Patents

Literature

30results about How to "Reduce internal strain" patented technology

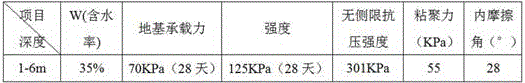

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonate resin composition, pellets thereof and molded article thereof

InactiveUS20040152806A1Increased durabilityHigh transparencySynthetic resin layered productsAbsorbent padsAlcoholCrack resistance

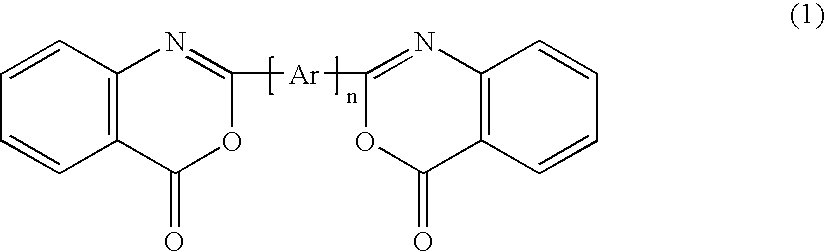

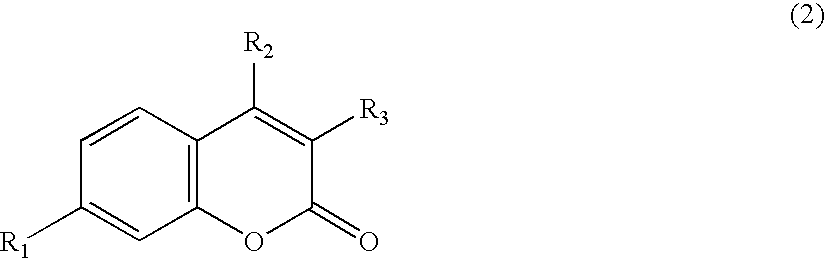

The object of the present invention is to provide a polycarbonate resin composition which has excellent transparency and durability against molding heat, which gives a molded article having an excellent mold release property, reduced strains, improved cracking resistance and, preferably, weatherability, and which is particularly suitable for a transparent member for a vehicle, pellets thereof and a molded article thereof, and the present invention provides a polycarbonate resin composition obtained by blending 100 parts by weight of a polycarbonate resin (Component A) and 0.005 to 2 parts by weight of a full ester (Component B) from an aliphatic polyhydric alcohol having 4 to 8 hydroxyl groups and 5 to 30 carbon atoms and an aliphatic carboxylic acid having 10 to 22 carbon atoms, said Component B having a 5% weight loss temperature, measured by TGA (thermogravimetric analysis), of 250 to 360° C. and having an acid value of 4 to 20, pellets thereof and a molded article thereof.

Owner:TEIJIN KASEK KK

Polycarbonate resin composition, pellets thereof and molded article thereof

InactiveUS7241825B2Increased durabilityHigh transparencySynthetic resin layered productsAbsorbent padsPolyolCrack resistance

The object of the present invention is to provide a polycarbonate resin composition which has excellent transparency and durability against molding heat, which gives a molded article having an excellent mold release property, reduced strains, improved cracking resistance and, preferably, weatherability, and which is particularly suitable for a transparent member for a vehicle, pellets thereof and a molded article thereof, and the present invention provides a polycarbonate resin composition obtained by blending 100 parts by weight of a polycarbonate resin (Component A) and 0.005 to 2 parts by weight of a full ester (Component B) from an aliphatic polyhydric alcohol having 4 to 8 hydroxyl groups and 5 to 30 carbon atoms and an aliphatic carboxylic acid having 10 to 22 carbon atoms, said Component B having a 5% weight loss temperature, measured by TGA (thermogravimetric analysis), of 250 to 360° C. and having an acid value of 4 to 20, pellets thereof and a molded article thereof.

Owner:TEIJIN KASEK KK

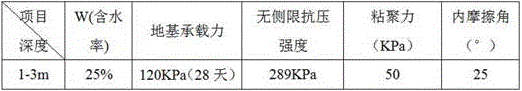

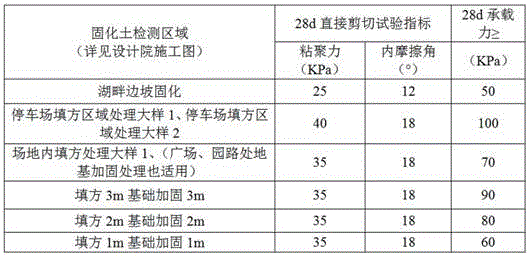

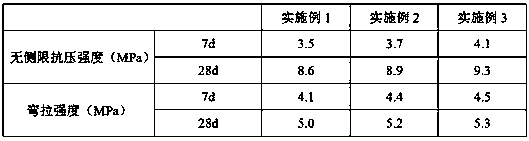

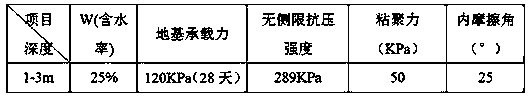

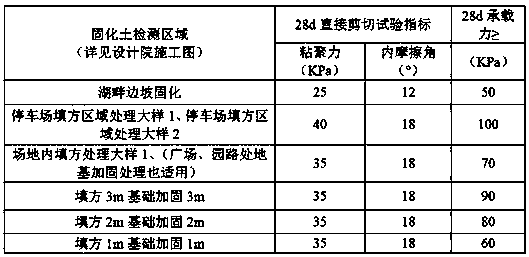

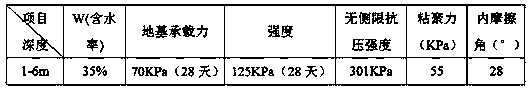

Silt solidification soil construction technology

The invention discloses a silt solidification soil construction technology which comprises the steps of surface cleaning drainage, silt sampling, detection analysis, excavation stacking, stirring and mixing, filling and grinding and stabilized soil maintenance. Through solidification soil in-situ solidification, silt and a curing agent are stirred and mixed to form silt solidification soil, and the curing agent is prepared through expanded graphite, activated carbon, cement, quick lime, gypsum, lignocelluloses, coal ash, granulated blast-furnace slag powder, coal gangue, caustic dross, hydroxypropyl methyl celluloses, furfural residues, medical stone and smectite clay. By means of the silt solidification soil construction technology, original flowing high-water-content low-strength high-compressibility silt is converted into high-compressive-strength excellent-entire-board-performance, good-durability and environment-friendly solidification soil, and the requirement of shallow ground earthwork materials for roads, storage yards, ports, reclamation projects, afforesting and the like can be met.

Owner:福建港湾岩土工程集团有限公司

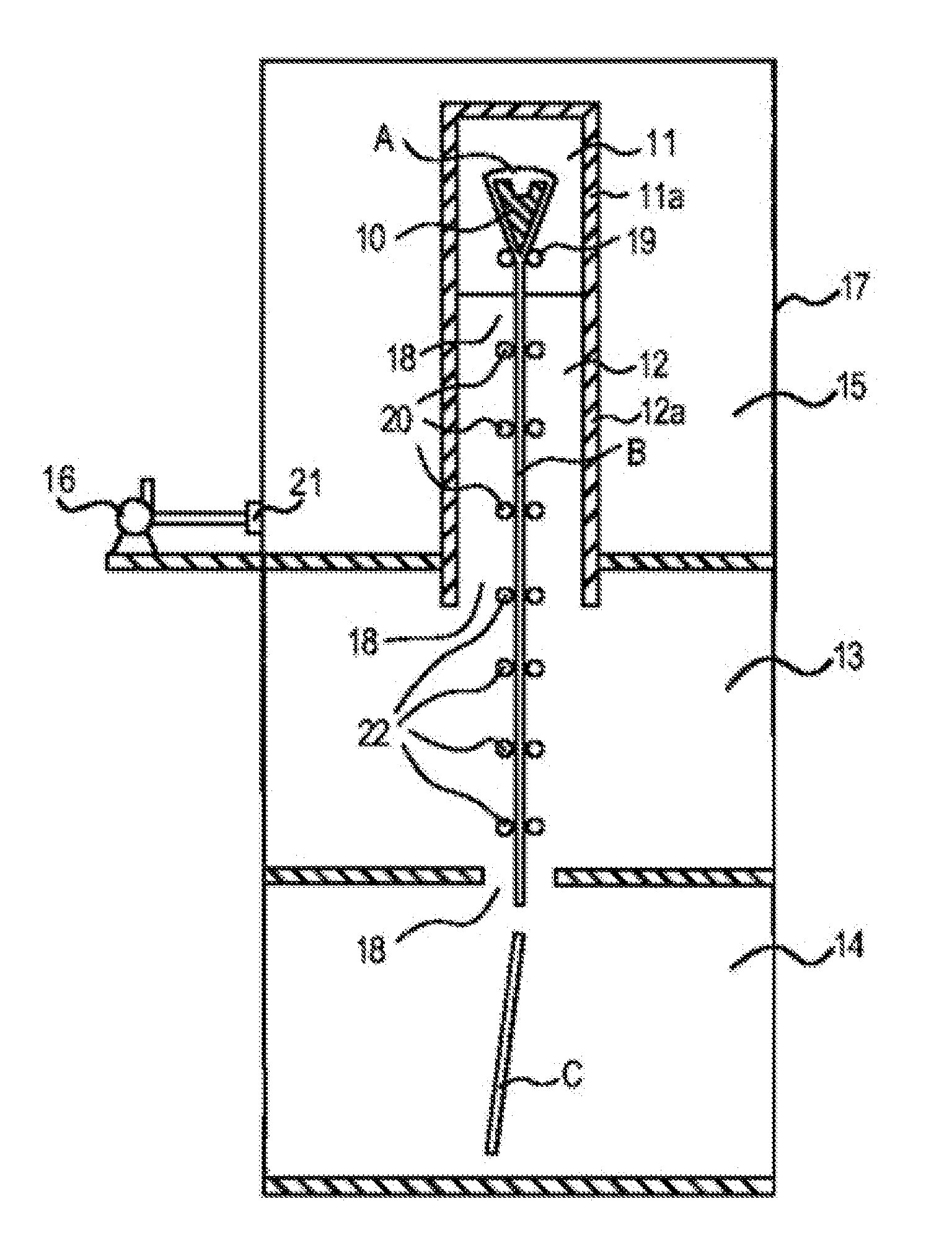

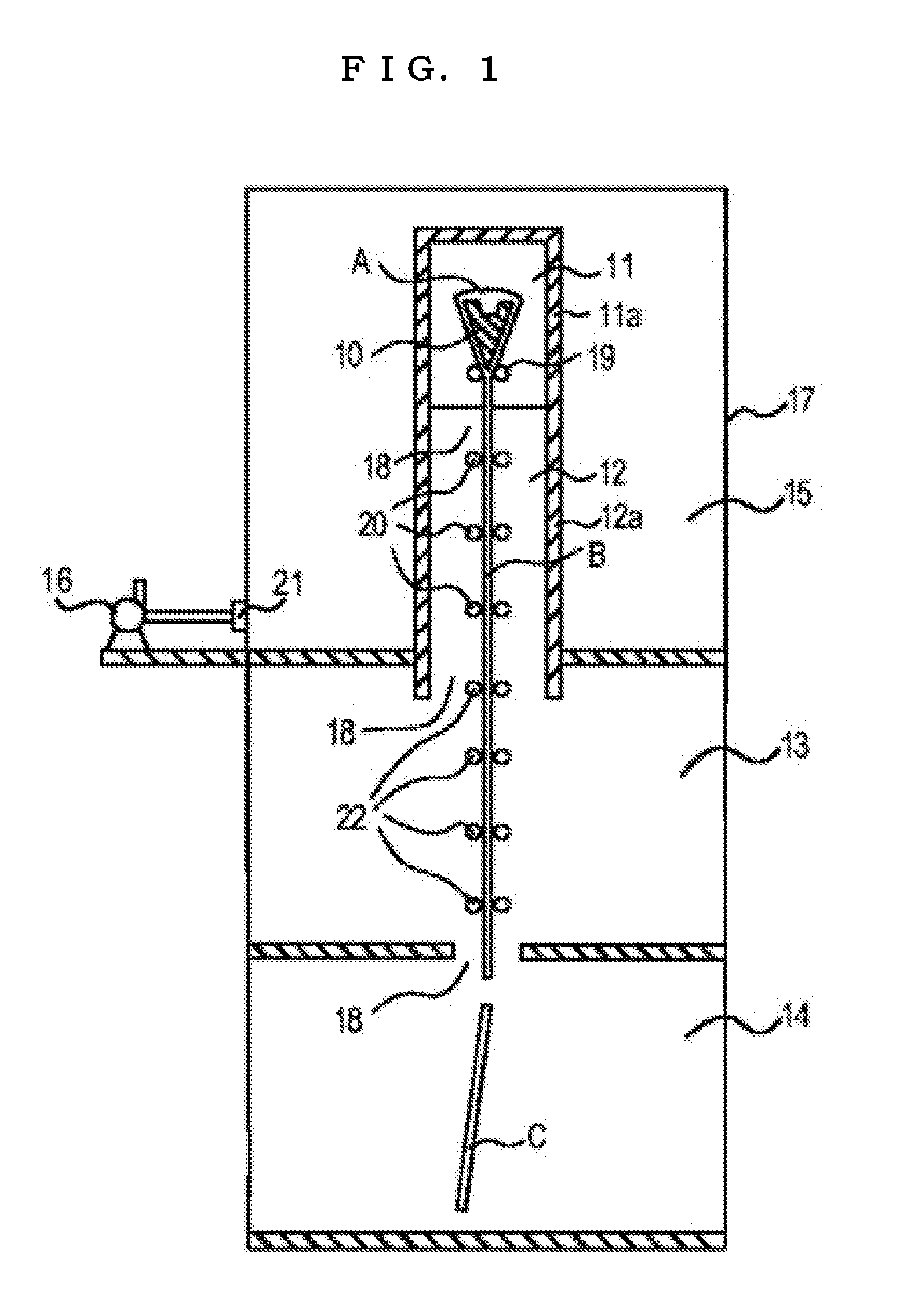

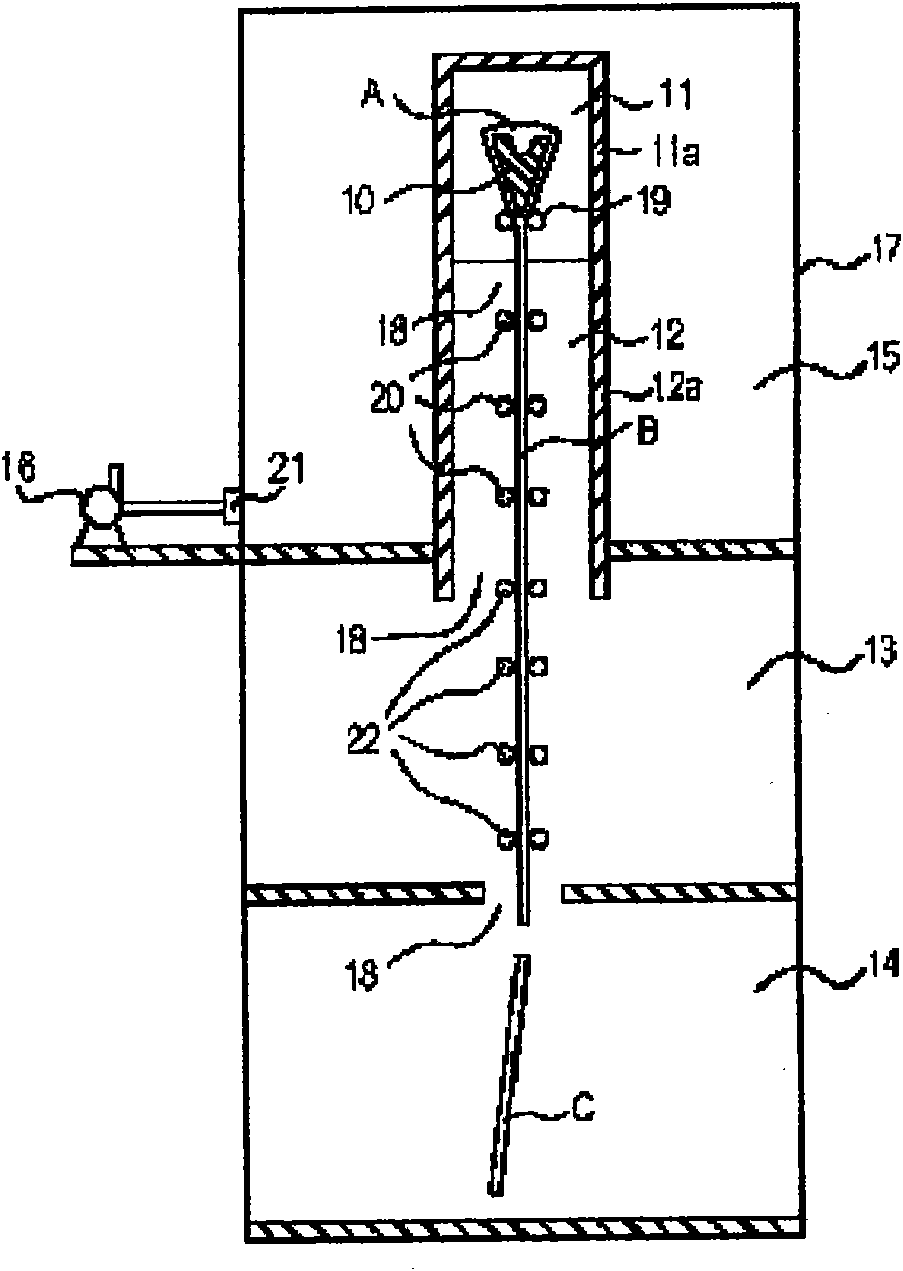

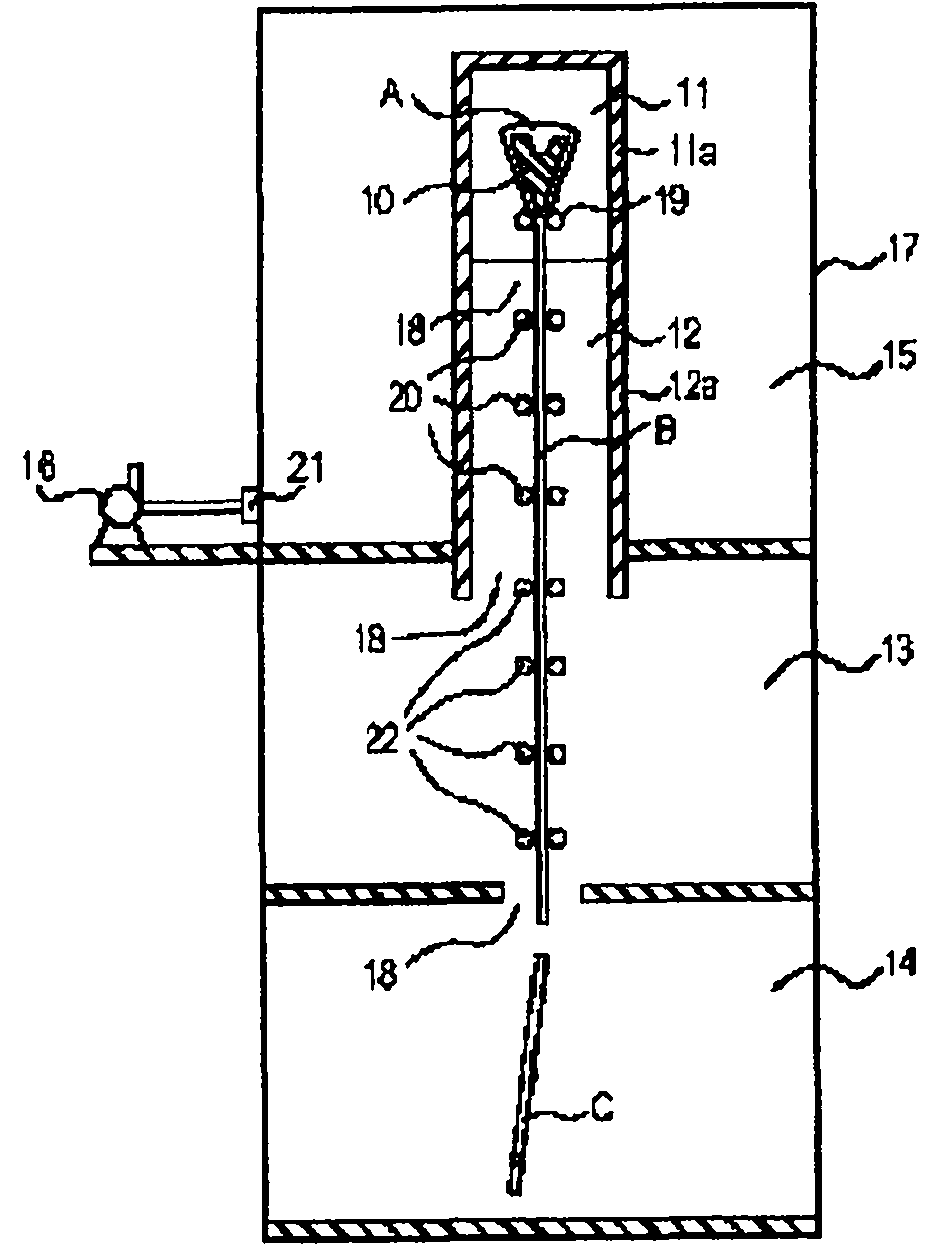

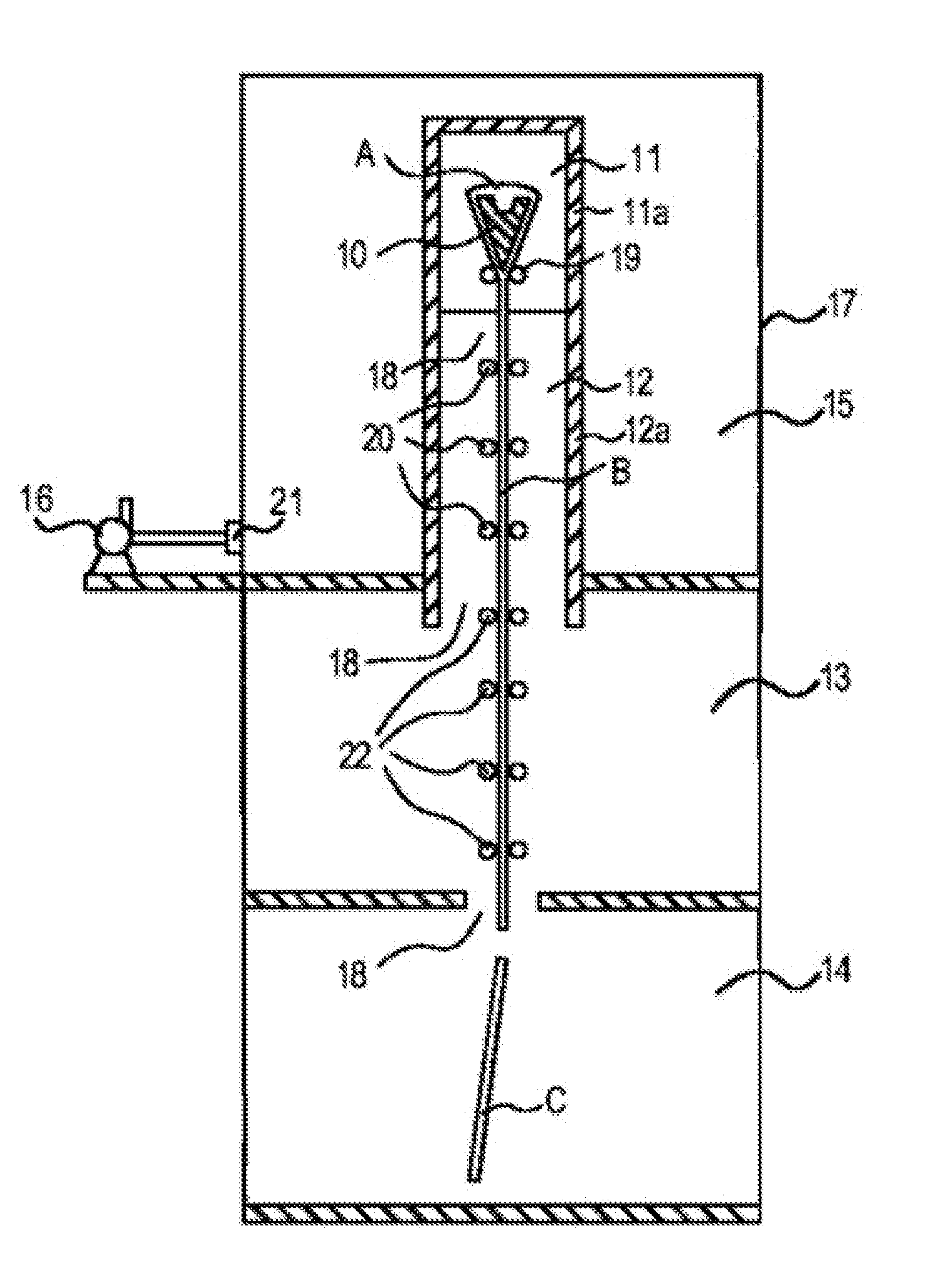

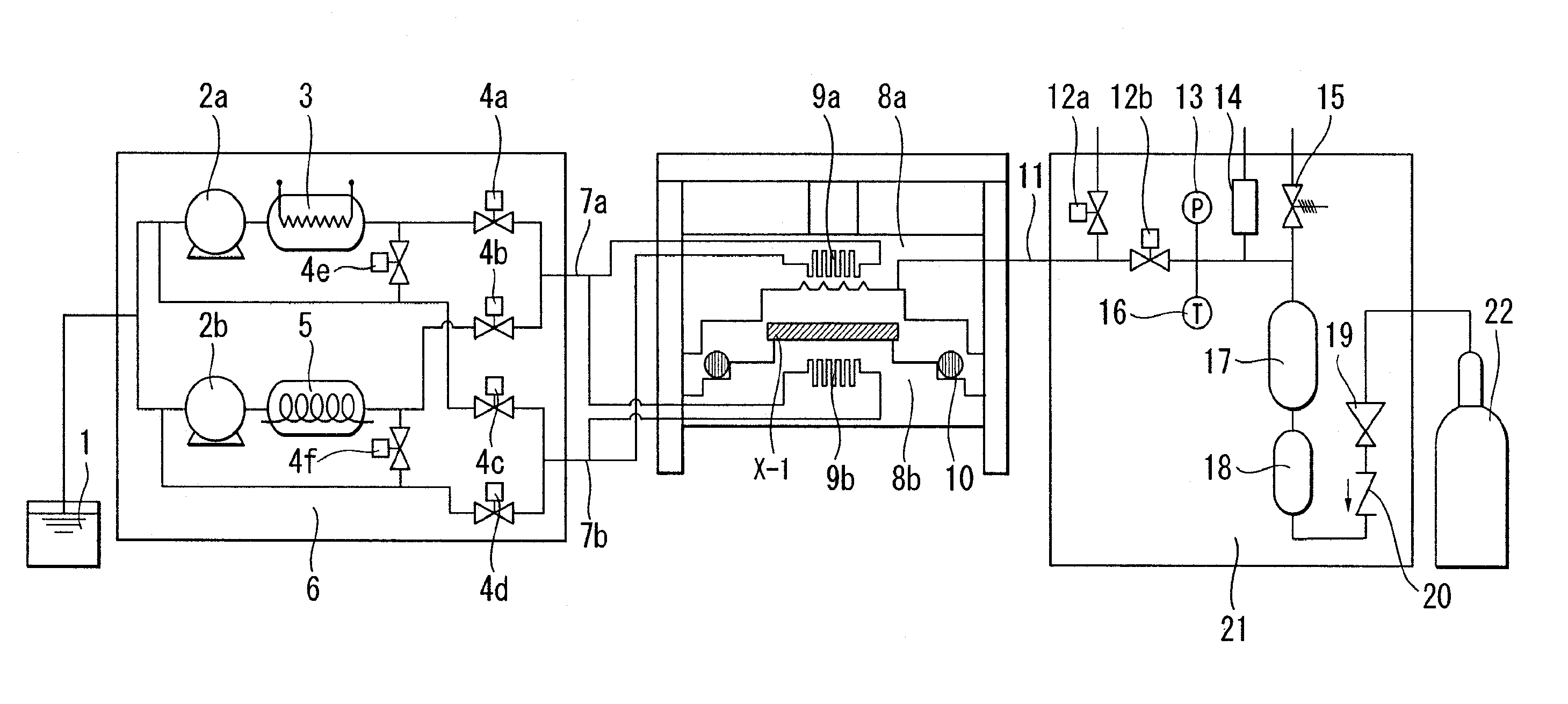

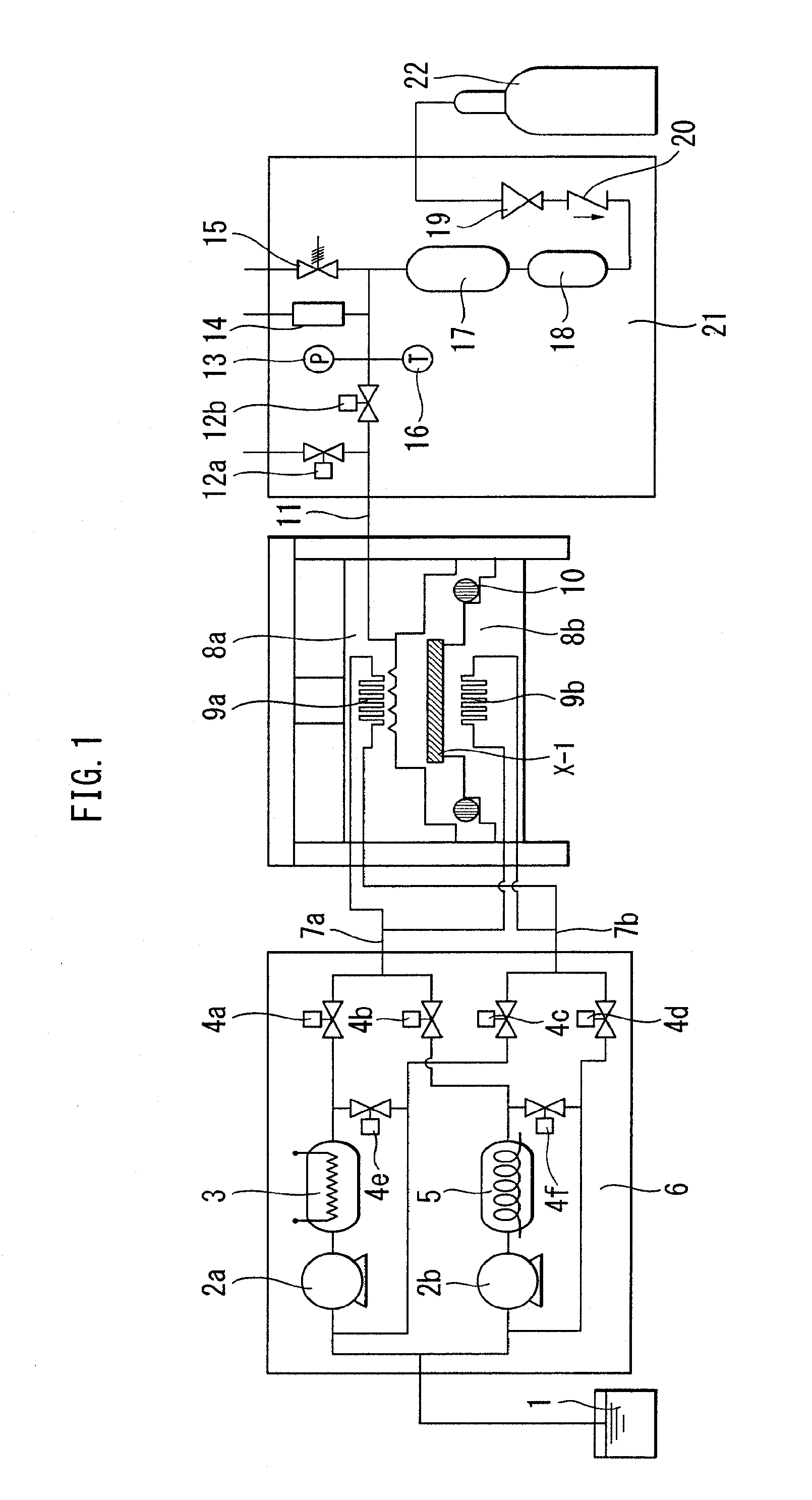

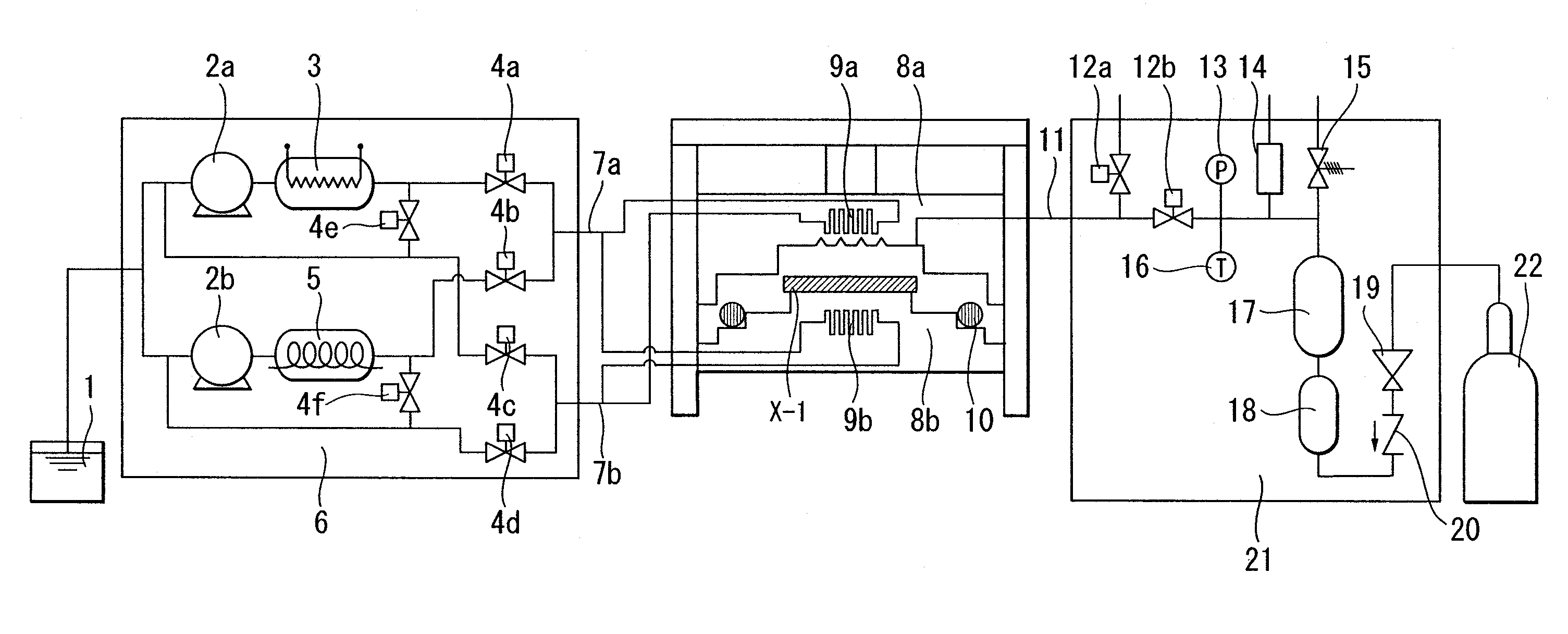

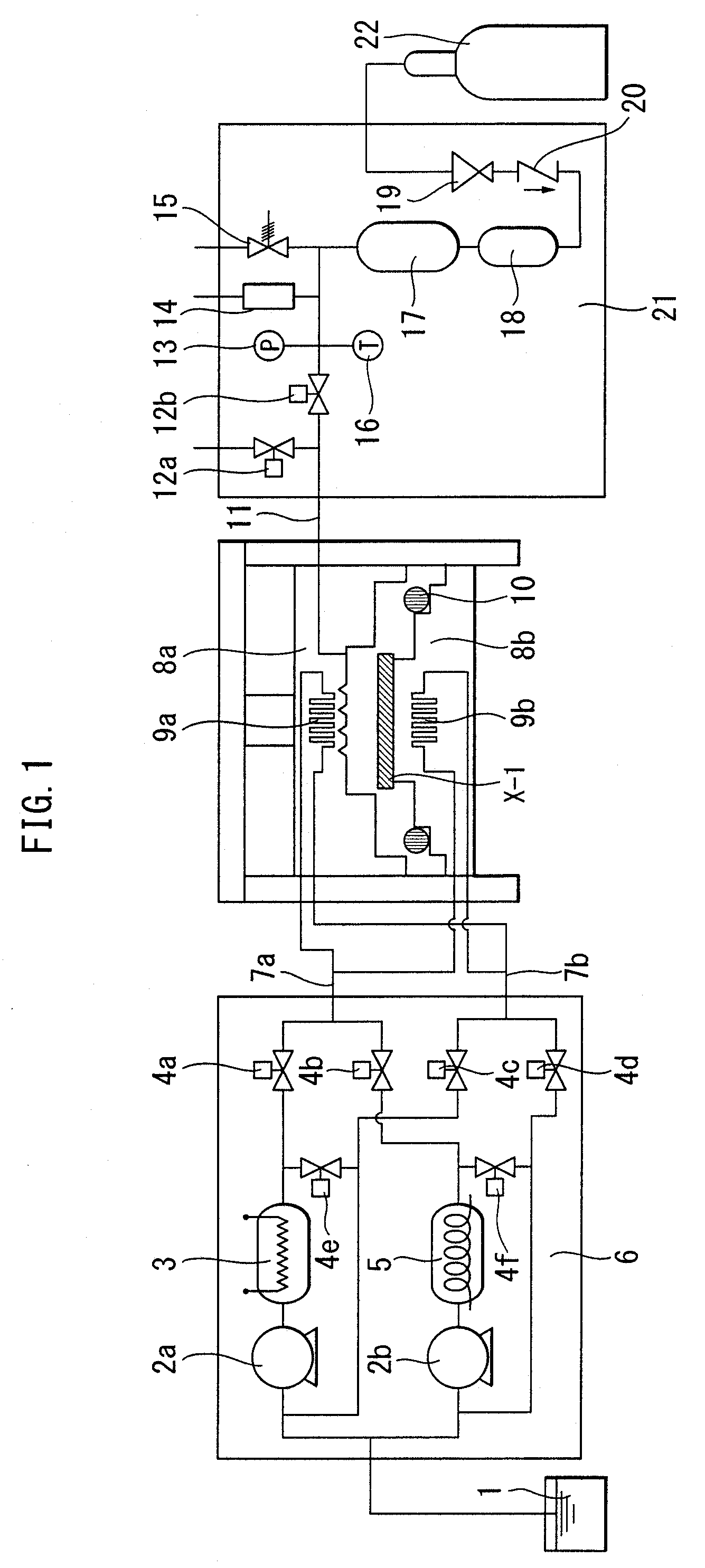

Process and apparatus for producing glass sheet

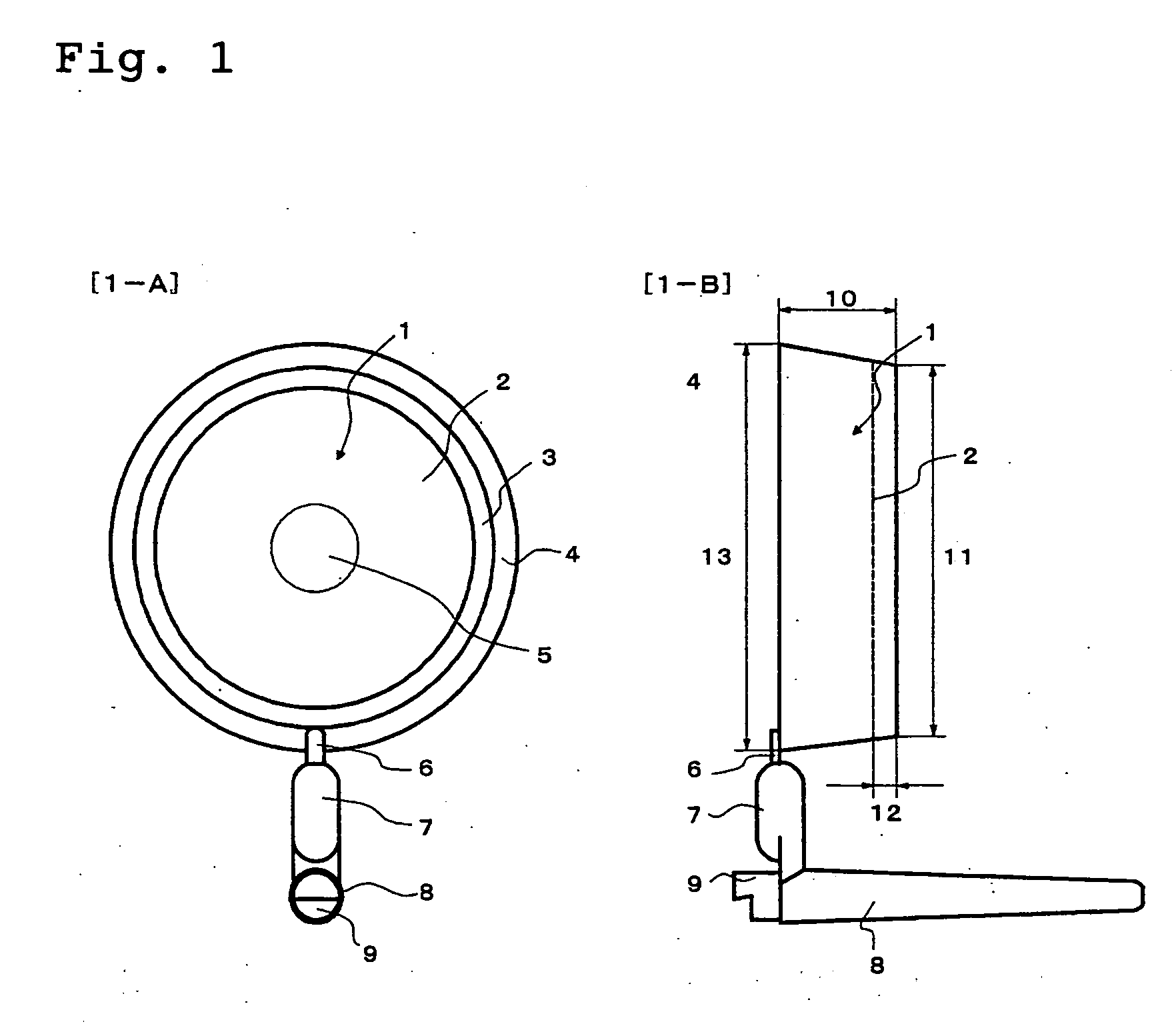

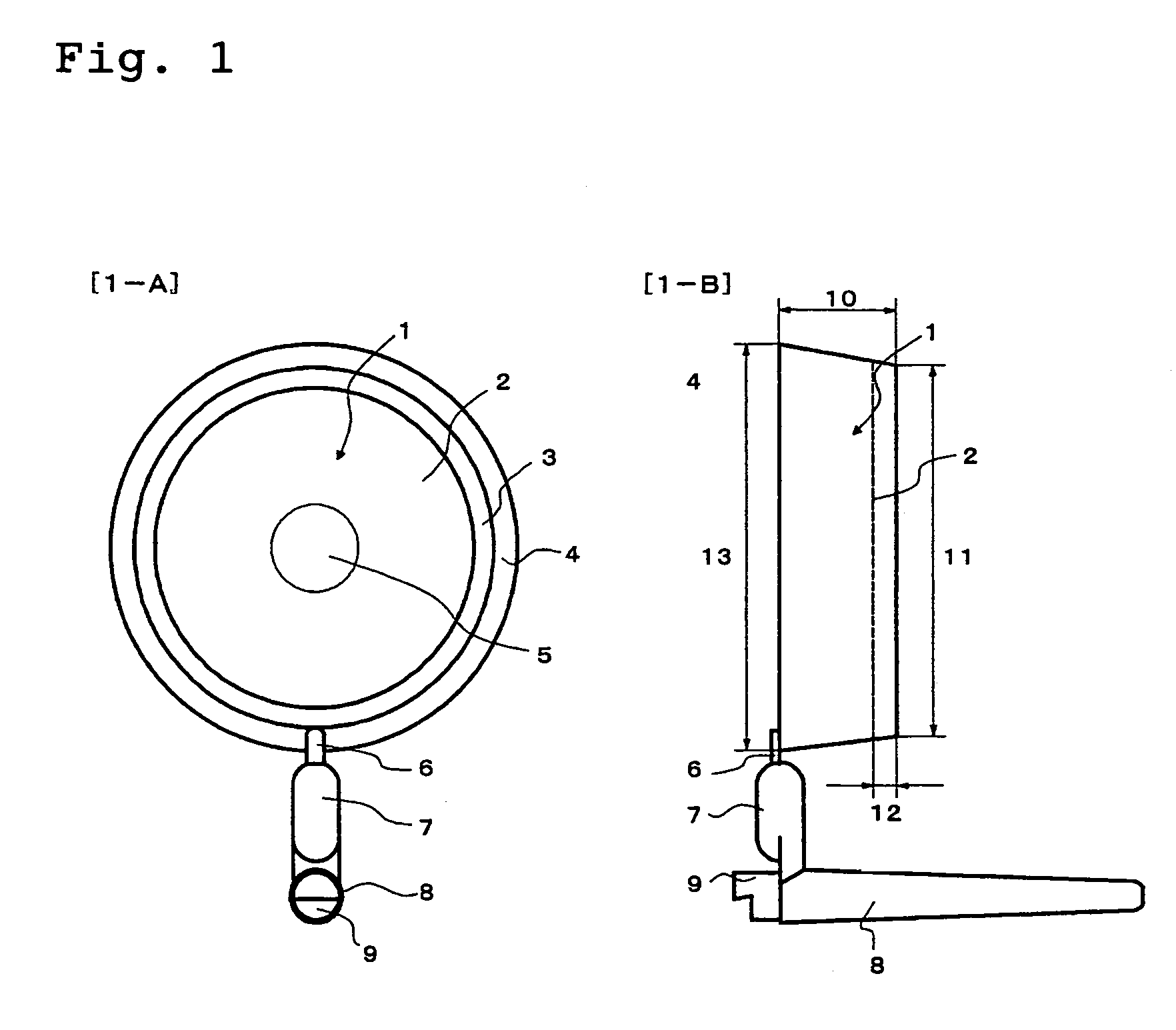

ActiveUS20100269542A1Sufficient in internal strainIncrease pressureGlass drawing apparatusGlass forming apparatusCutting glassRoom temperature

Provided is a process for producing a glass sheet including: a forming step of down-drawing a molten glass into a sheet-like glass ribbon, in which the molten glass is fed to a forming trough arranged in a forming furnace and the molten glass is caused to flow down from the forming trough through a conveyance passage extending vertically; an annealing step of removing an internal strain in the glass ribbon in an annealing furnace; a cooling step of cooling the glass ribbon to around room temperature; and a cutting step of cutting the glass ribbon in a given size, in which a pressure in an outside atmosphere of the forming furnace and / or the annealing furnace is elevated.

Owner:NIPPON ELECTRIC GLASS CO LTD

Process and apparatus for producing glass plate

ActiveCN101821209ASuppress changesIncrease air pressureGlass forming apparatusGlass productionRoom temperatureAtmospheric pressure

A process for producing a glass plate (C) which comprises: a forming step in which a molten glass (A) is fed to a trough (10) disposed in a forming furnace (11) and the molten glass (A) is caused to flow down from the trough (10) through a conveyance passage (18) extending vertically to thereby stretch and form the glass (A) into a platy glass ribbon (B); an annealing step in which internal strain in the glass ribbon (B) is removed in an annealing lehr (12); a cooling step in which the glass ribbon (B) is cooled to around room temperature; and a cutting step in which the glass ribbon is cut into a given size, the pressure of the atmosphere surrounding the forming furnace (11) and / or annealing lehr (12) being elevated.

Owner:NIPPON ELECTRIC GLASS CO LTD

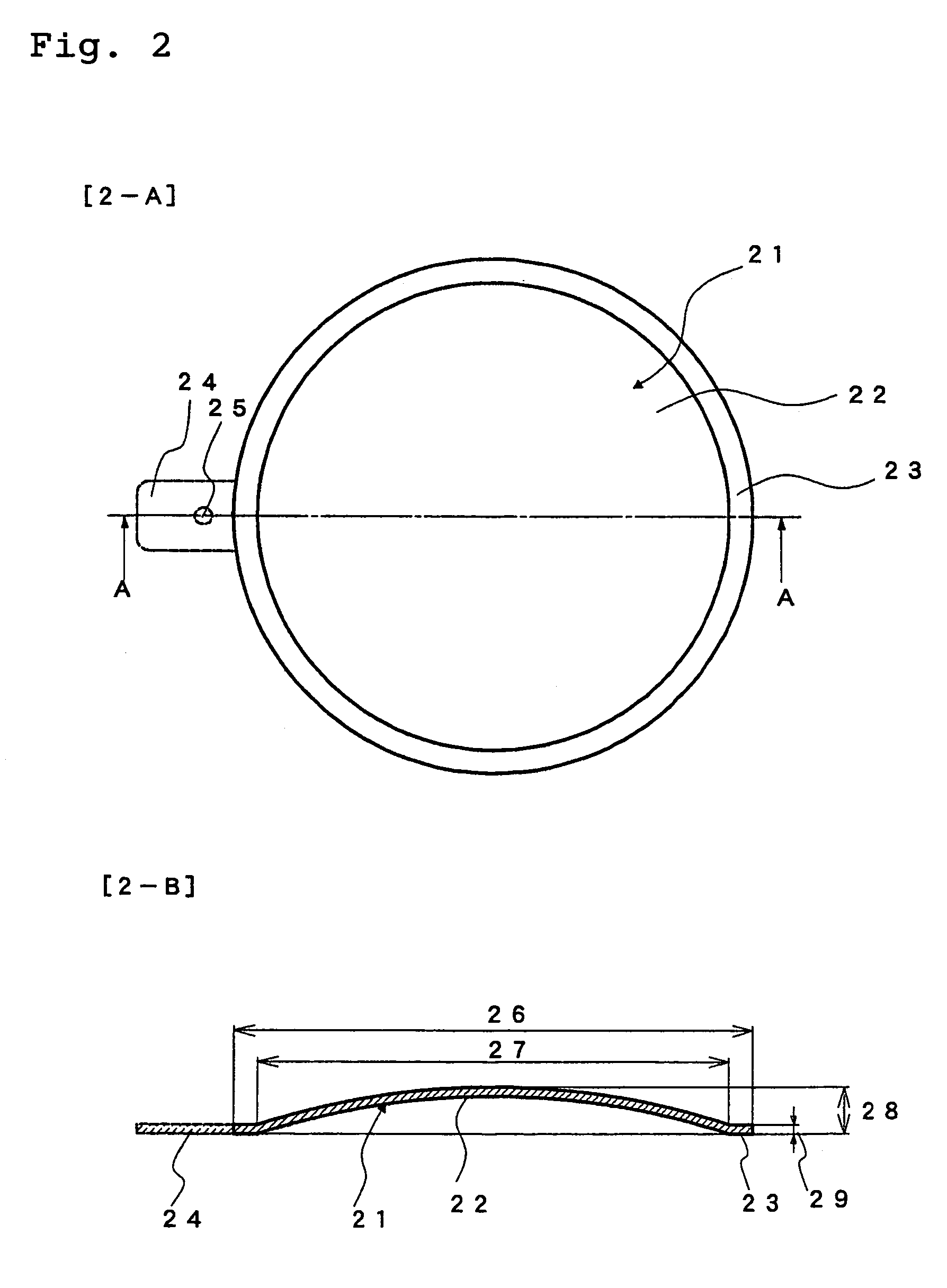

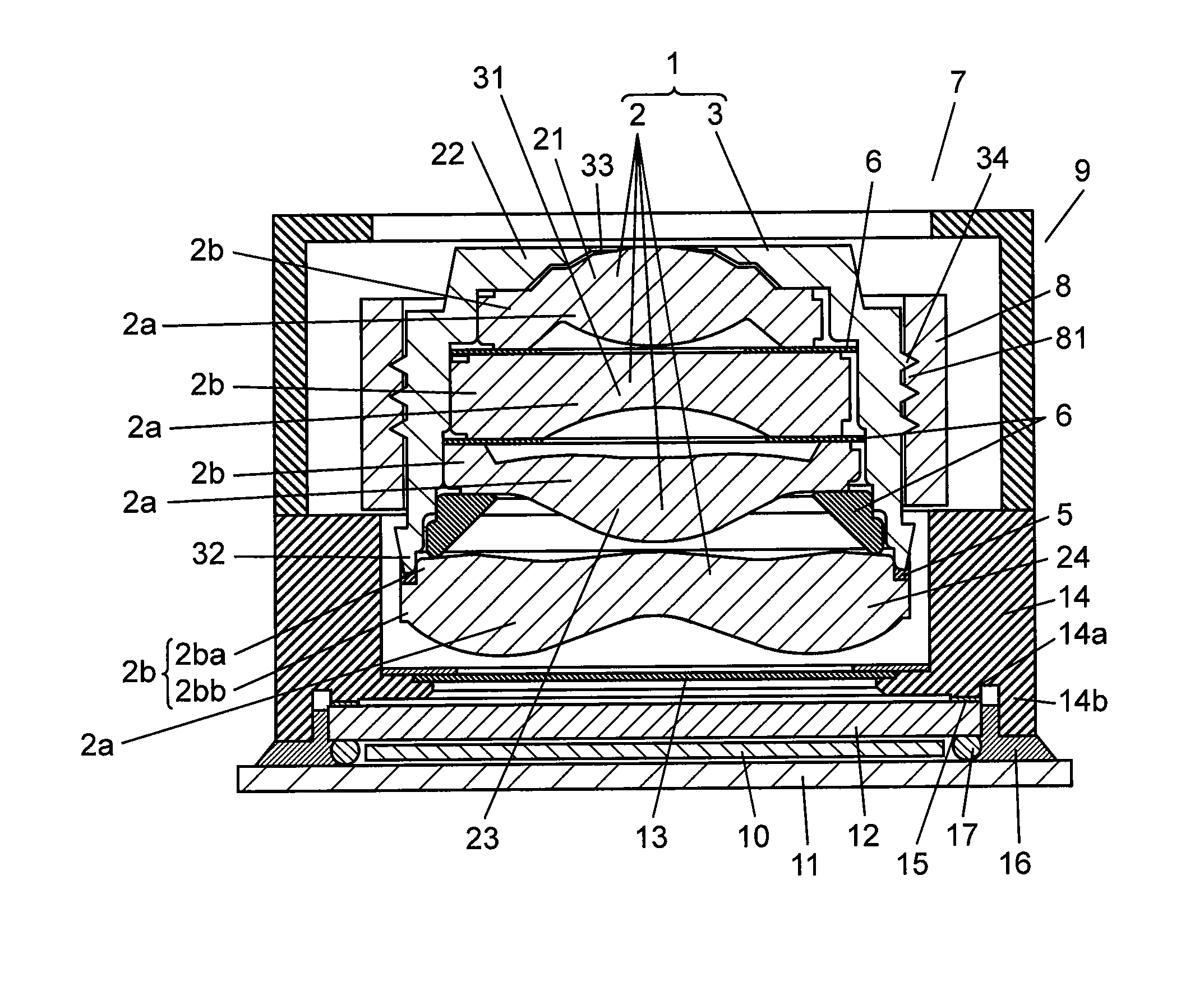

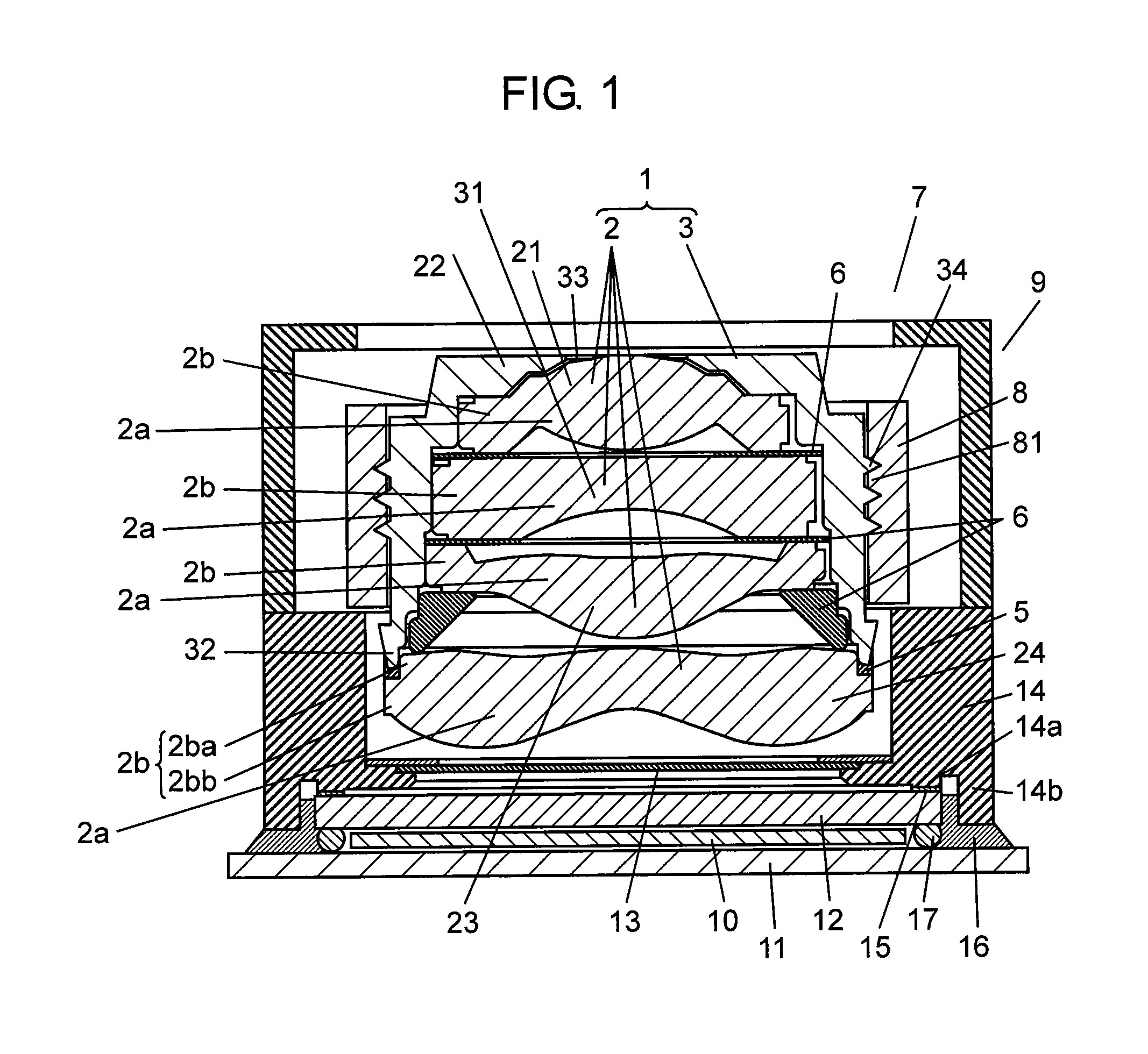

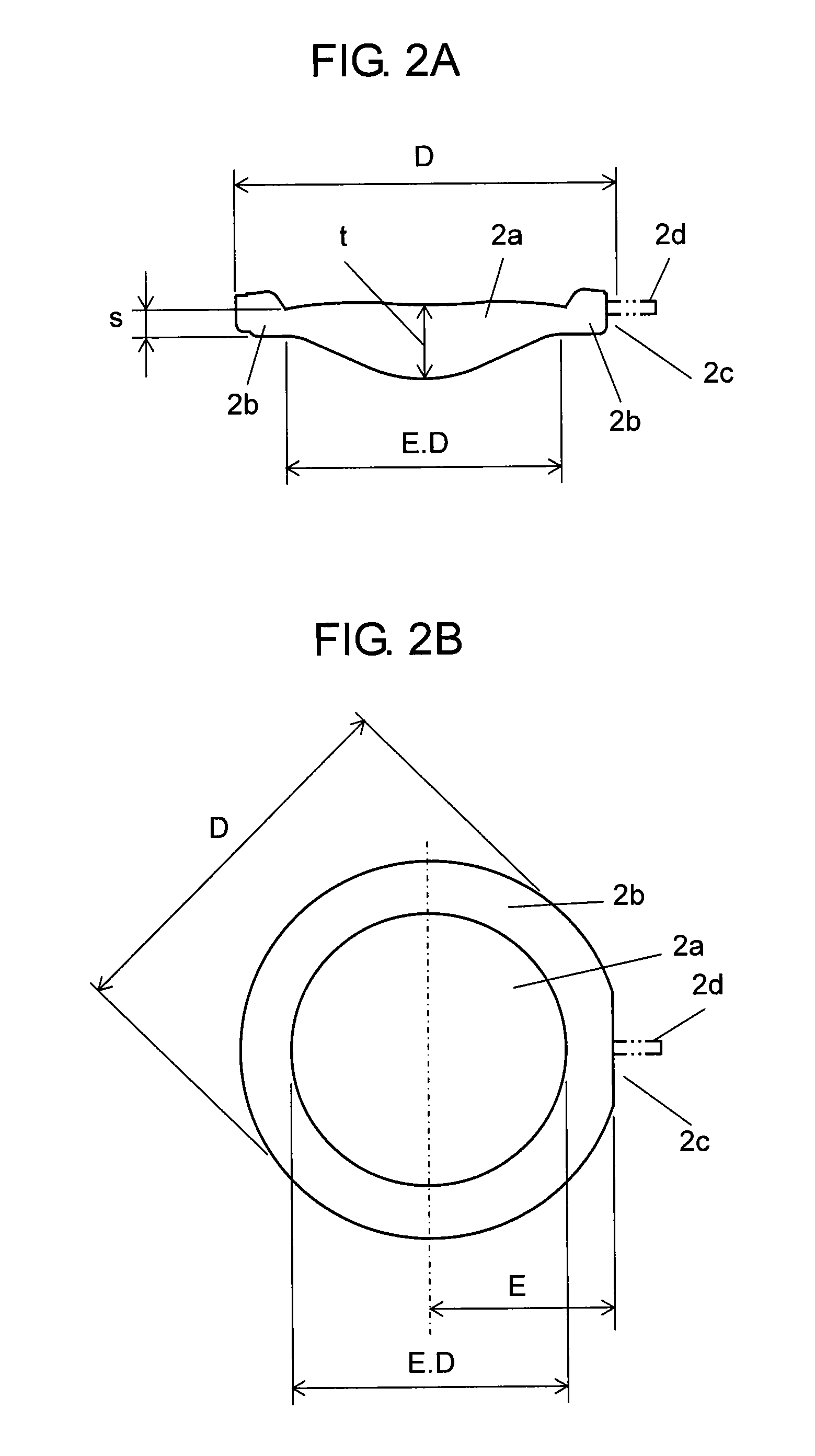

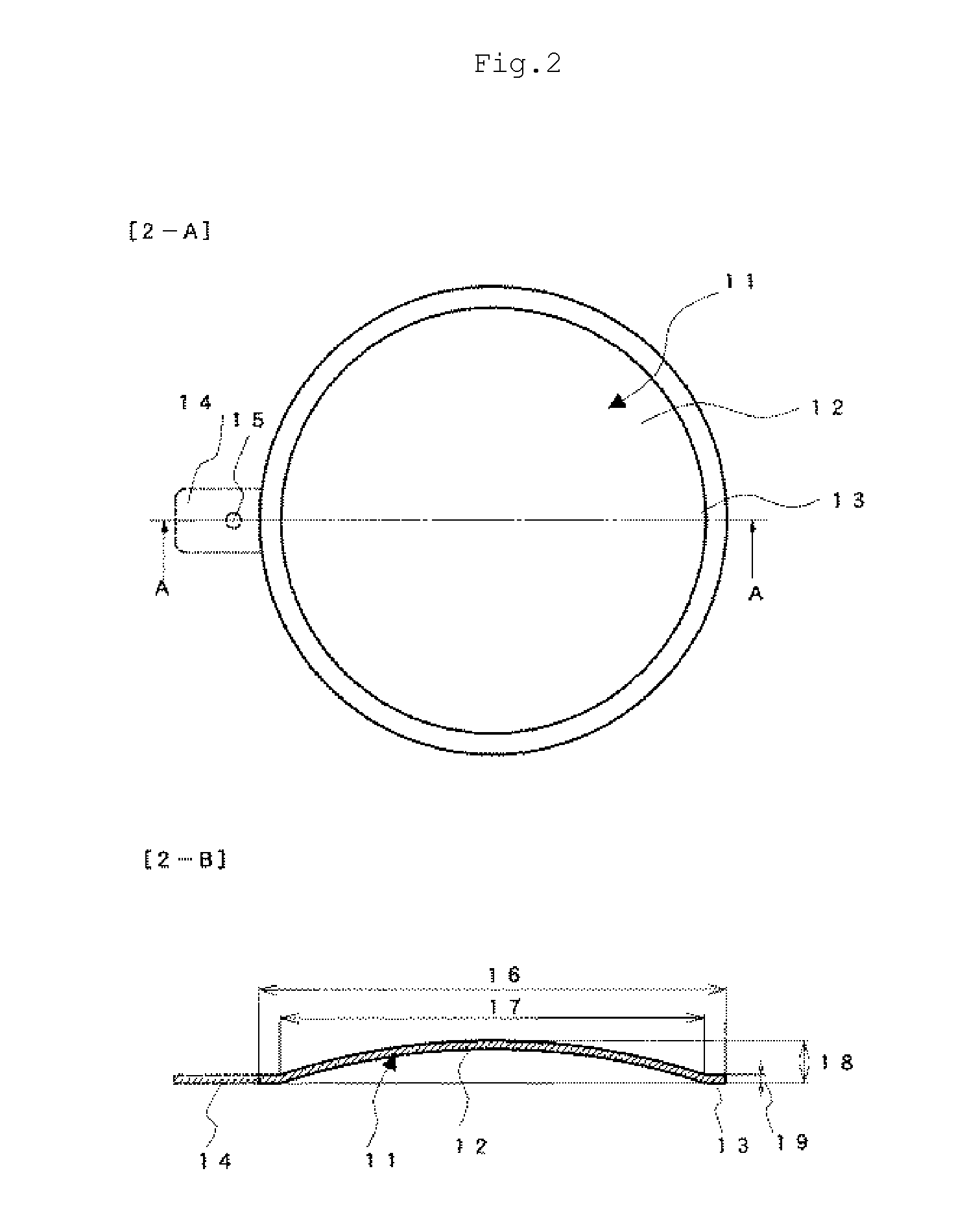

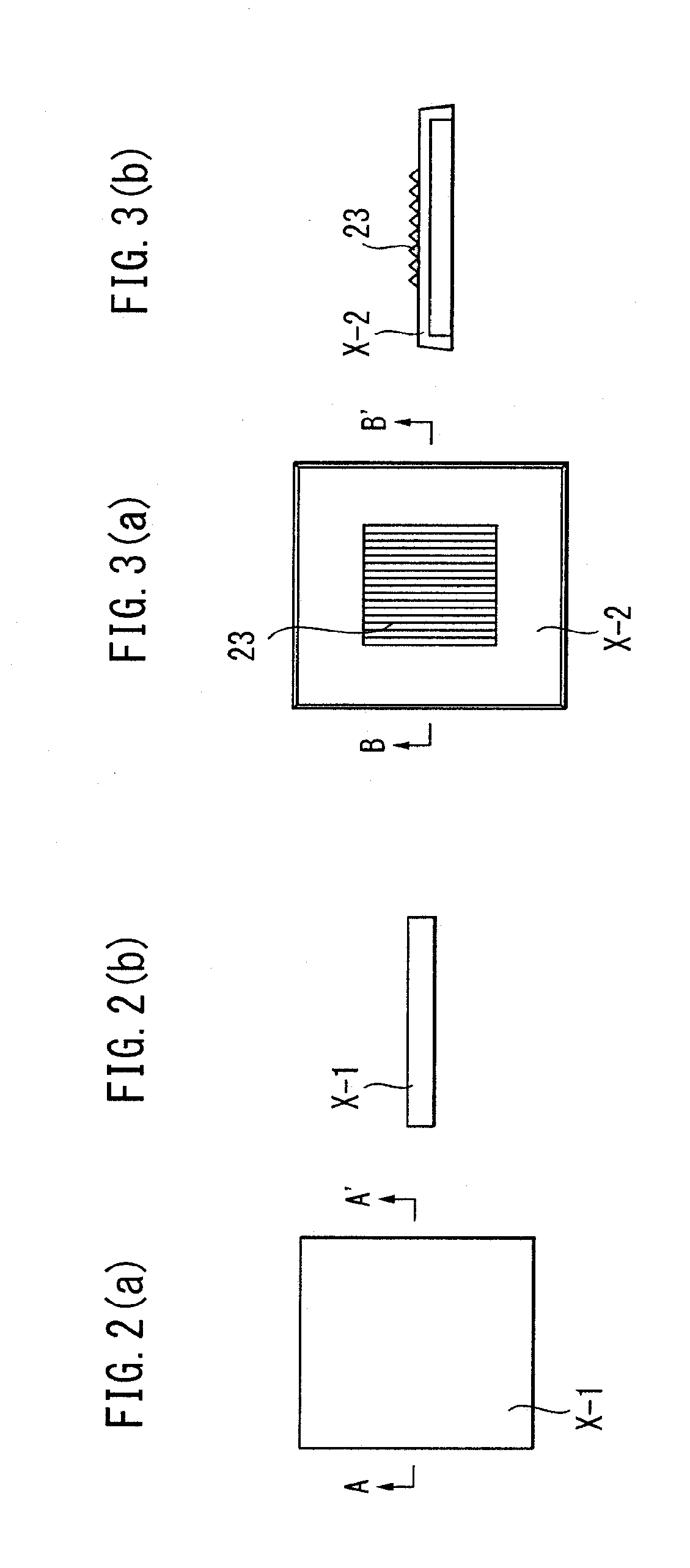

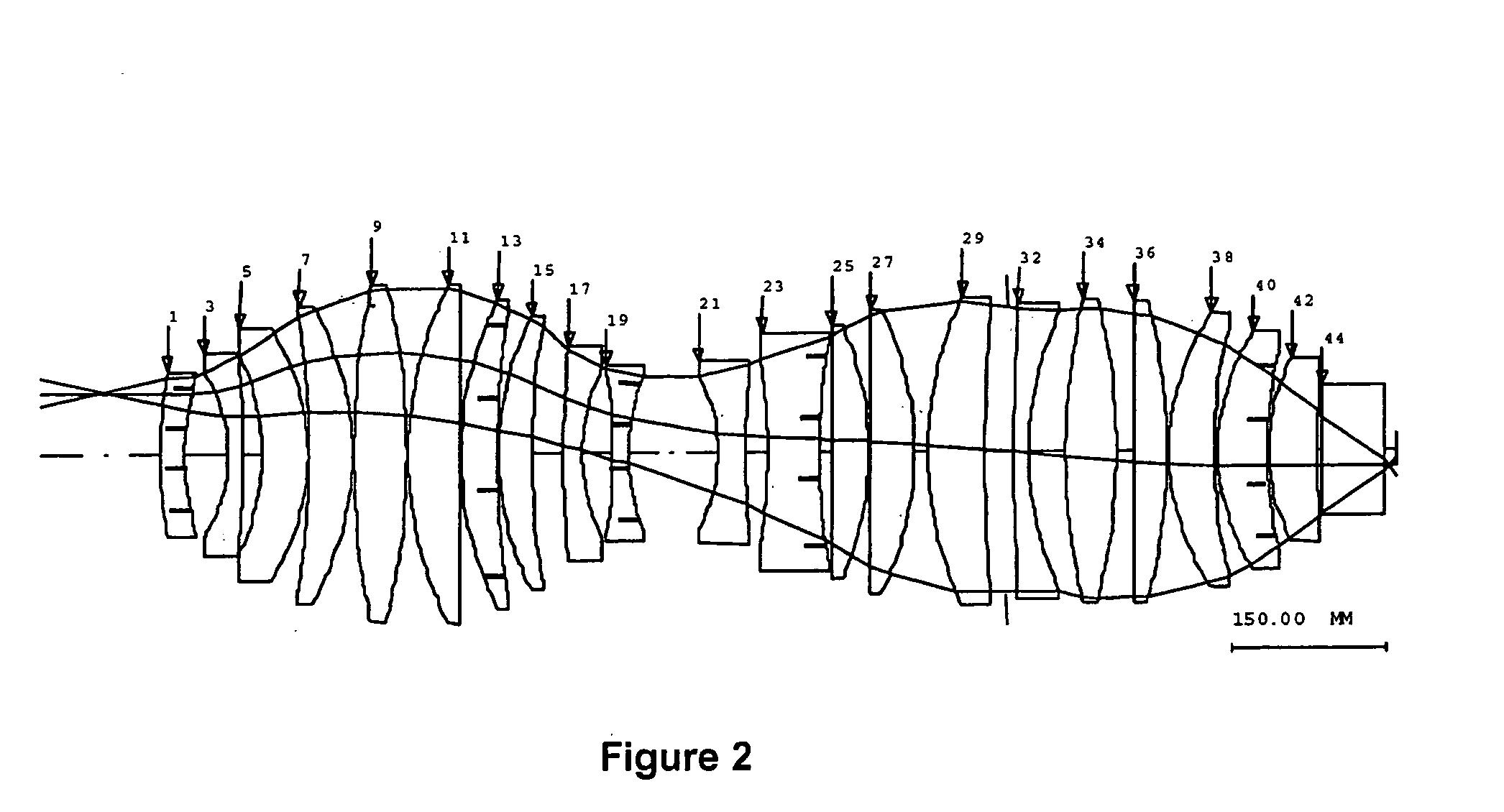

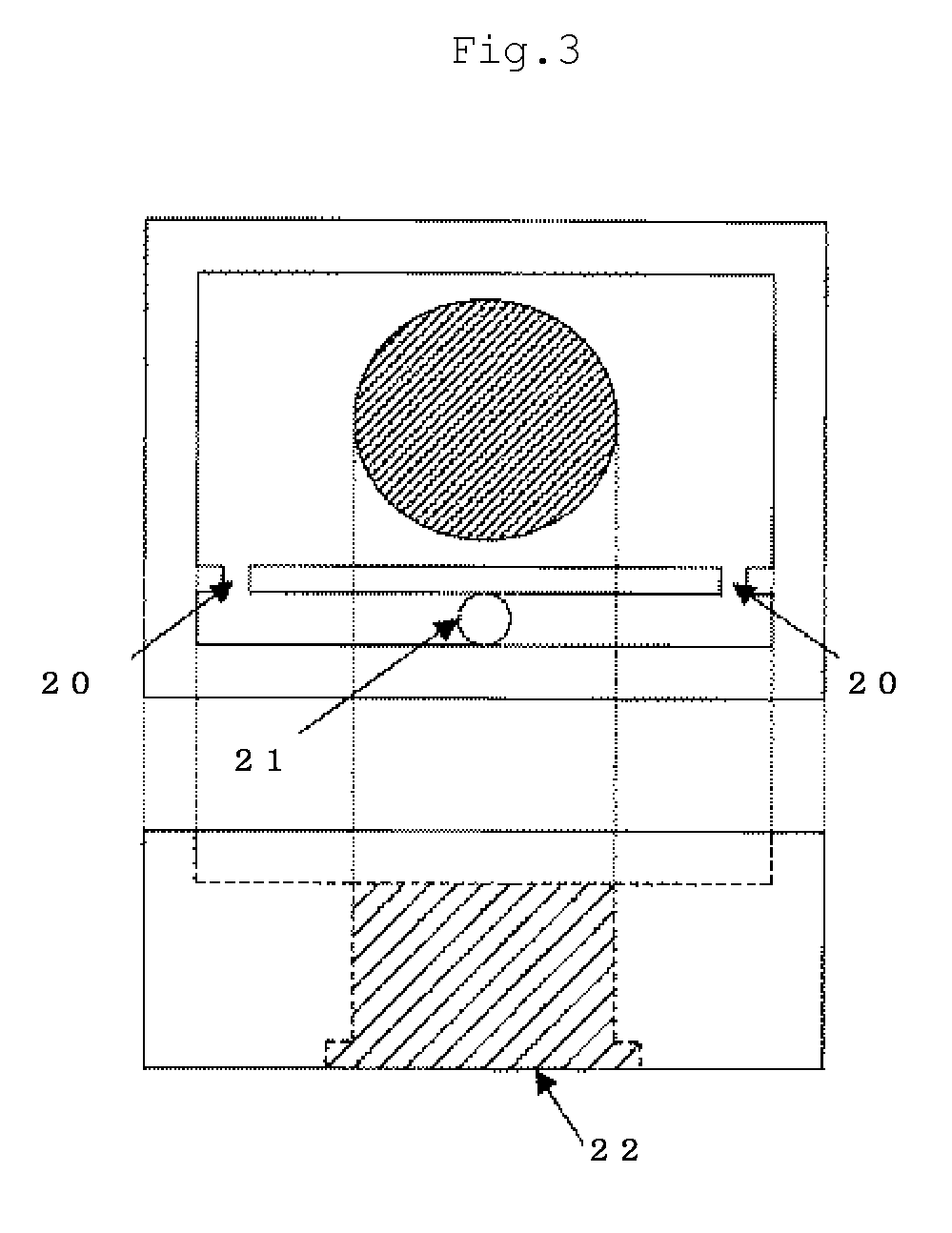

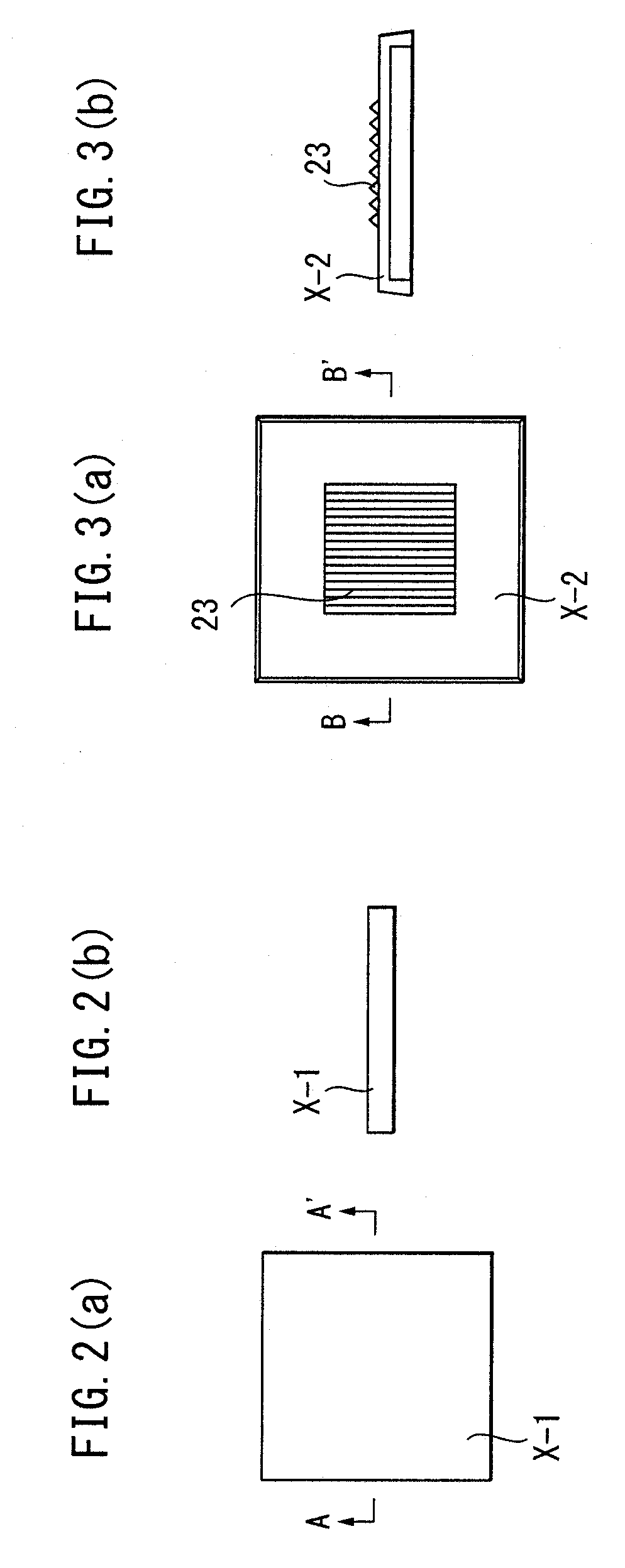

Plastic lens, photographing lens, imaging device, and portable device

InactiveUS20120314122A1High shape accuracyReduce internal strainTelevision system detailsColor television detailsFlangePhysics

A plastic lens includes a flange portion on an outer circumference of a lens effective-diameter portion and manufactured by injecting a resin into a mold via a gate portion. The plastic lens is characterized by having a shape satisfying conditions of s / t≦0.61 and E.D / D≧0.4 when s [mm] and t [mm] represent a peripheral thickness, a central thickness of the lens effective-diameter portion, E.D [mm] represents a lens effective diameter, and D [mm] represents a lens diameter.

Owner:PANASONIC CORP

Polycarbonate resin composition and molded article thereof

ActiveUS20120095141A1Good effectExcellent in releasabilityGroup 5/15 element organic compoundsUltravioletCarboxylic acid

This invention seeks to provide a resin composition and a molded article which are excellent in transparency, weatherability, resistance to boiling water and resistance to molding heat, which have an internal strain reduced and which are excellent in breaking durability.This invention is a resin composition comprising(A) 100 parts by weight of a polycarbonate resin (component A),(B) 0.005 to 1 part by weight of an ester (component B) of pentaerythritol and an aliphatic carboxylic acid,(C) 0.003 to 0.2 part by weight of an epoxy compound (component C),(D) 0.01 to 1 part by weight of an ultraviolet absorbent (component D), and(E) 0.001 to 0.5 part by weight of a phosphorus stabilizer (component E),wherein the components B and the component C have a critical stress of 12 MPa or more each when they are treated at a temperature of 120° C. for 24 hours in a one / fourth ellipse test method using a bisphenol A type polycarbonate resin sheet that is produced by a melt-extrusion method and has a viscosity average molecular weight of 24,500, and a molded article thereof.

Owner:TEIJIN KASEK KK

Sludge curing agent and preparation method thereof

InactiveCN106478012AReduce internal strainAvoid crackingSludge treatment by de-watering/drying/thickeningHydroxypropylmethyl celluloseHeavy metals

The invention discloses a sludge curing agent. The sludge curing agent comprises the following raw materials in parts by weight: 4-6 parts of ardealite, 15-18 parts of cement, 26-30 parts of quick lime, 7-9 parts of lime stone, 28-32 parts of flyash, 1-2 part of hydroxypropyl methyl cellulose, 6-8 parts of glass-cermic powder, 6-8 parts of ultrafine ceramic powder, 10-15 parts of furfural dregs, 4-6 parts of medical stone and 8-10 parts of smectite clay. By the sludge curing agent, the water content of high-water-content sludge can be reduced remarkably, internal stress of the cured sludge can be reduced effectively, cracking is prevented, the curing strength is high, the curing time is short, and the sludge curing agent can be set and hardened quickly; and heavy metals in the sludge can be effectively adsorbed and cured, and requirements of landfilling and building earth filling are met. By the sludge curing agent, resource utilization of the sludge is realized, and the problem of environmental pollution and the like caused by deposition of a large amount of sludge is solved. The sludge curing agent is energy-saving and environment-friendly, and is low in engineering cost and good in benefit.

Owner:福建港湾新材料有限公司

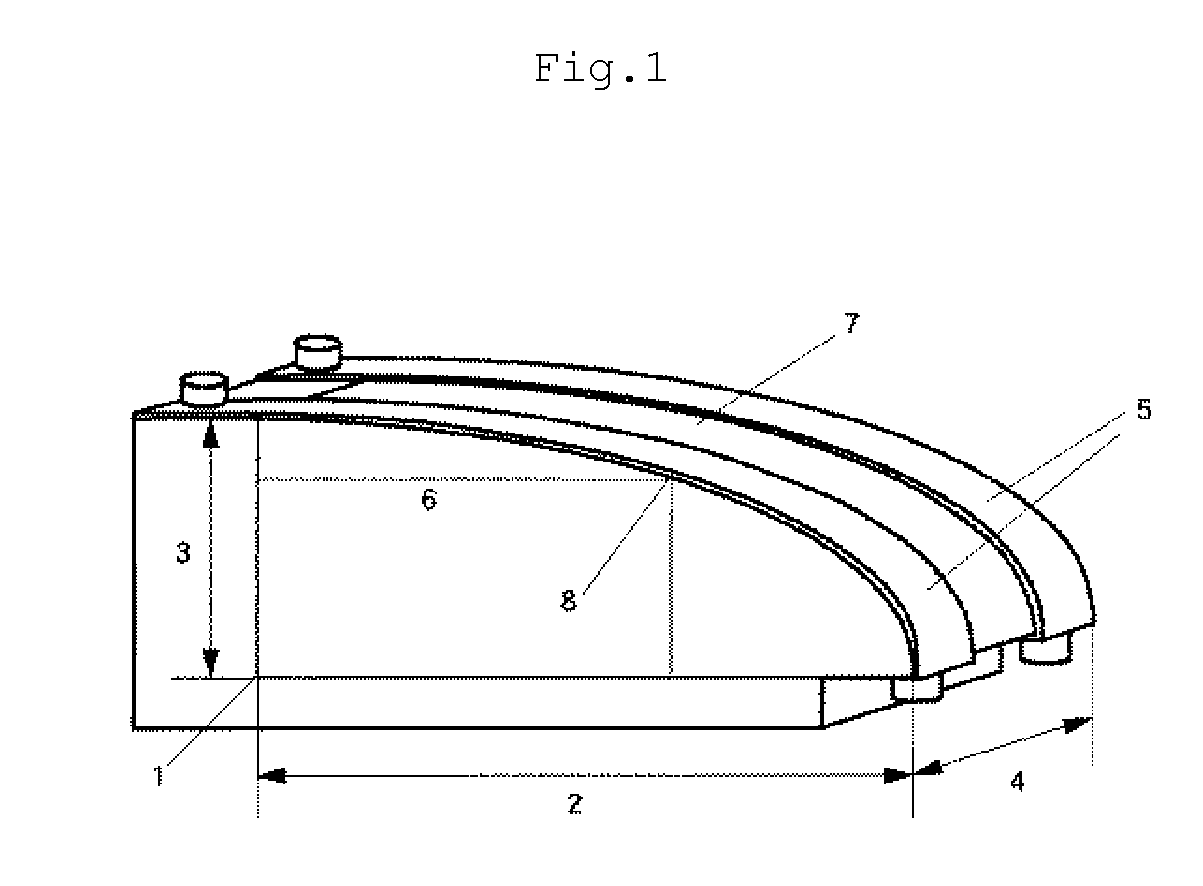

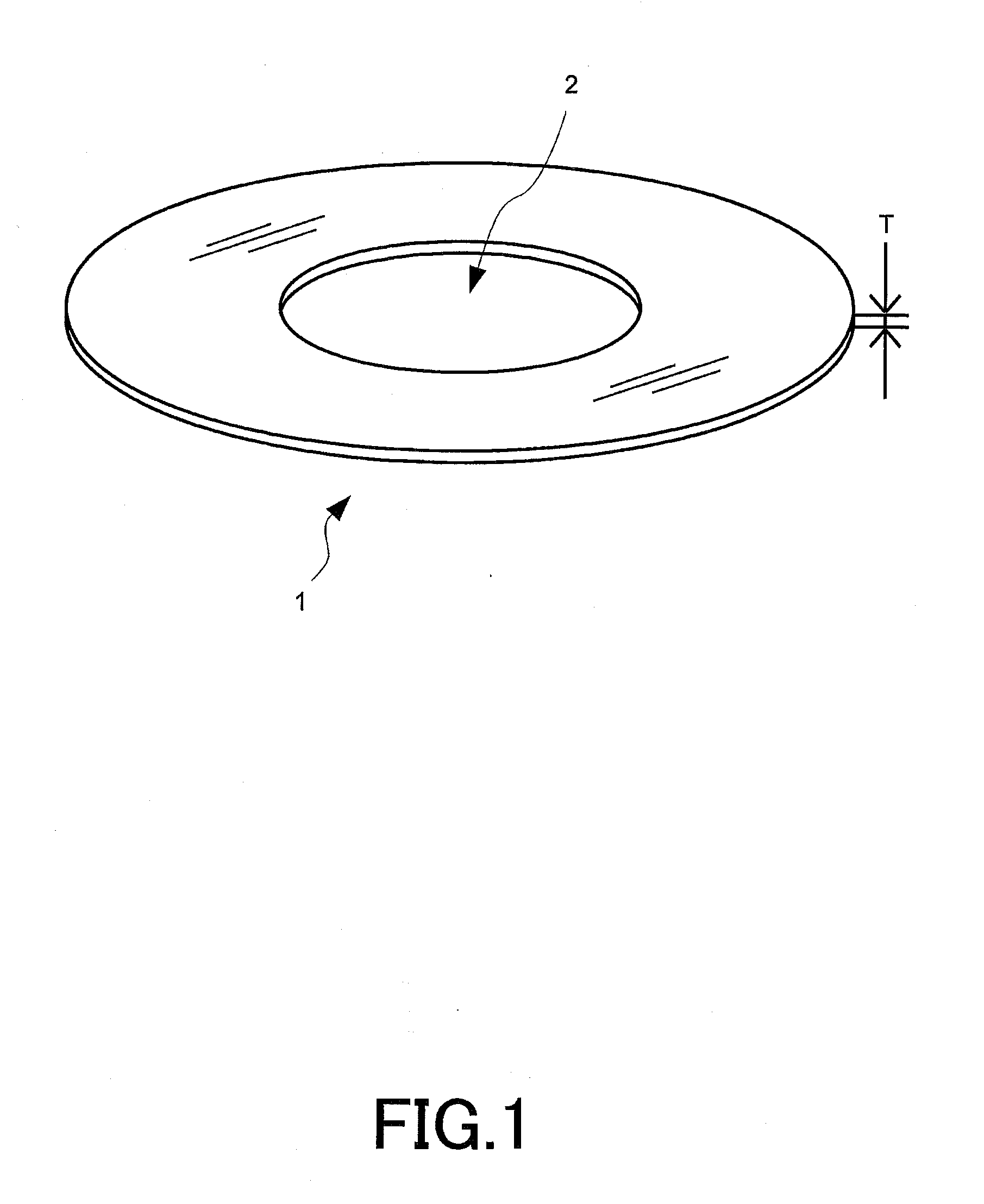

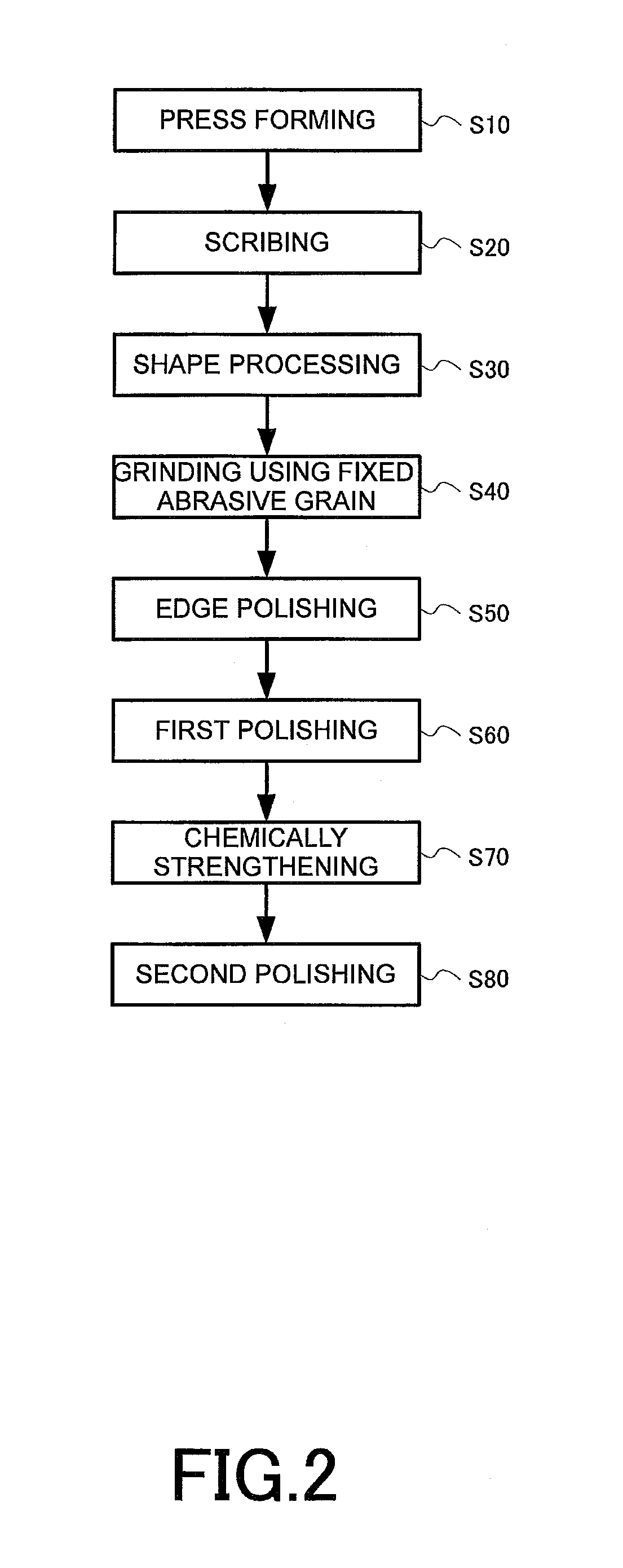

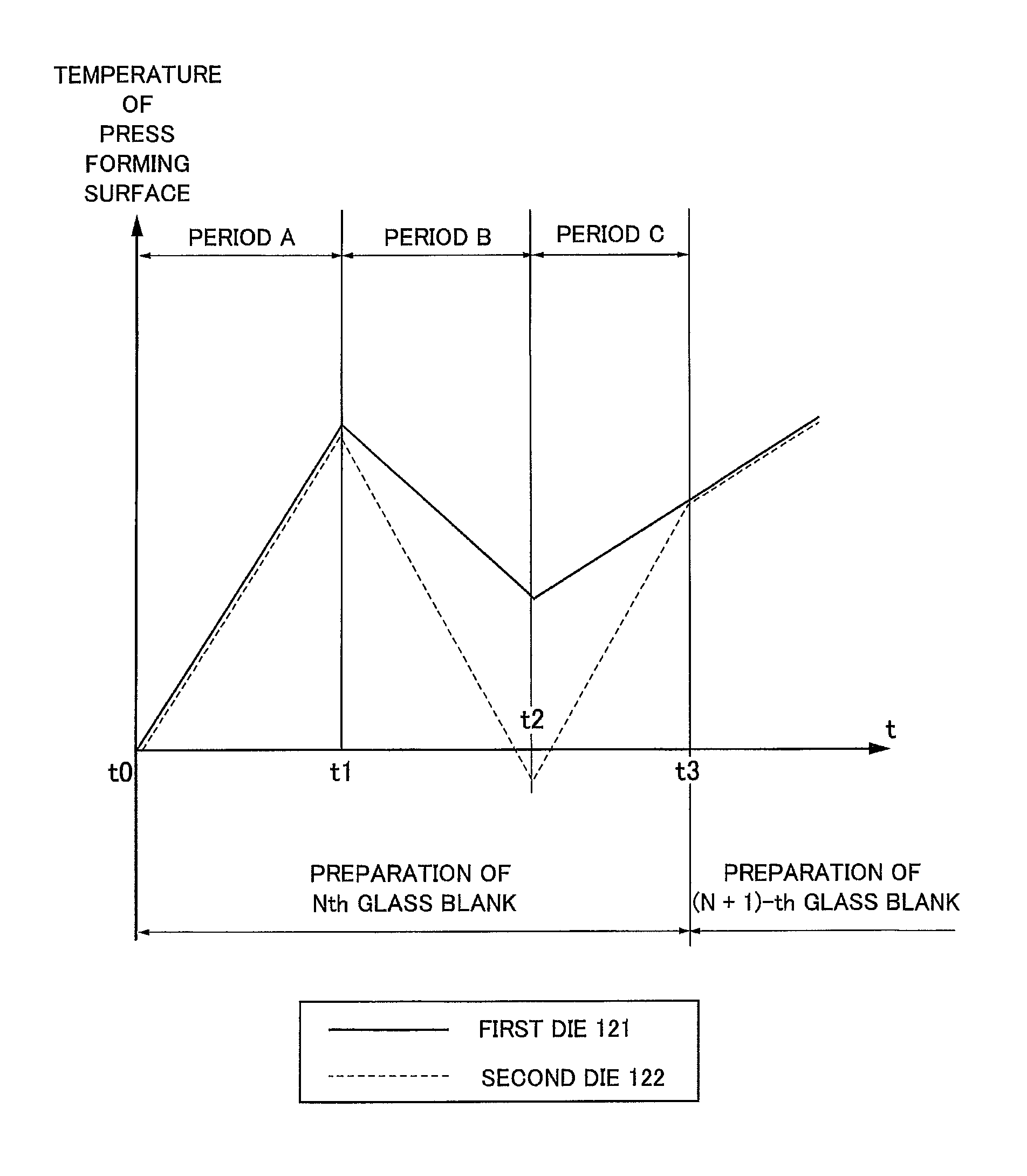

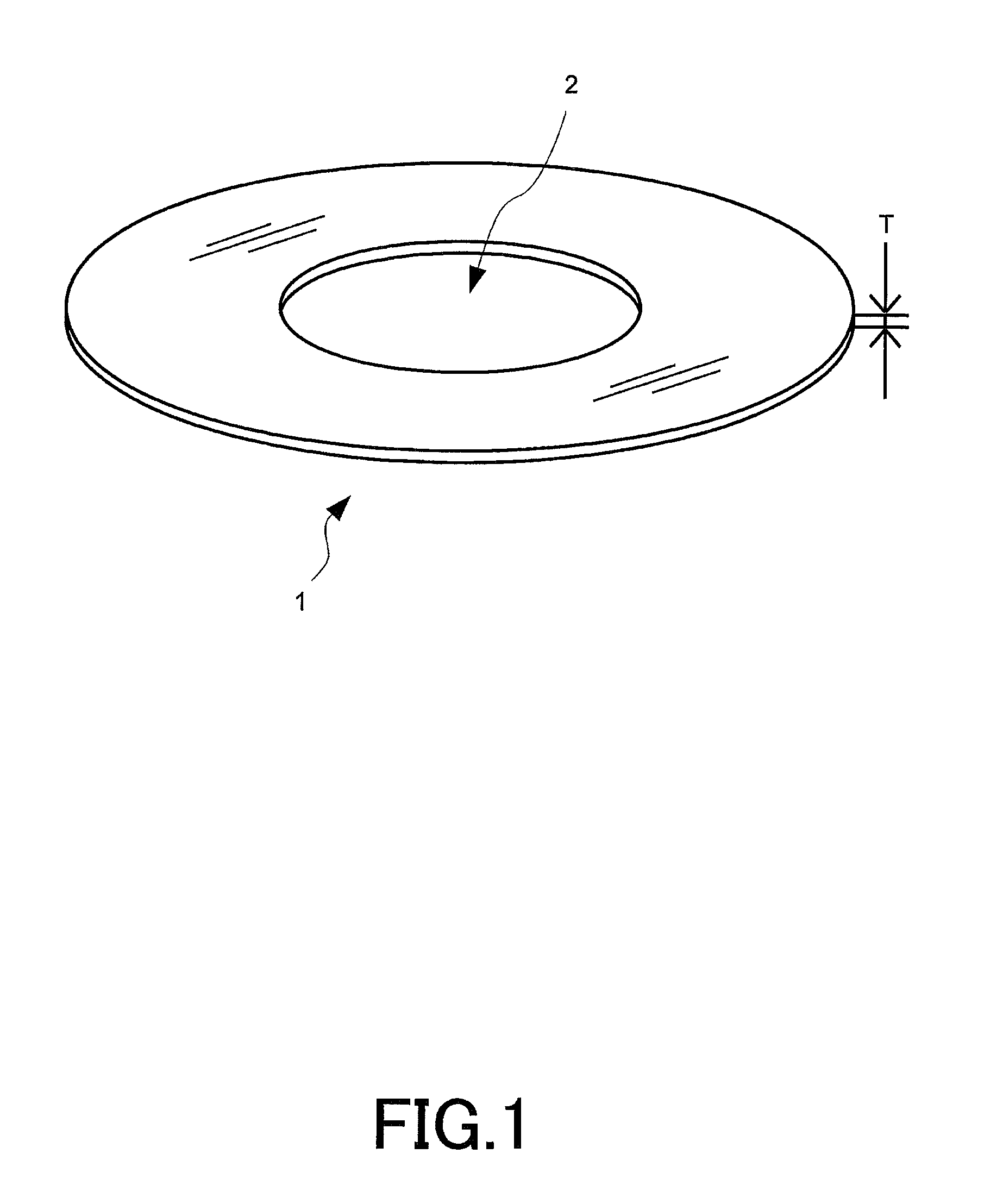

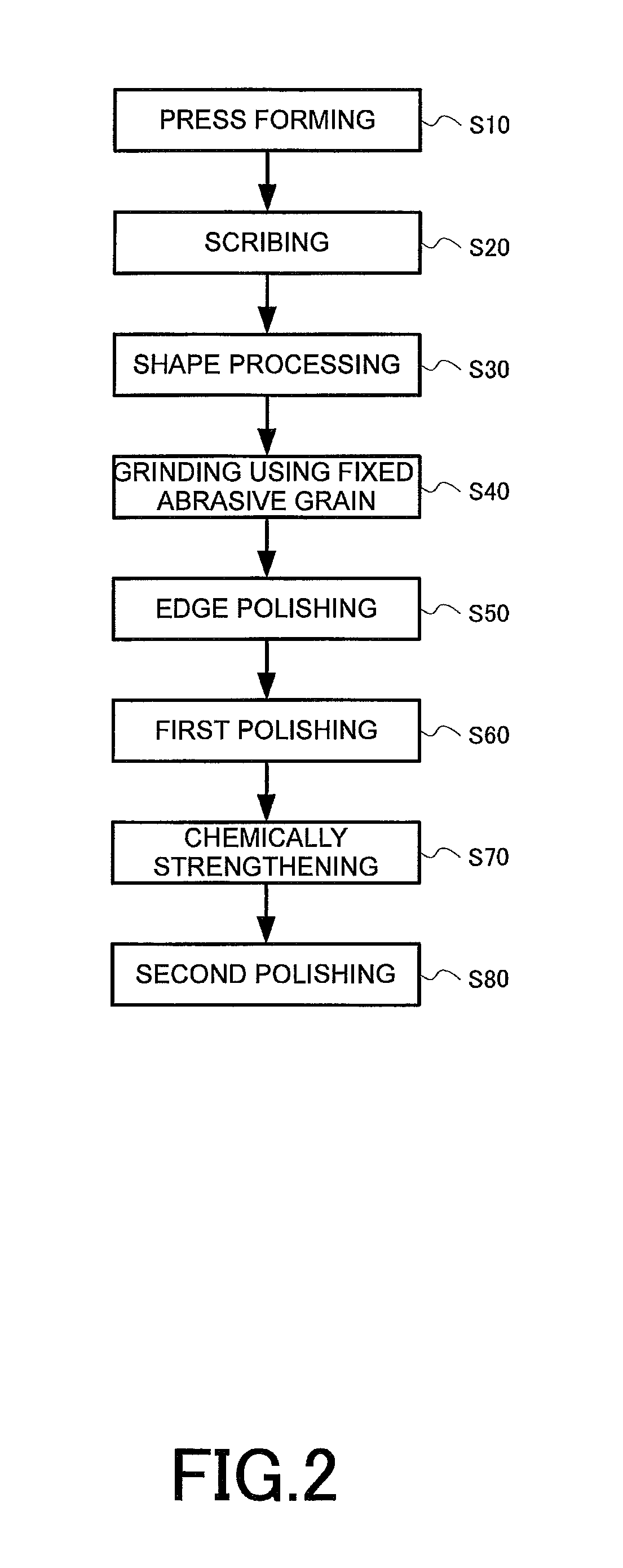

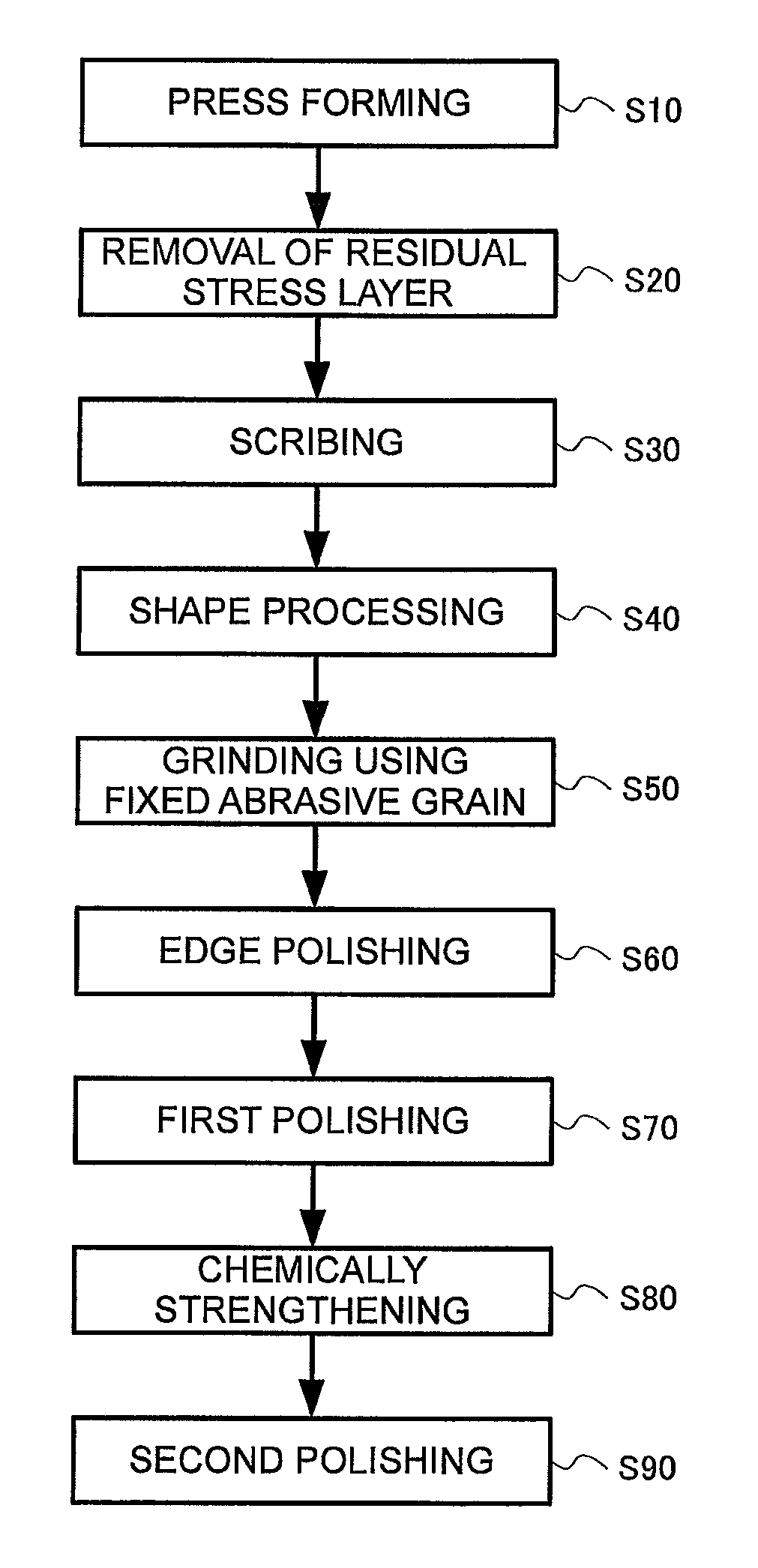

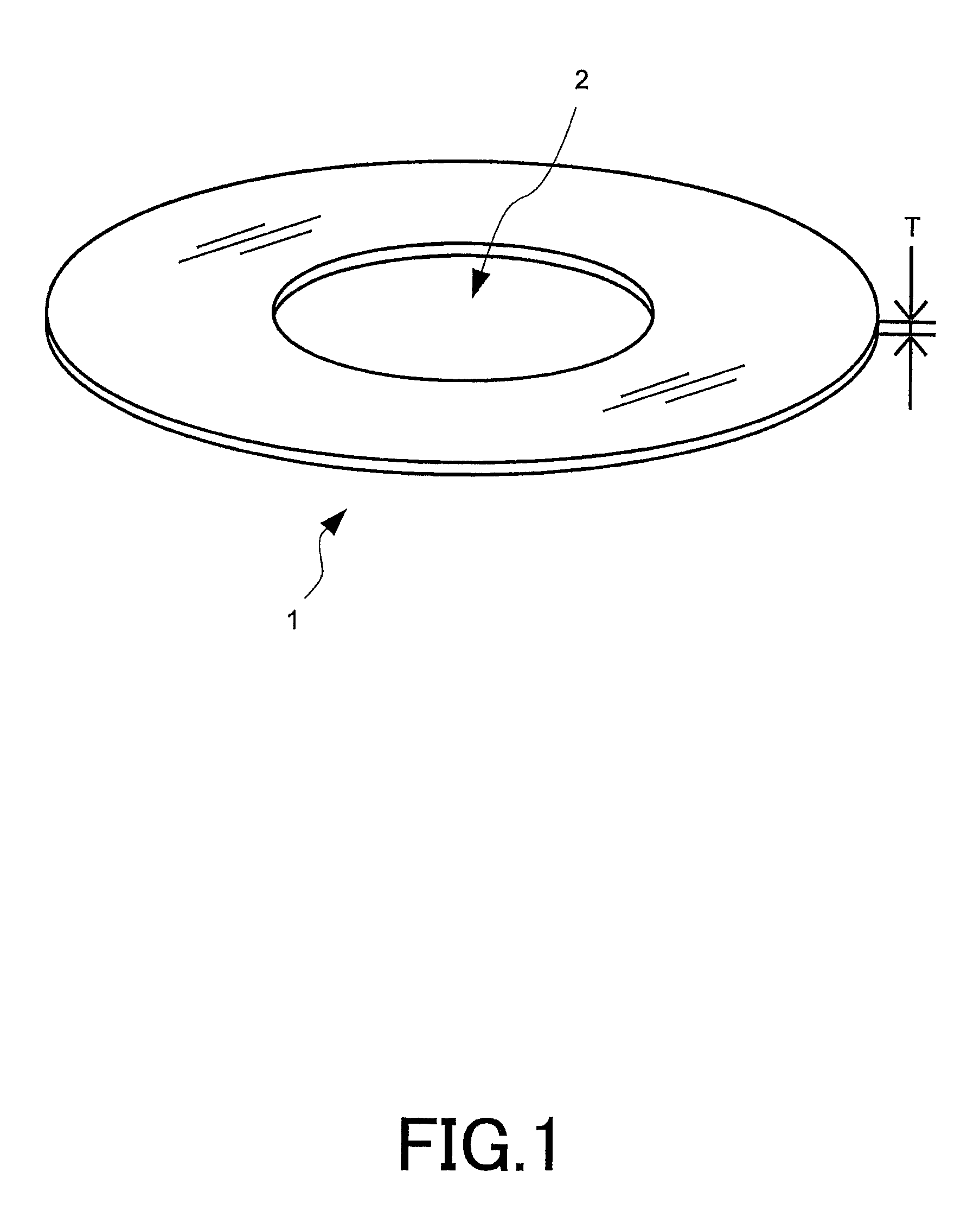

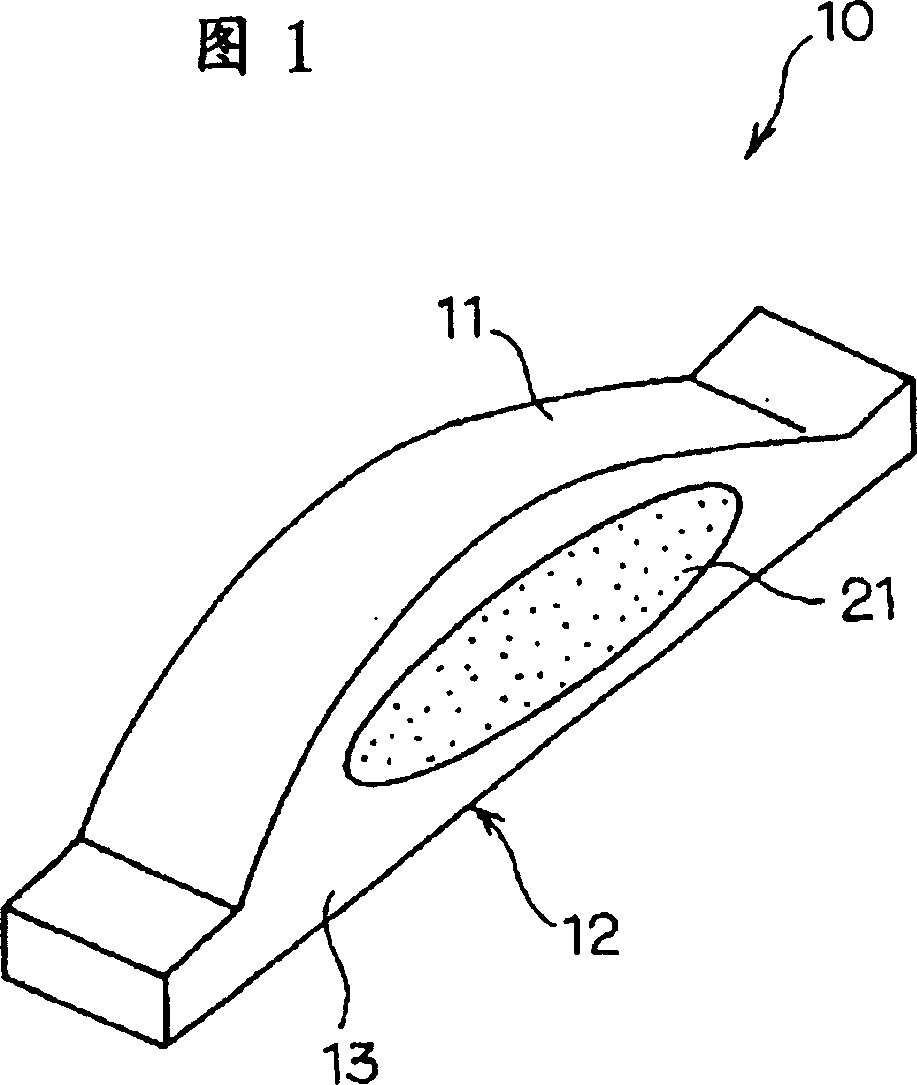

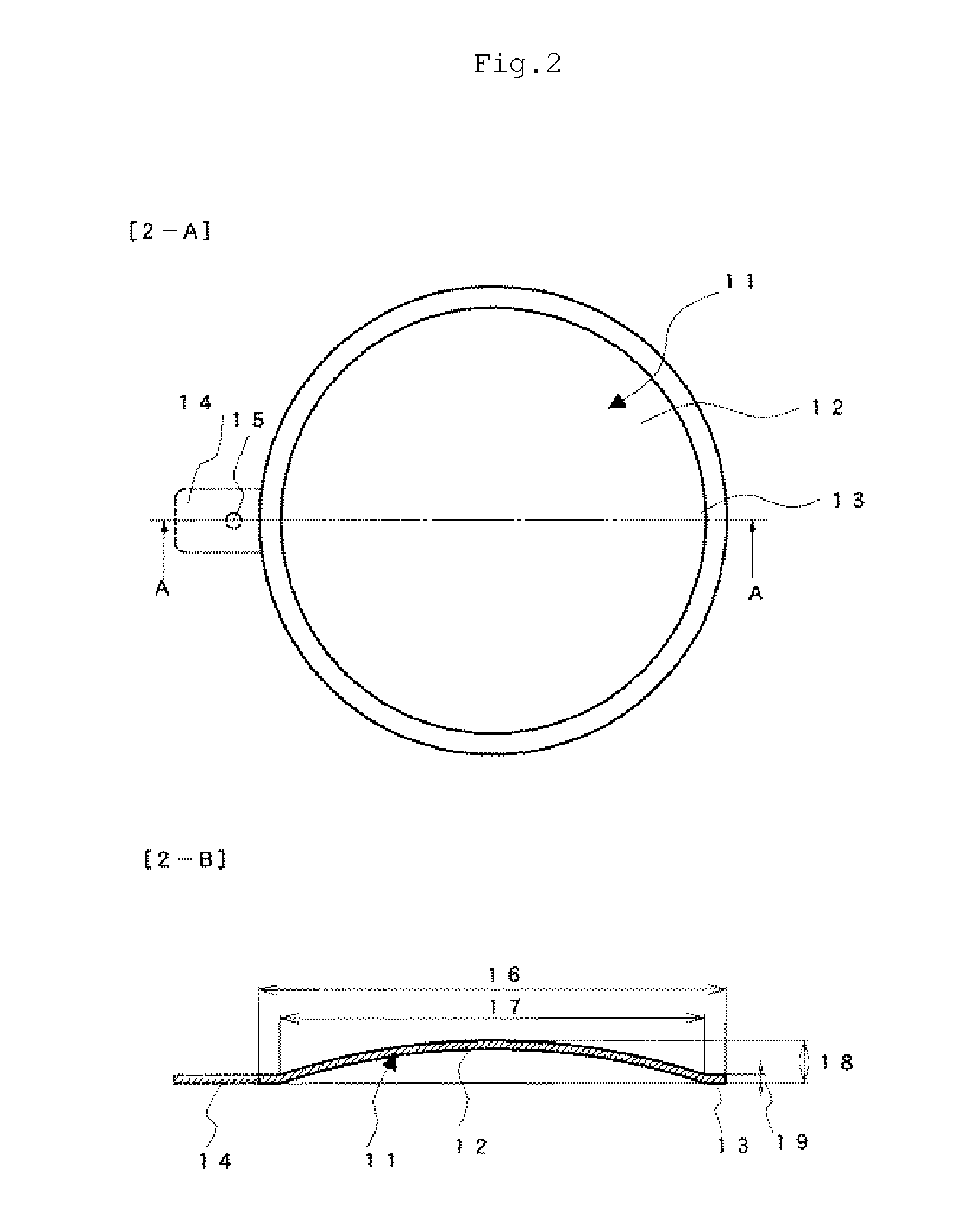

Manufacturing method of glass blank for magnetic disk, manufacturing method of glass substrate for magnetic disk, glass blank for magnetic disk, glass substrate for magnetic disk, and magnetic disk

InactiveUS20130316194A1Temperature differenceReduce internal strainMagnetic materials for record carriersGlass drawing apparatusForming processesMolten glass

To provide a method for manufacturing a glass blank for magnetic disk and a method for manufacturing a glass substrate for magnetic disk, which are capable of producing a glass blank for magnetic disk having a good surface waviness by press forming, and a method for manufacturing a glass substrate for magnetic disk. A method for manufacturing a glass blank for magnetic disk, which includes a forming process of press-forming a lump of molten glass using a pair of dies, wherein in the forming process, press forming is performed using thermally equalizing means for reducing a difference in temperature in the press forming surface of the die during pressing of the molten glass.

Owner:HOYA CORP

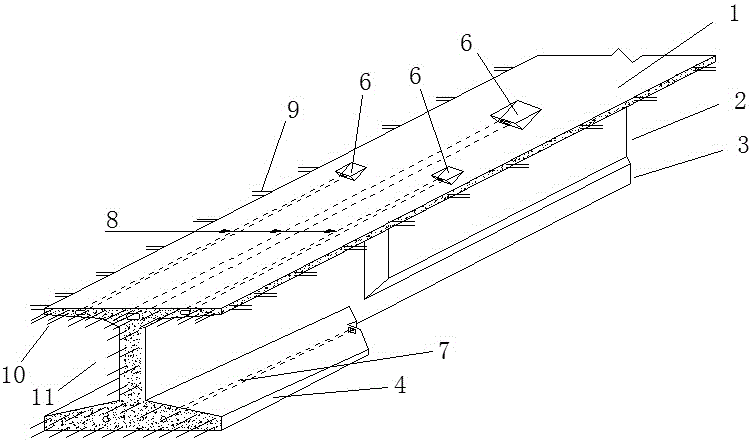

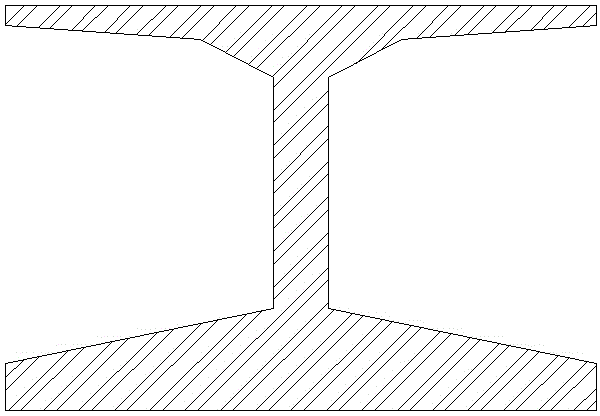

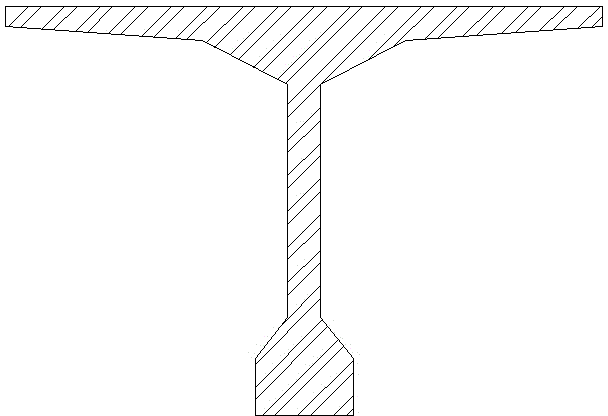

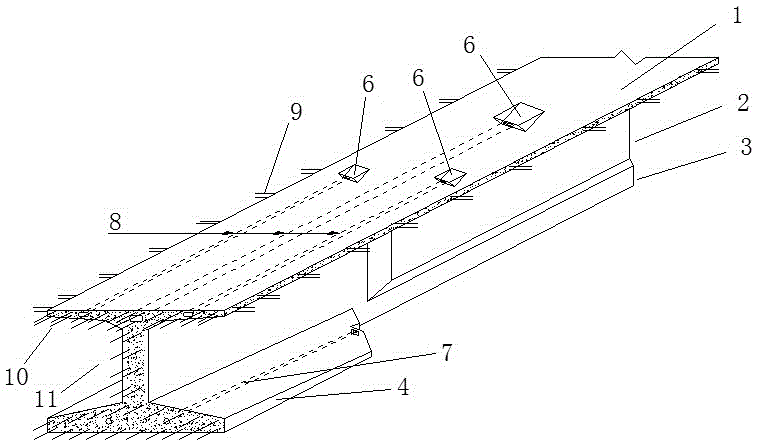

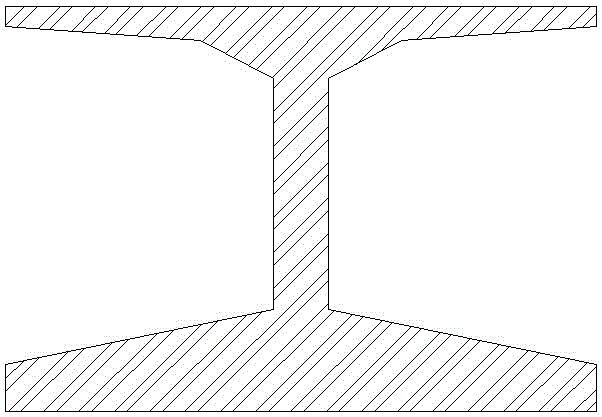

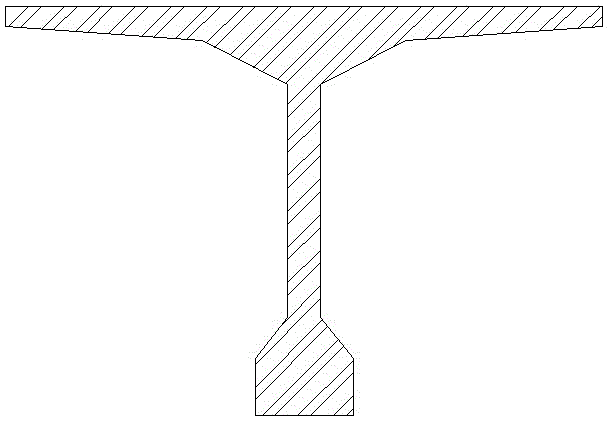

Prefabricated T-shaped beam and method of building continuous beam bridge by adopting prefabricated T-shaped beams

InactiveCN105019350AAvoid crackingReduces the possibility of crackingBridge structural detailsBridge erection/assemblyBridge engineeringTensile strain

The invention relates to a prefabricated T-shaped beam and a method of building a continuous beam bridge by adopting the prefabricated T-shaped beams, and belongs to the field of bridge engineering. The T-shaped beam is an improved form of the conventional prefabricated T-shaped beam, and bottom flanges are additionally arranged at the ends, so that the cross sections of the ends are I-shaped. Longitudinal prestressed ducts are formed in the bottom flanges, and the longitudinal prestressed ducts are also formed in top plates of the ends. The bridge is formed in a manner that the prefabricated T-shaped beams are spliced, simply supported and then connected. Longitudinal prestress is tensioned on the bottom flanges, and negative bending moment prestress is tensioned on the top plates. Certain prestress is exerted on compressed zones at the bottoms, so that cracks under the effects of temperature and the like can be avoided. The compression areas of the bottom flanges are increased, the compressive strain of the compressed zones is decreased under the effect of negative bending moment, correspondingly, the tensile strain at the tops is also decreased and thus the possibility of cracking of the bridge deck can be lowered. As the cross sections of the ends are changed to be I-shaped, transportation and installation are convenient, and the construction of the continuous beam bridge is also convenient. The method of building the continuous beam is convenient to construct, and cracks of the top plates at pier top areas are favorably decreased.

Owner:ZHENGZHOU UNIV

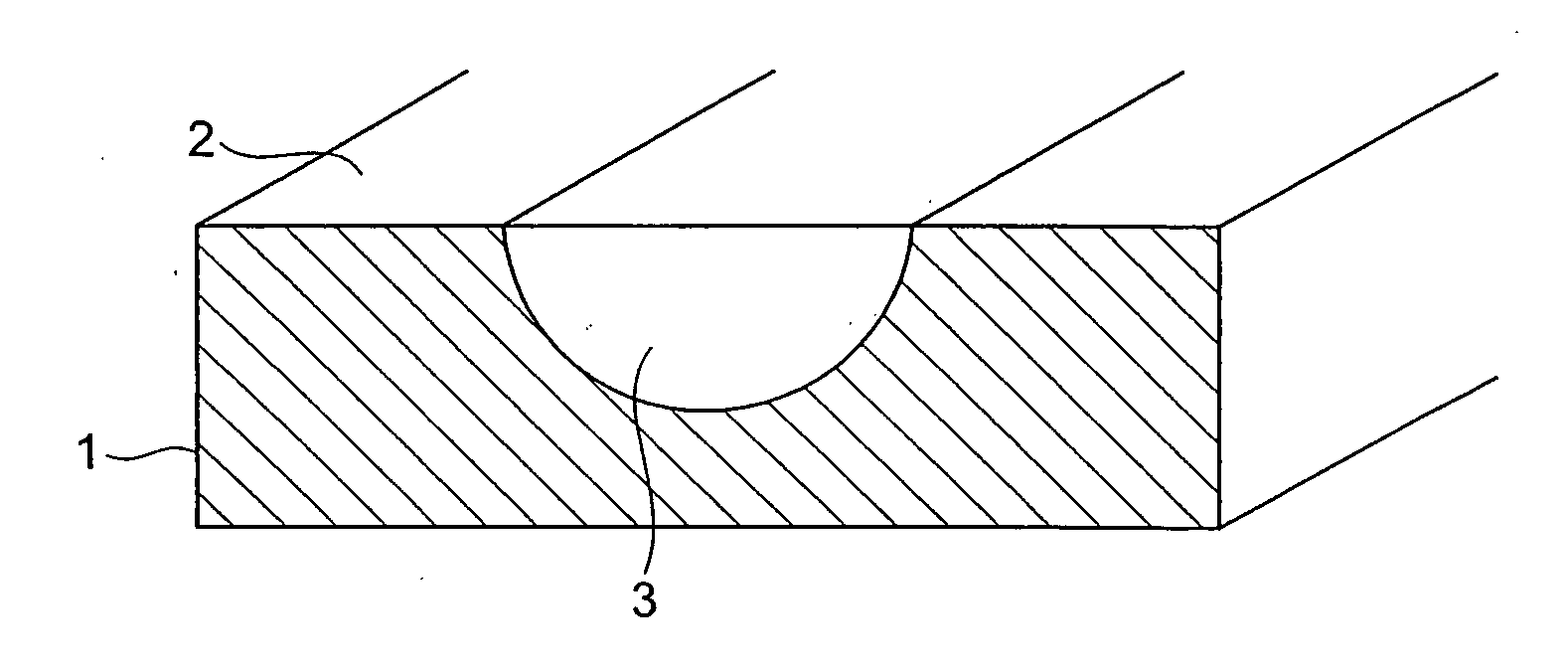

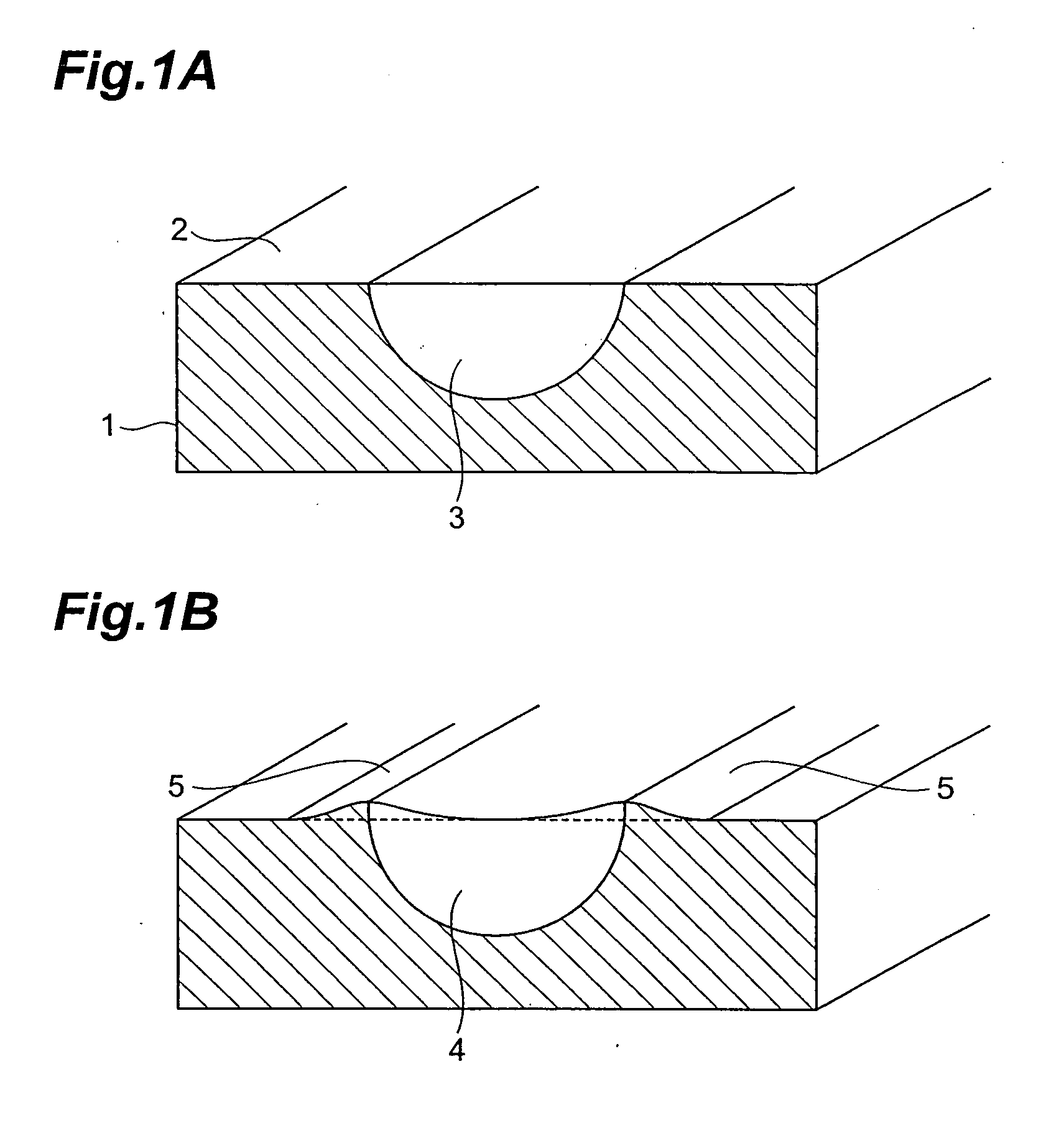

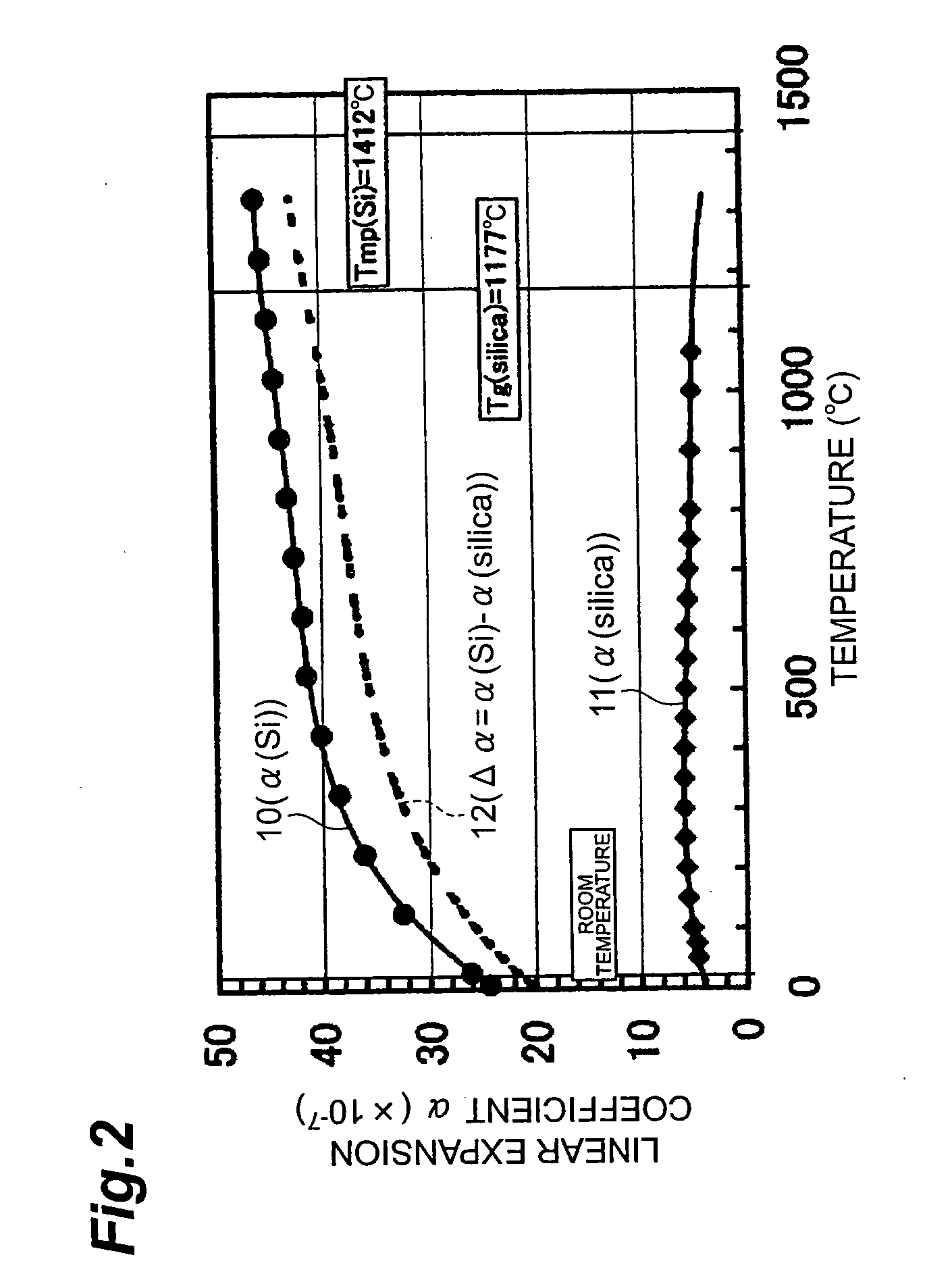

Silicon Substrate and Method of Forming the Same

InactiveUS20070275254A1Decreasing minimum transmission lossDecrease of TgLayered productsNanoopticsVitrificationVitreous Bodies

A silicon substrate 1 has a structure in which a depression of a silicon crystal is formed on at least one principal surface 2 side of a crystalline silicon substrate and which has a vitreous region 3 filled in the depression and consisting primarily of silicon oxide. The vitreous region 3 is formed so that the glass transition temperature Tg thereof is lower than that of pure silica glass and not more than 900° C. This configuration realizes the silicon substrate in which internal strain is reduced between glass and the silicon crystal, and a forming method thereof.

Owner:HAMAMATSU PHOTONICS KK +1

Process and apparatus for producing glass sheet

ActiveUS8322160B2Sufficient in internal strainIncrease pressureGlass drawing apparatusGlass forming apparatusRoom temperatureGlass sheet

Owner:NIPPON ELECTRIC GLASS CO LTD

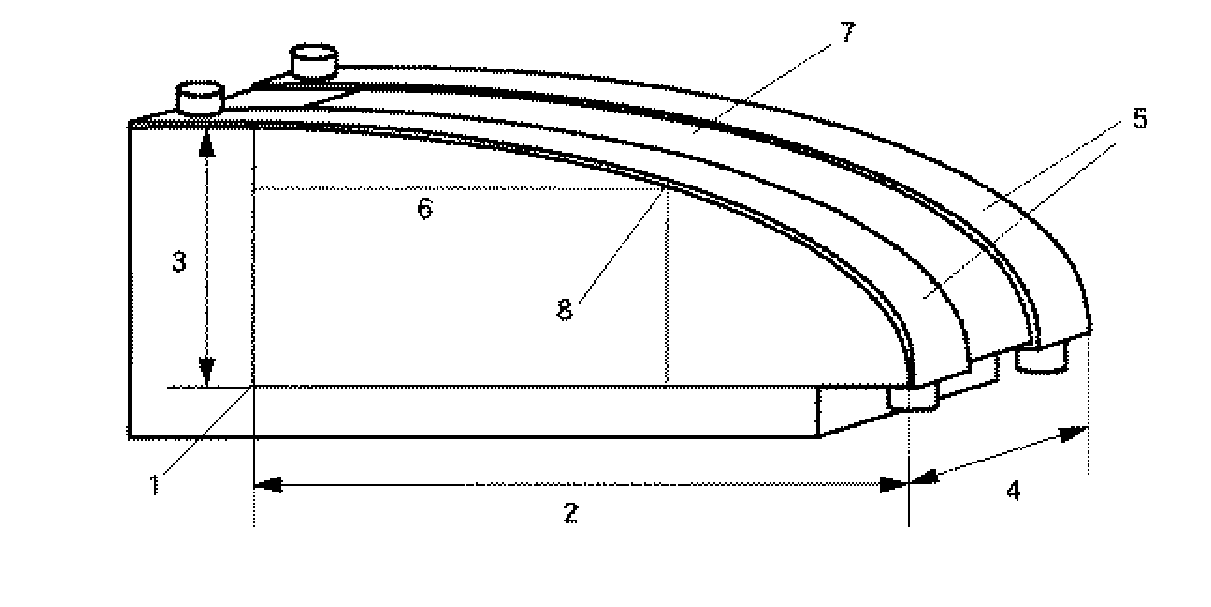

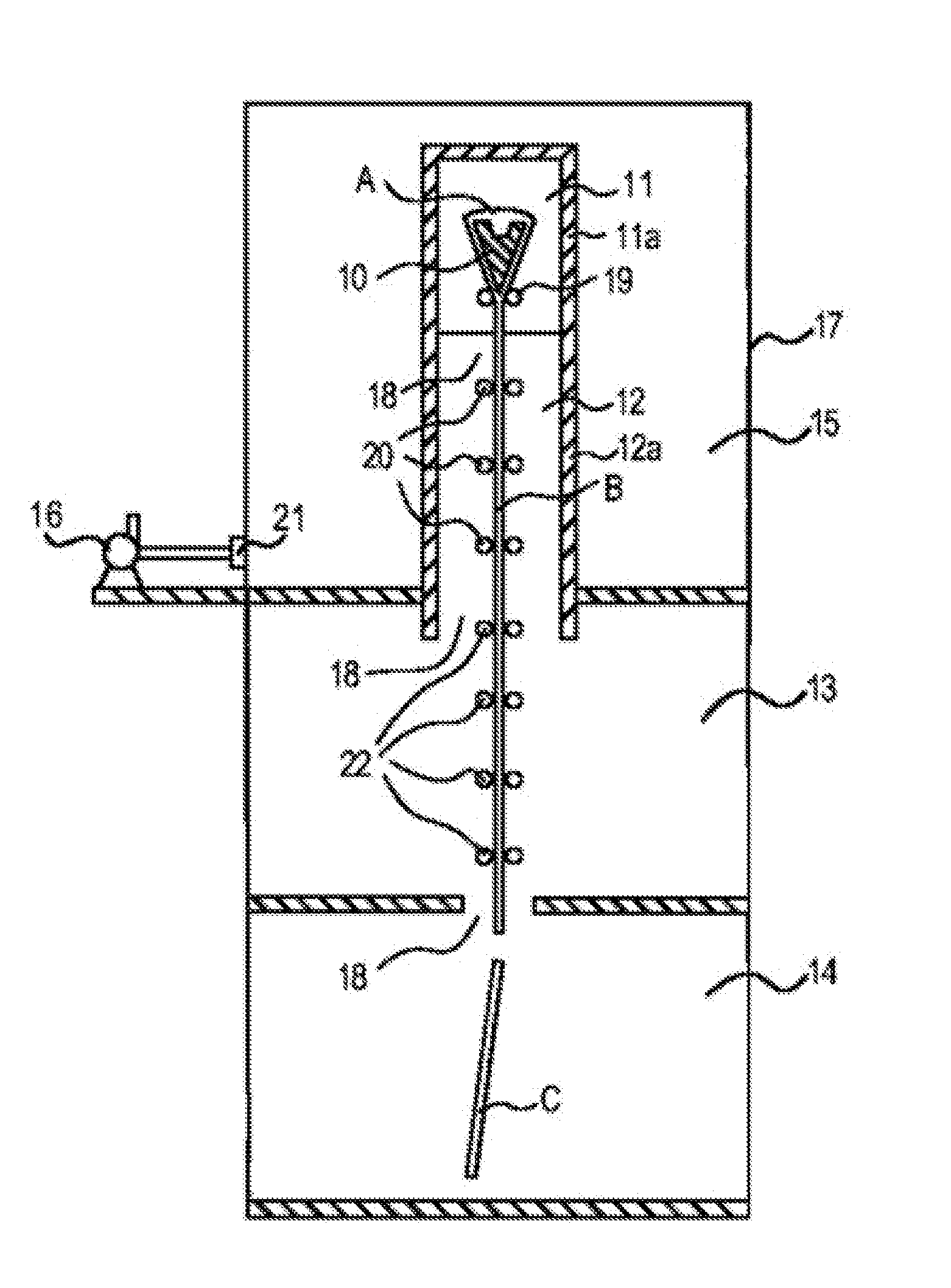

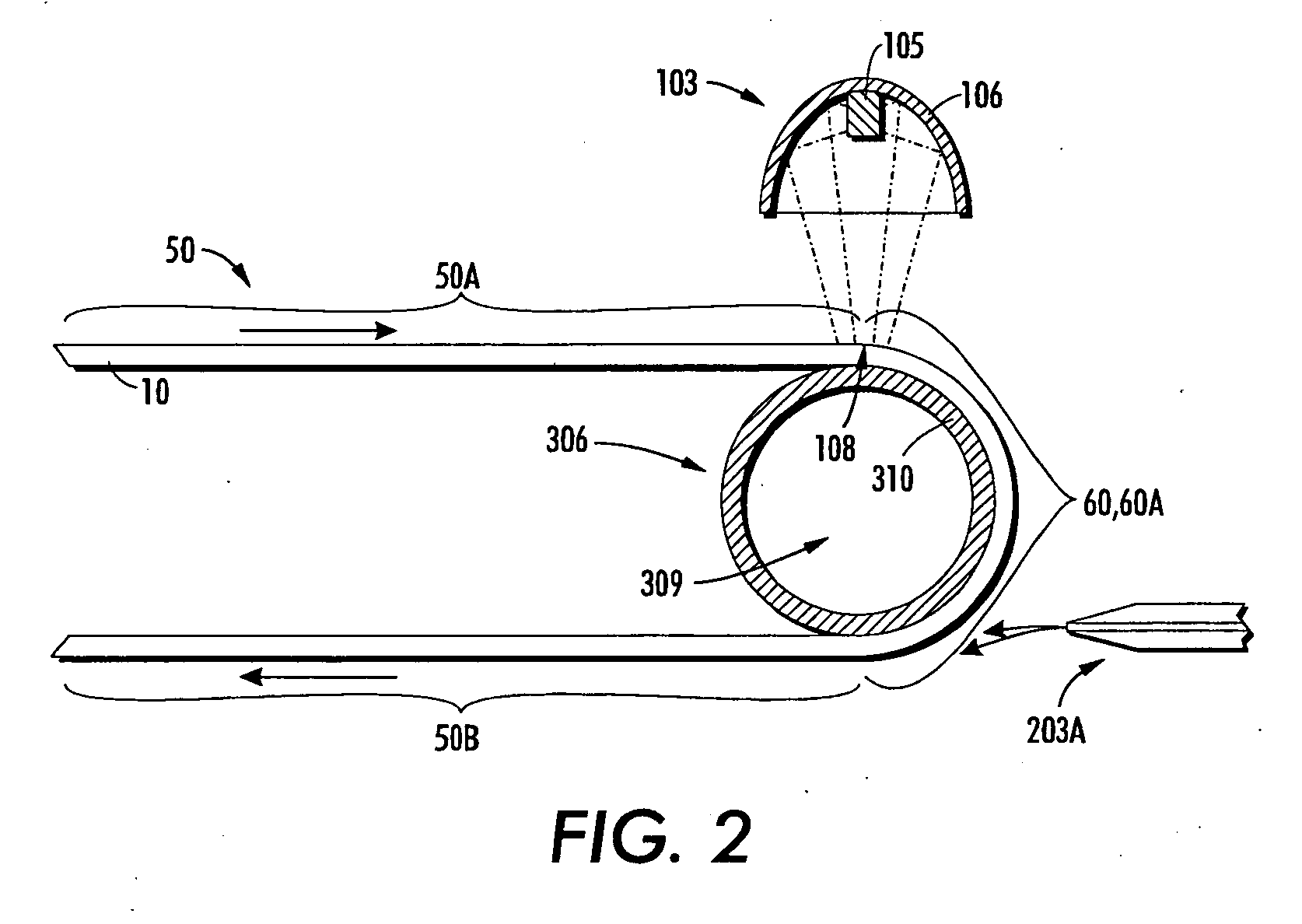

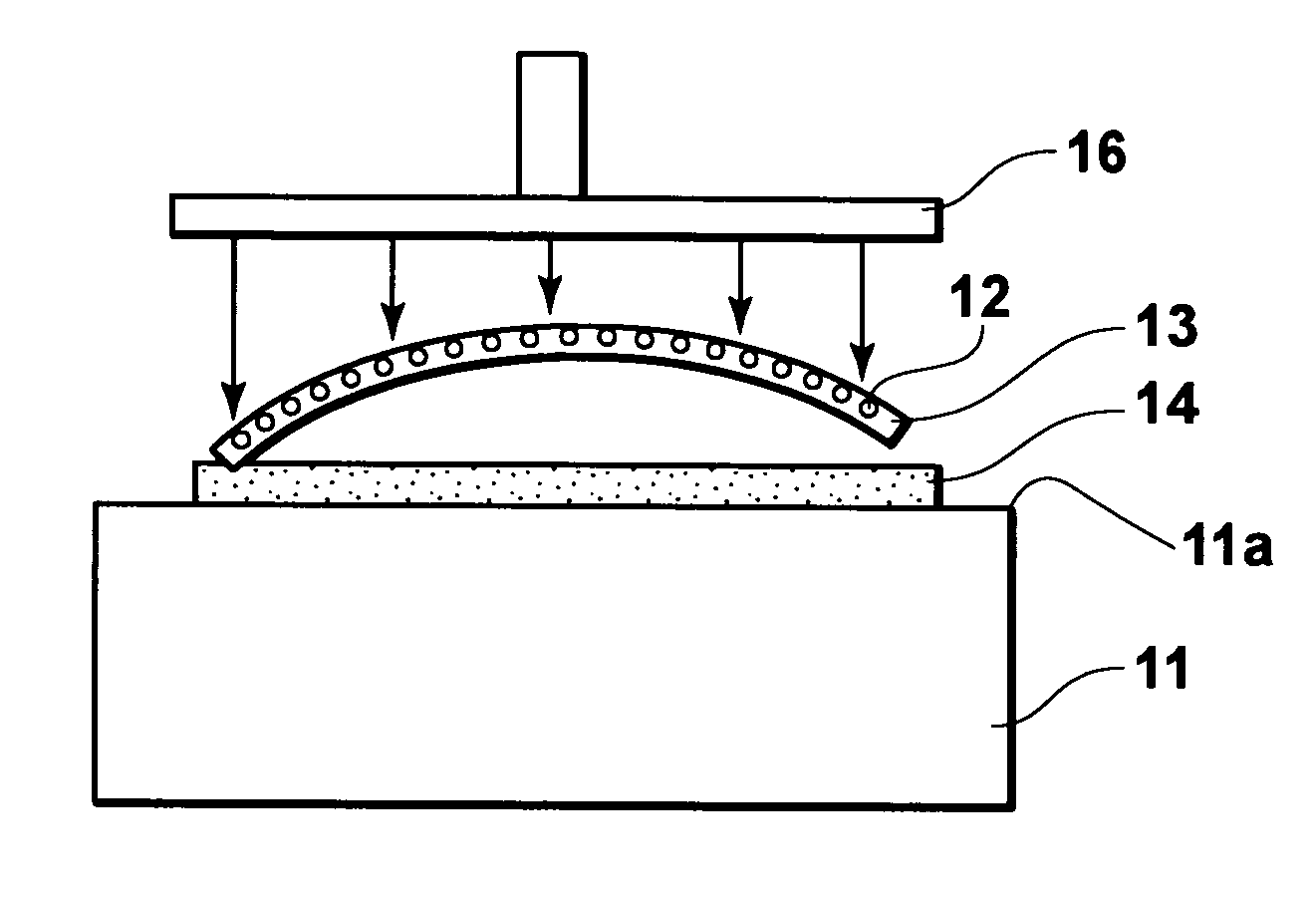

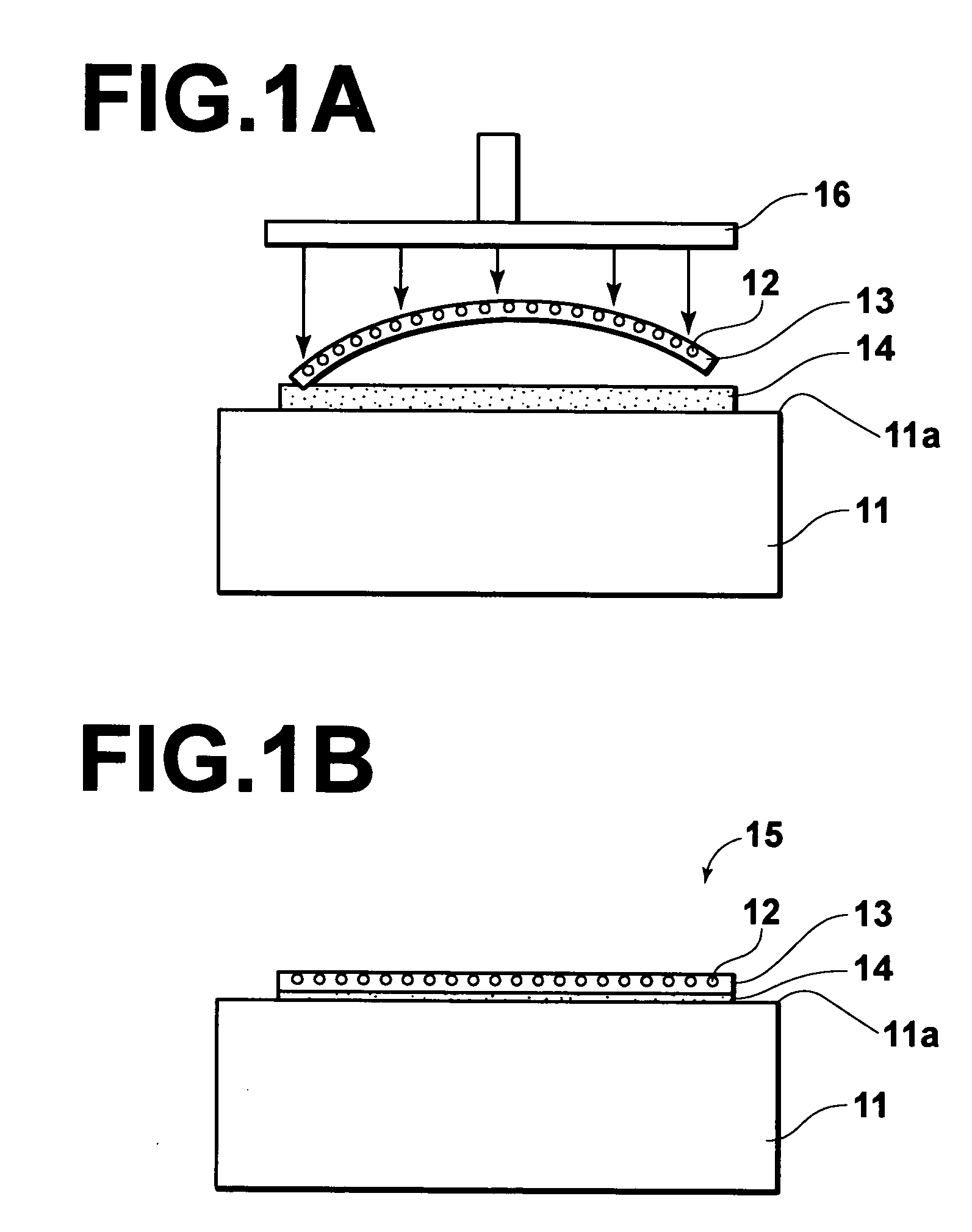

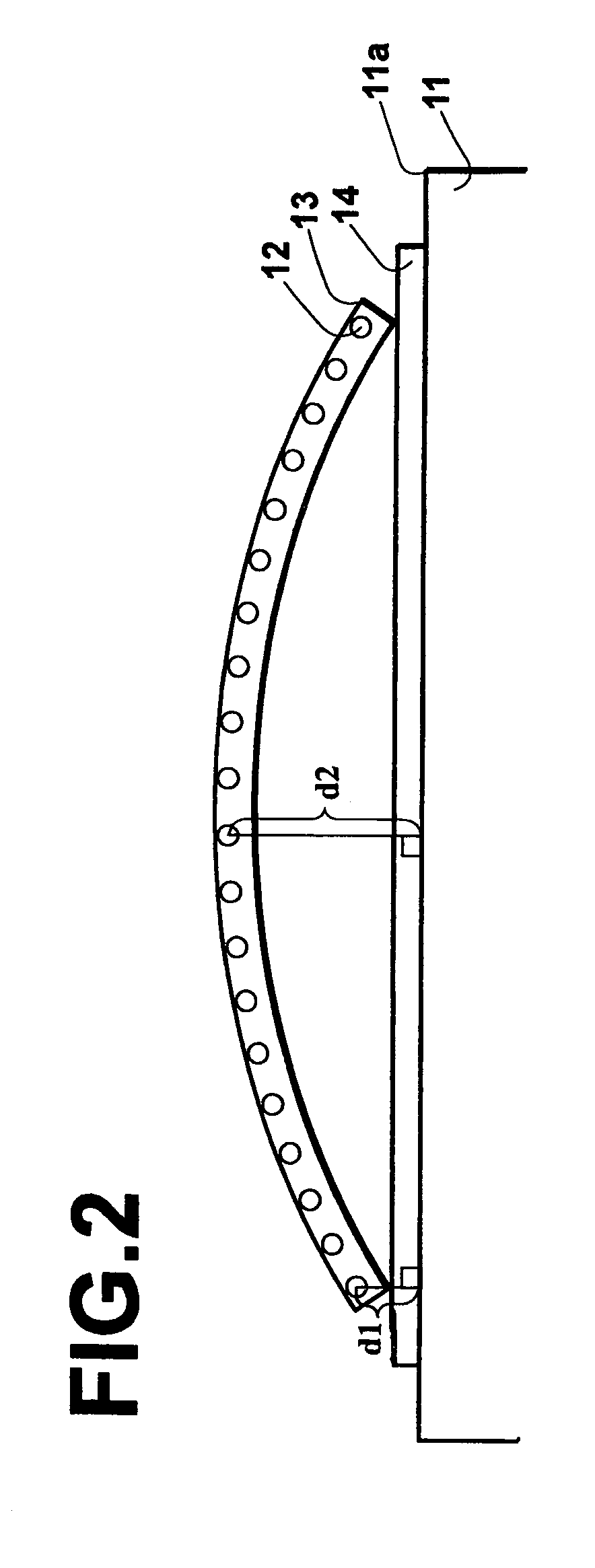

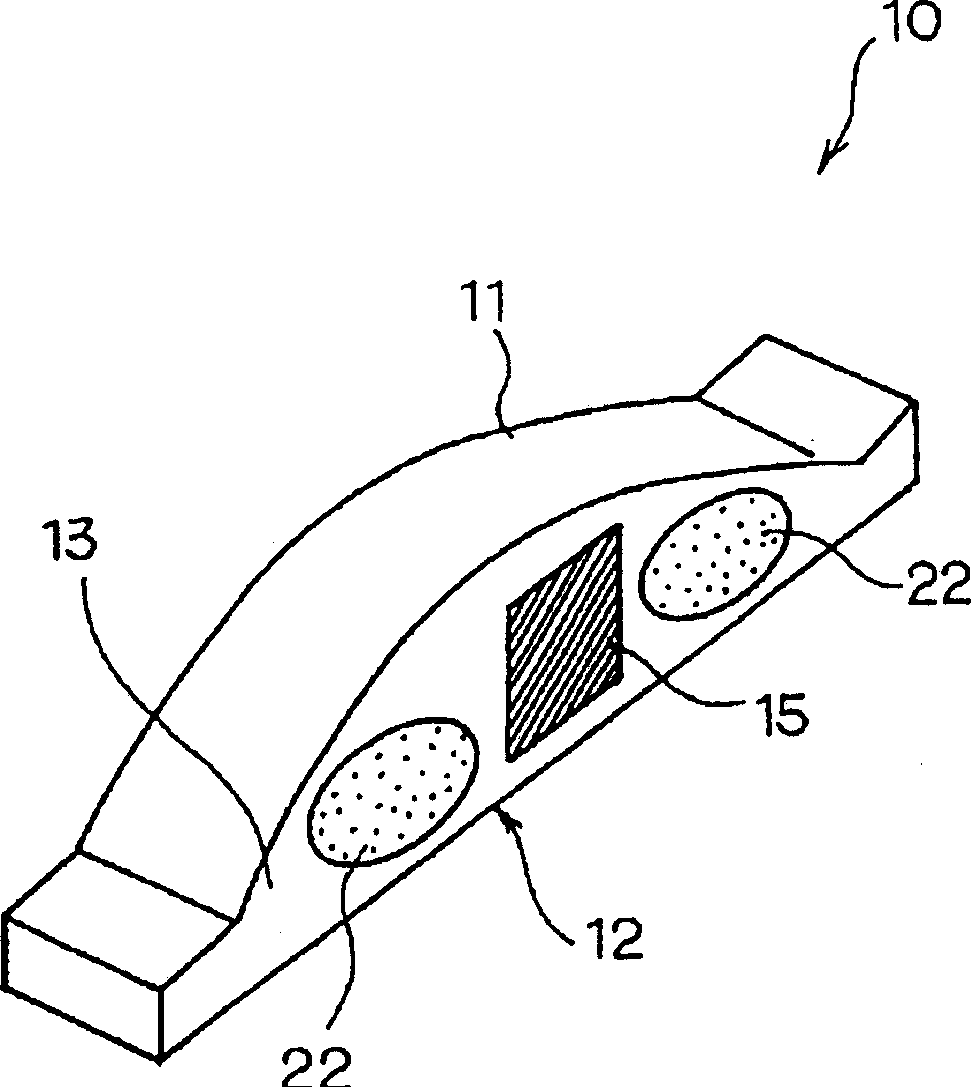

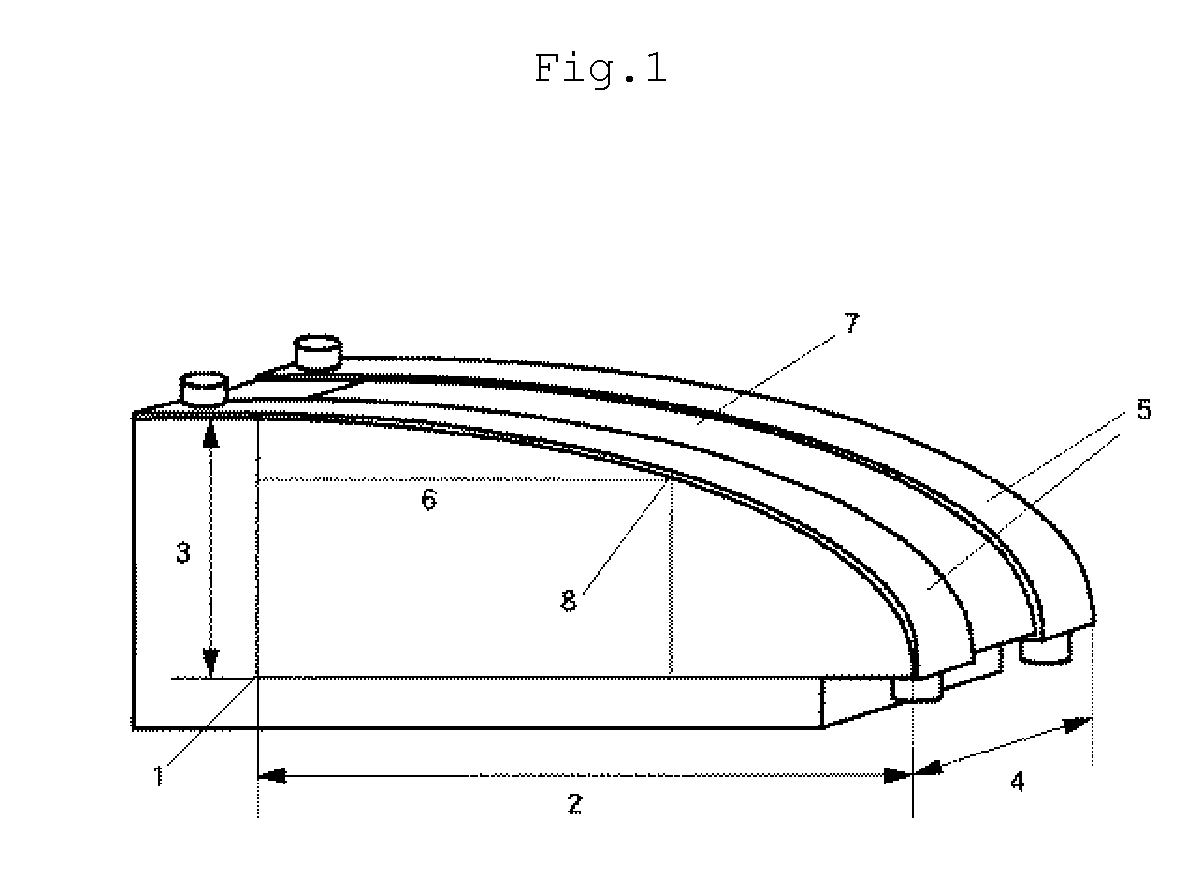

Apparatus and process for treating a flexible imaging member web stock

InactiveUS20060151922A1Reduce internal strainExtend mechanical lifeElectrography/magnetographyCoatingsEngineeringThermal expansion

Illustrated herein is a process for producing a stress relief electrostatographic imaging member web stock comprising: providing a multilayered imaging member web stock including at least one layer to be treated, the at least one layer to be treated having a coefficient of thermal expansion significantly differing from a coefficient of thermal expansion of another layer; passing the multilayered web stock over and making contact with a circular treatment tube having an outer concave arcuate circumferential surface that spontaneously creates a transverse web stock stretching force to offset the ripple causing transversal compression force in the at least one layer to be treated; heating at least one layer to be treated above the glass transition temperature (Tg) of the at least one layer to be treated to thereby create a heated portion of the at least one layer to be treated, a portion of the web stock in proximity to the heated portion of the at least one layer to be treated thereby becoming a heated portion of the web stock; inducing curvature conformance in the heated portion of the web stock; and, cooling the heated portion of the web stock at said curvature to a temperature below the Tg of the layer. Also included is the stress relieved imaging member web stock produced by this process.

Owner:XEROX CORP

Manufacturing method of glass blank for magnetic disk, manufacturing method of glass substrate for magnetic disk, glass blank for magnetic disk, glass substrate for magnetic disk, and magnetic disk

InactiveUS9242888B2Reduce internal strainReduce the differenceMagnetic materials for record carriersGlass drawing apparatusForming processesMolten glass

To provide a method for manufacturing a glass blank for magnetic disk and a method for manufacturing a glass substrate for magnetic disk, which are capable of producing a glass blank for magnetic disk having a good surface waviness by press forming, and a method for manufacturing a glass substrate for magnetic disk. A method for manufacturing a glass blank for magnetic disk, which includes a forming process of press-forming a lump of molten glass using a pair of dies, wherein in the forming process, press forming is performed using thermally equalizing means for reducing a difference in temperature in the press forming surface of the die during pressing of the molten glass.

Owner:HOYA CORP

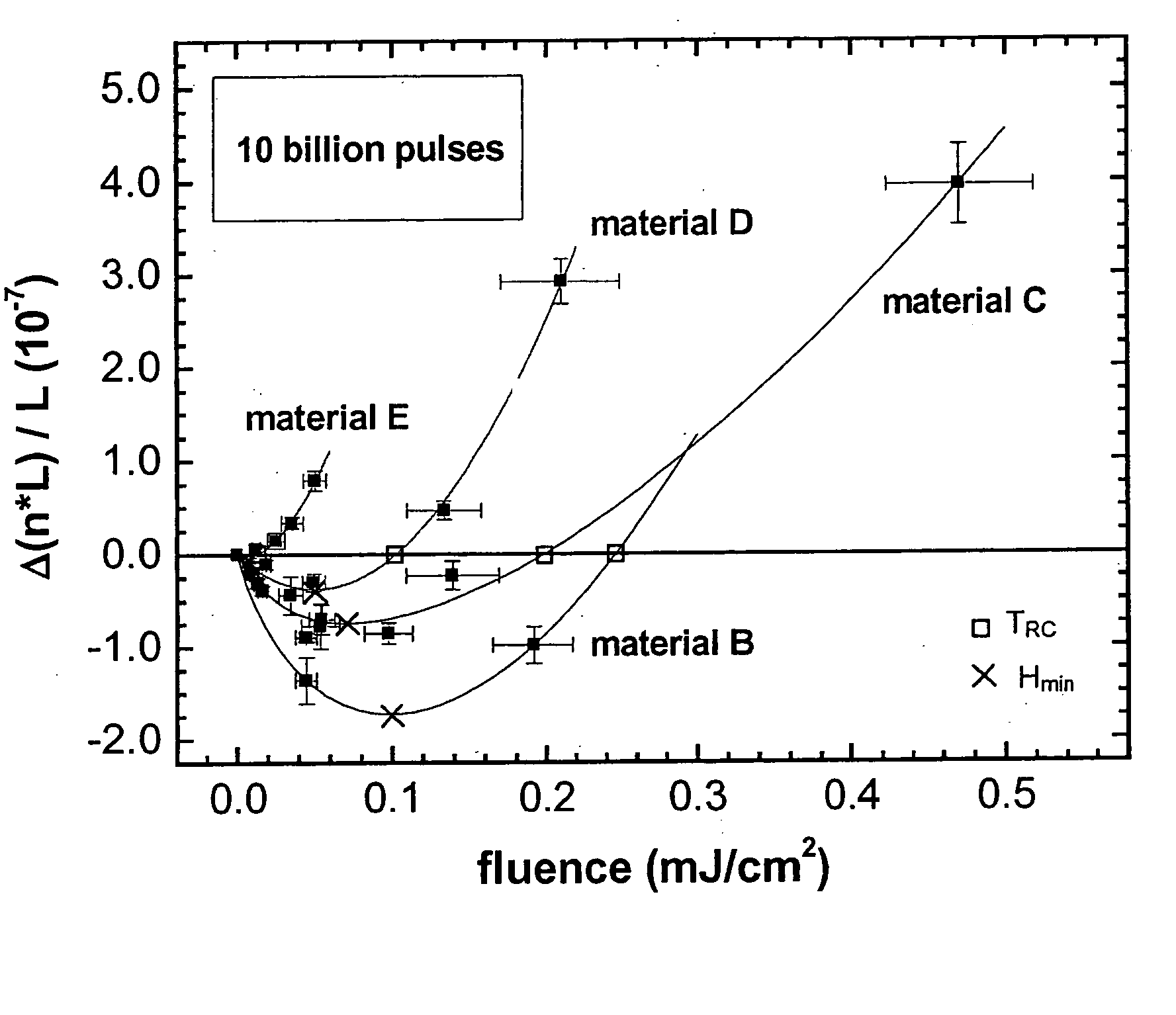

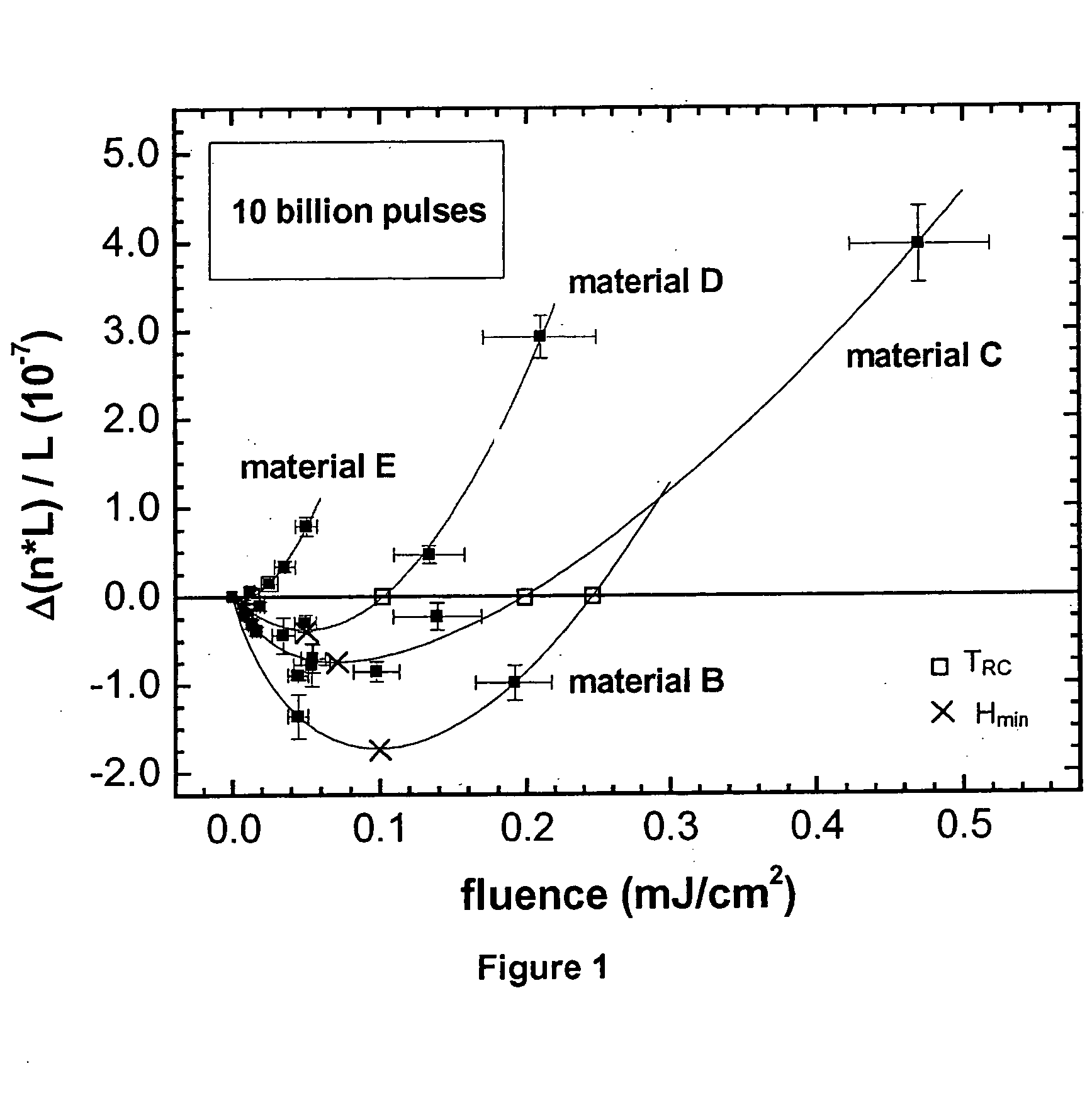

Projection optical system

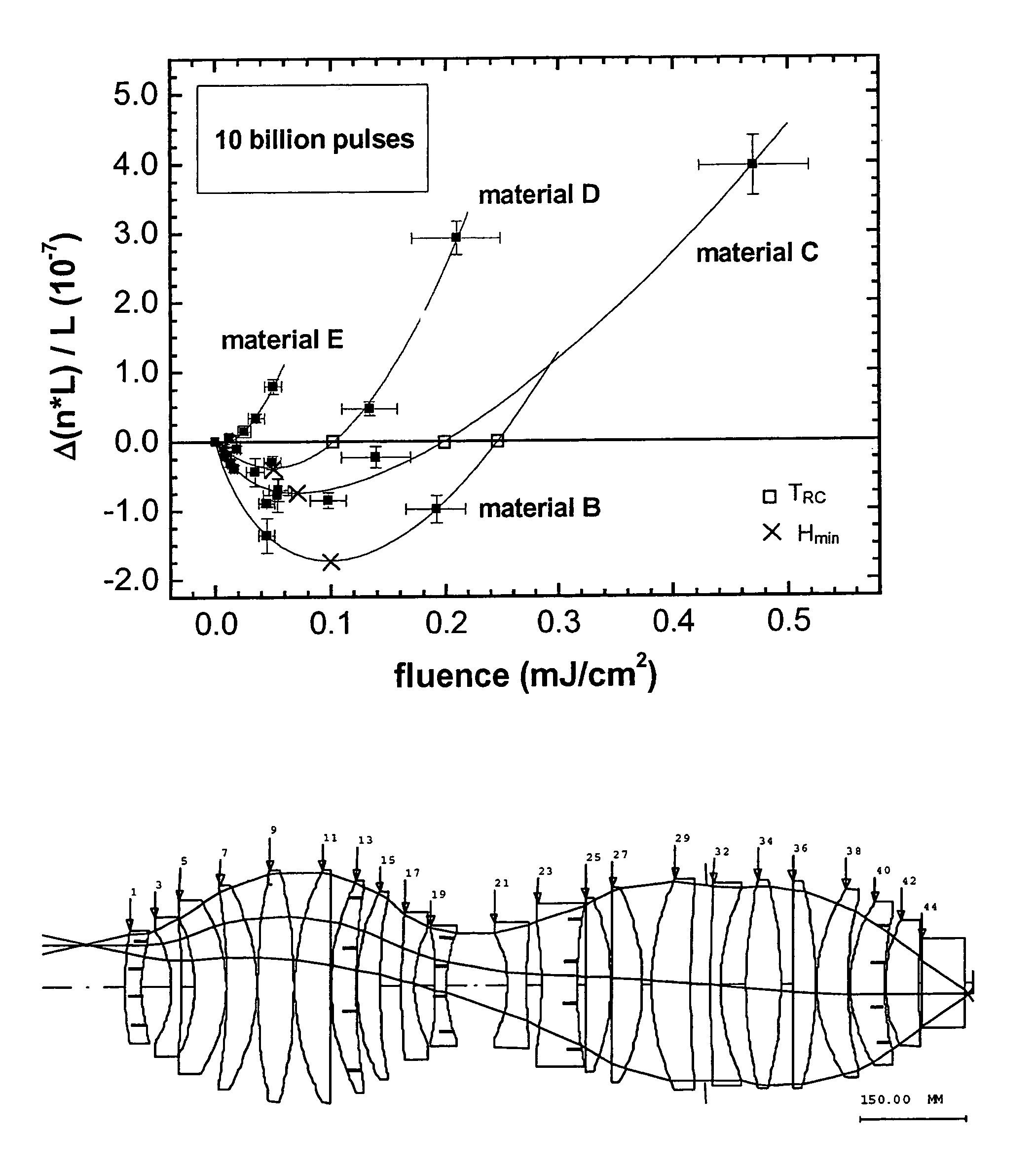

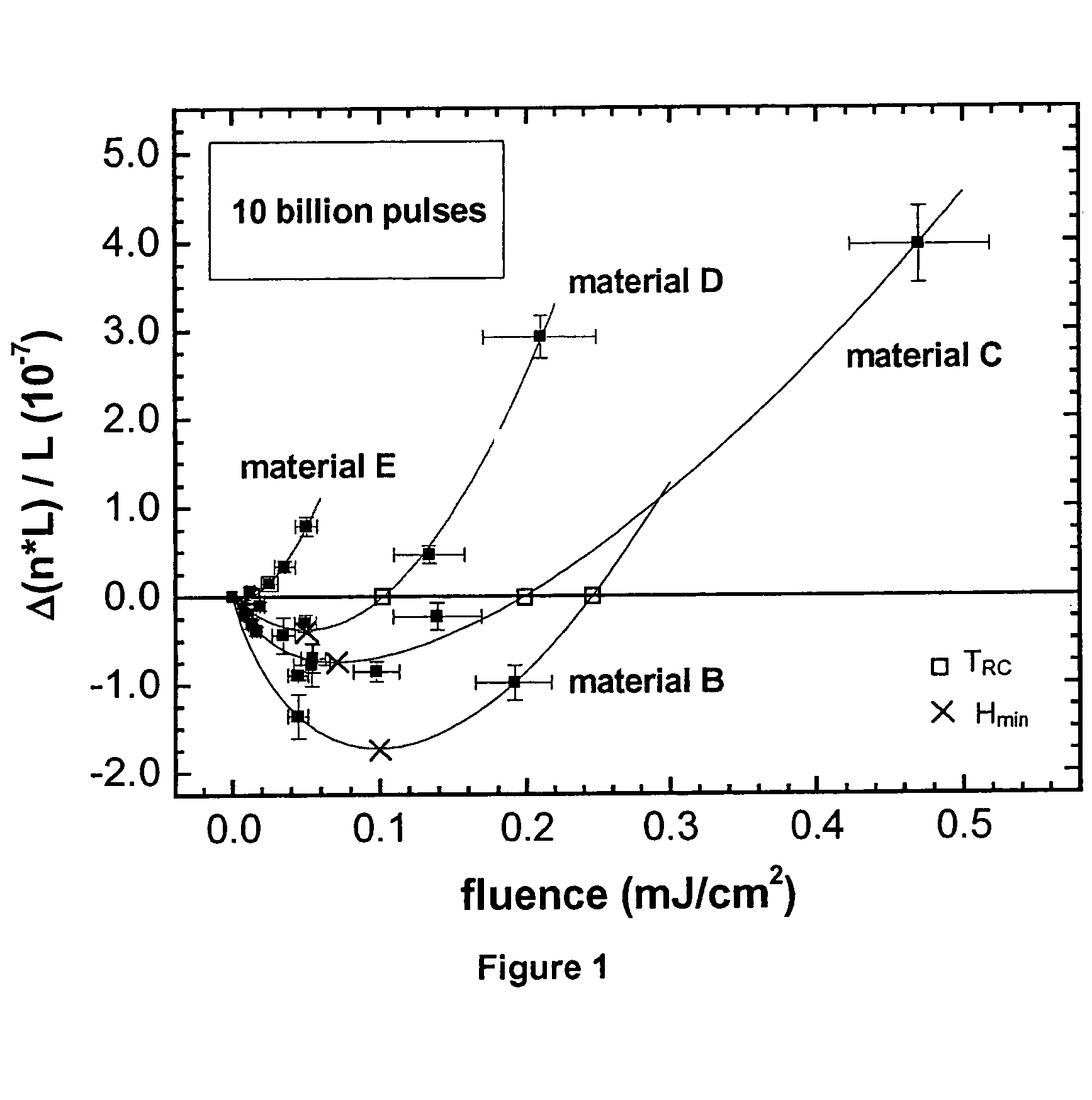

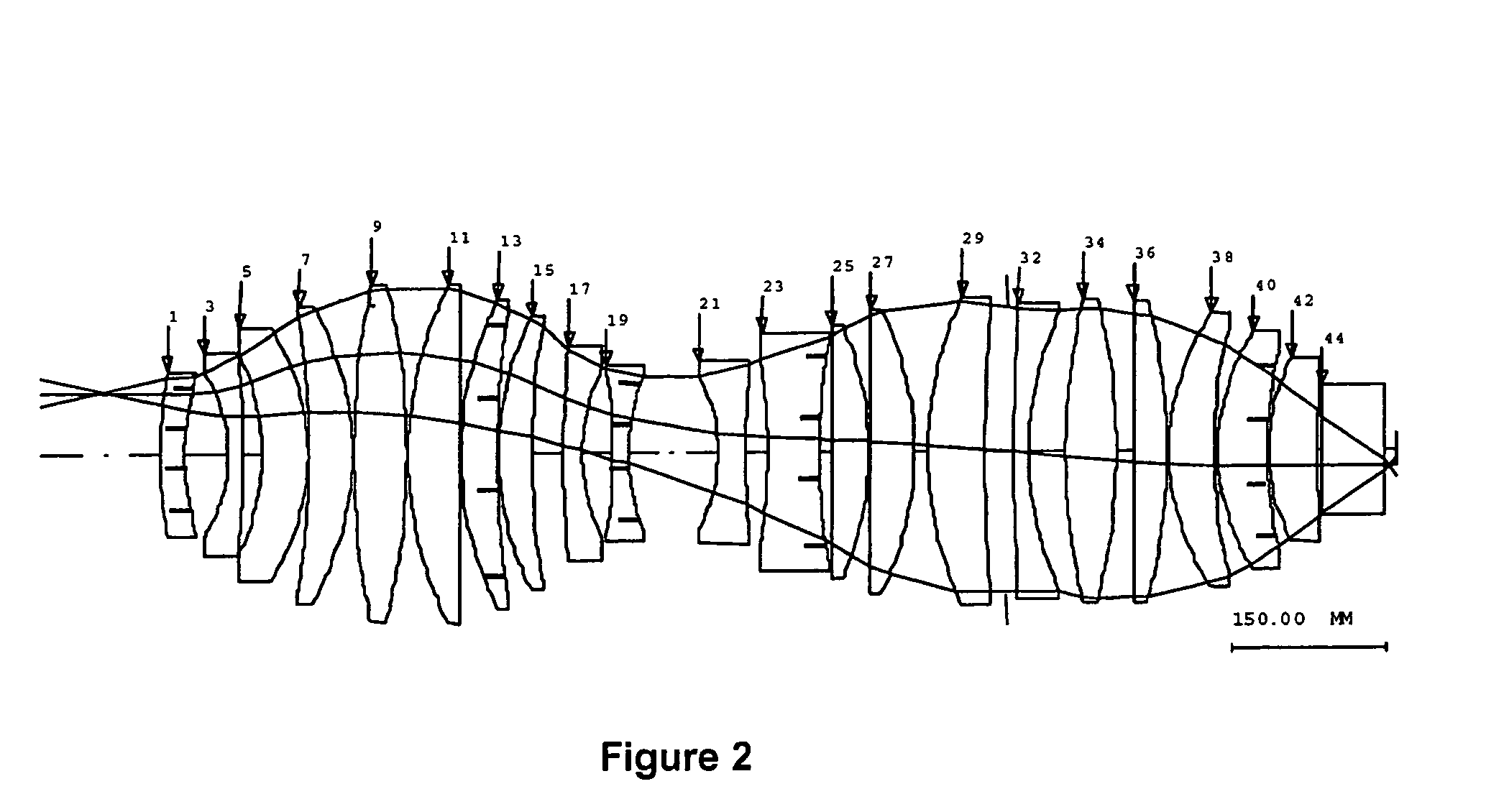

InactiveUS6992753B2Reduce decreaseLower performance requirementsPrismsSemiconductor/solid-state device manufacturingCamera lensTransition point

Radiation-induced damage to a lens material in a projection exposure system is reduced by selection of maximum design fluence values HD for lenses and at least one lens made of a material having a characteristic transition point TRC after exposure to a given amount of radiation, wherein, for instance, TRC<0.8. HD among other relationships and / or characteristics of the lenses.

Owner:CARL ZEISS SMT GMBH

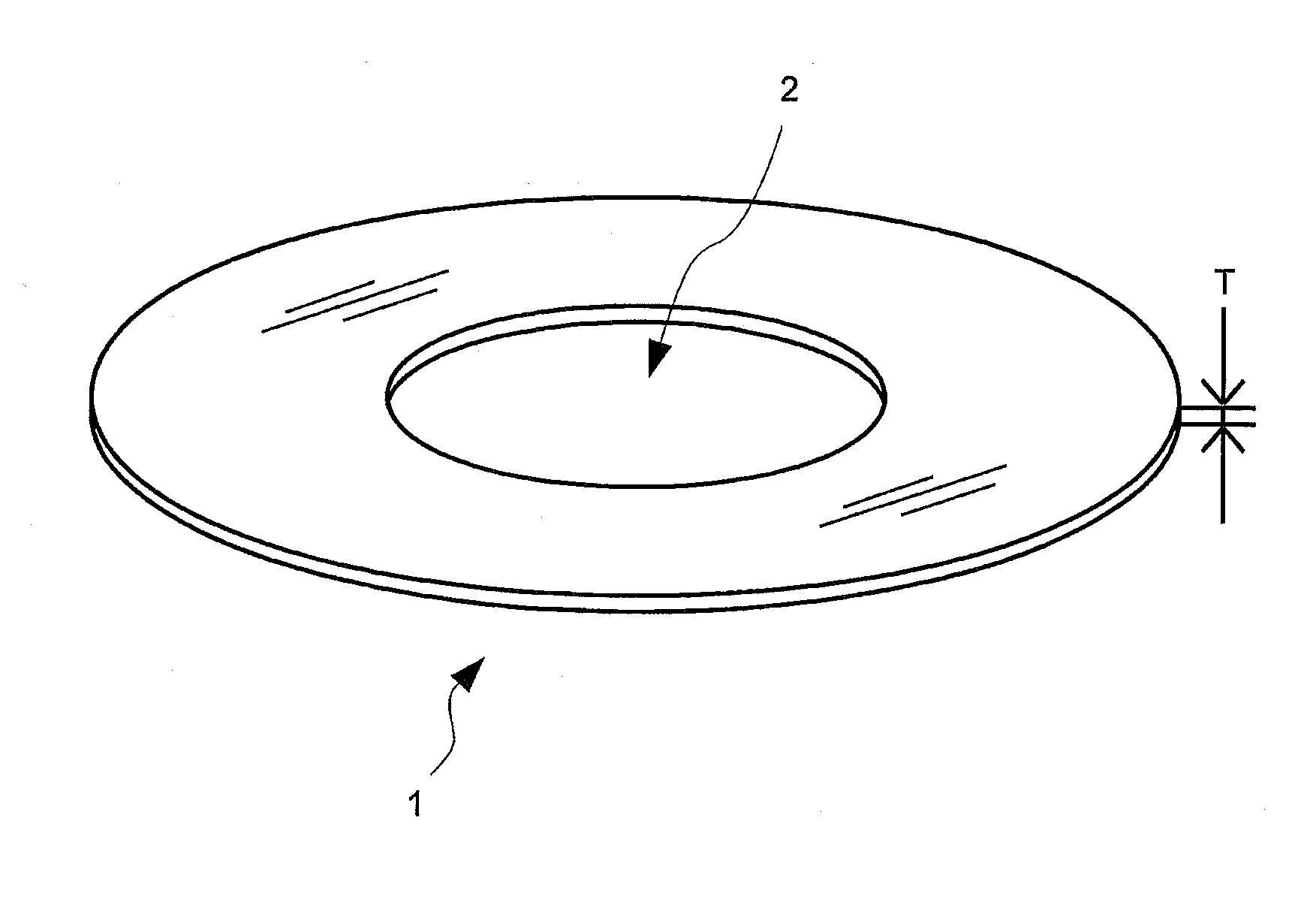

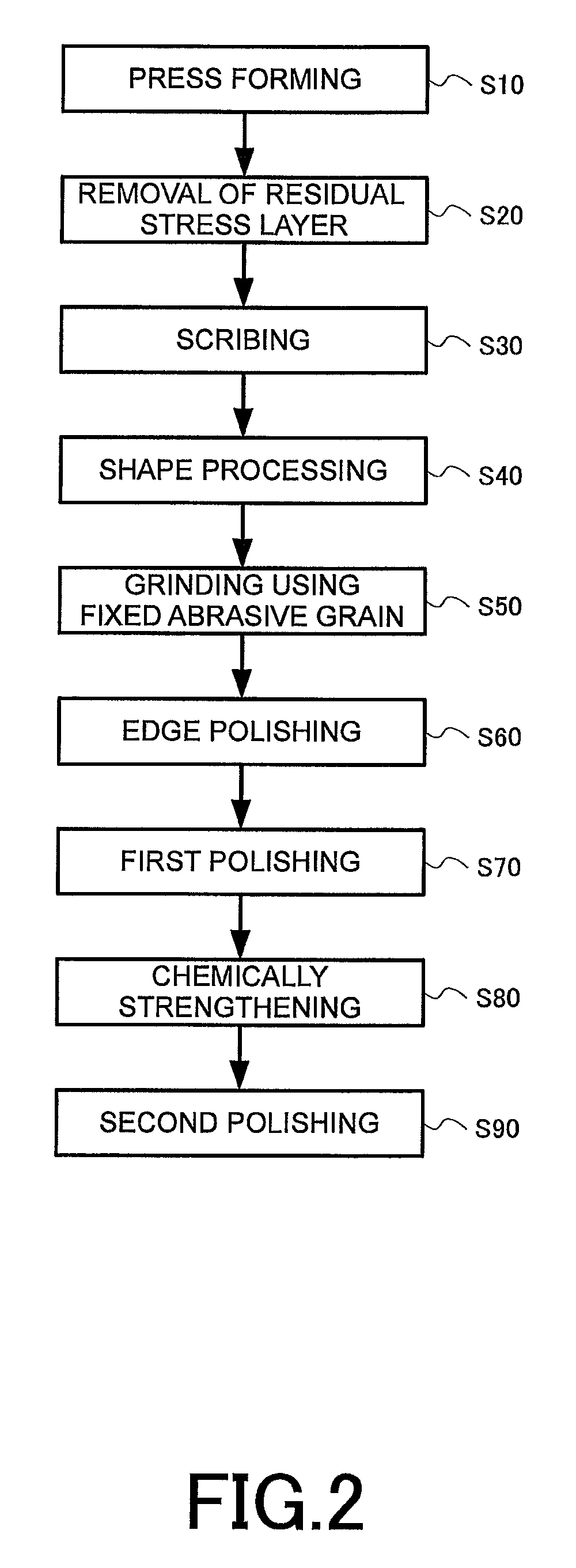

Method for manufacturing glass substrate for magnetic disk

ActiveUS9153269B2Low thermal conductivityImprove flatnessBase layer manufactureMachiningForming processes

A method for manufacturing a glass substrate for magnetic disk, the internal strain of which is reduced without performing annealing treatment, is provided. The method includes a forming process of forming a plate-shaped glass blank by pressing a lump of molten glass using a pair of dies, wherein the method includes: a removing process of removing at least a part of a residual stress layer formed on the principal face of the glass blank press-formed in the forming process; and a process of forming a donut-shaped glass substrate by subjecting the glass blank after the removing process to machining.

Owner:HOYA CORP

A kind of prefabricated T-beam and its method of building continuous beam bridge

InactiveCN105019350BAvoid crackingReduces the possibility of crackingBridge structural detailsBridge erection/assemblyBridge engineeringTensile strain

The invention relates to a prefabricated T-shaped beam and a method of building a continuous beam bridge by adopting the prefabricated T-shaped beams, and belongs to the field of bridge engineering. The T-shaped beam is an improved form of the conventional prefabricated T-shaped beam, and bottom flanges are additionally arranged at the ends, so that the cross sections of the ends are I-shaped. Longitudinal prestressed ducts are formed in the bottom flanges, and the longitudinal prestressed ducts are also formed in top plates of the ends. The bridge is formed in a manner that the prefabricated T-shaped beams are spliced, simply supported and then connected. Longitudinal prestress is tensioned on the bottom flanges, and negative bending moment prestress is tensioned on the top plates. Certain prestress is exerted on compressed zones at the bottoms, so that cracks under the effects of temperature and the like can be avoided. The compression areas of the bottom flanges are increased, the compressive strain of the compressed zones is decreased under the effect of negative bending moment, correspondingly, the tensile strain at the tops is also decreased and thus the possibility of cracking of the bridge deck can be lowered. As the cross sections of the ends are changed to be I-shaped, transportation and installation are convenient, and the construction of the continuous beam bridge is also convenient. The method of building the continuous beam is convenient to construct, and cracks of the top plates at pier top areas are favorably decreased.

Owner:ZHENGZHOU UNIV

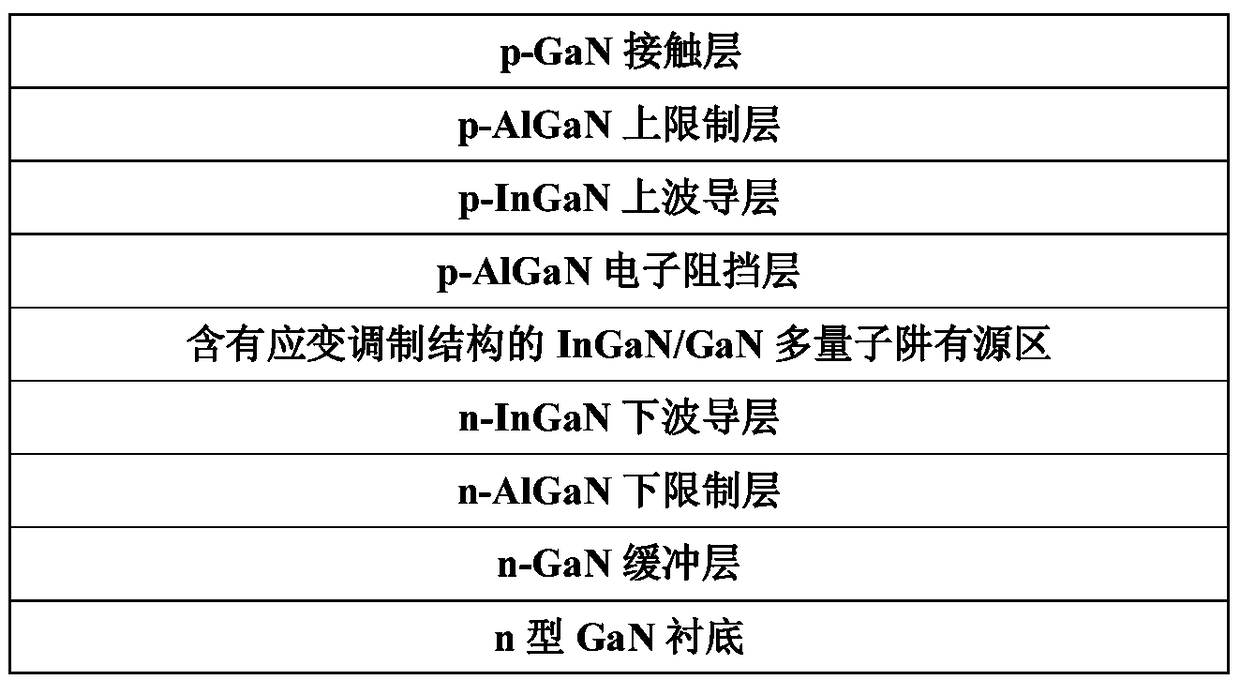

Laser element, method of producing the laser element, and a laser module employing the laser element

InactiveUS7120177B2Easy to manufactureSufficient alignmentSemiconductor laser arrangementsLaser active region structureLight emissionNitride

In a method for producing a laser element, a brazing material is placed between a nitride-based semiconductor laser bar and a fixation surface of a heat sink, where the brazing material contains gold and one of tin and silicon as main components, the nitride-based semiconductor laser bar has at least three light-emission points formed on a substrate, the heat sink is made of copper or copper alloy, and the fixation surface has a predetermined shape. Then, the nitride-based semiconductor laser bar is fixed to the fixation surface of the heat sink by melting and solidifying the brazing material while pressing the nitride-based semiconductor laser bar toward the heat sink with a tool having a shape corresponding to the predetermined shape of the fixation surface.

Owner:ADTEC ENG +1

Method for molding thermoplastic resin

Owner:MUNEKATA TAKATUKI OSAKA JP

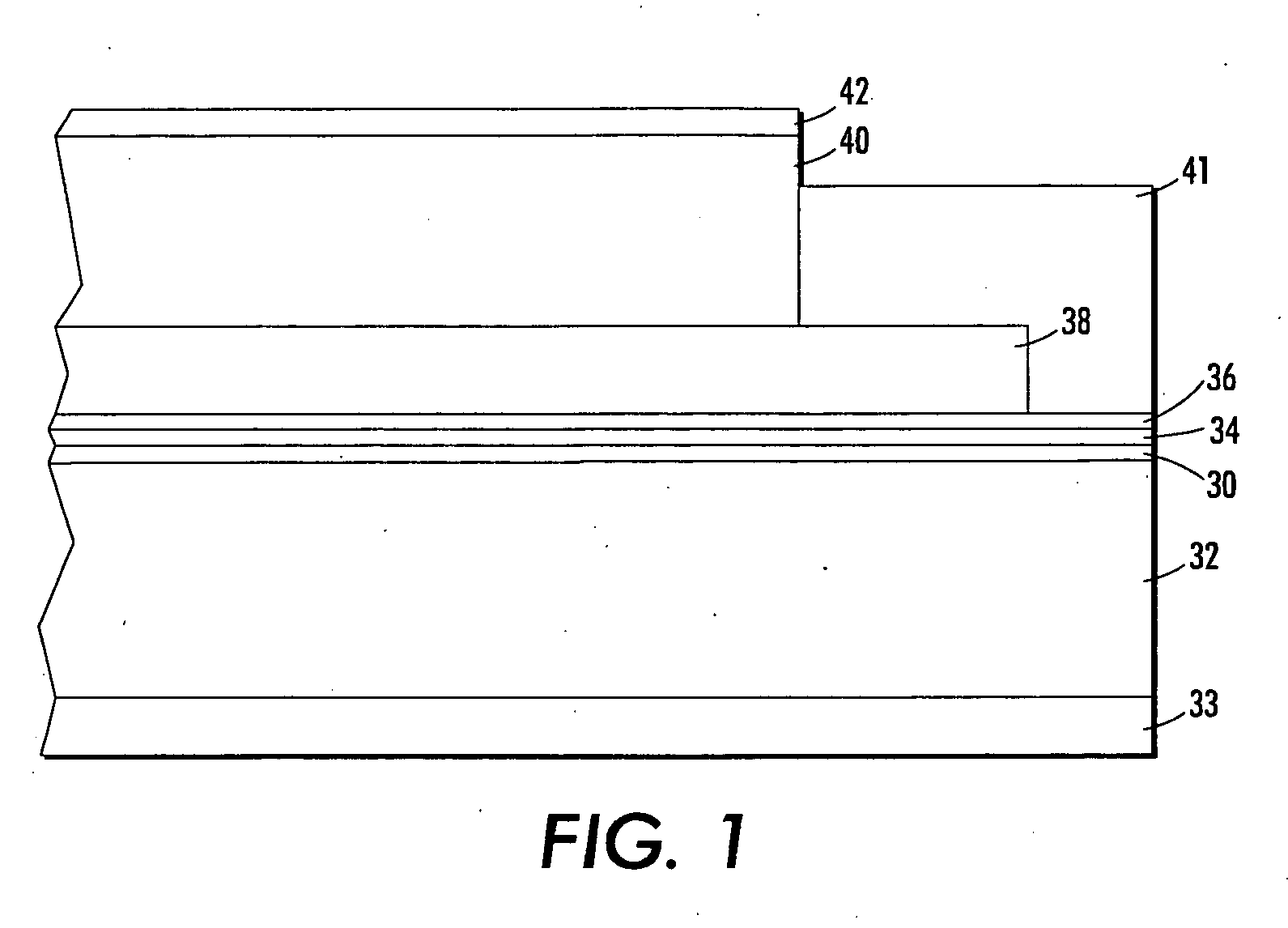

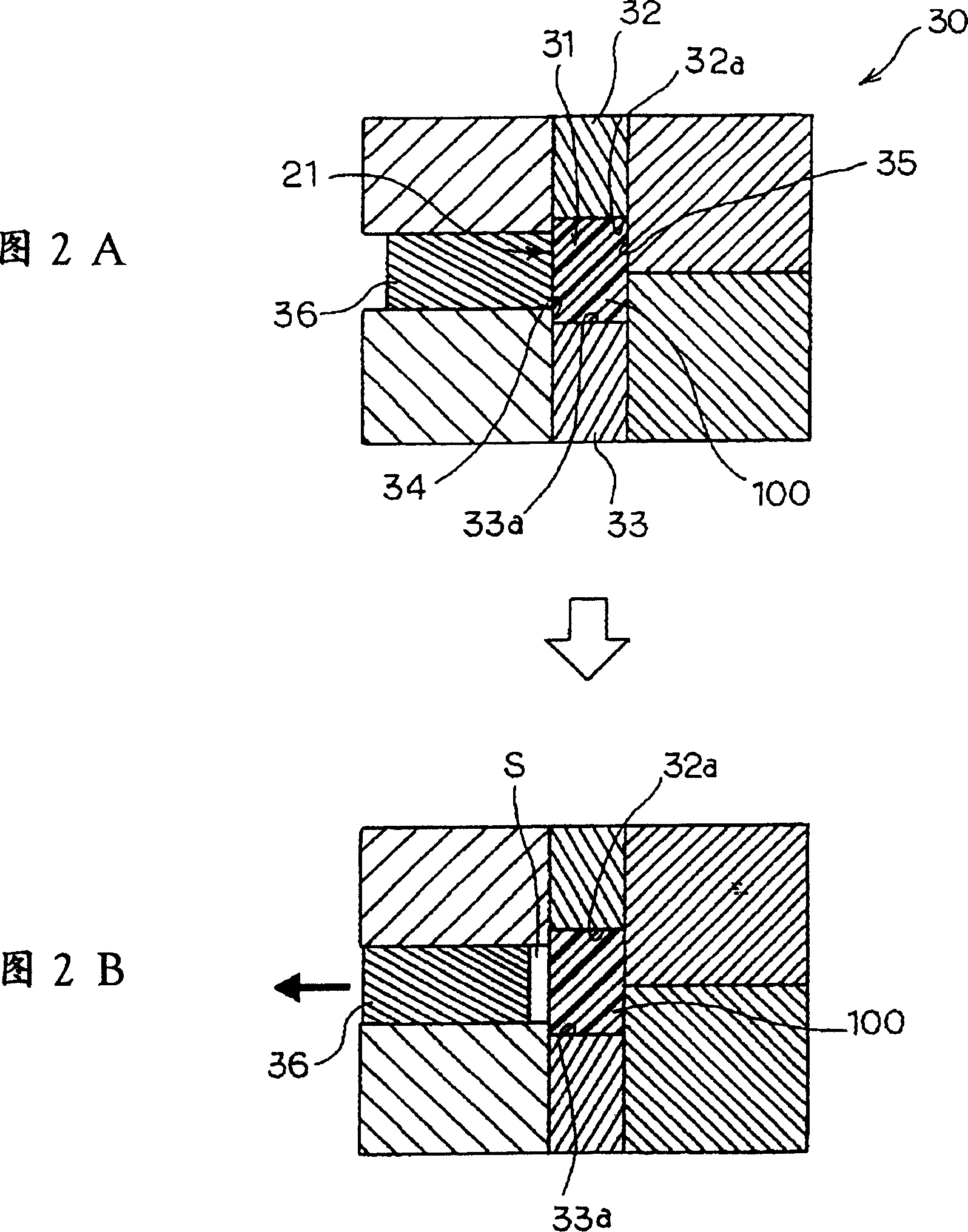

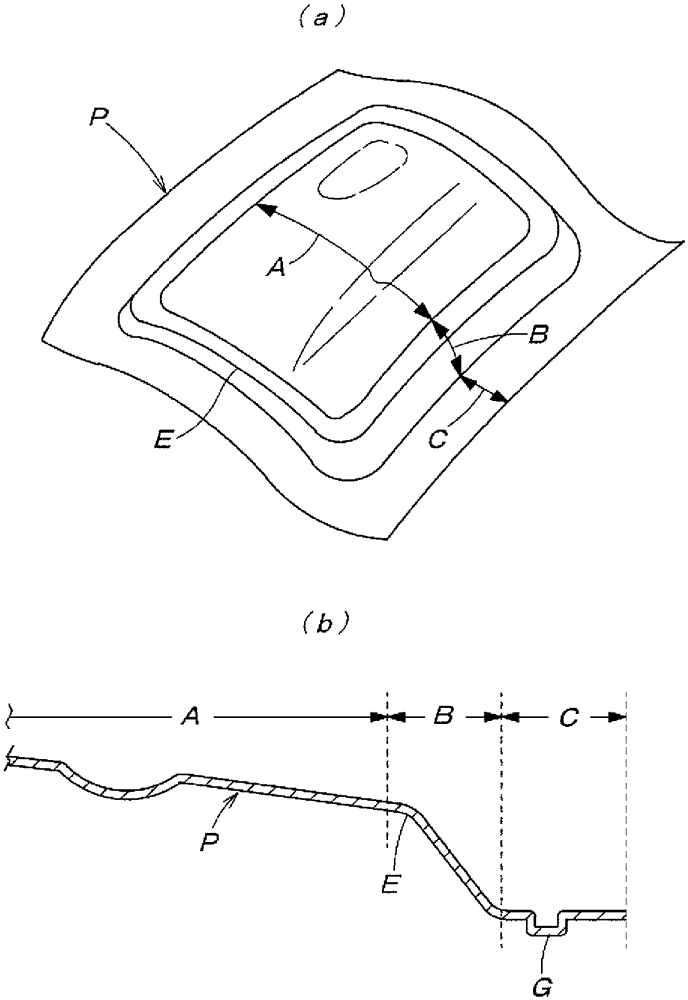

Plastic moulding article, moulding method and metal mould for the moulding thereof

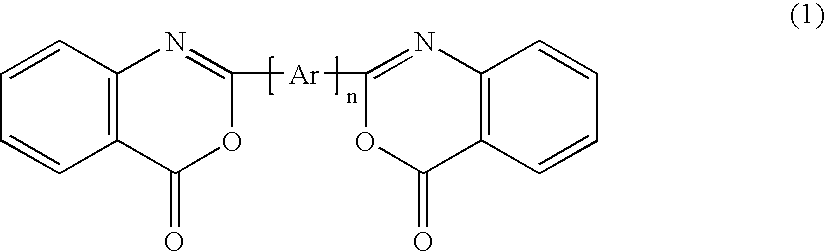

InactiveCN1222399CReduce internal pressureReduce internal strainOptical articlesThin material handlingPlastic moldingMaterials science

A plastic molding having high accuracy includes at least one transfer surface and at least one imperfect transfer portion having a concave or convex shape. The mold assembly includes a cavity into which molten resin is injected, a slide cavity piece which is capable of being slid at a prescribed time so that a gap is formed between the resin and the slide cavity piece, and a vent hole for supplying a compressed gas in the cavity. A method of producing the plastic molding includes the steps of heating resin to provide a molten resin, injecting the molten resin into a cavity of a molding, applying a resin-pressure to the molten resin, cooling the resin, sliding the slide cavity piece, and opening the mold assembly.

Owner:RICOH KK

Projection optical system

InactiveUS20050140954A1Reduce decreaseLower performance requirementsPrismsSemiconductor/solid-state device manufacturingTransition pointLens materials

Radiation-induced damage to a lens material in a projection exposure system is reduced by selection of maximum design fluence values HD for lenses and at least one lens made of a material having a characteristic transition point TRC after exposure to a given amount of radiation, wherein, for instance, TRC<0.8. HD among other relationships and / or characteristics of the lenses.

Owner:CARL ZEISS SMT GMBH

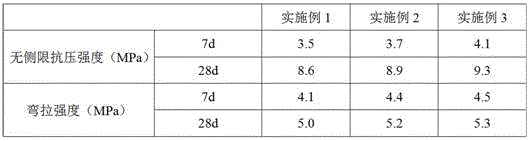

A kind of stone powder curing agent and preparation method thereof

The invention discloses a mountain flour curing agent. The mountain flour curing agent is prepared from the following raw materials in parts by weight: 4 to 6 parts of gypsum, 15 to 18 parts of cement, 28 to 30 parts of quick lime, 8 to 10 parts of limestone, 30 to 35 parts of mineral powder, 1 to 2 parts of ethoxyl methyl cellulose ether, 6 to 8 parts of cast stone powder, 6 to 8 parts of ceramic micro-powder, 10 to 15 parts of furfural residue and 4 to 6 parts of medical stone. According to the mountain flour curing agent provided by the invention, mountain flour wastes are cured so that resource utilization is realized; problems that a lot of mountain flour is stacked so that a soil body is occupied and the environment is polluted and the like are solved; the mountain flour curing agent has the advantages of energy conservation and environment friendliness, low construction cost and good benefits; the cured mountain flour has good compression resistance and flexural-tensile property. Furthermore, the mountain flour curing agent provided by the invention can replace a traditional cement stirring pile, can be directly mixed with the mountain flour to carry out curing treatment, so that the construction efficiency is greatly improved and the construction cost is reduced.

Owner:福建港湾新材料有限公司

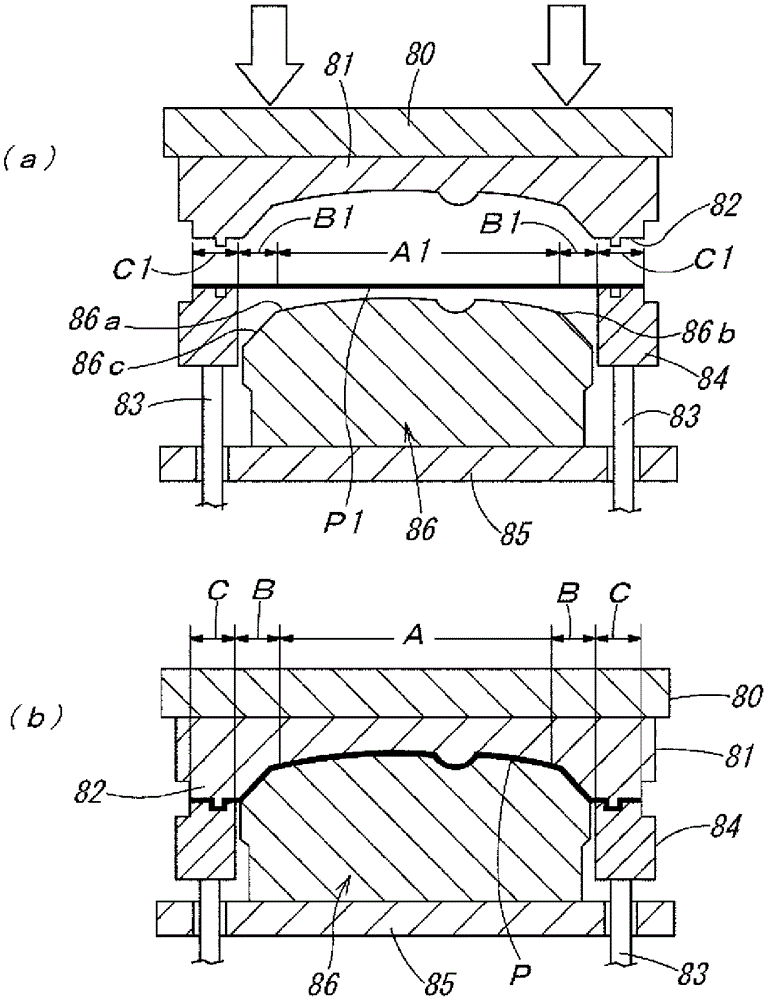

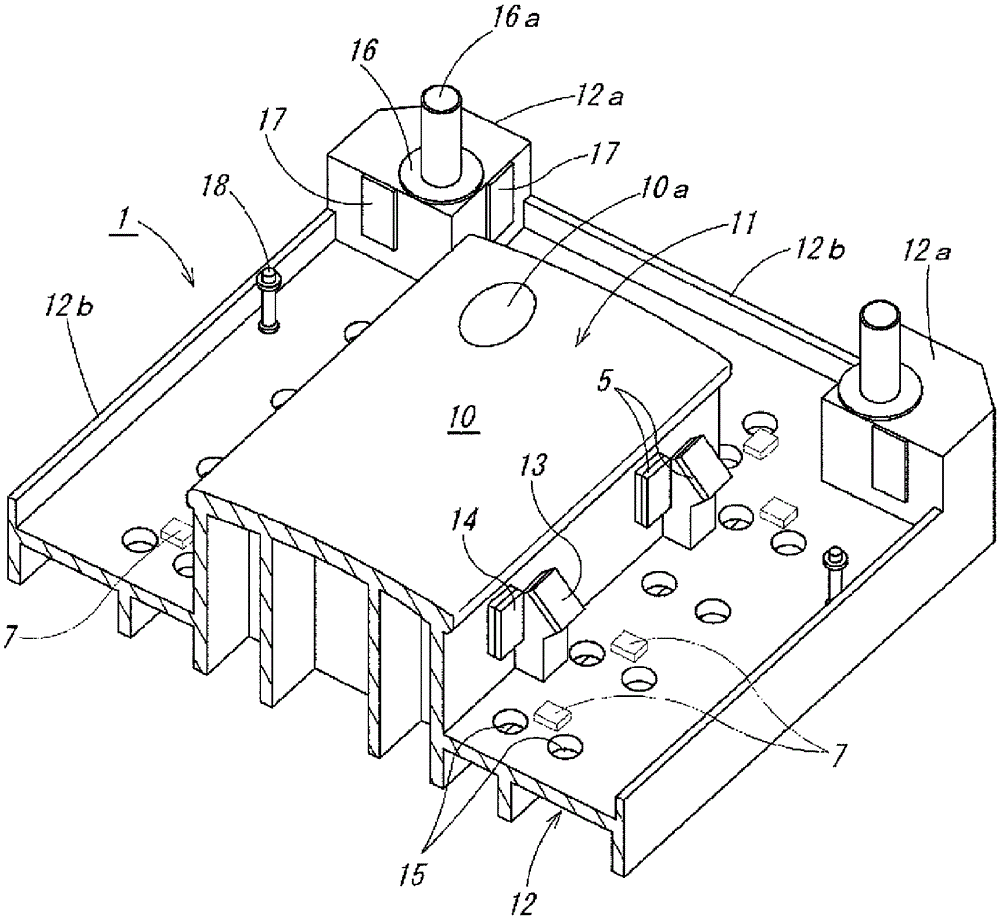

Pressure forming method and pressure forming device

InactiveCN104023868BReduce internal strainReduce resistanceShaping toolsEngineeringMechanical engineering

Provided is a means for efficiently imparting high tensile stiffness to a press stamping product by high forming stability, wherein that means can narrow a sacrificial constricted part, can greatly improve material yields, and can effectively resolve strain due to actual cross-sectional length differences in punch shapes in press forming accompanied by restriction of a sheet-shaped workpiece. When pressing between a punch (11) and a die (21) accompanied by expansion from a peripheral side while constraining the peripheral part of the sheet shaped workpiece (P1) by a plurality of blank holders (3) formed from a pair of sandwiching members (3a, 3b), in a process up to pressing after contact of a sheet shaped workpiece (P1) with a forming surface (10) of the punch (11), each blank holder (3) is displaced in the pressing direction and the sheet shaped workpiece (P1) is superimposed on the forming surface (10) of the punch (11), and then displaced in the outside direction and the sheet shaped workpiece (P1) is expanded. After completion of pressing, each blank holder (3) is displaced along the opposite of the pressing direction, and the press stamping product (P1) is disengaged from the punch (11). Furthermore, after both sandwiching members (3a, 3b) are made to detach and the press stamping product (P) removed, both sandwiching members (3a, 3b) are displaced toward the inside direction, and a sheet shaped workpiece (P1) is returned to an initial position prior to being constrained.

Owner:MS KK

Polycarbonate resin composition and molded article thereof

ActiveUS8697788B2Good effectExcellent in releasabilityGroup 5/15 element organic compoundsUltravioletCarboxylic acid

This invention seeks to provide a resin composition and a molded article which are excellent in transparency, weatherability, resistance to boiling water and resistance to molding heat, which have an internal strain reduced and which are excellent in breaking durability.This invention is a resin composition comprising(A) 100 parts by weight of a polycarbonate resin (component A),(B) 0.005 to 1 part by weight of an ester (component B) of pentaerythritol and an aliphatic carboxylic acid,(C) 0.003 to 0.2 part by weight of an epoxy compound (component C),(D) 0.01 to 1 part by weight of an ultraviolet absorbent (component D), and(E) 0.001 to 0.5 part by weight of a phosphorus stabilizer (component E),wherein the components B and the component C have a critical stress of 12 MPa or more each when they are treated at a temperature of 120° C. for 24 hours in a one / fourth ellipse test method using a bisphenol A type polycarbonate resin sheet that is produced by a melt-extrusion method and has a viscosity average molecular weight of 24,500, and a molded article thereof.

Owner:TEIJIN KASEK KK

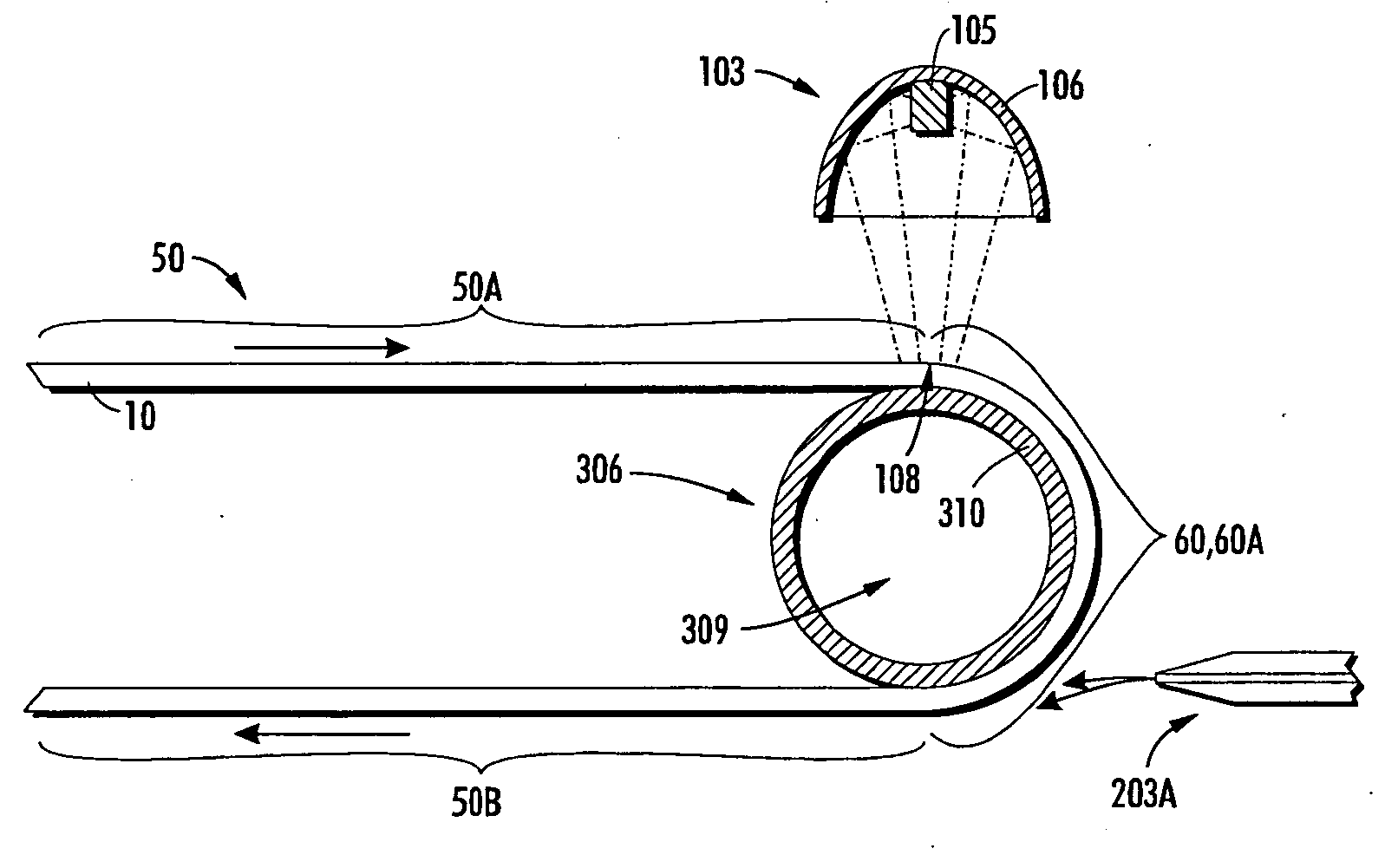

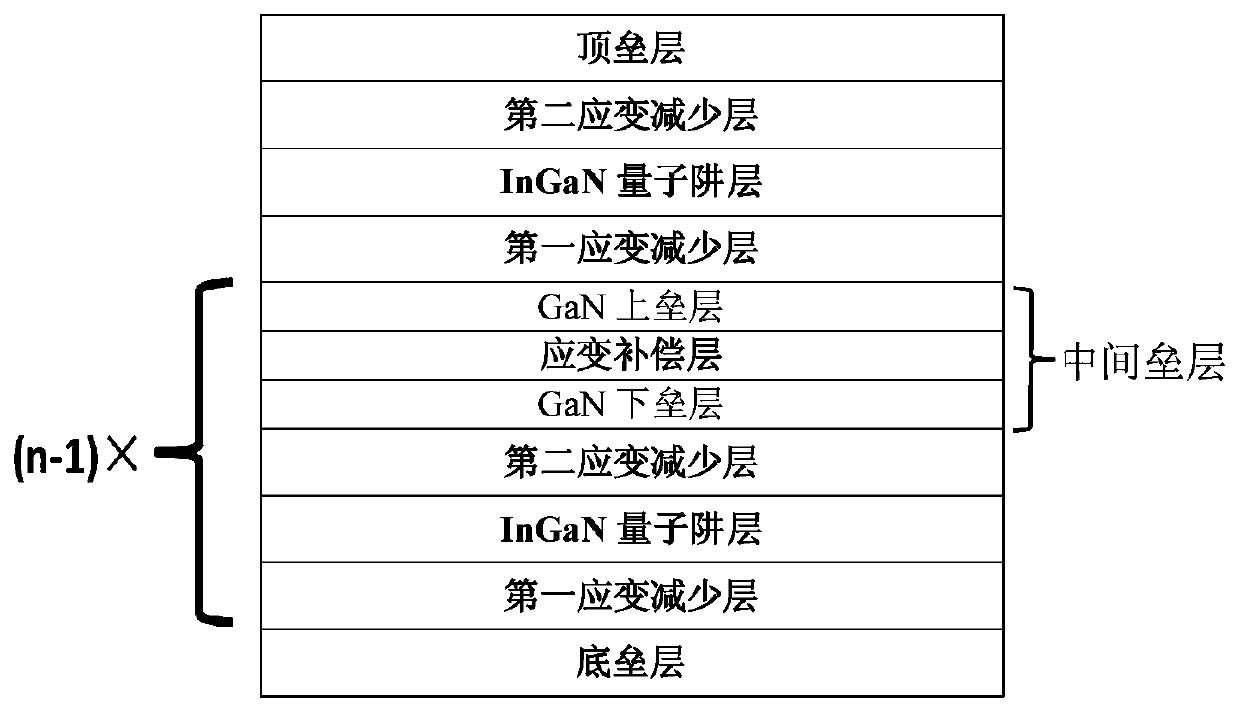

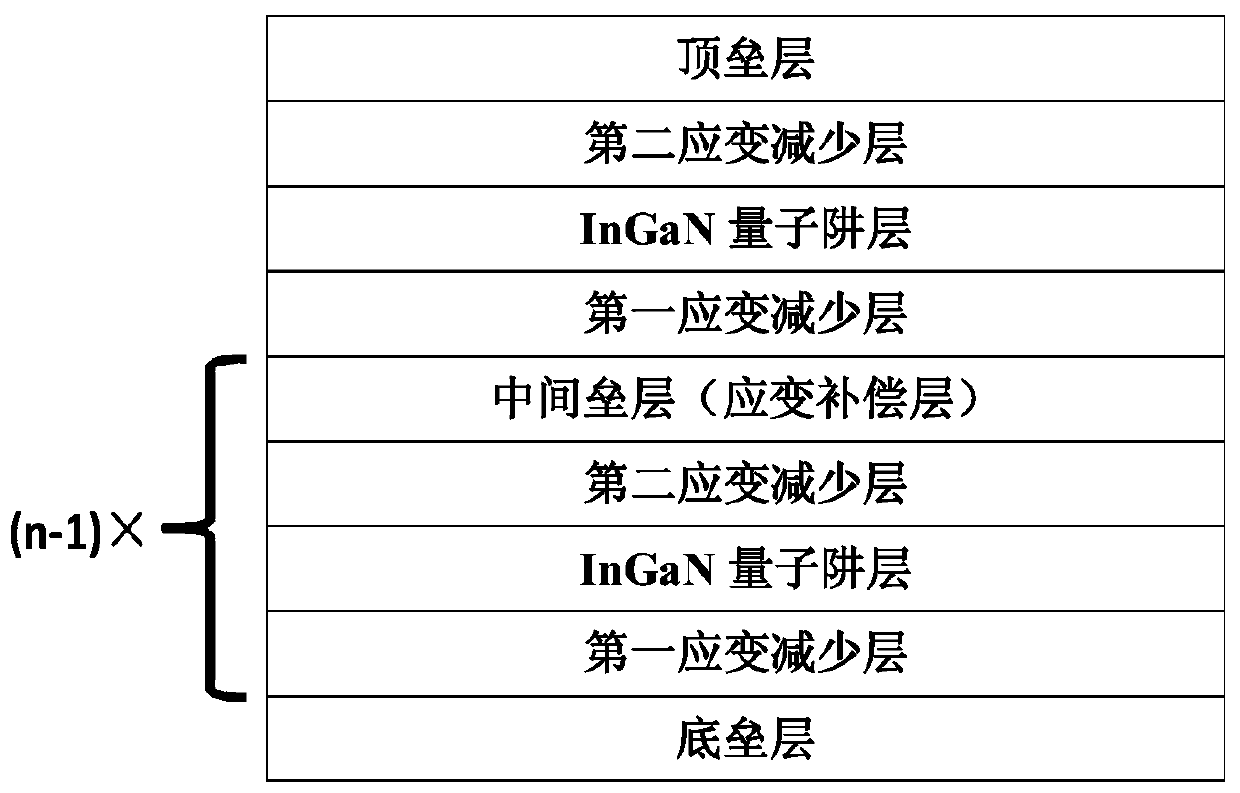

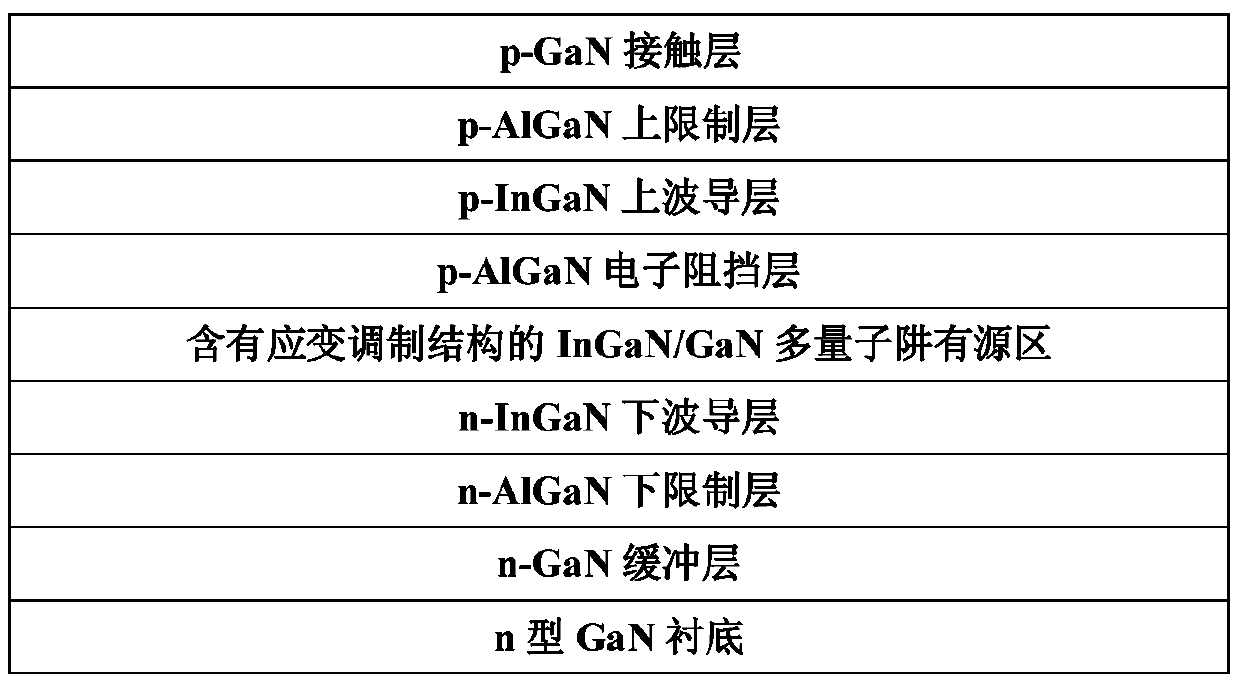

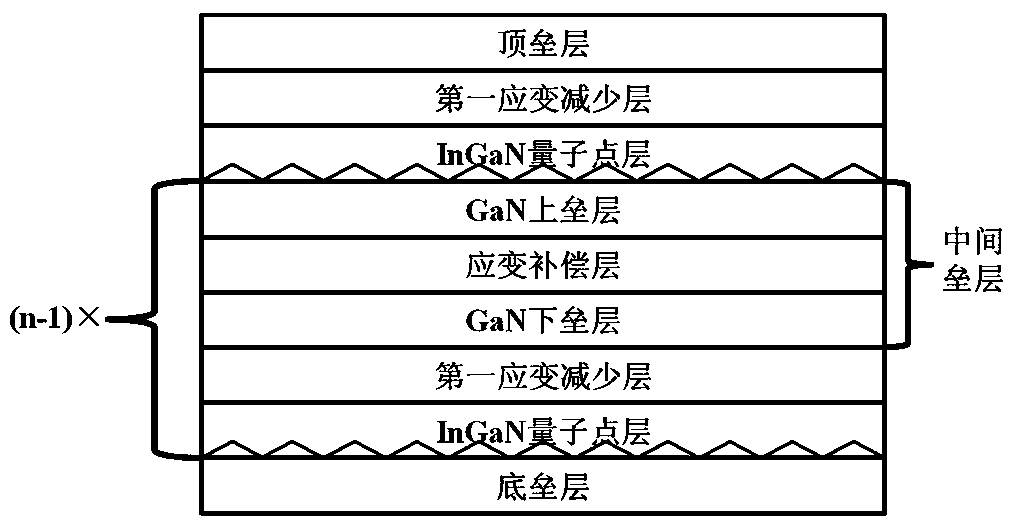

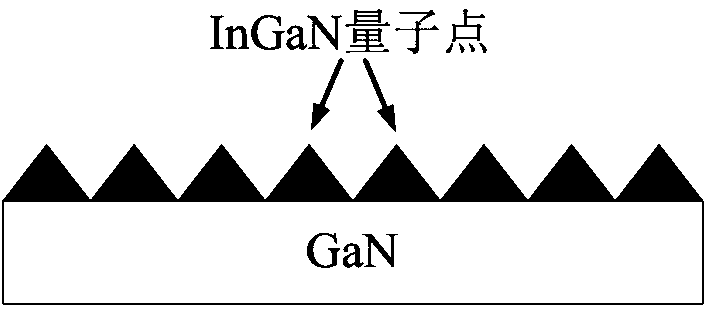

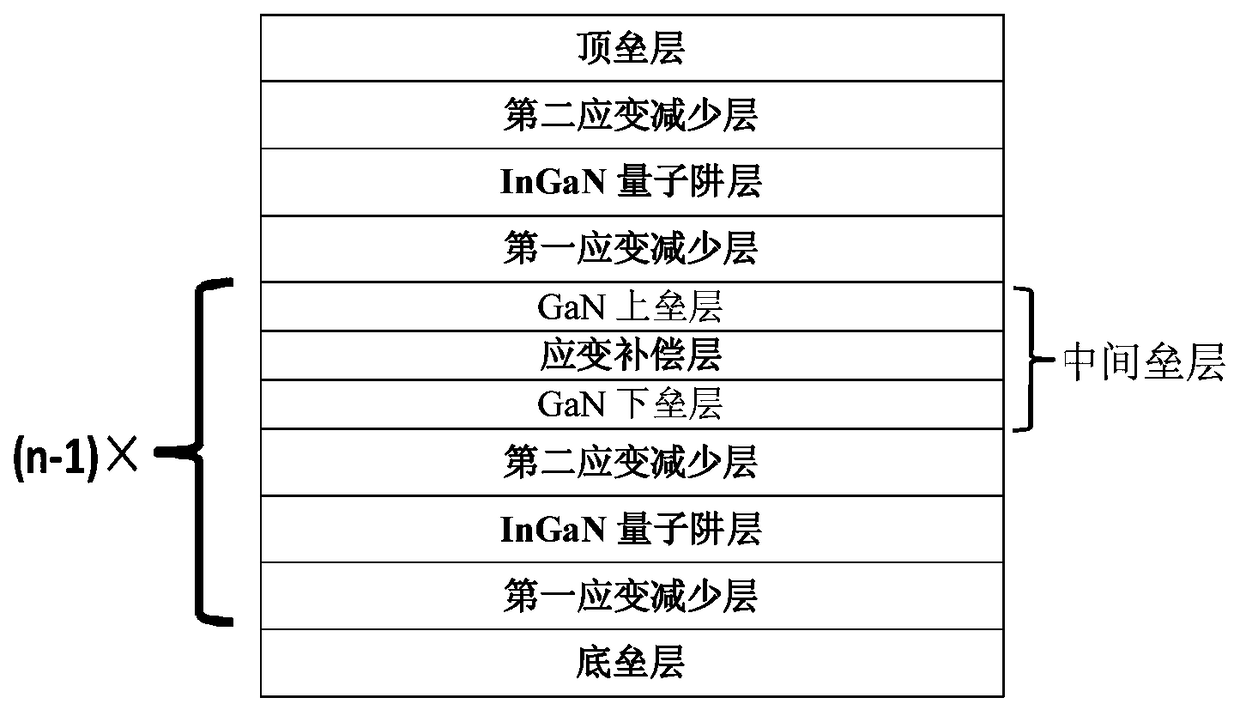

An Ingan/gan Multiple Quantum Well Structure Containing a Strain Modulated Structure

ActiveCN109065684BReduce internal strainReduce mismatchSemiconductor devicesErbium lasersParticle physics

The invention relates to the field of group III nitride semiconductor optoelectronic materials, An InGaN / GaN multiple quantum well structure with strain modulation structure is proposed, include an underbarrier layer, a top barrier layer, a plurality of InGaN quantum well layers located between the bottom barrier layer and the top barrier layer, and an intermediate barrier layer disposed between the respective InGaN quantum well layers, characterized by, A first strain reduction layer immediately adjacent to and disposed beneath the InGaN quantum well layer is also included, and a second strain reduction layer disposed immediately adjacent to and above the InGaN quantum well layer, The first strain reduction layer and the second strain reduction layer are InGaN layers having an In component of less than 10%, and the intermediate barrier layer comprises a strain compensation layer having a lattice constant smaller than that of the bottom barrier layer and the top barrier layer. The invention provides a novel active region structure for improving the efficiency of a GaN-based blue-green LED and a laser.

Owner:TAIYUAN UNIV OF TECH

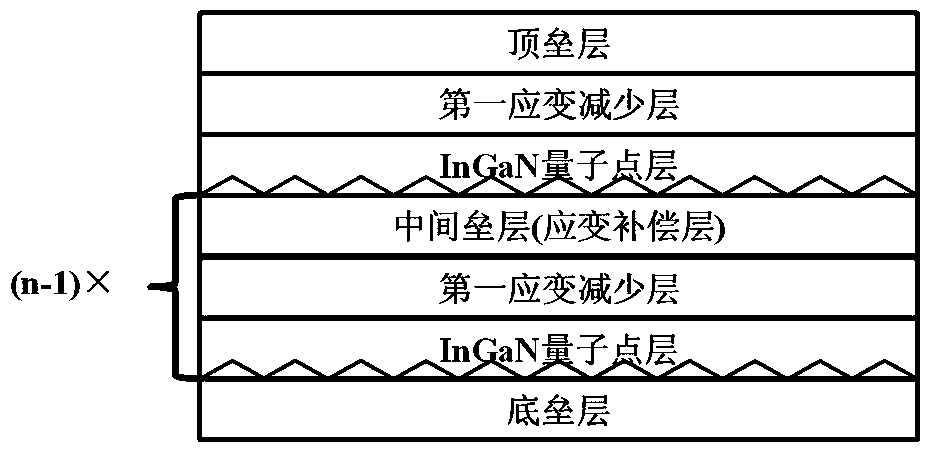

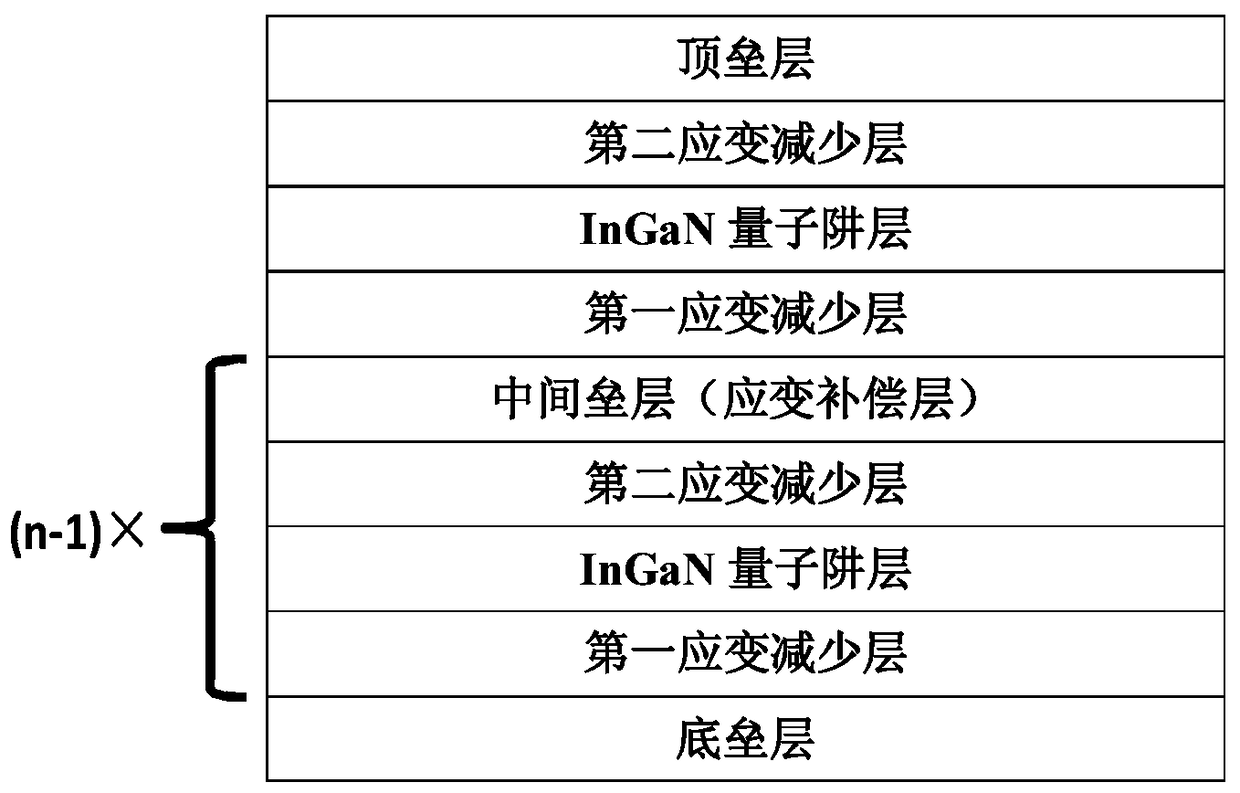

A multilayer ingan quantum dot structure containing a strain-modulated structure

The invention relates to the field of group III nitride semiconductor optoelectronic materials, and provides A multilayer InGaN quantum dot structure with a strain-modulated structure the structure includes an underbarrier lay, a top barrier layer, a plurality of InGaN quantum dot layers located between the bottom barrier layer and the top barrier layer, and an intermediate barrier layer disposedbetween the respective InGaN quantum dot layers, characterized in that it further comprises a first strain reduction layer disposed immediately adjacent to and above the InGaN quantum dot layer, wherein the first strain reduction layer is an InGaN layer having an In component of less than 10%, and the intermediate barrier layer comprises a strain compensation layer, wherein the strain compensationlayer is a barrier layer having a lattice constant smaller than that of GaN. The invention provides a novel active region structure for improving the performance of GaN-based LEDs and lasers and widening the luminous wavelength range thereof.

Owner:TAIYUAN UNIV OF TECH

Construction technology of a kind of silt solidified soil

The invention discloses a silt solidification soil construction technology which comprises the steps of surface cleaning drainage, silt sampling, detection analysis, excavation stacking, stirring and mixing, filling and grinding and stabilized soil maintenance. Through solidification soil in-situ solidification, silt and a curing agent are stirred and mixed to form silt solidification soil, and the curing agent is prepared through expanded graphite, activated carbon, cement, quick lime, gypsum, lignocelluloses, coal ash, granulated blast-furnace slag powder, coal gangue, caustic dross, hydroxypropyl methyl celluloses, furfural residues, medical stone and smectite clay. By means of the silt solidification soil construction technology, original flowing high-water-content low-strength high-compressibility silt is converted into high-compressive-strength excellent-entire-board-performance, good-durability and environment-friendly solidification soil, and the requirement of shallow ground earthwork materials for roads, storage yards, ports, reclamation projects, afforesting and the like can be met.

Owner:福建港湾岩土工程集团有限公司

Method for molding thermoplastic resin

Owner:MUNEKATA TAKATUKI OSAKA JP

Mountain flour curing agent and preparation method thereof

InactiveCN106431160ASolve the soil occupied by stackingSolve environmental problemsResource utilizationEther

The invention discloses a mountain flour curing agent. The mountain flour curing agent is prepared from the following raw materials in parts by weight: 4 to 6 parts of gypsum, 15 to 18 parts of cement, 28 to 30 parts of quick lime, 8 to 10 parts of limestone, 30 to 35 parts of mineral powder, 1 to 2 parts of ethoxyl methyl cellulose ether, 6 to 8 parts of cast stone powder, 6 to 8 parts of ceramic micro-powder, 10 to 15 parts of furfural residue and 4 to 6 parts of medical stone. According to the mountain flour curing agent provided by the invention, mountain flour wastes are cured so that resource utilization is realized; problems that a lot of mountain flour is stacked so that a soil body is occupied and the environment is polluted and the like are solved; the mountain flour curing agent has the advantages of energy conservation and environment friendliness, low construction cost and good benefits; the cured mountain flour has good compression resistance and flexural-tensile property. Furthermore, the mountain flour curing agent provided by the invention can replace a traditional cement stirring pile, can be directly mixed with the mountain flour to carry out curing treatment, so that the construction efficiency is greatly improved and the construction cost is reduced.

Owner:福建港湾新材料有限公司

An InGaN/GaN multiple quantum well structure with strain modulation structure

ActiveCN109065684AEliminates stress buildupPrevents stress from being transmitted upwardsSemiconductor devicesMultiple quantumOptoelectronic materials

The invention relates to the field of group III nitride semiconductor optoelectronic materials, An InGaN / GaN multiple quantum well structure with strain modulation structure is proposed, include an underbarrier layer, a top barrier layer, a plurality of InGaN quantum well layers located between the bottom barrier layer and the top barrier layer, and an intermediate barrier layer disposed between the respective InGaN quantum well layers, characterized by, A first strain reduction layer immediately adjacent to and disposed beneath the InGaN quantum well layer is also included, and a second strain reduction layer disposed immediately adjacent to and above the InGaN quantum well layer, The first strain reduction layer and the second strain reduction layer are InGaN layers having an In component of less than 10%, and the intermediate barrier layer comprises a strain compensation layer having a lattice constant smaller than that of the bottom barrier layer and the top barrier layer. The invention provides a novel active region structure for improving the efficiency of a GaN-based blue-green LED and a laser.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com