Polyamide composite material for safety device of run-flat tire inner support body and preparation method thereof

A technology for safety devices and inner supports, applied in the field of polyamide composite materials for inner support safety devices of run-flat tires and its preparation, achieving the effect that the preparation method is simple and easy, and suitable for large-scale production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

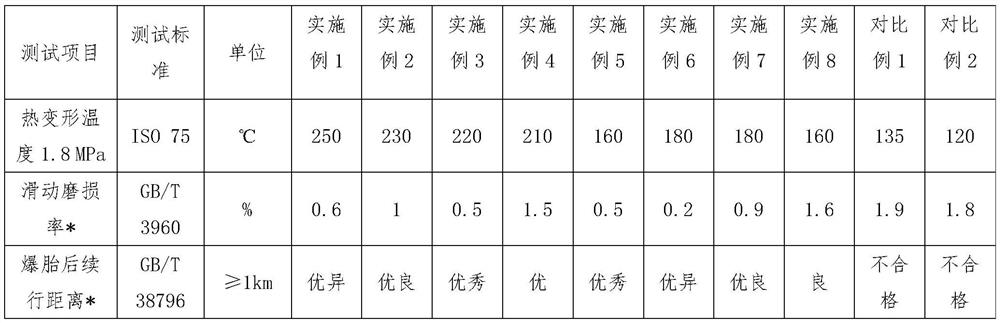

Examples

Embodiment 1-8

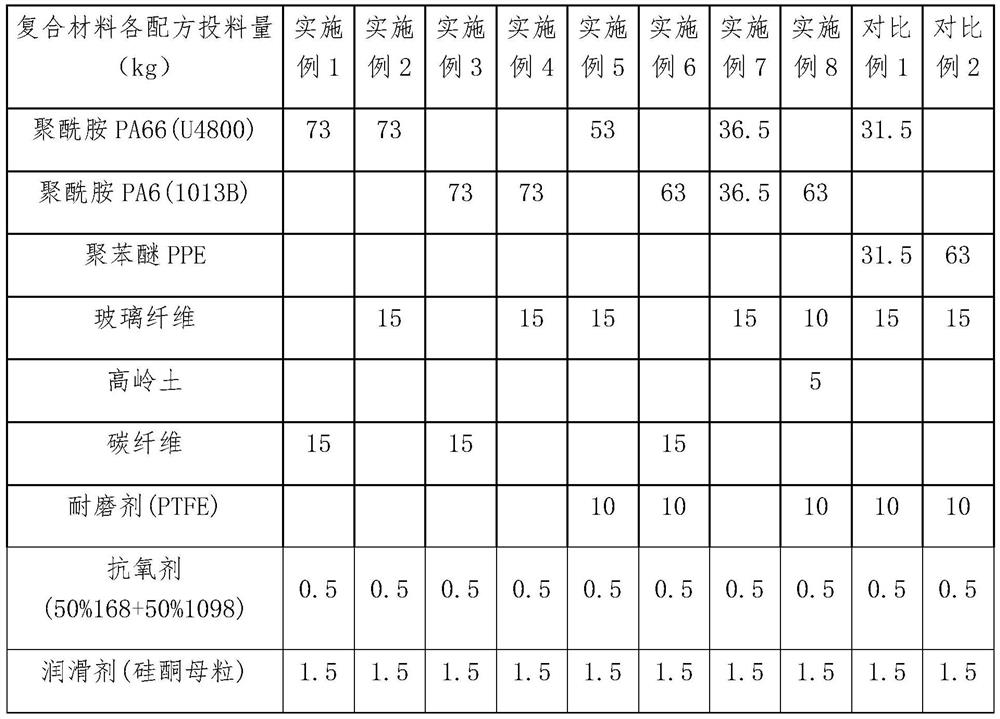

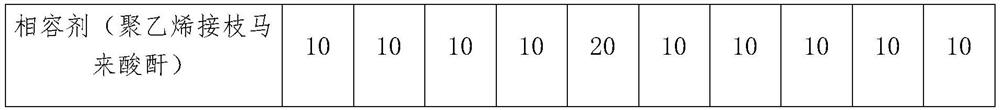

[0032] Example 1-8: Preparation of Polyamide Composite Material for Safety Device of Inner Support Body of Run-flat Tire of the Present Invention

[0033] S1, material preparation: take each raw material component according to the formula in Table 1;

[0034] S2. Premix: Mix polyamide resin, antioxidant, wear-resistant agent, mineral, lubricant, and compatibilizer in a low-speed mixer to obtain a premix; main feed from the prepared plastic extruder blanking;

[0035] S3. Side material of extruder: lower glass fiber or carbon fiber;

[0036] S4. Melt extrusion: the premixed material + side material is melted and extruded by a twin-screw extruder at 235-255 ° C, and after melt extrusion, it is pelletized by hot ring cutting to obtain polyamide, a safety device for the inner support of the explosion-proof tire composite materials;

[0037] S5. Dry the prepared polyamide composite material for the inner support body safety device of a run-flat tire at 110° C. for 5 hours;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com