Moving head dough press

a technology of moving head and dough press, which is applied in the field of moving head dough press, can solve the problems of large and heavy platen press with sufficient strength for pressing a plurality of dough balls into flat tortilla shapes, serious injuries, and hazards in the work place, and achieve the effect of substantial power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The inventions disclosed herein have applicability to presses used in conjunction with continuously moving conveyor systems. However, an understanding of the inventions disclosed herein is facilitated with the following description of the application of the principles of the present inventions to dough pressing, and in particular, pressing dough pieces into tortillas.

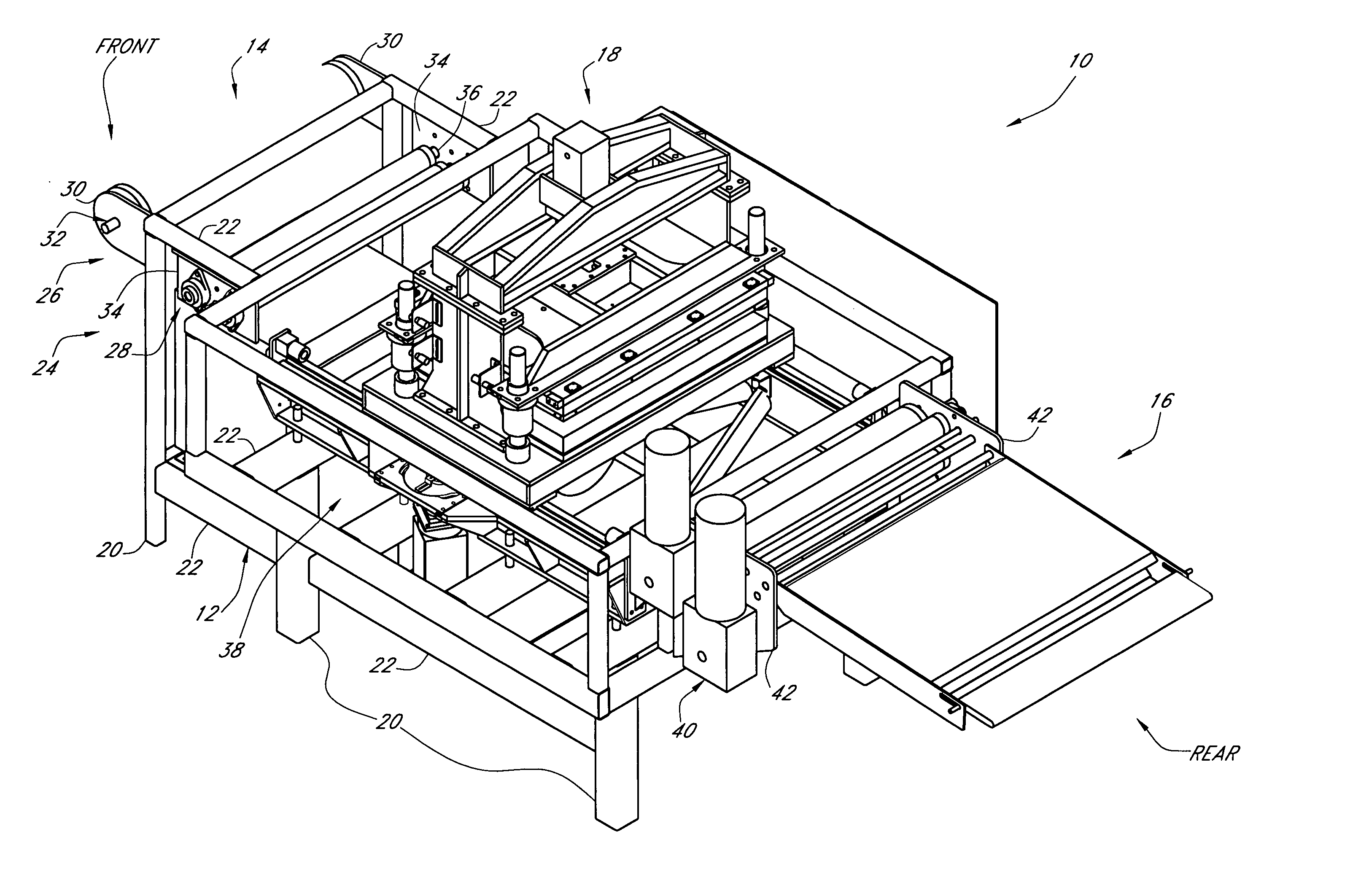

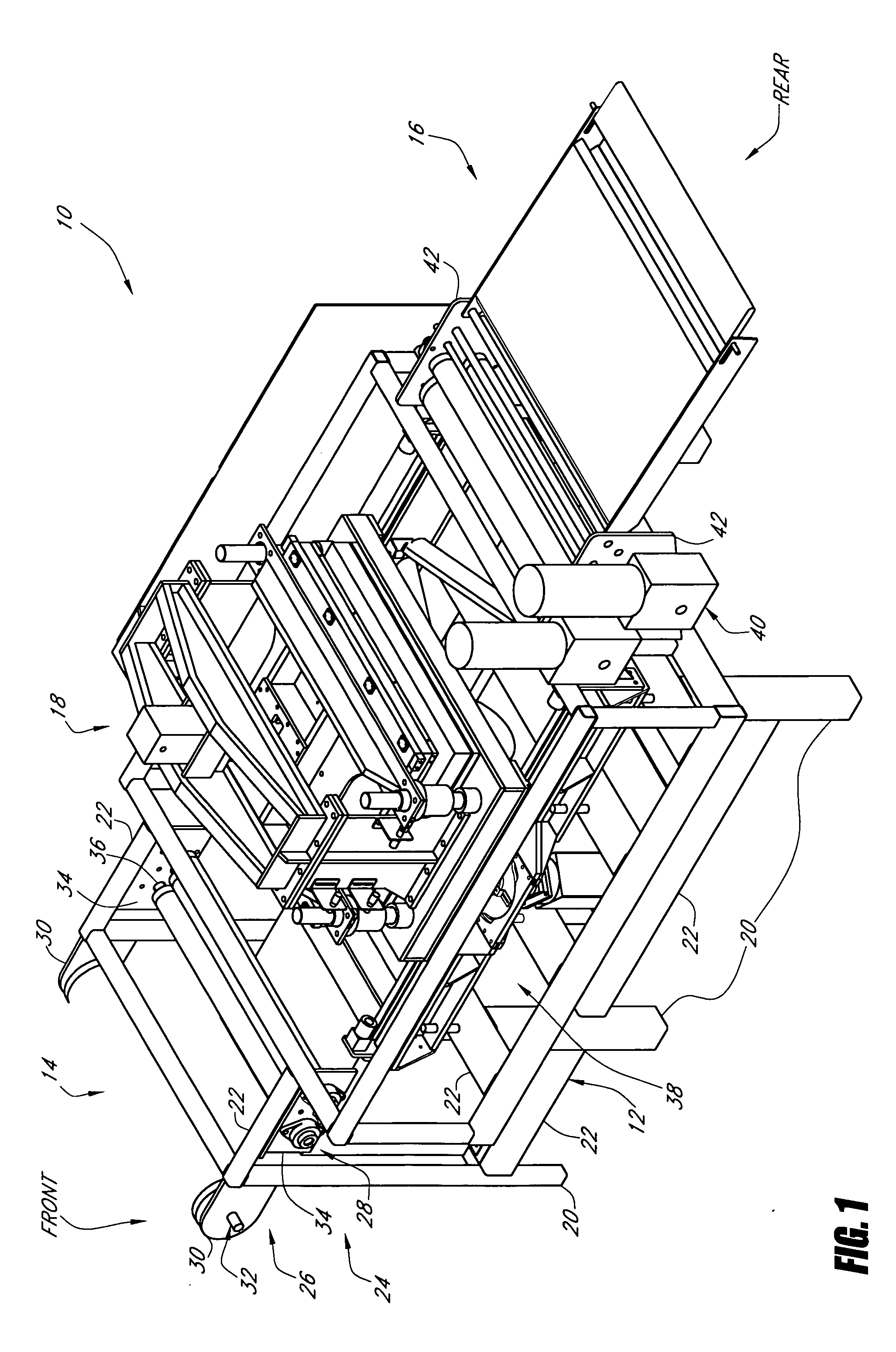

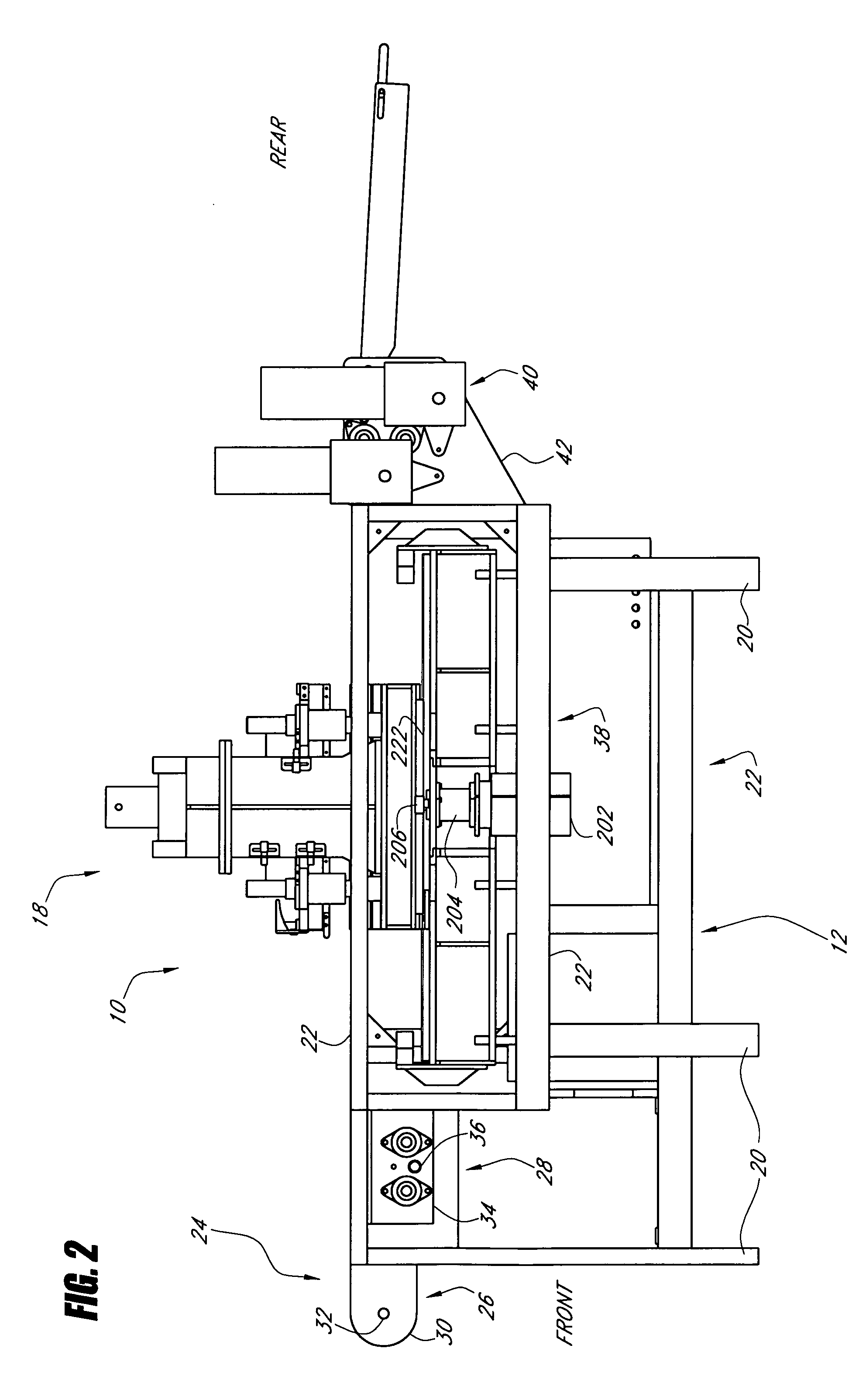

[0040] With initial reference to FIGS. 1-5, a reciprocating press system 10 includes a support frame 12, a feed belt drive system 14, a discharge belt drive system 16, and a reciprocating press assembly 18. In operation, pre-formed dough balls are fed to the feed belt system 14 in a timed fashion, such that rows of dough balls are released onto a conveyor belt of the feed belt system 14. The belt moves the dough pieces between platens of the reciprocating press assembly 18. The press assembly 18 reciprocates back and forth in directions parallel to the direction along which the belt moves. The press assembly 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com