Locking mechanism for unfolding and folding of undercarriage of unmanned aerial vehicle

A locking mechanism and landing gear technology, applied in the chassis and other directions, can solve the problems of complex structure, high cost, low stability, etc., and achieve the effect of reliable connection, high promotion value, and smooth retraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

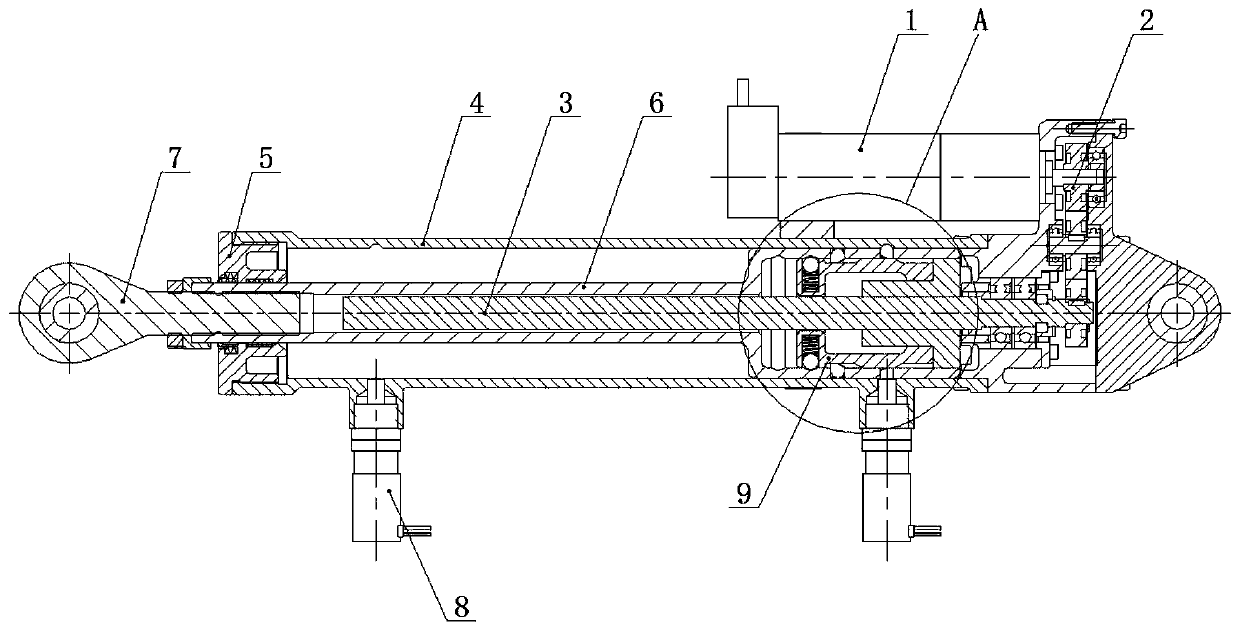

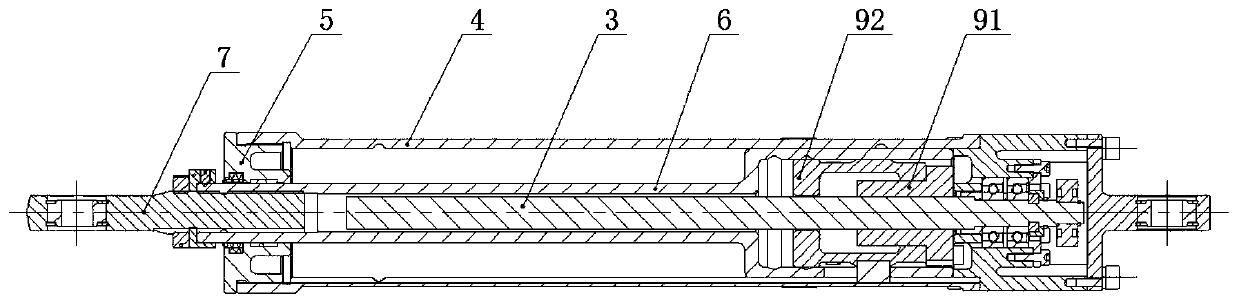

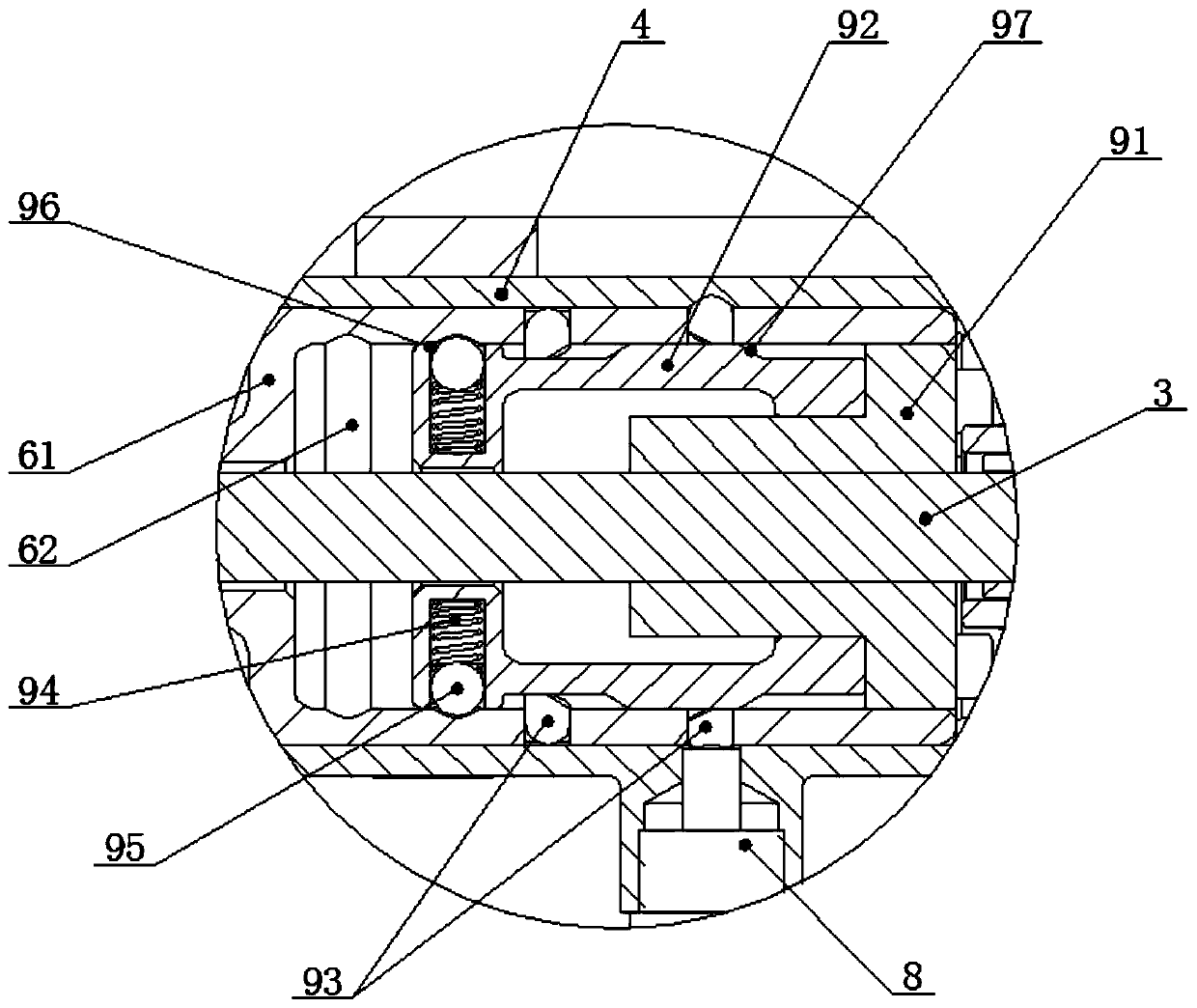

[0015] Such as Figure 1 ~ Figure 3 As shown, the UAV landing gear retractable locking mechanism provided in this embodiment includes a cylinder 4, a piston rod 6 slidably arranged in the cylinder 4, and a power assembly that drives the movement of the piston rod 6. The piston rod 6 A through hole is opened along its axis, one end of the piston rod 6 passes through the cylinder 4 and a guide sleeve 5 is arranged between the cylinder 4, and a rod head 7 for connecting other components is fixed in the through hole at the end of the piston rod 6, The other end of the piston rod 6 is formed with a sliding sleeve 61 that slides with the inner wall of the cylinder barrel 4. The outer diameter of the sliding sleeve 61 is 1.5 to 2.5 times, preferably 2 times, the outer diameter of the piston rod 6. The inner diameter of the sliding sleeve 61 is The diameter of the through hole of the piston rod 6 is 1.5 to 2.5 times, preferably 2 times, so as to ensure a higher connection support stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com