Process and apparatus for producing glass plate

一种制造方法、制造设备的技术,应用在玻璃制造设备、玻璃的成型、玻璃的成型等方向,能够解决损伤、退火炉气氛温度易变动、对流防止板无法进行充分隔断等问题,达到抑制低温空气流的上升、减少内部应变的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

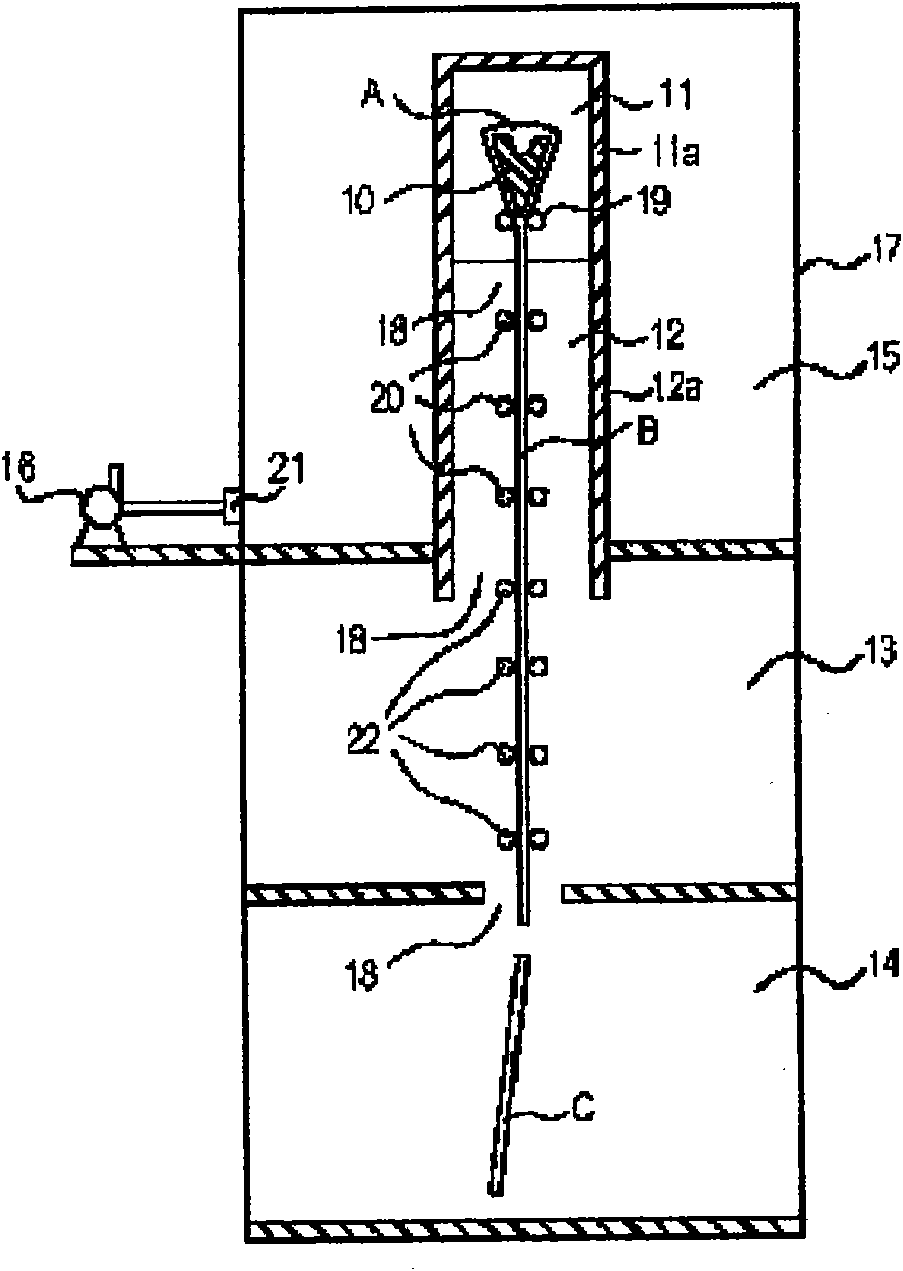

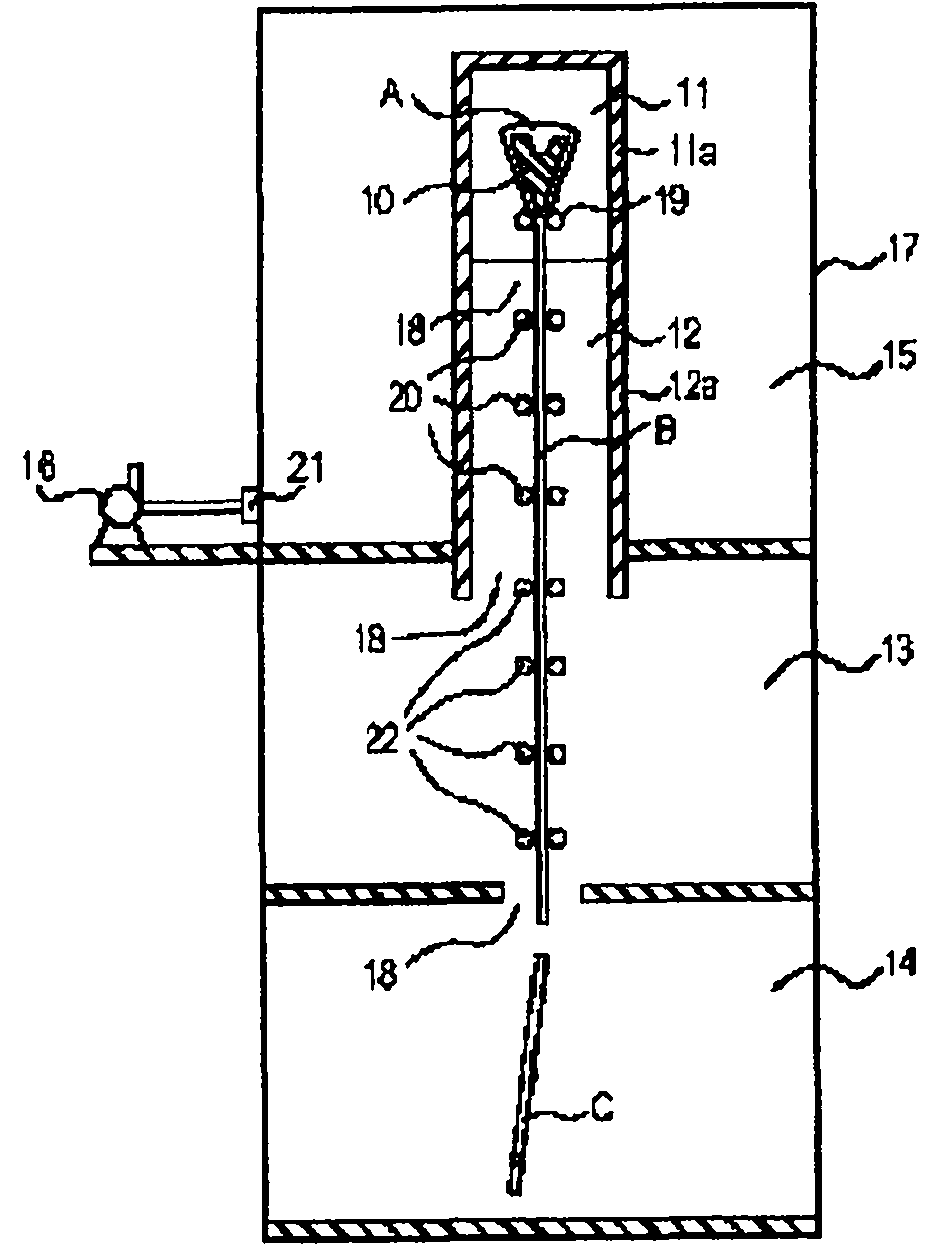

[0068] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0069] figure 1 It is a schematic front view showing the manufacturing facility of the glass plate of this invention. This manufacturing facility is for manufacturing a glass plate (glass substrate) for a liquid crystal display by an overflow down-draw method, and is provided in order from above: Glass A overflows from the top and is fused at its lower end, thereby forming a glass ribbon B; an annealing furnace 12 for removing internal strain while annealing the glass ribbon B; The ribbon B is fully cooled; the cutting chamber 14 cuts the cooled glass ribbon B into a prescribed size. Furthermore, the molding furnace 11 and the annealing furnace 12 are surrounded by a molding chamber 15 , and a blower 16 is provided outside the molding chamber 15 . The cooling chamber 13, cutting chamber 14, and forming chamber 15 adjacent to each other in the vertical direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com