Method For Manufacturing Optical Elements

A technology of optical elements and manufacturing methods, applied in optical elements, optical elements, optics, etc., can solve the problems of reduced productivity, complicated procedures, and inability to obtain uniformity of ink layers, and achieve cost simplification, low cost, and prevention of color mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

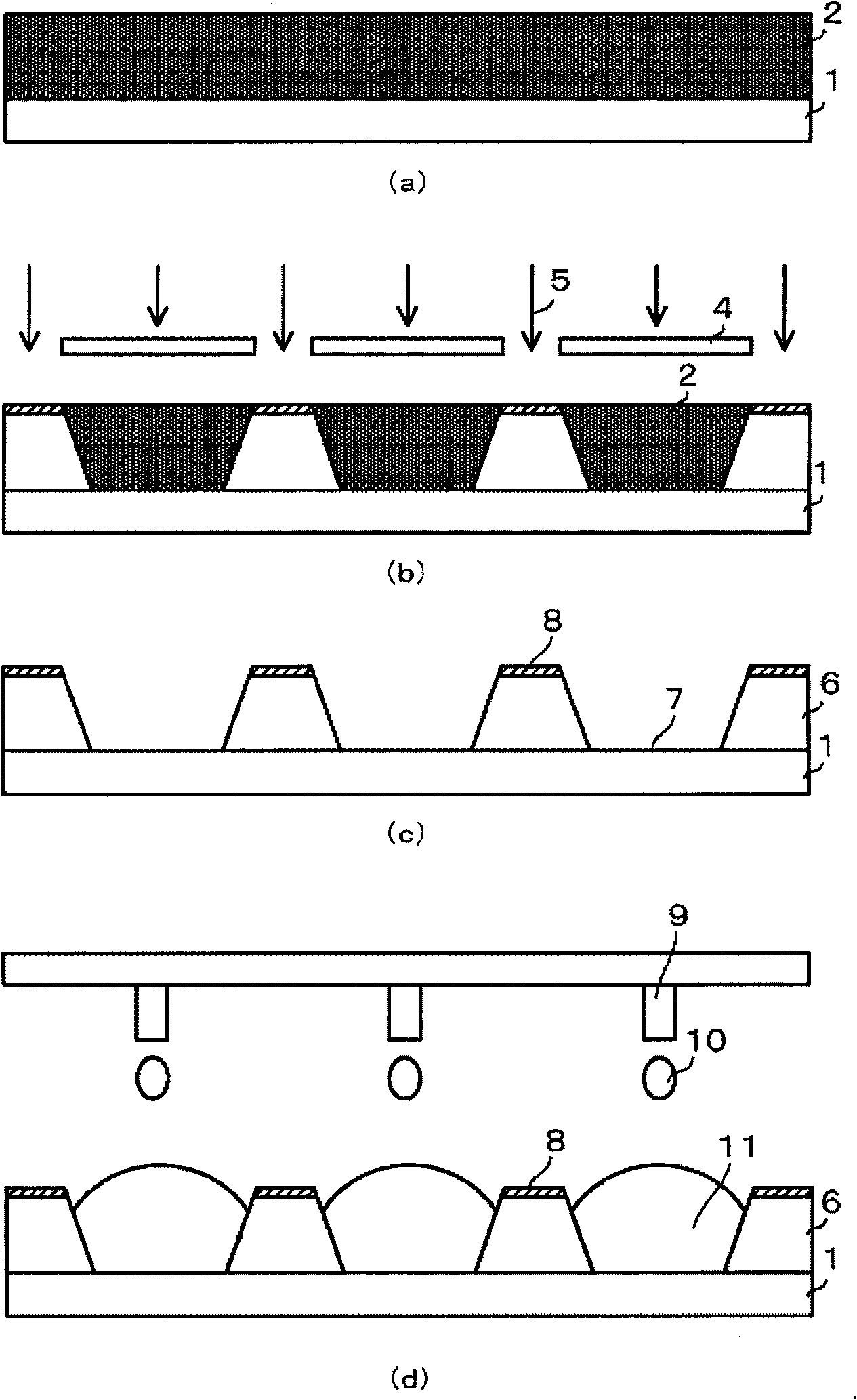

Method used

Image

Examples

Embodiment 1

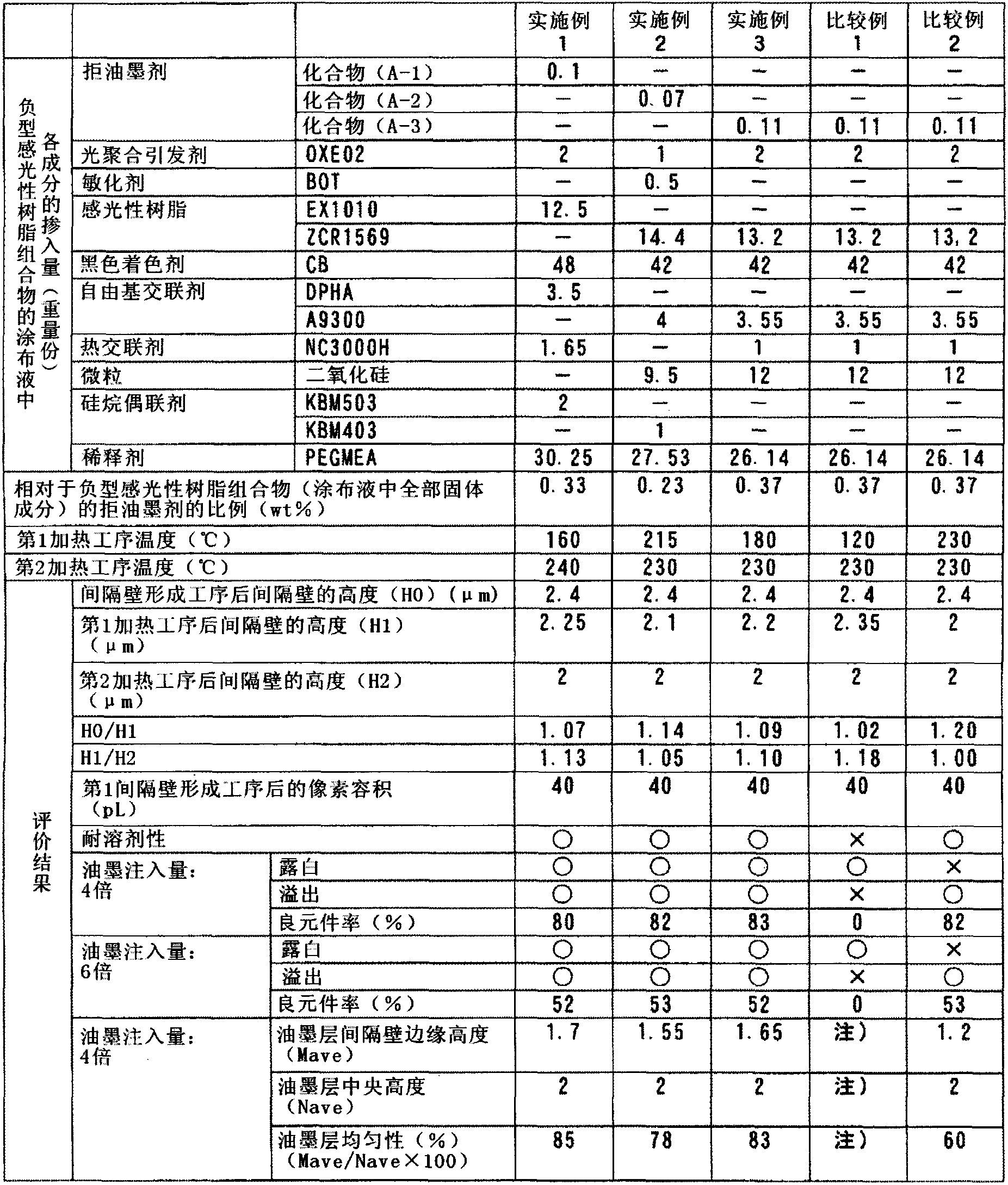

[0253] (Preparation of coating liquid for negative photosensitive resin composition)

[0254] The compound (A-1) (0.10 parts) as an ink repellent agent obtained above, OXE02 (2.0 parts) as a photopolymerization initiator, EX1010 (12.5 parts) as a solution of a photosensitive resin, and a black coloring agent CB (48.0 parts) of the dispersion, DPHA (3.5 parts) as a free radical crosslinking agent, NC3000H (1.65 parts) as a thermal crosslinking agent / epoxy resin, KBM503 (2.0 parts) as a silane coupling agent, and PGMEA (30.25 parts) as a solvent was mixed to obtain a coating liquid of a negative photosensitive resin composition. The content of the ink repellent relative to the total solids in the coating liquid of the negative photosensitive resin composition, in other words, the content of the ink repellent in the negative photosensitive resin composition, that is, the content of the compound (A-1) The content is 0.33%.

[0255] Next, using the coating liquid of the negative photo...

Embodiment 2、3

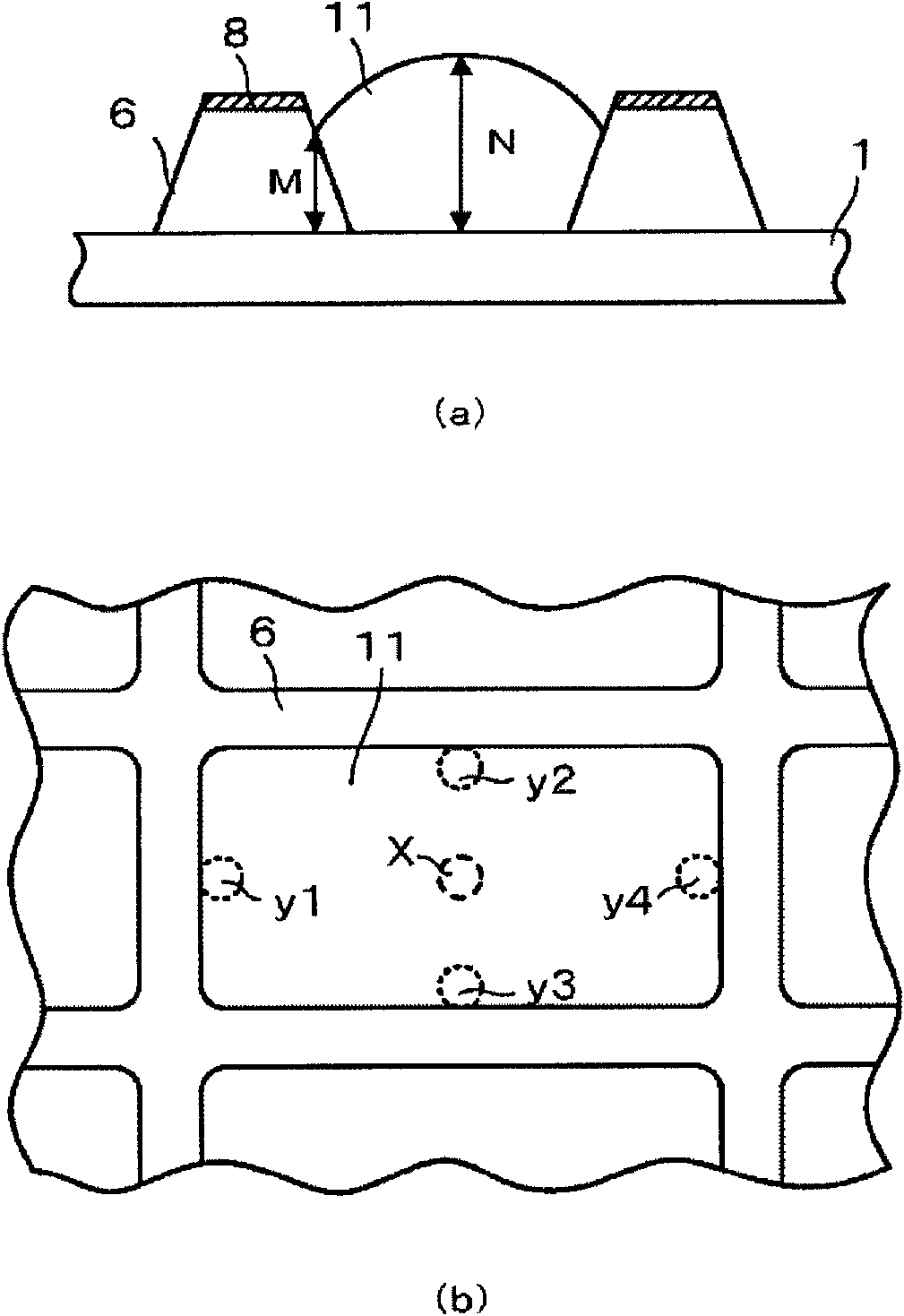

[0270] The mixing amount of each component contained in the negative photosensitive resin composition coating liquid was changed to the amount shown in Table 1, and the first heating step (2) and / or the second heating step (4) were The heating temperature was changed to the temperature shown in Table 1 within the preferred range of the present invention. Except for this, the same operation as in Example 1 was carried out to obtain a test optical element, which has a function of dividing the upper surface of the glass substrate into multiple units. A partition wall composed of a cured resin and a pixel composed of a plurality of ink layers formed in a region partitioned by the partition wall on the substrate.

Embodiment 4~7、 comparative example 3

[0274] Using the mixed negative photosensitive resin composition coating liquid shown in Table 2, partition walls were produced as follows. In addition, in each example, the values of H0, H1, and H2 and the volume of the opening are shown in Table 2.

[0275] (1) Partition wall formation process

[0276] In the same manner as in Example 1, a coating film of a negative photosensitive resin composition having a film thickness of 2.4 μm was formed on the glass substrate AN100. Using an ultra-high pressure mercury lamp to irradiate the coating film of the negative photosensitive resin composition on the glass substrate obtained above through a mask, 30mW / cm based on i-line (365nm) 2 Light for 1.7 seconds at 50mJ / cm 2 Exposure at the exposure level. In addition, the mask is a grid pattern with a light-shielding part of 150 μm×300 μm and a light-transmitting part of 20 μm, and the volume of the area partitioned by the partition wall formed on the glass substrate, that is, the volume o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com