems such as hydraulic props not being able to give way instantly, and achieve the effects of shortening the time to resume production, preventing damage, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

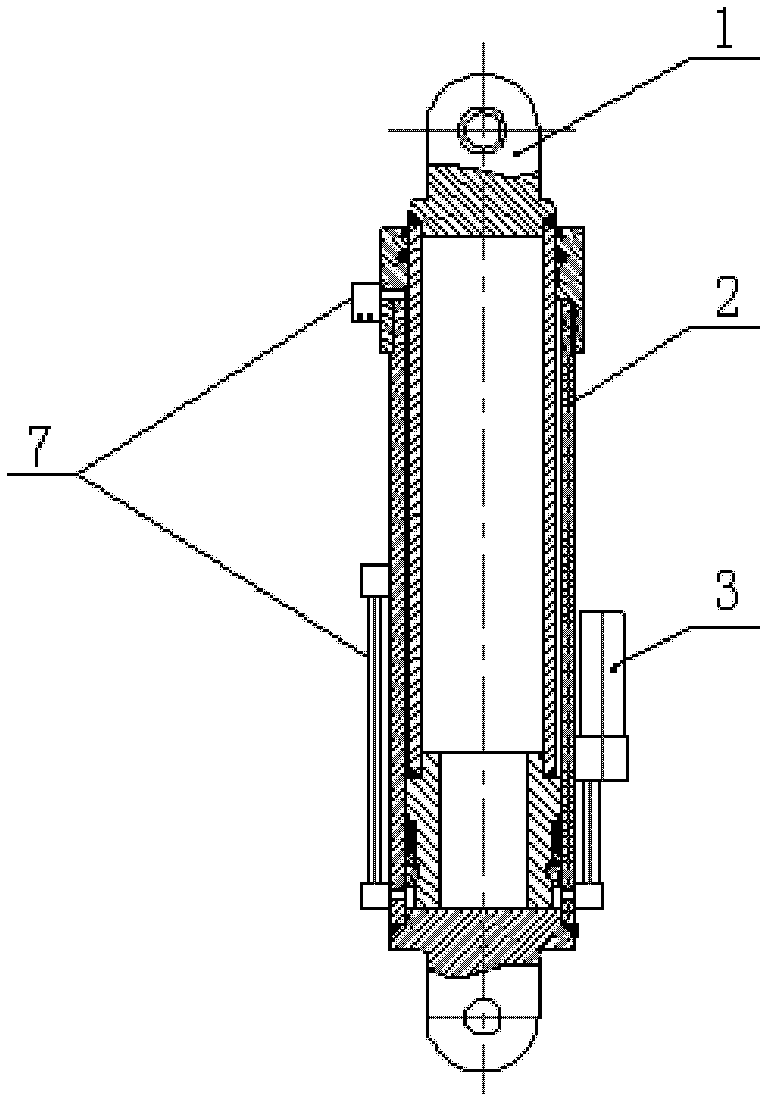

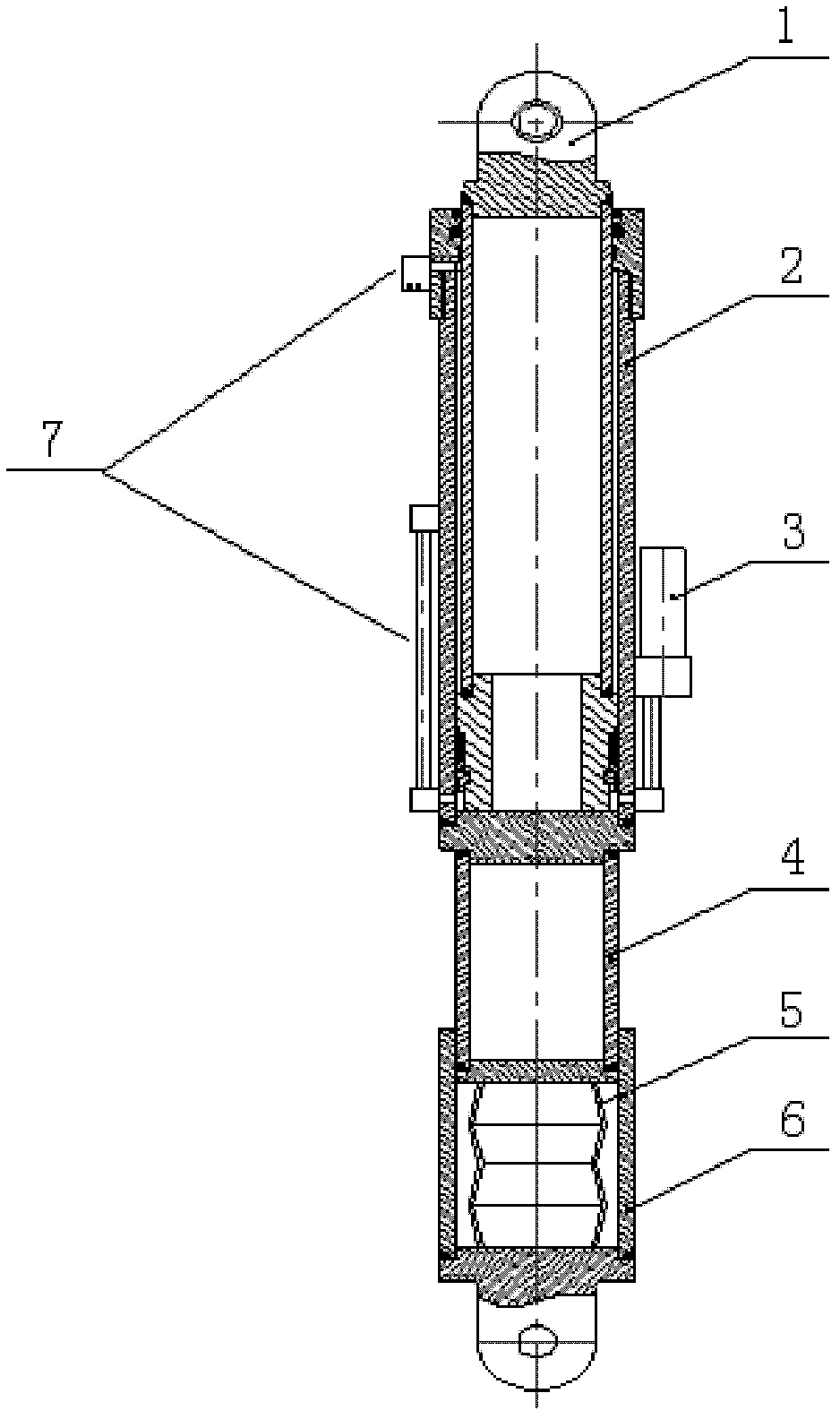

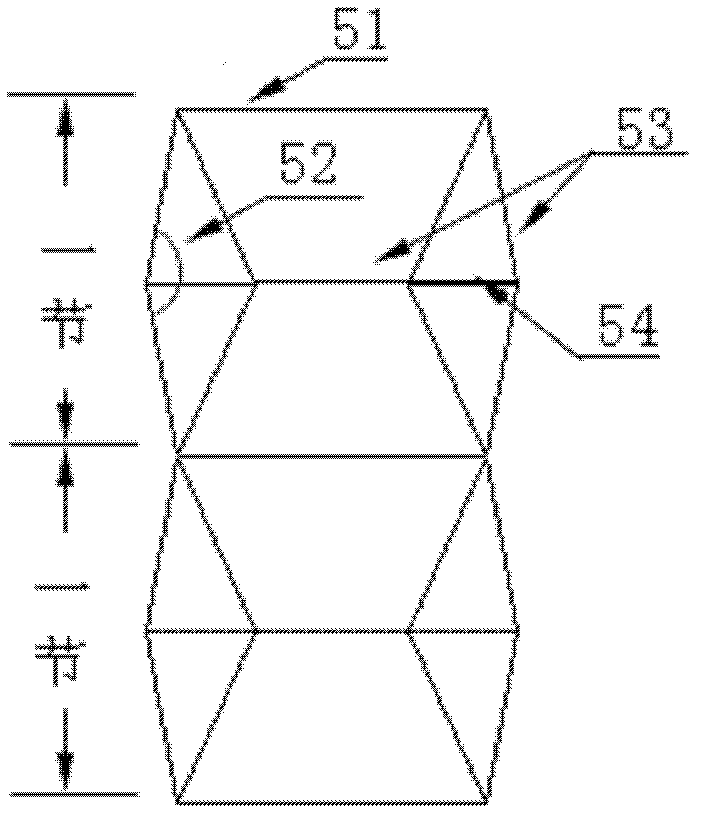

[0019] figure 2 It is a structural schematic diagram of a hydraulic prop used in a hydraulic support system according to the present invention. Such as figure 2 As shown, the anti-shock relief hydraulic prop consists of a live column 1, a cylinder body 2, a safety valve 3, an energy-absorbing transition section 4, an energy-absorbing anti-shock relief member 5, and a movable column bottom 6 as a whole. Among them, the energy-absorbing anti-shock relief component 5 is placed in the movable column bottom 6, one end of the energy-absorbing transition section 4 is placed in one end of the movable column bottom 6, and the other end of the energy-absorbing transition section 4 is embedded in the hydraulic single pillar 7 Inside. The live column 1 is placed in the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com