Steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method

A technology of comprehensive mechanization and coal mining methods, applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of narrow mining space in steeply inclined coal seams, many hidden dangers of production safety, and complex roof beam management, etc., to achieve improved mining efficiency and resource utilization, avoid coal wall flakes helping people, and improve the effect of gas dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

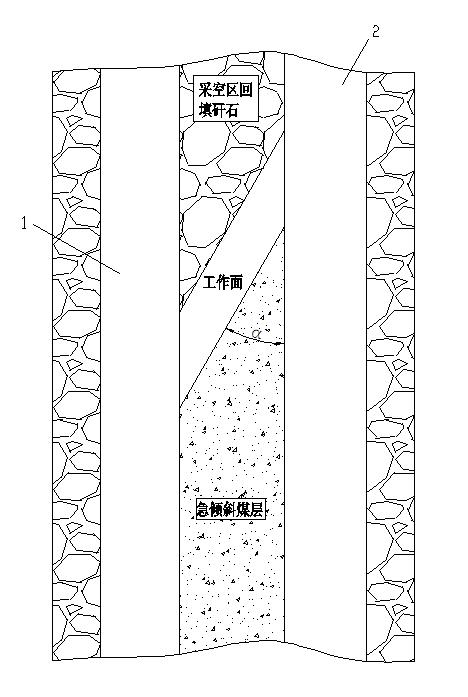

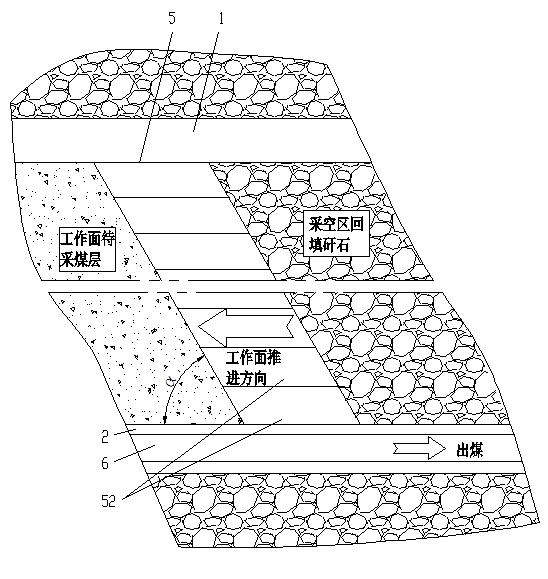

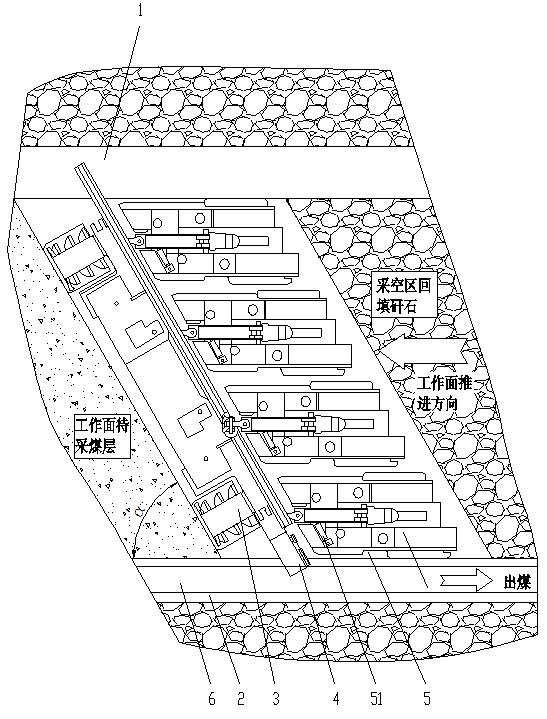

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , a longwall comprehensive mechanized coal mining method in a steeply inclined coal seam, including the following steps:

[0025] a. Preparation: Excavate two parallel first roadways 1 and second roadways 2 at the upper and lower ends of the steeply inclined coal seam, the first roadway 1 and the second roadway 2 are perpendicular to the inclination angle of the steeply inclined coal seam, the first roadway 1 and the second roadway The two roadways 2 are used for air return and coal transportation respectively; a cut hole is dug between the two roadways to form a primary mining face with a false dip angle α of 30°, and the top view shape of the working face is a parallelogram; The coal shearer 3 controlled by the electric contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com