Hydraulic support push rod

A hydraulic support and push rod technology, which is applied to pillars/supports, mining equipment, earth-moving drilling, etc. Simple process and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

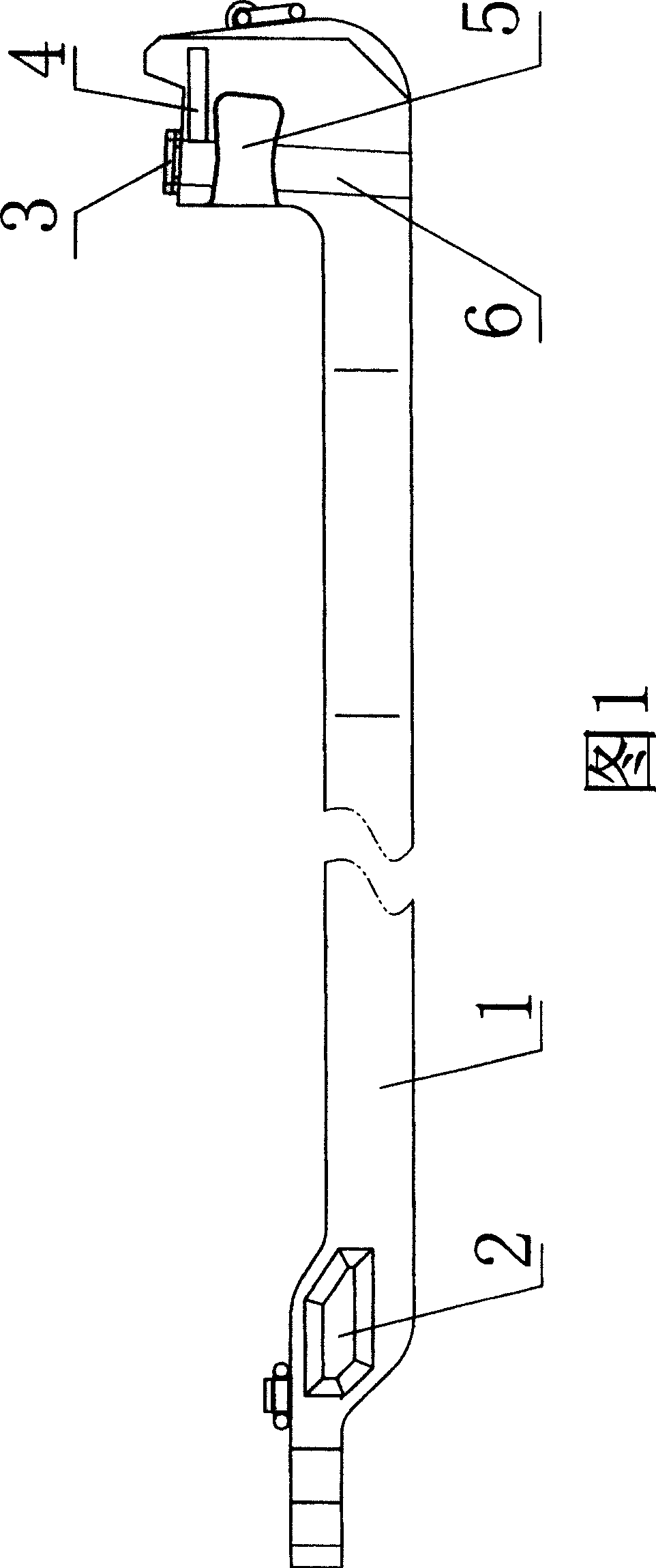

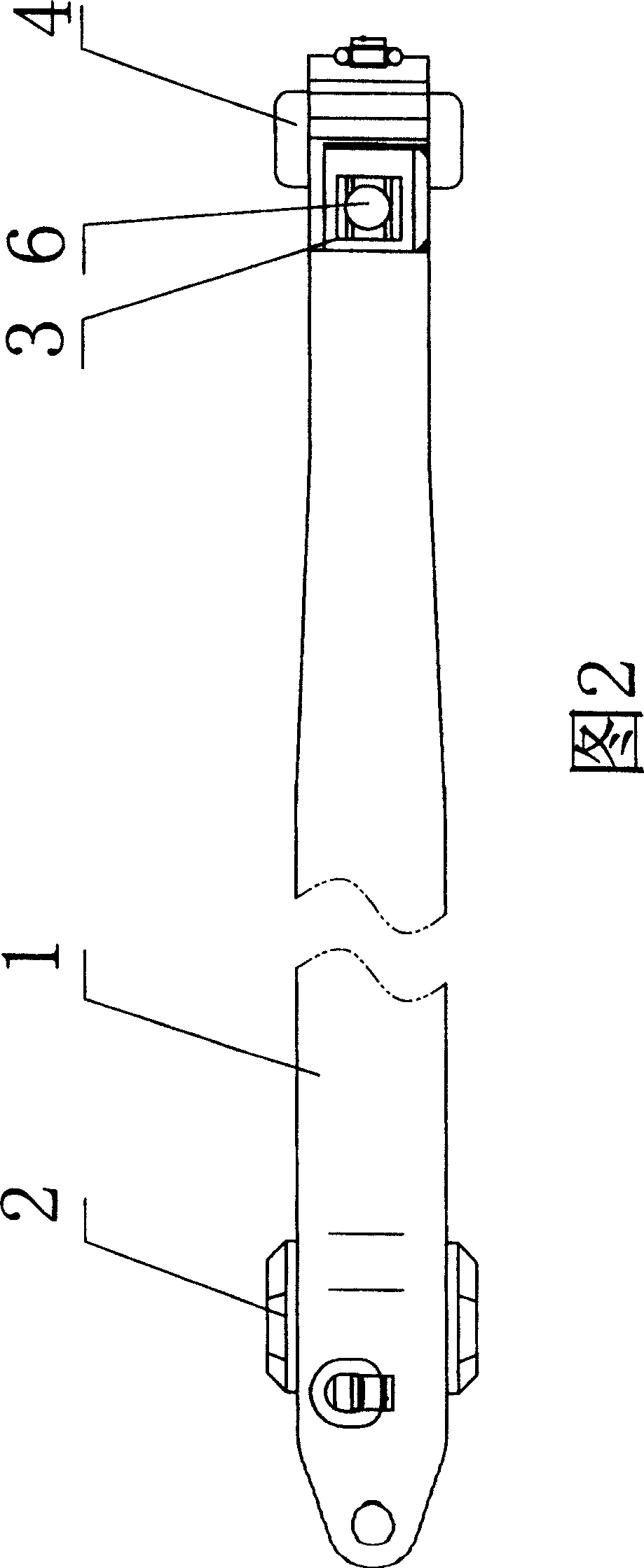

[0012] As shown in Figure 1 and Figure 2, a hydraulic support push rod includes a push rod body 1, reinforcing blocks 2 welded on both sides of the head of the push rod body 1, and a limit block welded above the tail of the push rod body 1 3. The guide plate 4 welded on both sides of the tail of the push rod body 1, wherein the limit block 3 is provided with a pin hole 6, and the pin hole 6 runs through the tail of the push rod body 1, and the pin hole 6 is used to connect the connecting pin The shaft is limited, and the push rod body 1 is forged as a whole. In order to solve the processing problem of the connecting notch between the tail of the push rod body and the push jack, during the forging process of the push rod body, the notch at the tail of the push rod body 1 is The side is opened, and after forging, it is sealed and welded with the pasting plate 5. In use, push the base of the jack into the notch. The push rod is made of alloy structural steel with a yield point h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com