Capsule endoscope

A capsule endoscope and PCB board technology, which is applied in the field of medical devices, can solve the problems such as cracking or breaking of the FPC flexible cable 3, the capsule endoscope cannot work normally, and the expected requirements cannot be met, so as to avoid cracking or breaking. Break, ensure performance and service life, cleverly designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

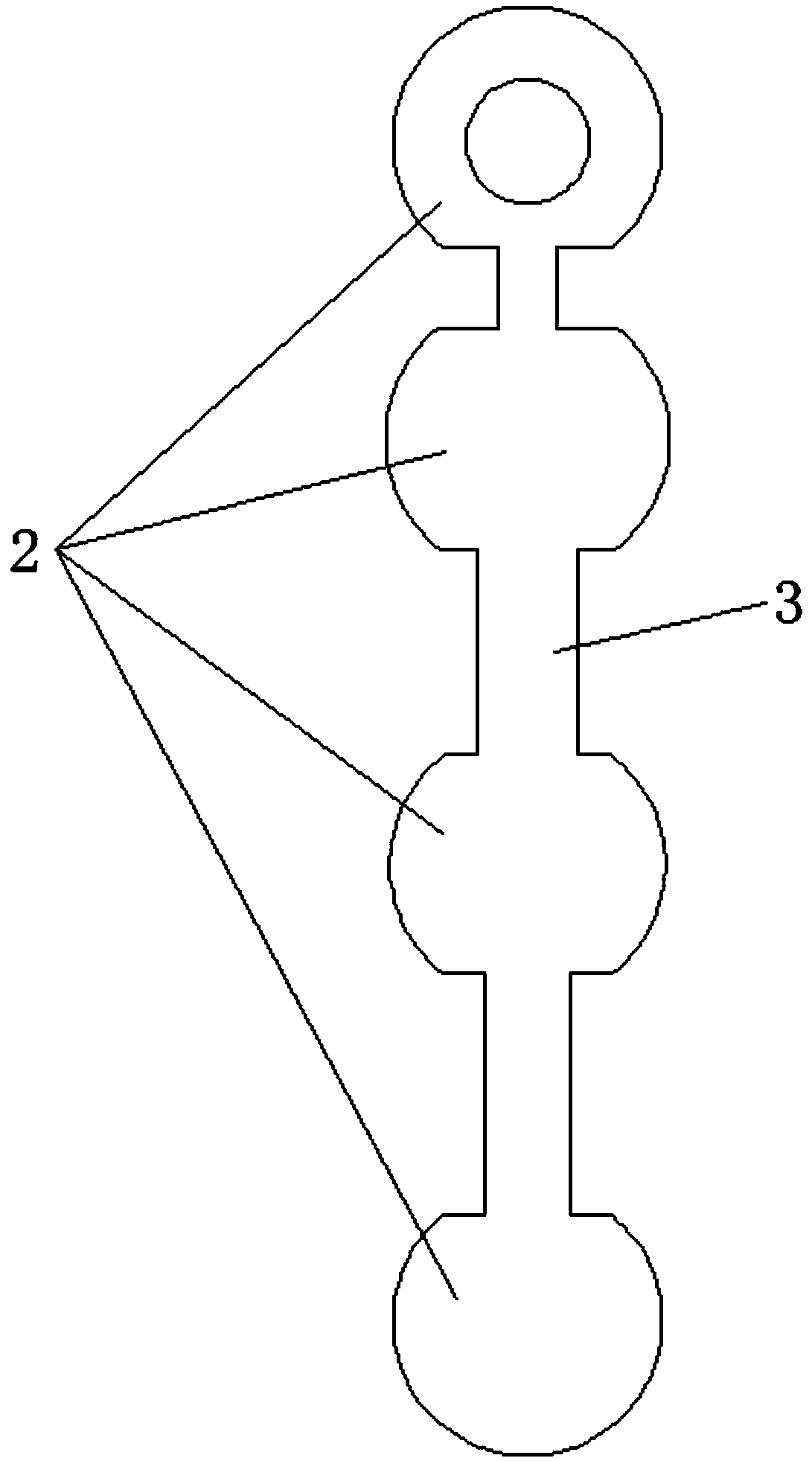

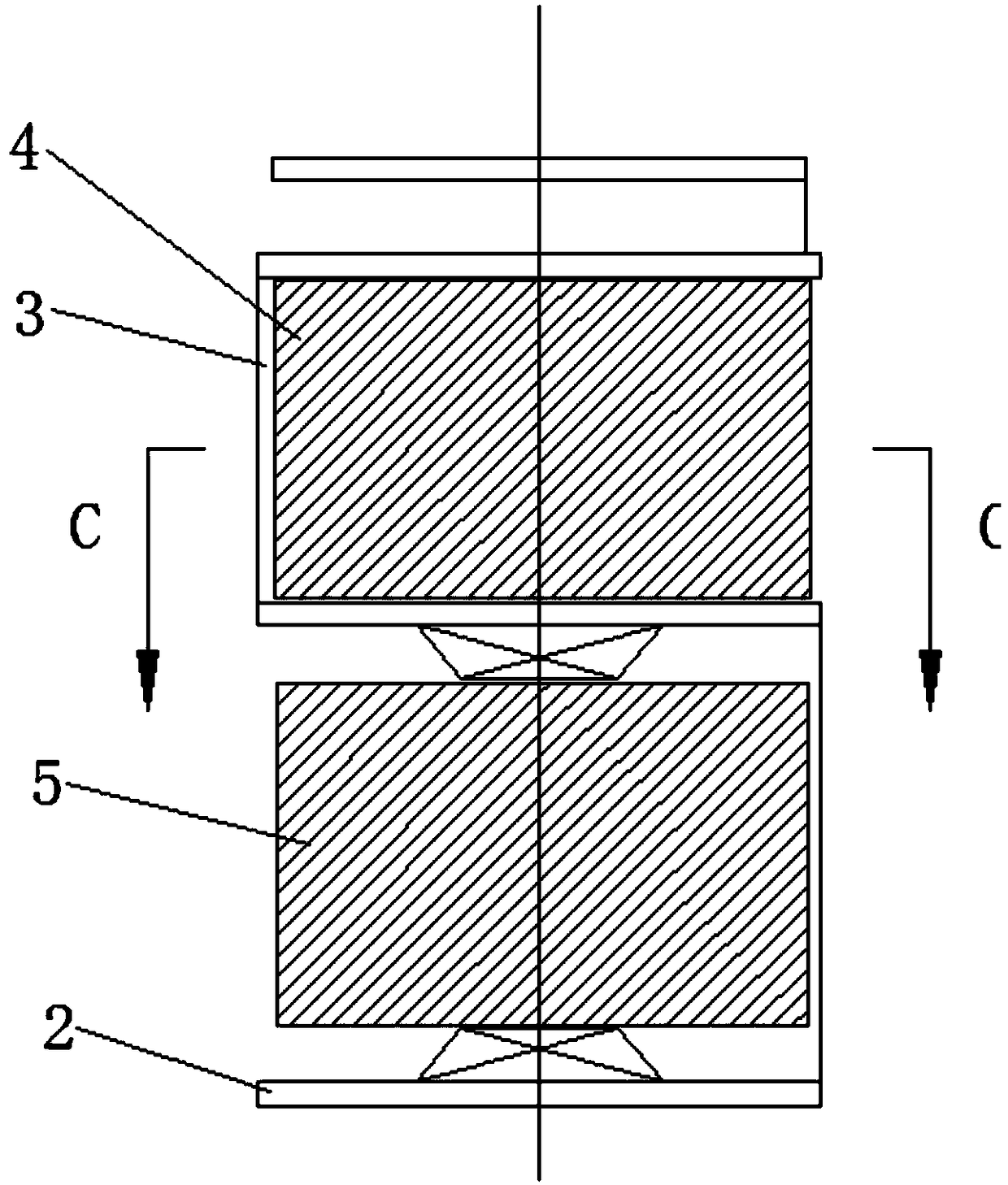

[0027] Such as Figure 1-Figure 7 As shown, the present invention is composed of a housing 1, a PCB board 2, an FPC flexible cable 3, a magnet 4, a battery 5, an optical front cover 7, a spring 8, a camera (not shown in the figure) and the like. Wherein, the number of PCB boards 2 is determined according to actual needs, and only four PCB boards 2 are used for illustration in this embodiment. Two adjacent PCB boards 2 are connected by FPC flexible cable 3, and after folding, a multi-layer PCB board layer structure parallel to each other is formed. The PCB board layer structure can be "S" shape, or "bow" shape or other suitable shapes.

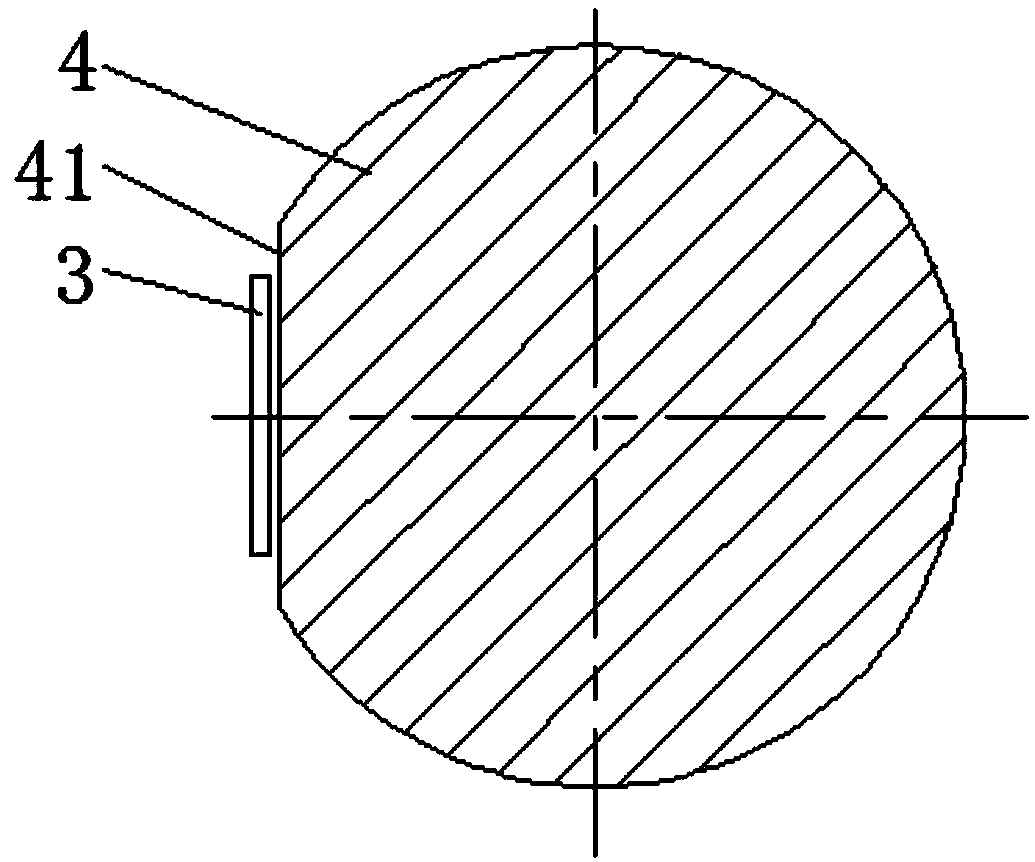

[0028] Such as Figure 2-Figure 6 As shown, the layered structure of the PCB board is located in the closed inner cavity surrounded by the housing 1 and the optical front cover 7, and the magnet 4 and the battery 5 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com