Automatic tapping machine

A technology of automatic tapping machine and machine base, which is applied in the direction of thread cutting machine, metal processing equipment, thread cutting device, etc., to achieve the effect of simple and fast adjustment method, saving time and labor cost, and low operating noise of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

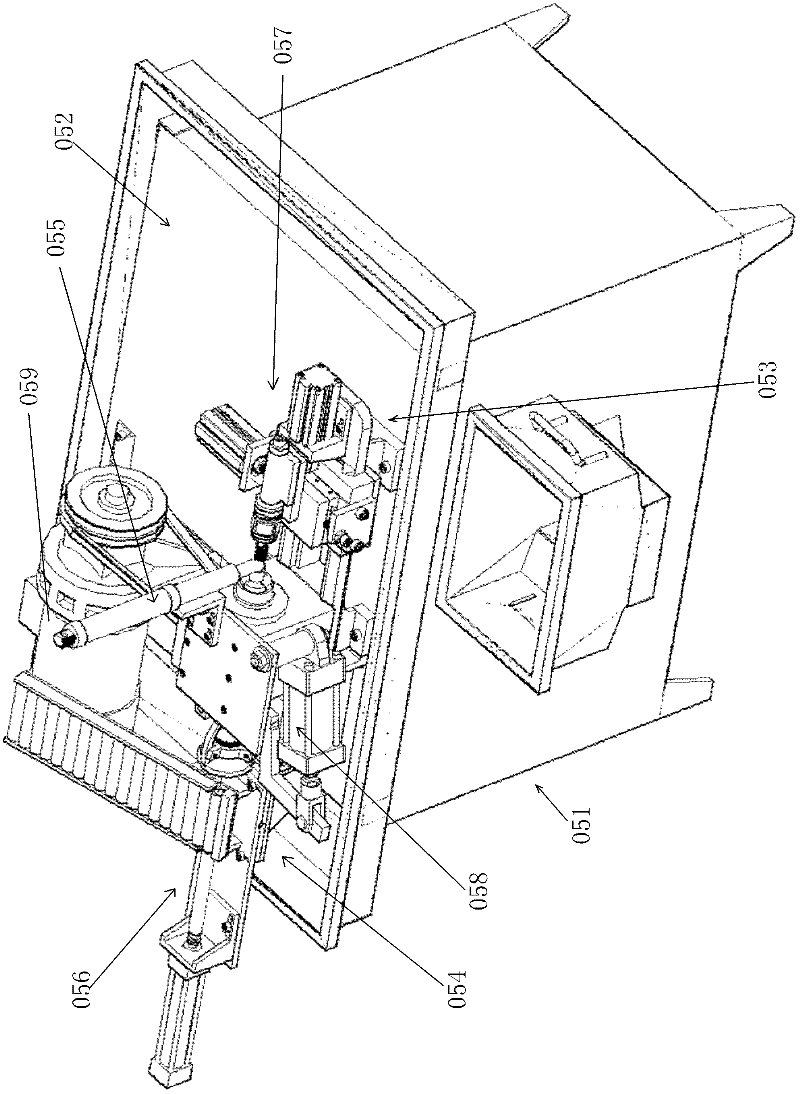

[0043] Such as figure 1 As shown, the automatic tapping machine of the present invention includes a PLC control circuit, a machine base 051, a marble slab 052, an instrument lathe 053, a positioning adjustment device 054, a limit device 055, a feeding device 056, a tapping device 057 and a clamping device 058. Gear motor 059.

[0044] The marble plate 052 is placed on the machine base 051 to increase the quality of the machine base, improve the stability of the equipment foundation, and avoid resonance. The positioning adjustment device 054 and the instrument lathe 053 are fixed on the marble slab 052 in left and right order, and the reduction motor 059 is installed on one side of the instrument lathe 053, and the distance and position are adjusted with the positioning mark on the marble slab 052 as a reference point, so that the installation The reference coordinates of other devices on it are accurate.

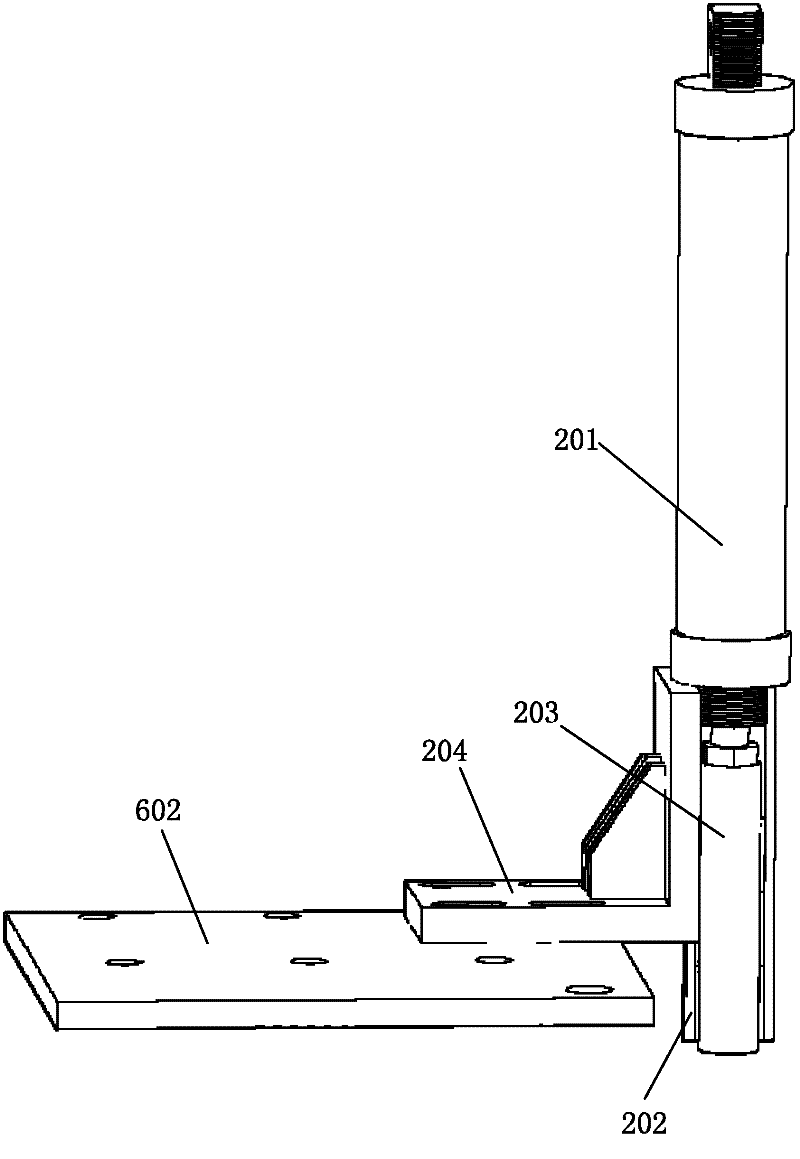

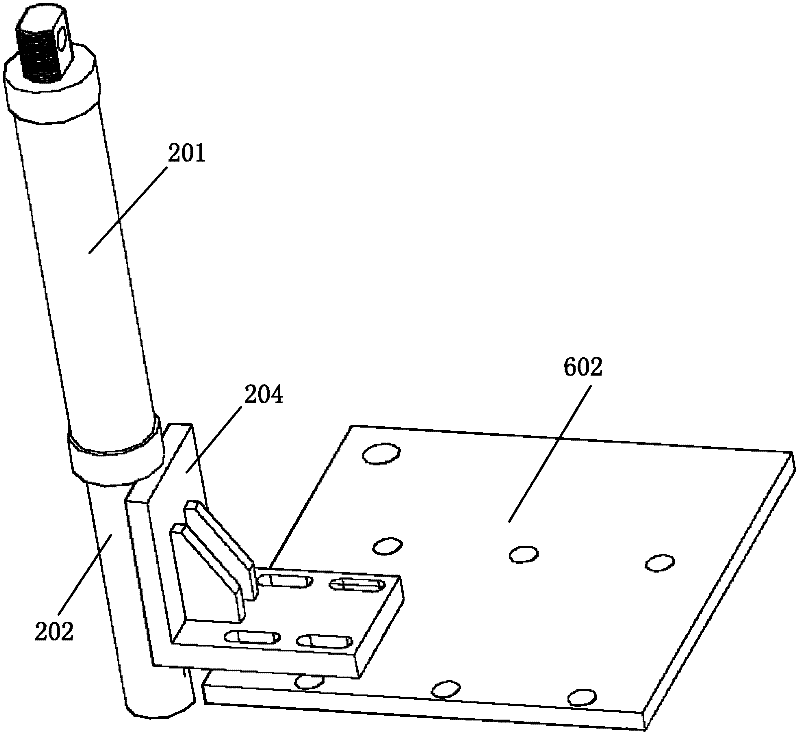

[0045] By adjusting the offset distances in X, Y, and Z directions on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com