Plastic moulding article, moulding method and metal mould for the moulding thereof

A technology for molded products and plastics, applied in the field of plastic molded products and their forming, can solve problems such as poor shape accuracy, deformation of molded products, increase birefringence, etc., to improve shape accuracy and optical accuracy, and ease resin internal pressure or internal strain , The effect of simplifying the metal mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments of the present invention will be described below with reference to the accompanying drawings.

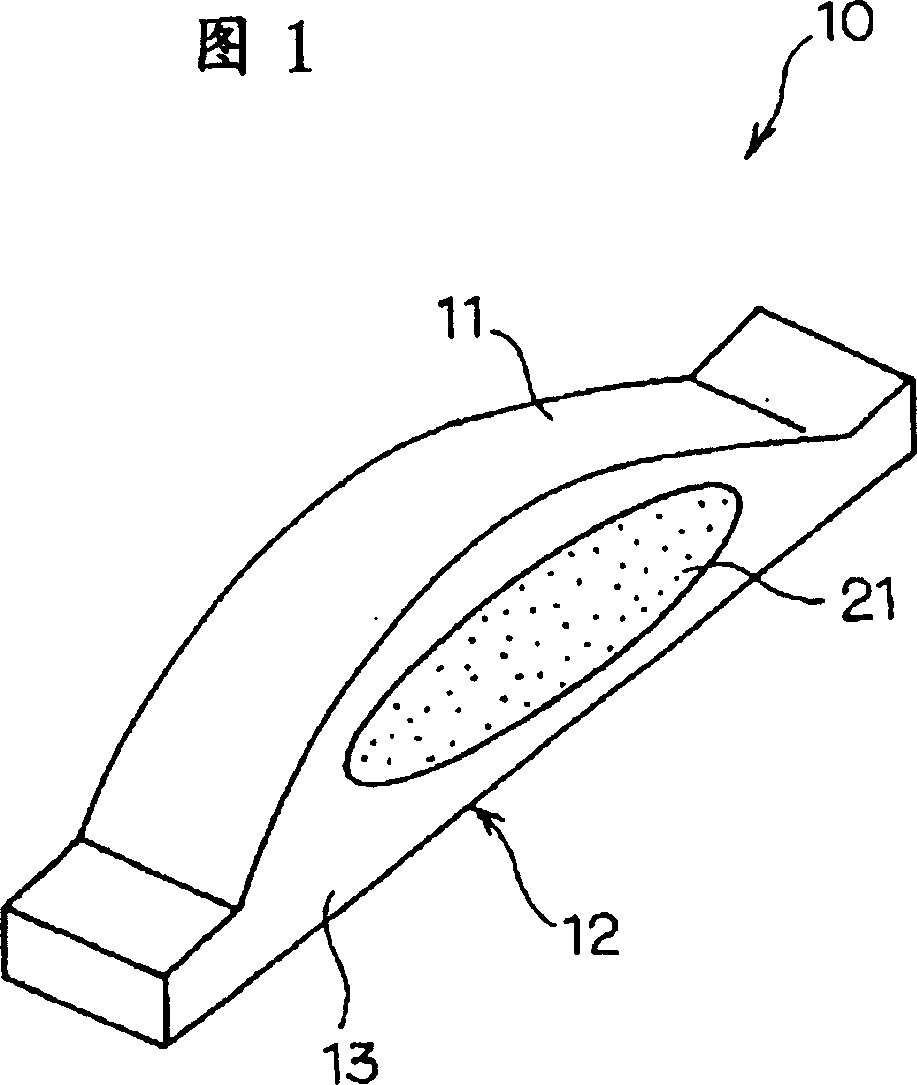

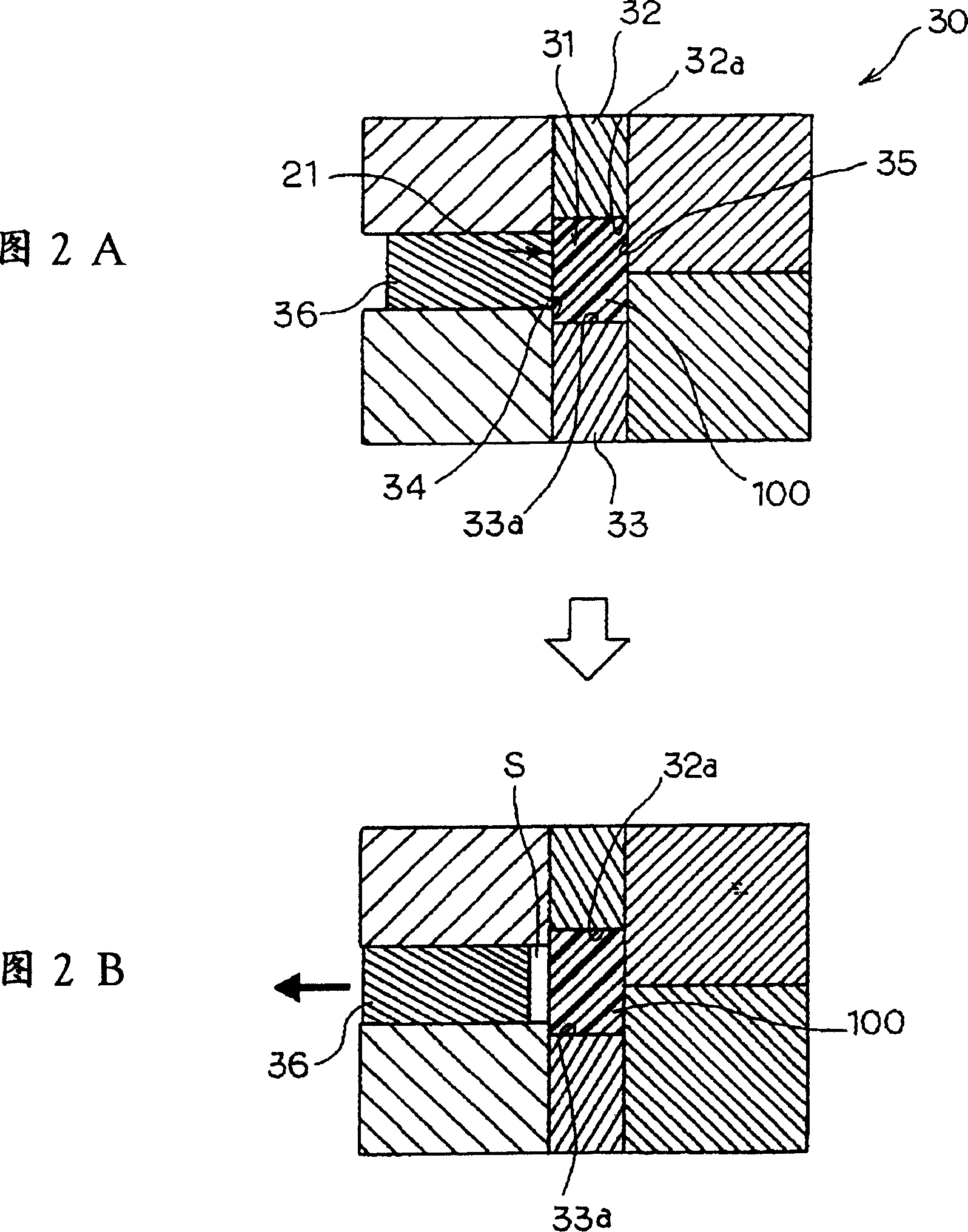

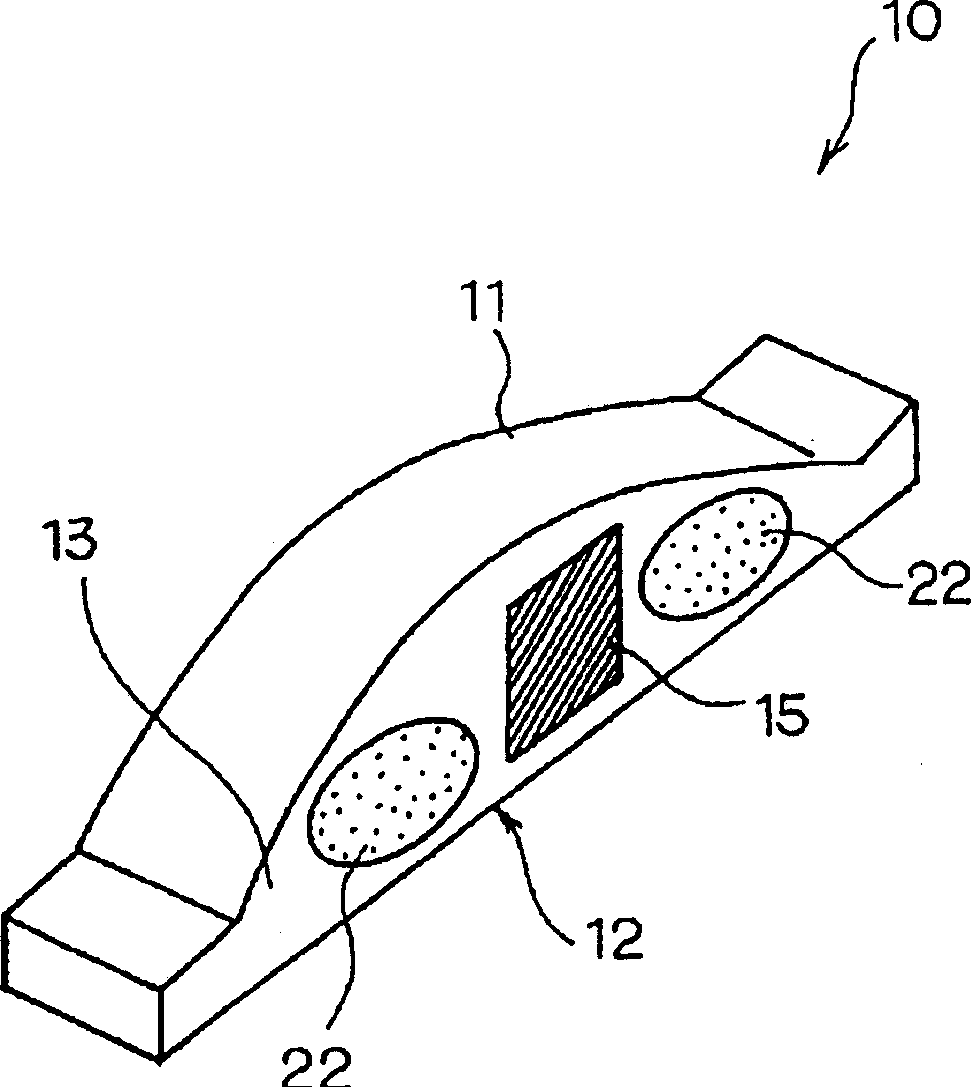

[0075] 1 and 2 show a first embodiment of the present invention, FIG. 1 is a perspective view of a plastic molded product according to the first embodiment, and FIG. 2 is a longitudinal sectional view of an injection molding metal mold.

[0076] In FIG. 1, 10 is a plastic lens (optical element), which is in the shape of a wall with unequal thickness. The plastic lens 10 includes a curved optical mirror surface (replication surface) 11, a mirror surface 12, and a side surface (non-replicating surface) located between the mirror surfaces 11 and 12. Copying surface) 13, the center of the above-mentioned optical mirror surface 11 is formed with a thick wall, the mirror surface 12 is opposite to the mirror surface 11, and is formed into a flat surface, using the molding metal mold 30 shown in FIG. An incomplete replica 21 of a concave or convex shape is formed.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com