Up-mounted advancing mechanism and thin coal seam hydraulic support

A technology of pushing mechanism and hydraulic support, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of difficult free design of support pushing mechanism and low working resistance of the minimum height of support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The preferred embodiment of the dress pushing mechanism of the present invention is:

[0017] It includes a front pushing rod, a pushing jack, and a rear pushing rod. The front pushing rod is provided with a round steel guide rail, and the rear pushing rod is provided with a steel pipe slideway, and the round steel guide rail is inserted into the steel pipe slideway , the front end of the pushing jack is connected with the front pushing rod, and the rear end of the moving jack is connected with the rear pushing rod.

[0018] The front pushing rod is connected and fixed with the round steel guide rail, and the inner side of the middle part of the round steel guide rail is provided with a connecting ear plate, which is connected with a connecting head, and the rear end of the connecting head is connected with the piston of the pushing jack. Rod front connection;

[0019] The cylinder body of the pushing jack is provided with a fixed ear plate, which is connected with the...

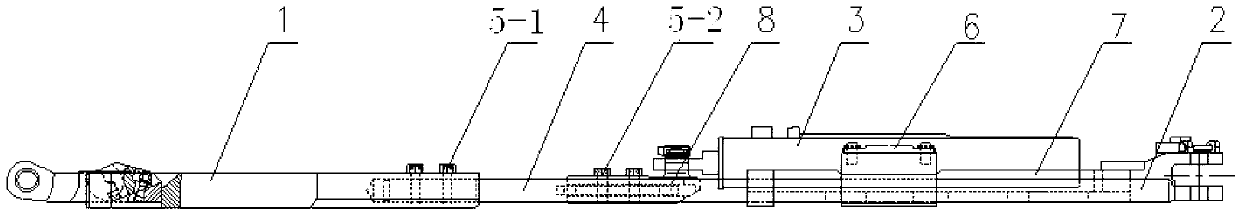

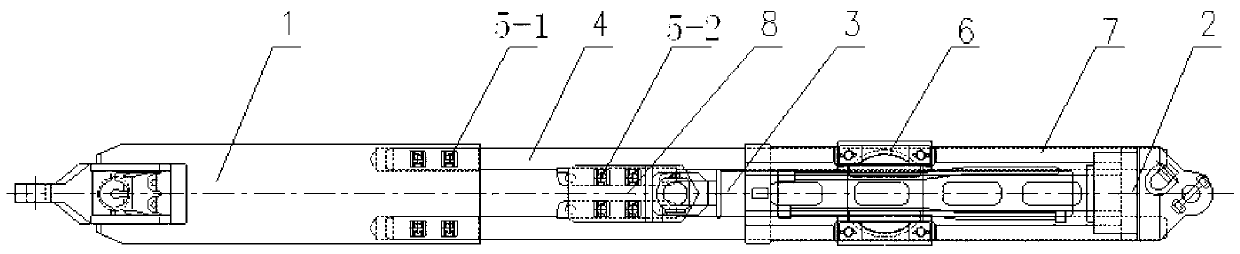

specific Embodiment

[0027] Such as figure 1 , figure 2 Shown, the front portion pushing rod 1 is connected and fixed with the round steel guide rail 4 by the bearing pin 5-1, and each side of the bearing pin 5-1 can be two or more pieces. The inner side of the middle part of the round steel guide rail 4 is welded with a connecting lug plate, which is connected to the connecting head 8 through the pin shaft 5-2. The piston rod end of 3 is connected; the rear part of the round steel guide rail 4 is inserted into the steel pipe slideway 7 of the rear push rod 2, and can slide back and forth in the slideway, and the cylinder body of the push jack 3 is welded with a fixed lug plate. The plate is connected with the rear pushing bar 2 and fixed with a pressing plate 6;

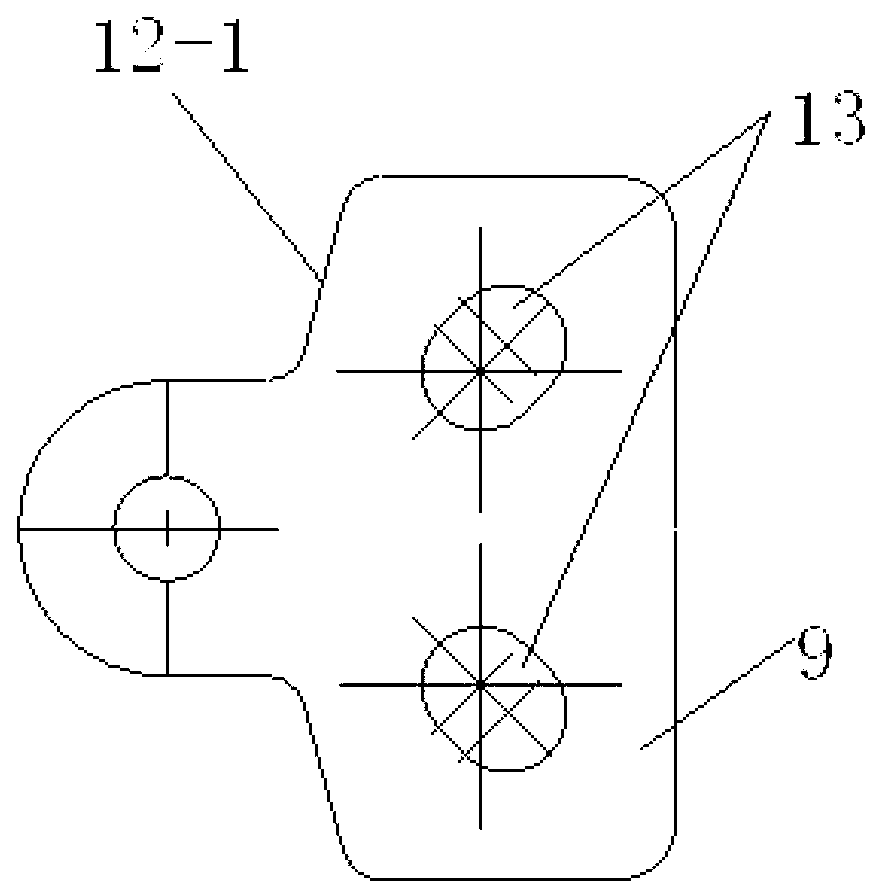

[0028] Such as image 3 , Figure 4 , Figure 5 As shown, the rear end of the rear pushing rod 2 has a group of ear plates, which are connected with the single hole at the front end of the connecting plate 9 through the pin shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com