Patents

Literature

33results about How to "Does not cause environmental problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

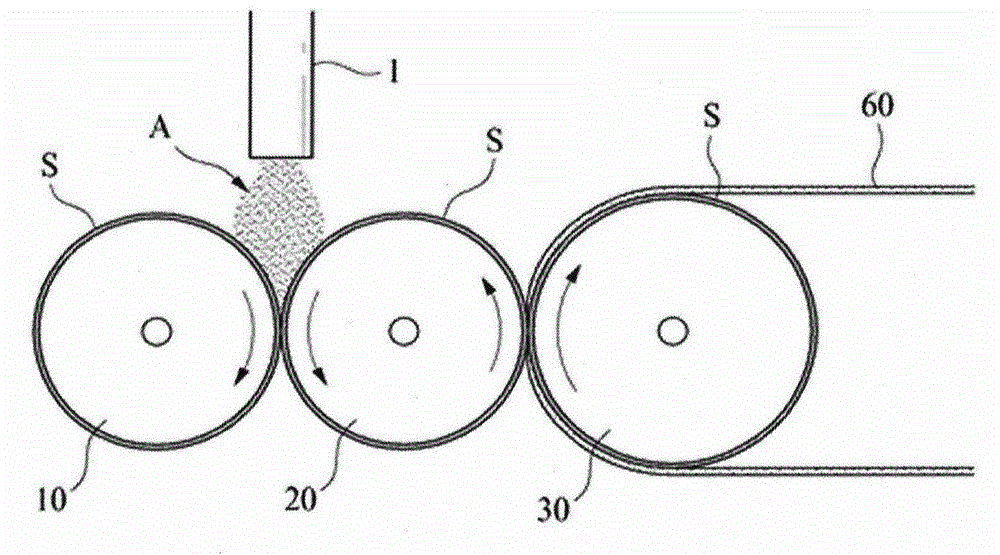

Method for preparation of coated release-controlled granular fertilizer

InactiveCN1884227ASimple equipmentReduce energy consumptionFertiliser formsFertilizer mixturesFertilizerChemical reaction

The invention discloses a preparing method of integument controlled release grain fertilizer, which comprises the following steps: blending 2-4 kinds of organic composition to form mixing solution; adding filming activist and filming accelerant to form film mixing liquid; spraying 1-20% film mixing liquid on the grain fertilizer surface evenly under -20-50 deg.c; forming integument on the surface of grain surface after 2-120 min.

Owner:SOUTH CHINA AGRI UNIV

Anti-corrosion paint for steel with polyaniline

InactiveCN1639278AImprove protectionImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSurface layerSolvent

The invention discloses an anticorrosion coating which uses polyaniline as an anticorrosion pigment for preventing corrosion of steel materials. The anti-corrosion coating has excellent and long-lasting anti-corrosion effect, high durability and outstanding coating characteristics for controlling the anti-corrosion effect, and does not use metals that cause environmental pollution as anti-corrosion pigments. In particular, the top coat paint is used to enhance the protection and anti-corrosion effect of the primer coat paint in the anti-corrosion paint. The top coat paint includes 40-89wt% of matrix resin, 5-54wt% of coloring pigment, 1-50wt% of additives and 5-54wt% of mixed solvent, and the said bottom coat paint includes 3-49wt% The polyaniline, 40-86wt% matrix resin, 1-47wt% additive and 10-56wt% mixed solvent. The anti-corrosion paint has the advantages of maintaining excellent anti-corrosion effect for a long time without causing environmental problems.

Owner:朴进雨

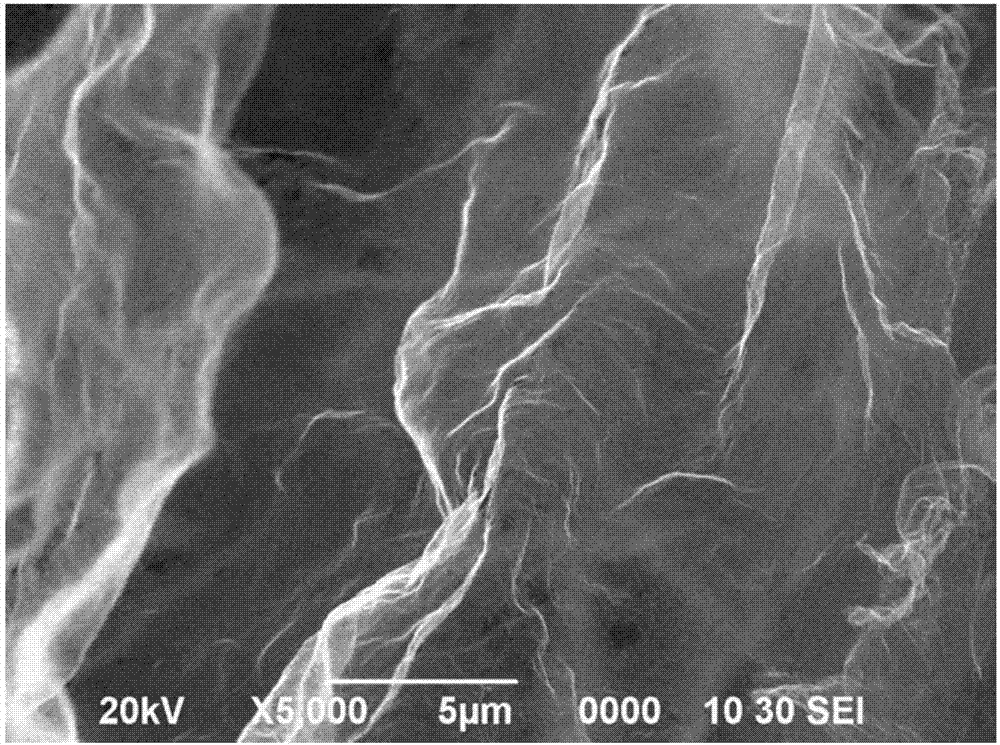

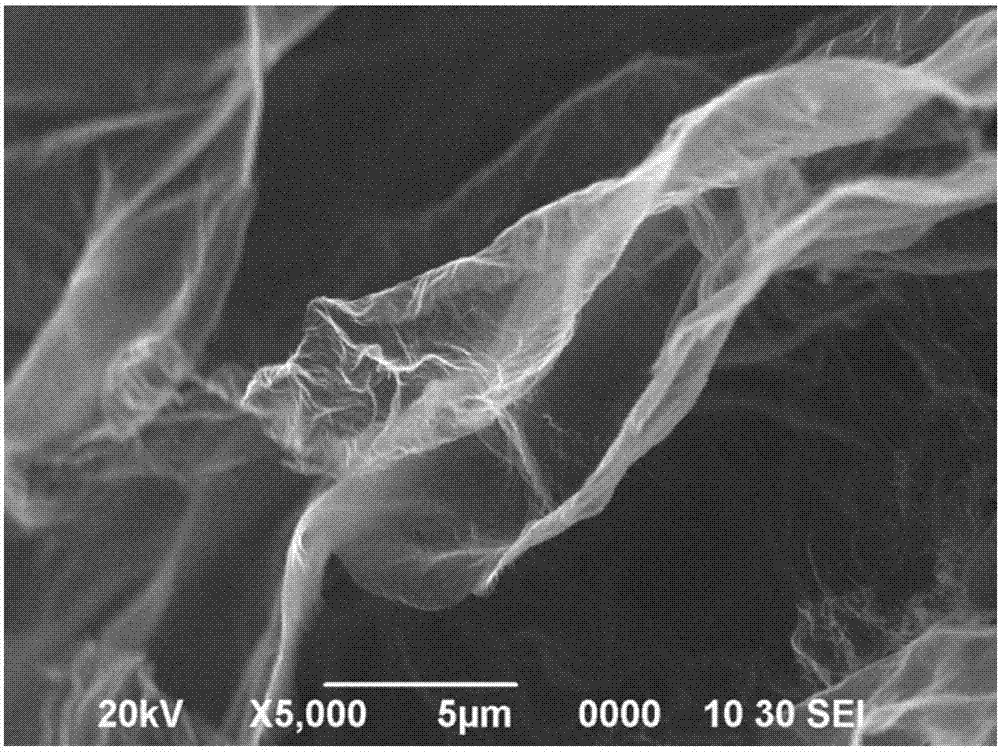

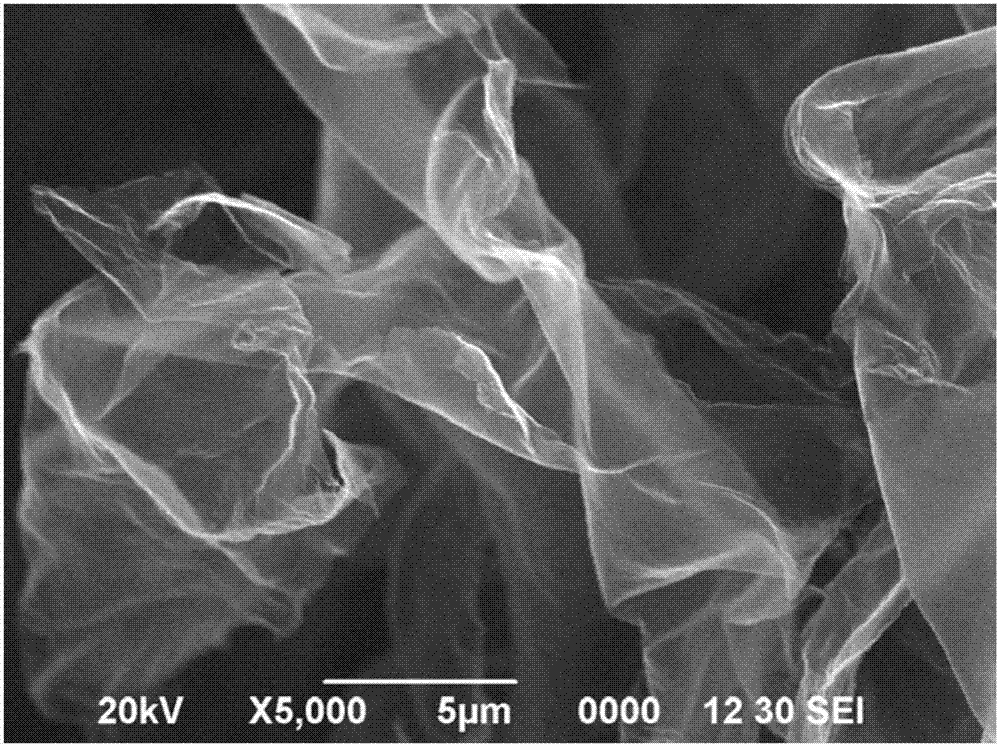

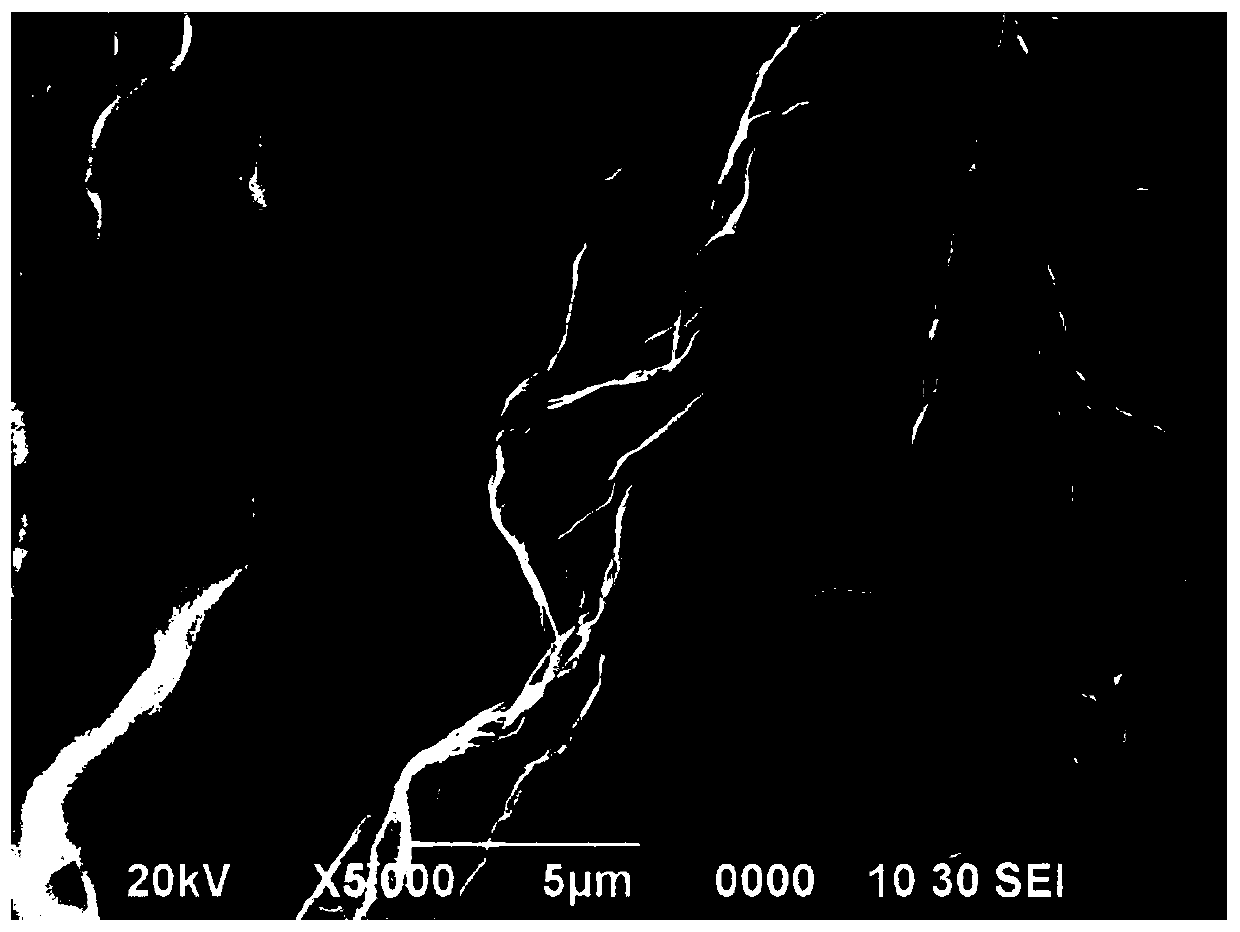

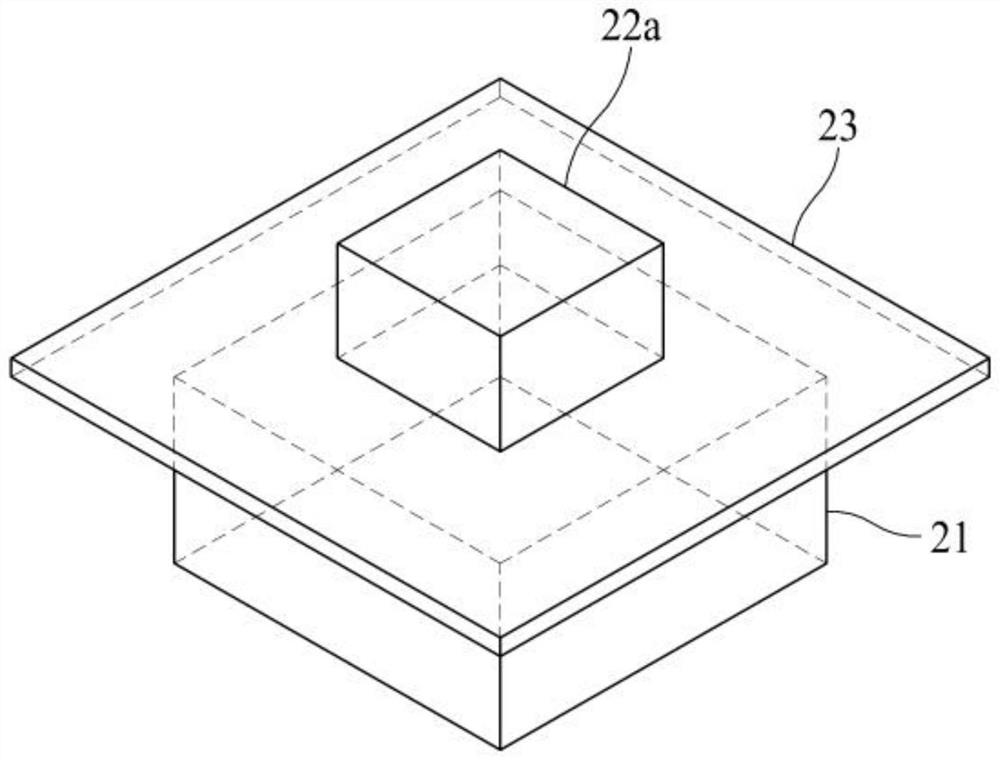

Preparation method of cellulose nanofiber/silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material

InactiveCN107331865AWide variety of sourcesLow costHybrid capacitor electrodesCell electrodesCelluloseFreeze-drying

The invention relates to a preparation method of a cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material and belongs to the technical field of carbon electrode materials. The preparation method of the cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material comprises steps as follows: a cellulose nanofiber suspension and a silk fibroin solution are mixed uniformly, and a compound suspension is obtained; the composite suspension is treated in hydrochloric acid steam for 1-12 h, and cellulose nanofiber / silk fibroin composite hydrogel is prepared; the cellulose nanofiber / silk fibroin composite hydrogel is frozen in liquid nitrogen for 5-60 DEG C and then freeze-dried, and composite aerogel is prepared; in the protective atmosphere, the composite aerogel is carbonized at 700-1,300 DEG C for 1-8 h and activated, and the cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material is obtained. The cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material prepared with the method has the characteristics of being large, good in flexibility, porous and the like and also has the microstructure morphology of 2D graphene morphology.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

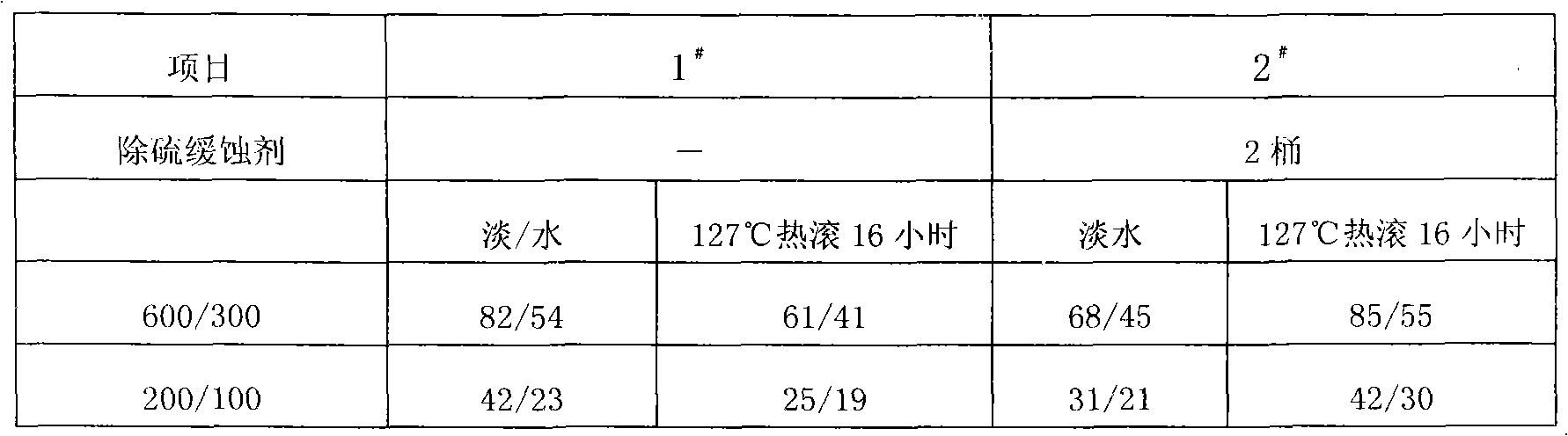

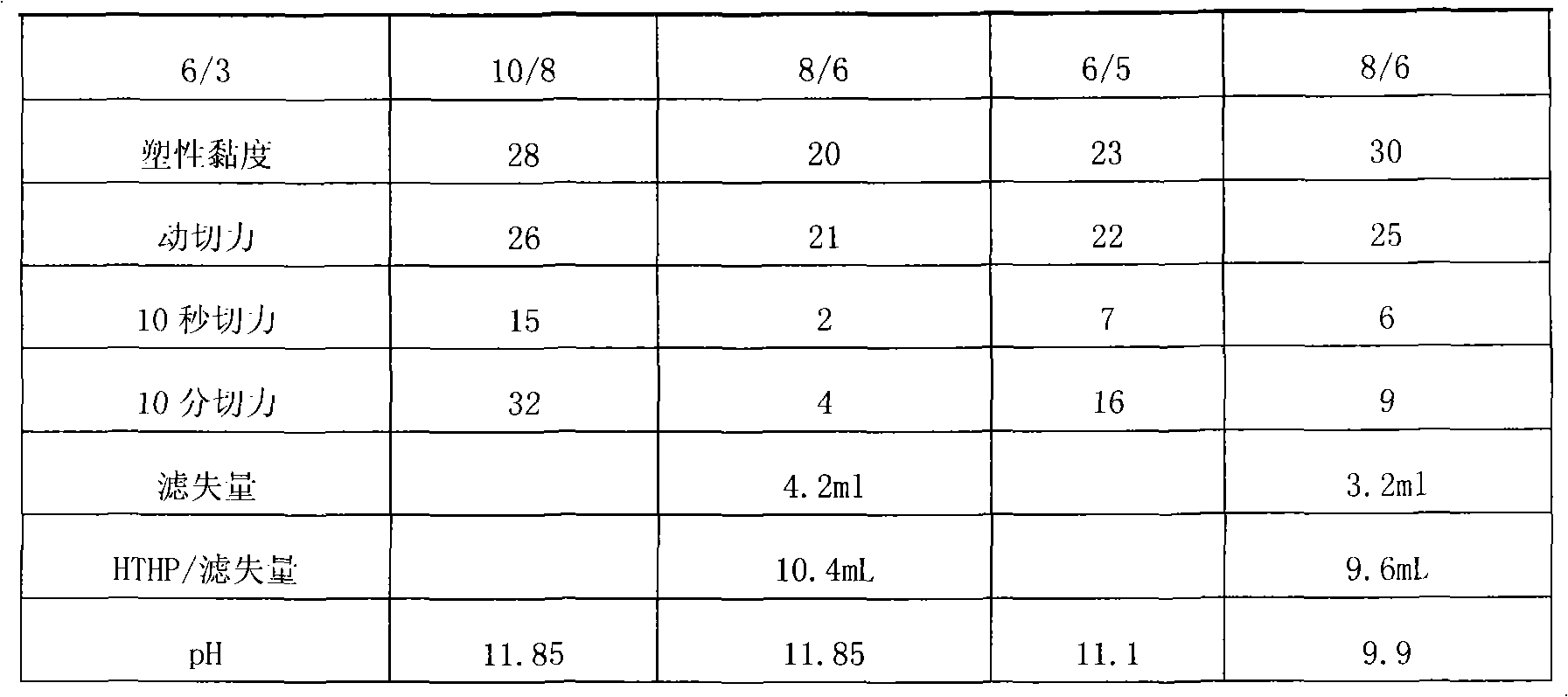

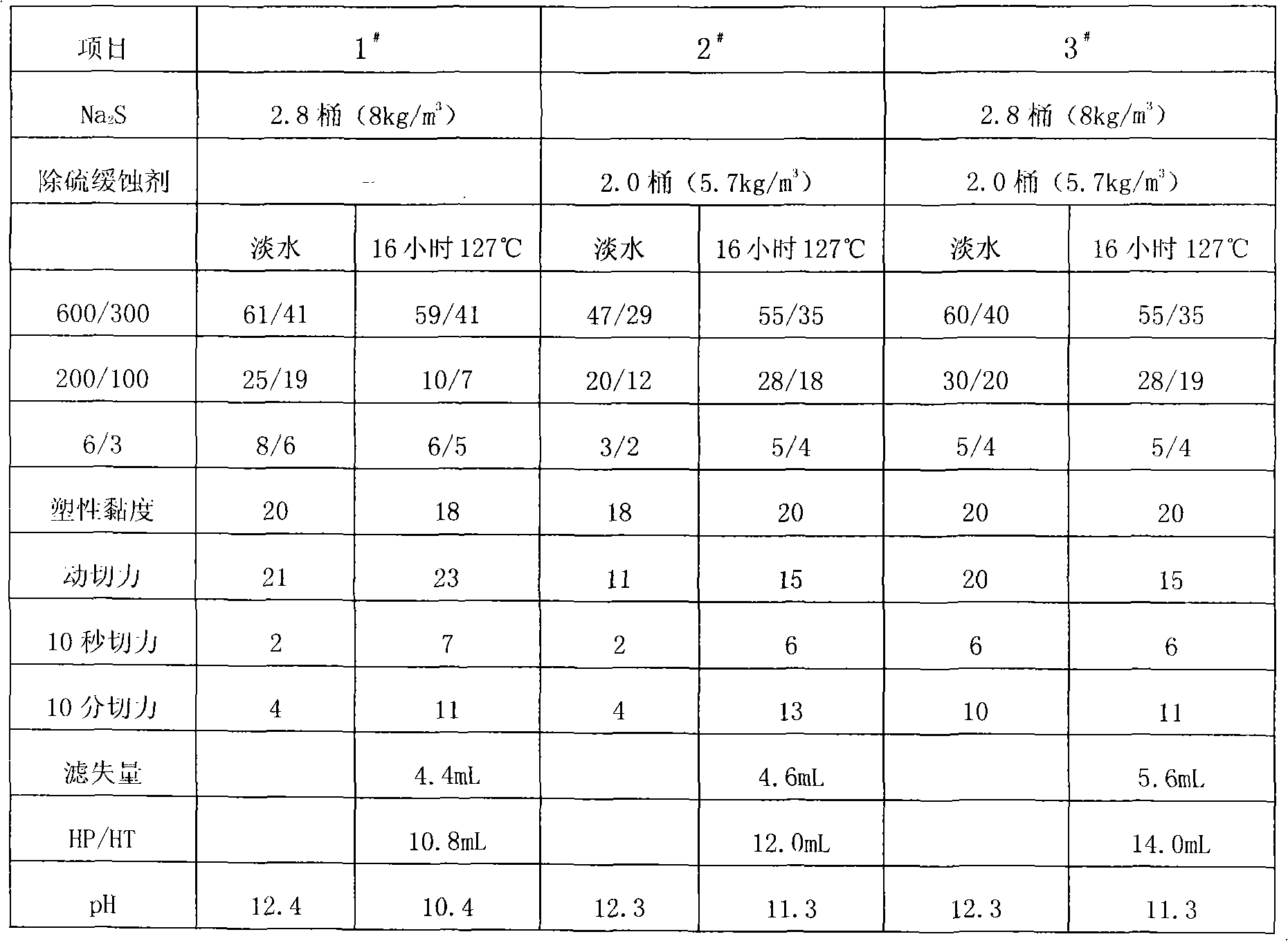

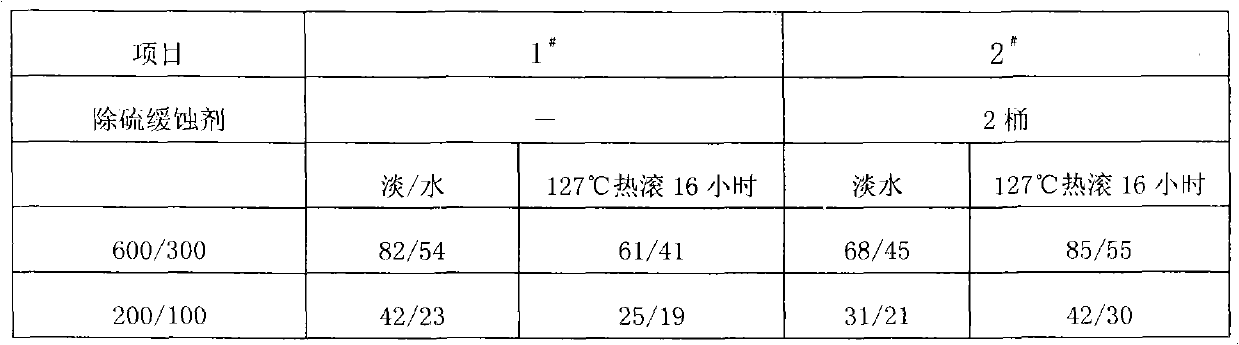

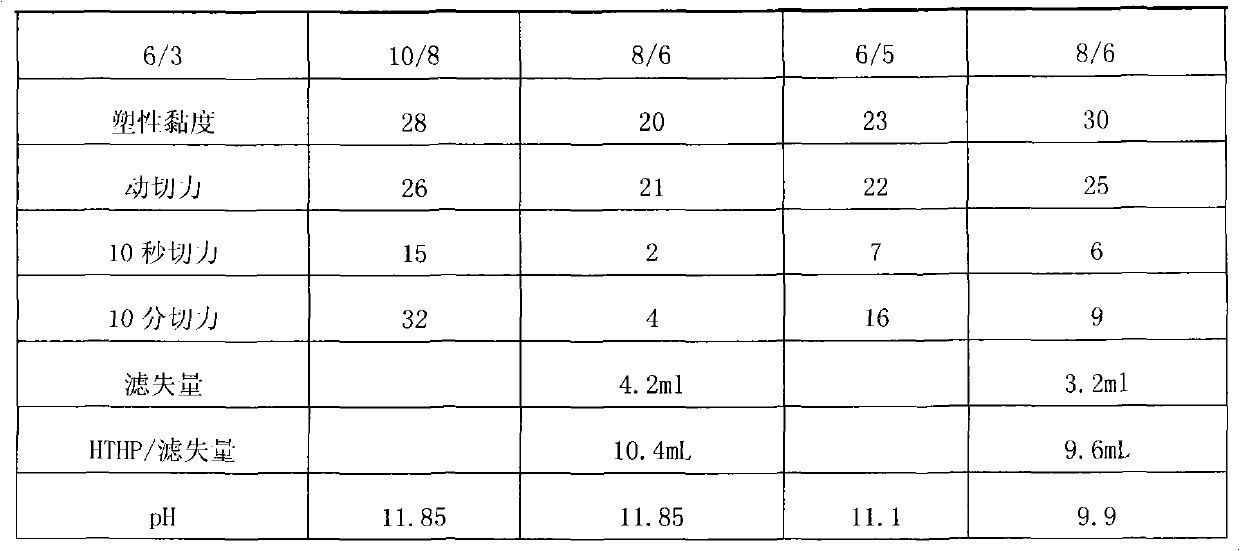

Sulphur removal corrosion inhibitor and preparation method thereof

ActiveCN101955766ALittle impact on performanceNo pollution in the processDrilling compositionBorehole/well accessoriesGluconic acidStearic acid

The invention relates to a sulphur removal corrosion inhibitor, which is prepared from the following components in percentage by weight: 26% of calcium gluconate, 18% of ferrous sulfate, 10% of basic zinc carbonate, 9% of stearic amide and the balance of water. The sulphur removal corrosion inhibitor is insensitive to the pH value, has no effect on the rheological behavior of drilling fluid and simultaneously has good compatibility with other finishing agents in the drilling fluid. Ferrous ions in the sulphur removal corrosion inhibitor are easy to absorb by organic matters, a complex compound of the ferrous ions and organic acid is environment-friendly, and the discharge of drilling cuttings and the drilling fluid containing iron ion filtrate cannot cause environmental problems.

Owner:SICHUAN ZHENGRONG IND +1

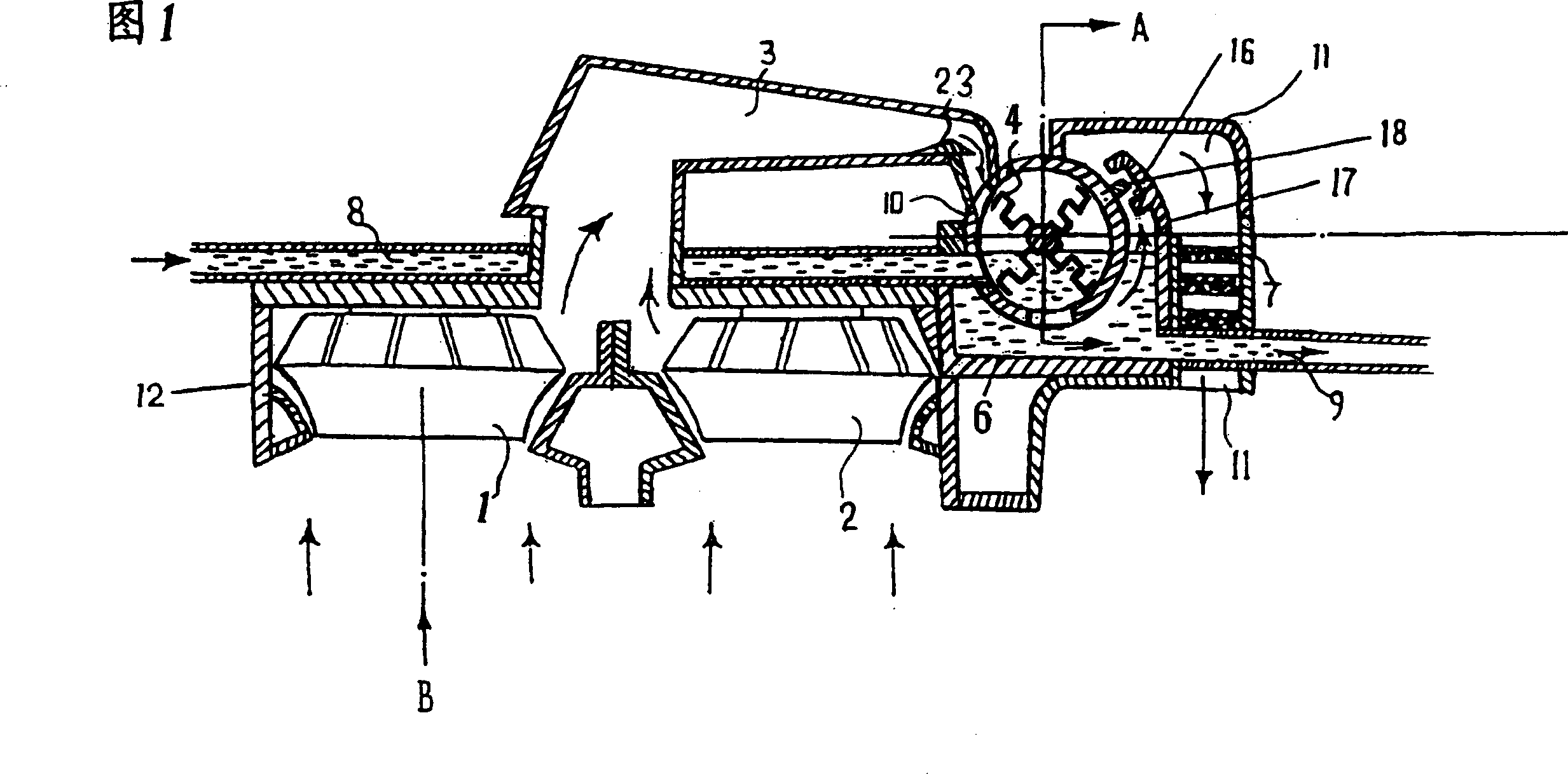

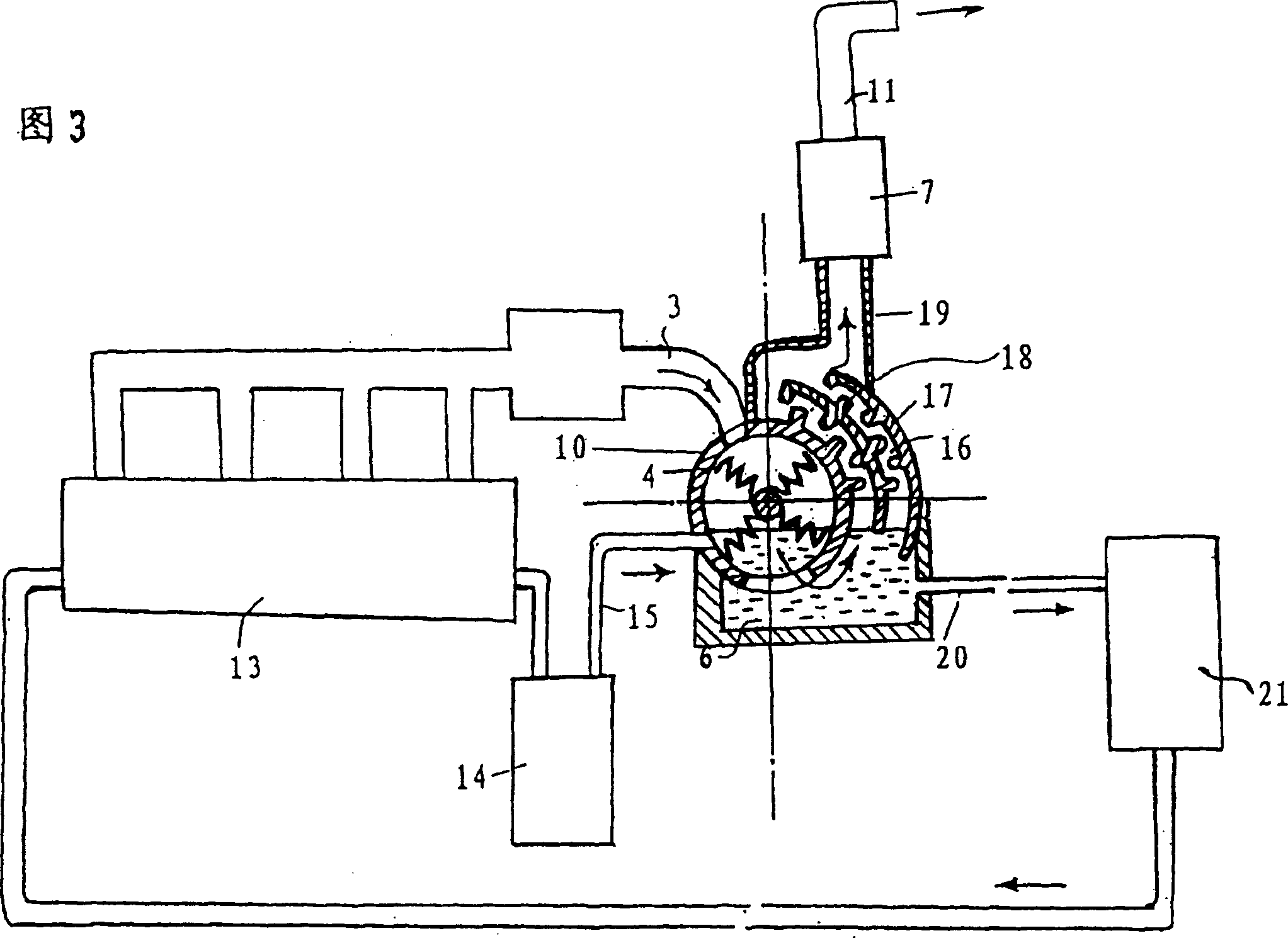

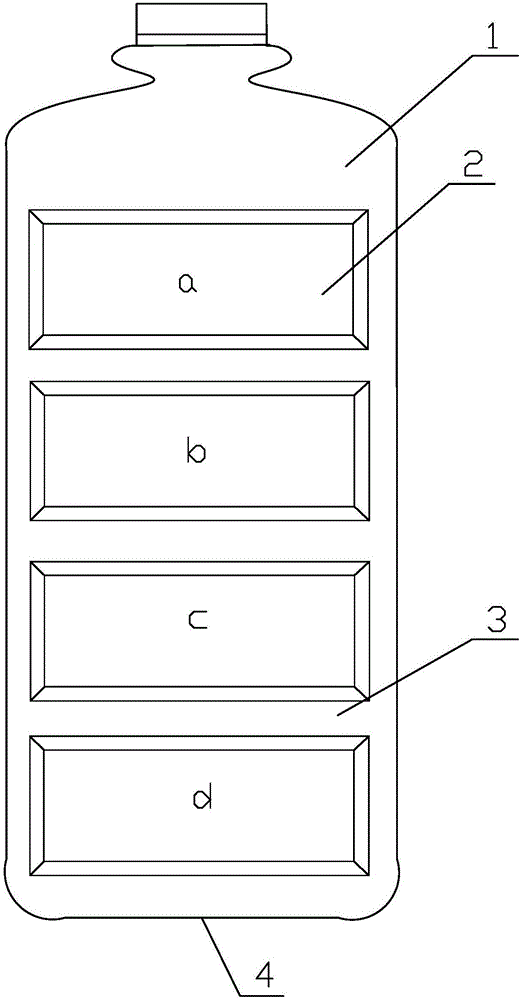

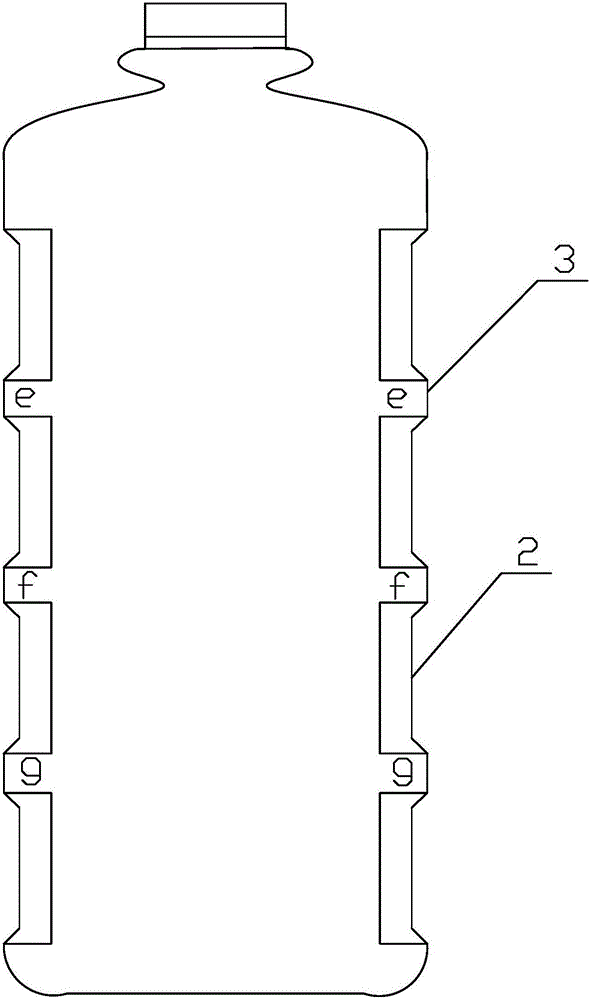

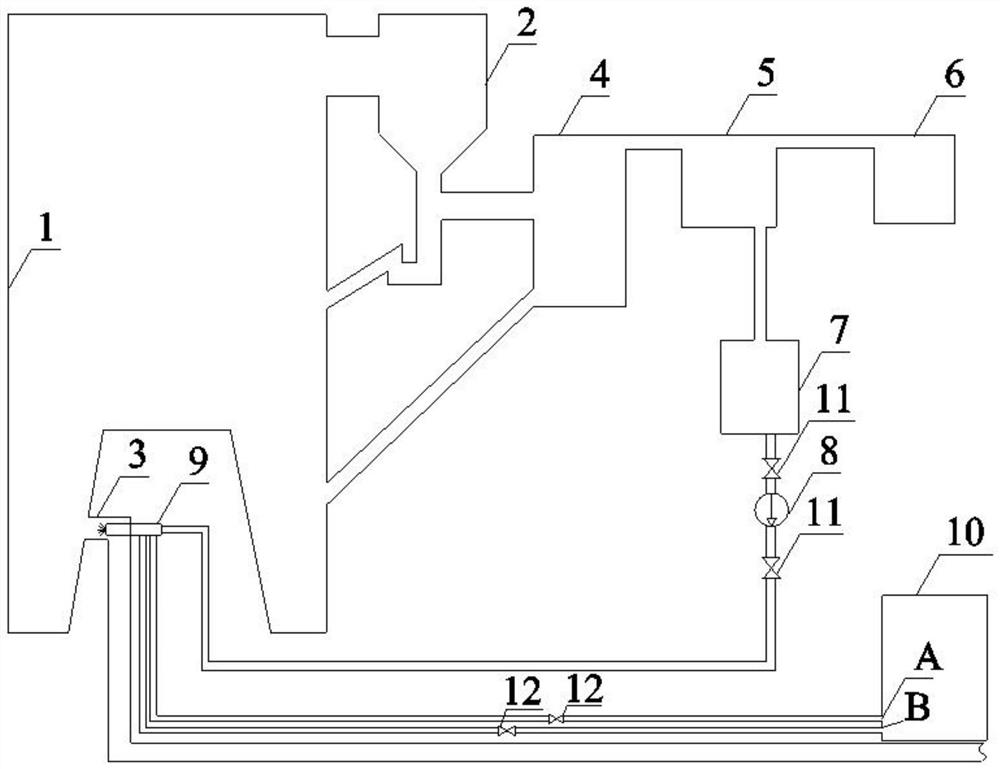

Waste gases filtering equipment

InactiveCN101095994ASimple structureReduce power consumptionCombination devicesExhaust apparatusExhaust fumesExhaust pipe

The invention relates to a filtering device for waste gas, comprising exhaust pipe, of which one end is connected with generating device of waste gas; double filtering device constituted by a filtering device of water tank and a filter, which is connected with the other end of exhaust pipe; and fish-gill anti-overflow device. The filter is located in the middle of gas outlet pipe. The gas outlet pipe is used to connect the filtering device of water tank and the filter. The invention is provided with simple structure, lower power exhaustion, lower cost and smaller cubage. It can be used in waste gas discharging systems of vehicle and ship, lampblack presser, refreshing machine for indoor air and various factories.

Owner:陈友年

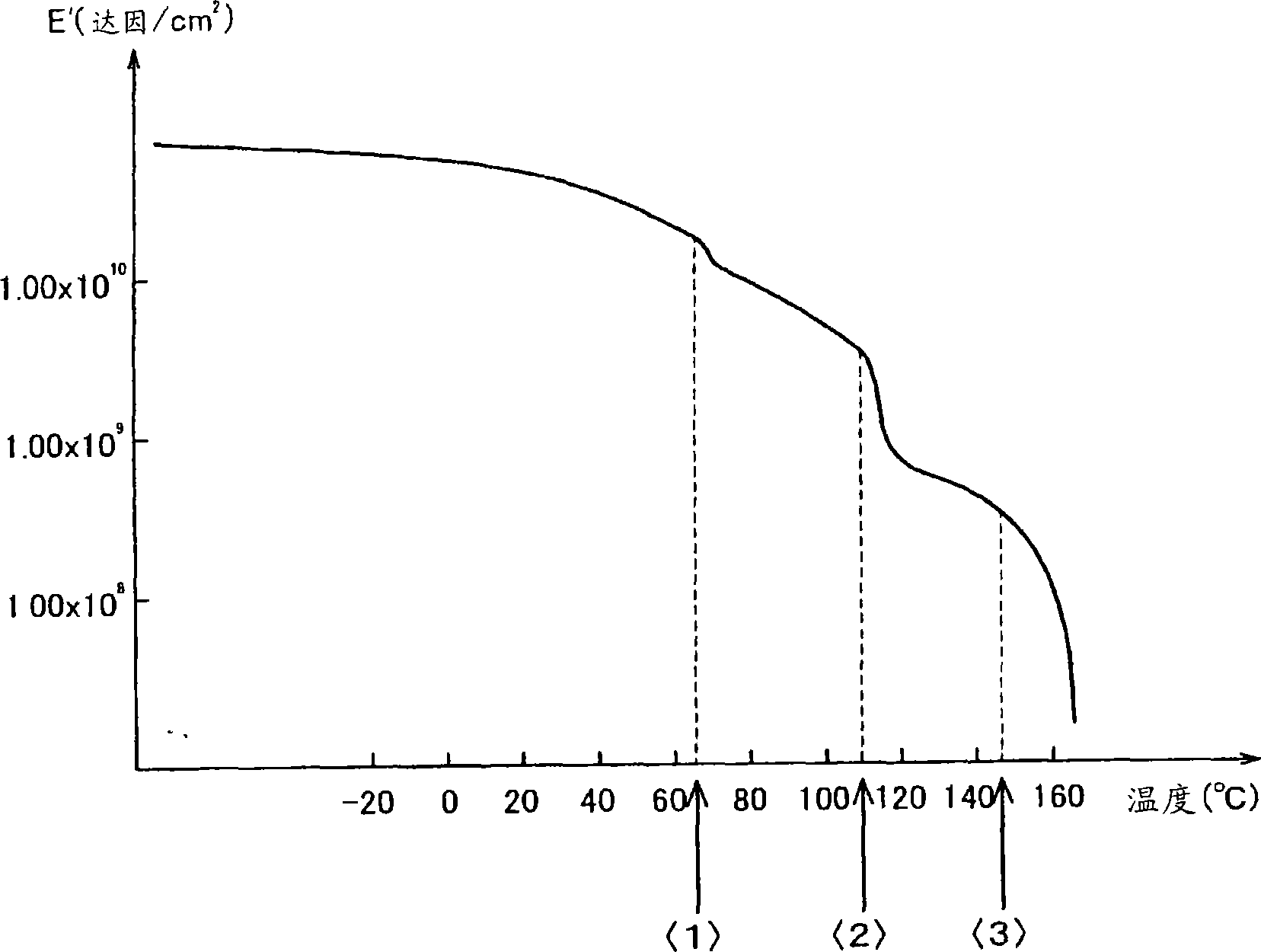

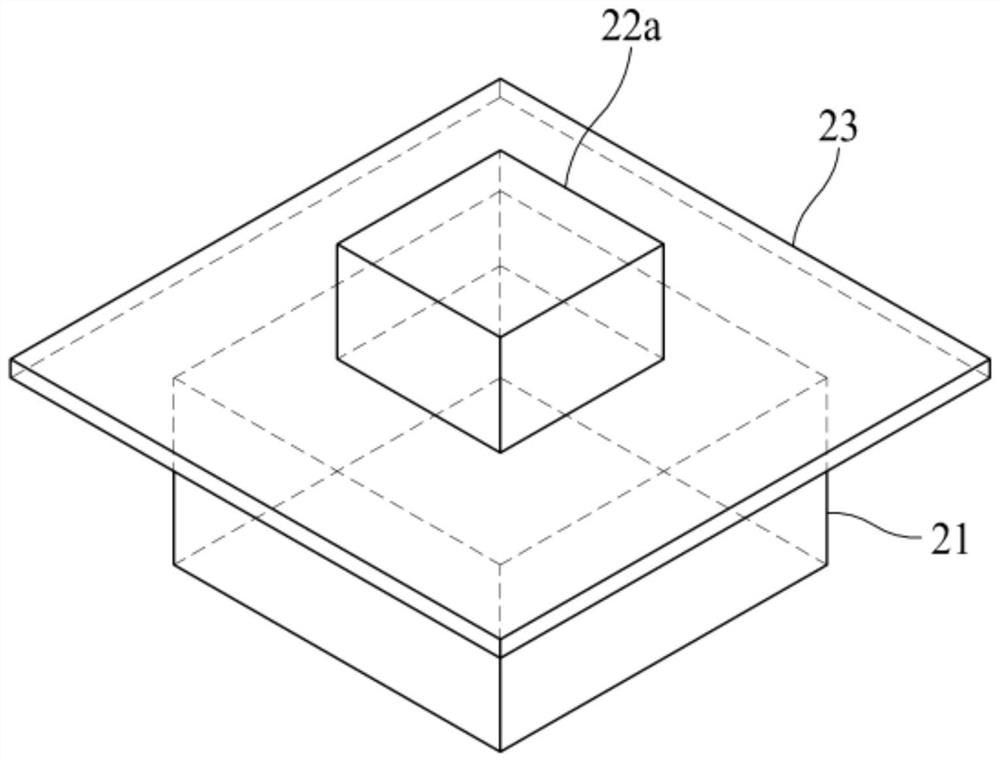

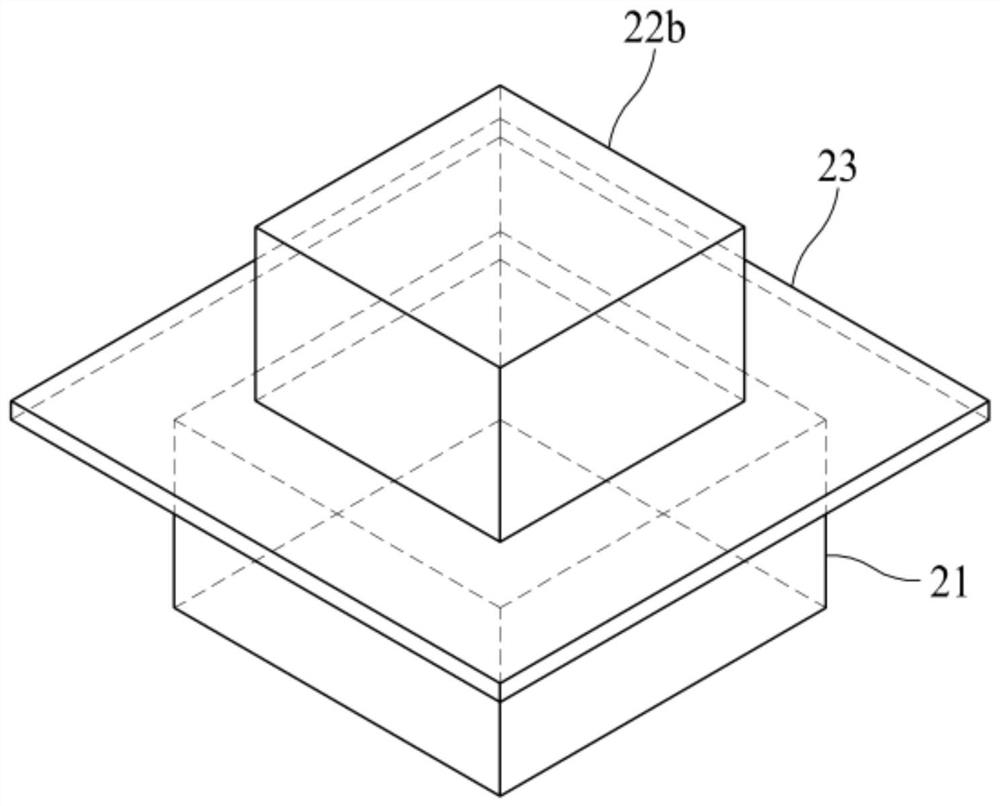

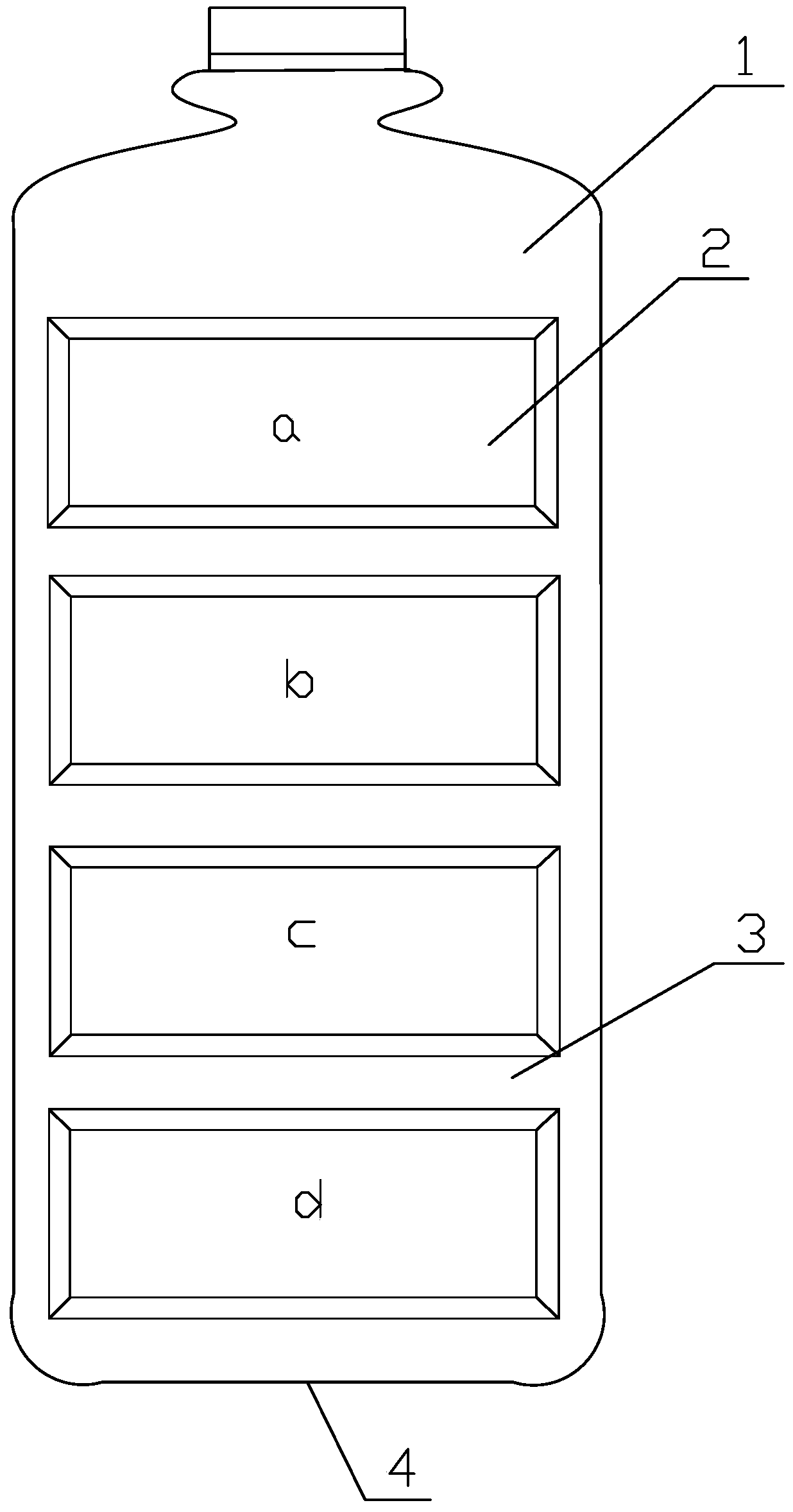

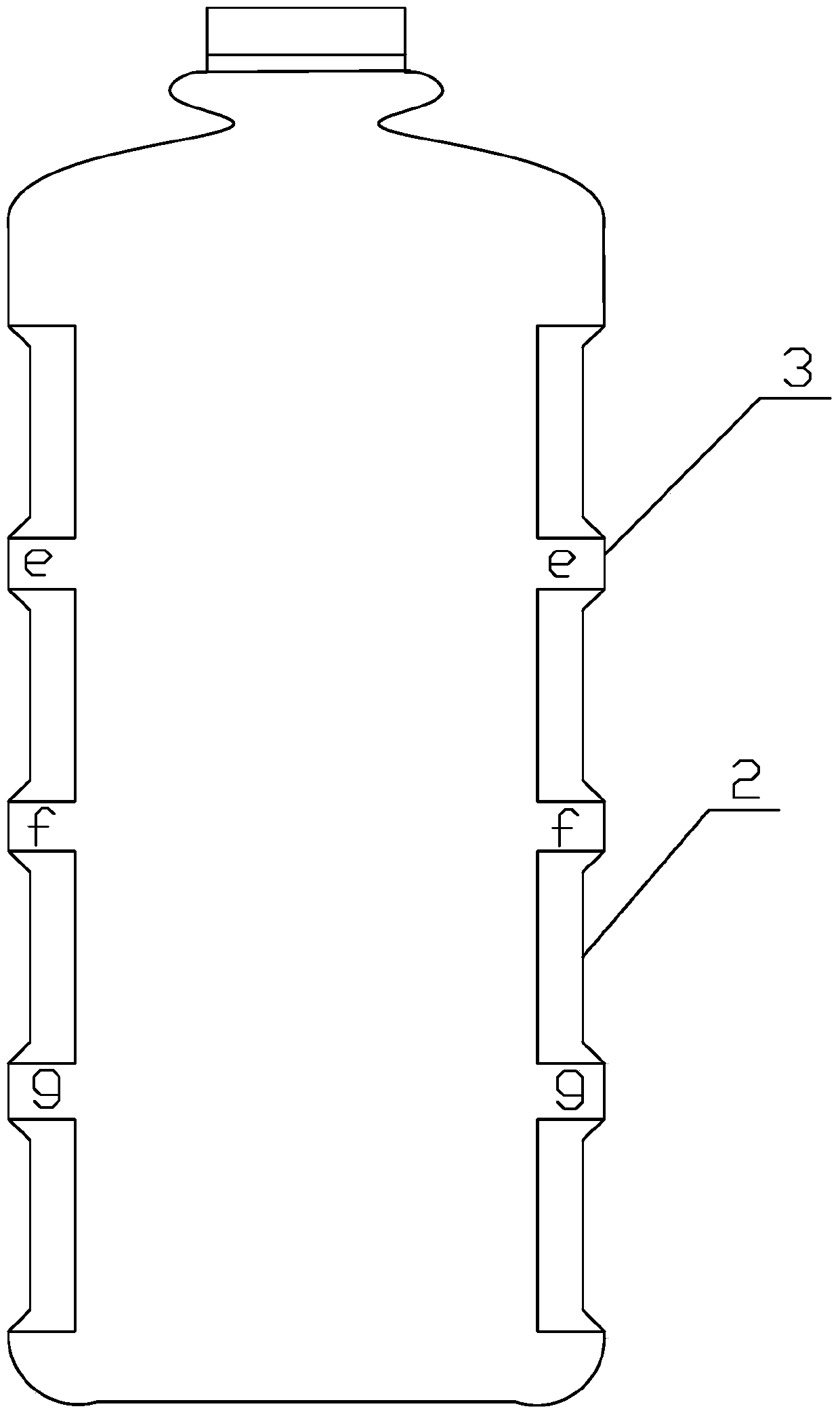

Biodegradable layered sheet

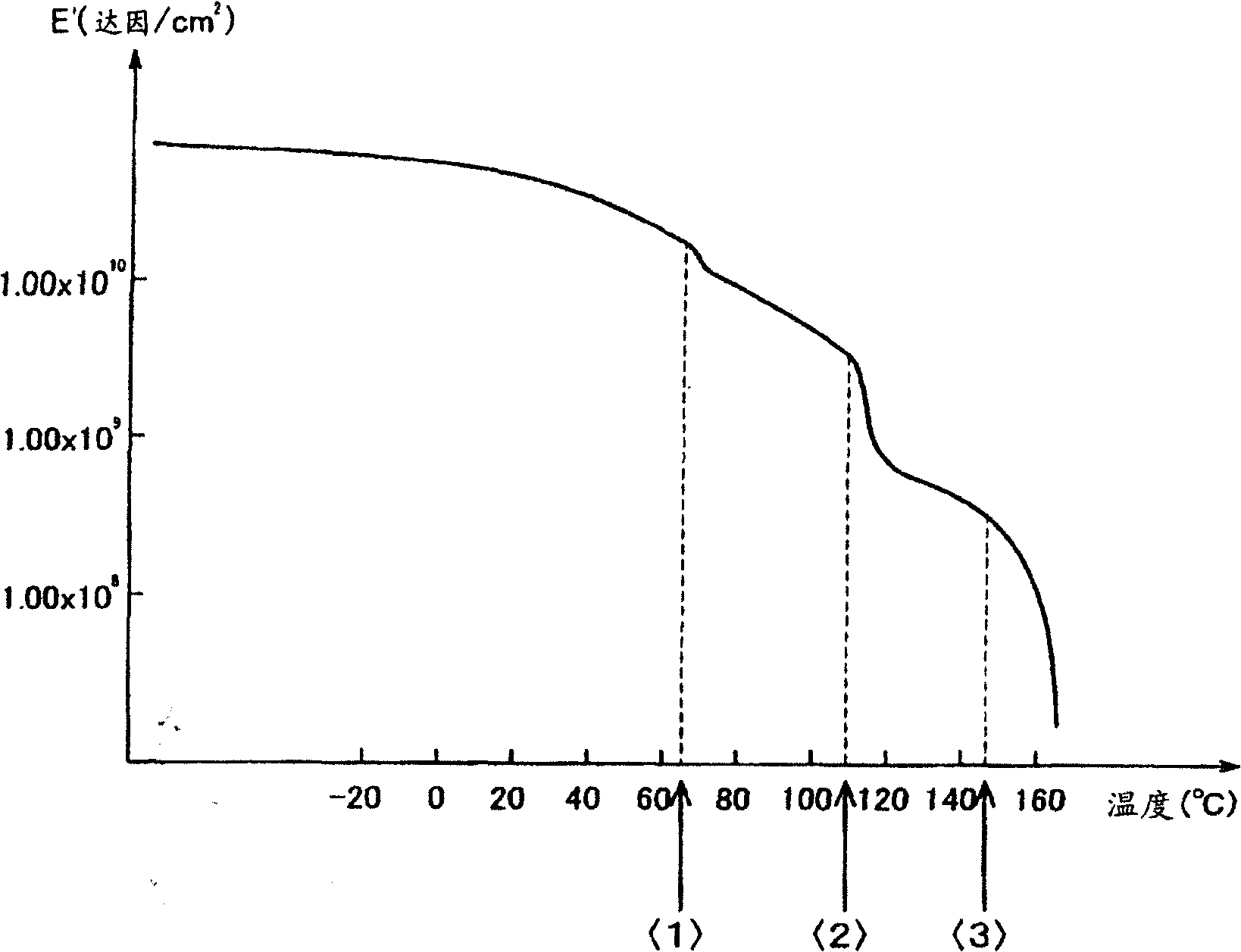

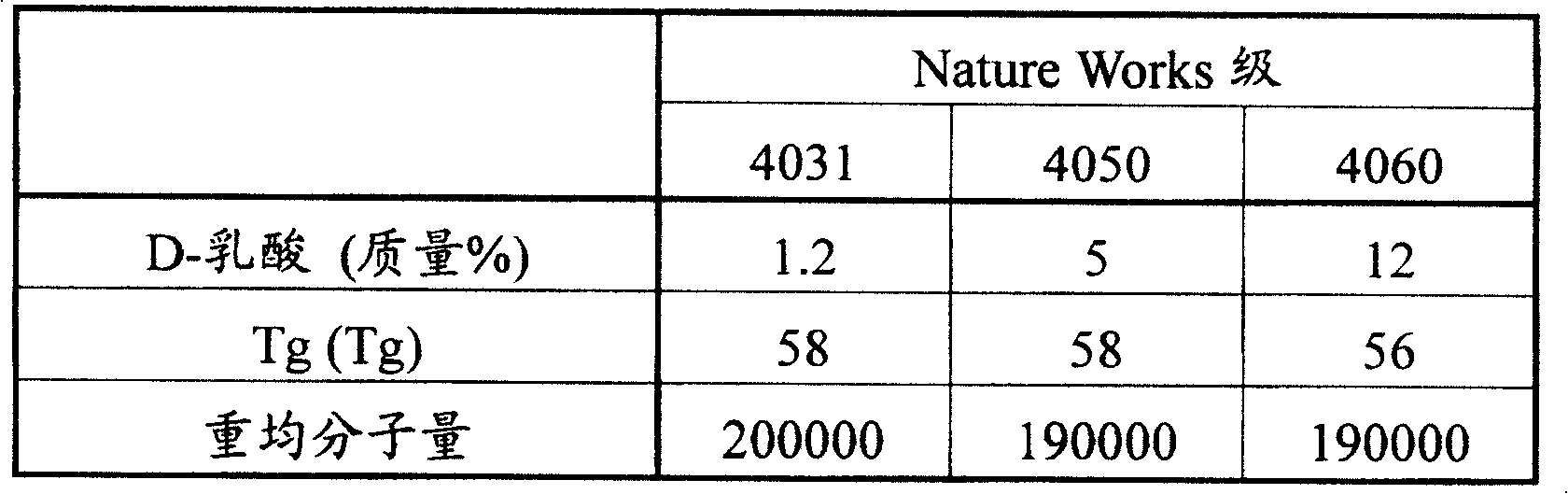

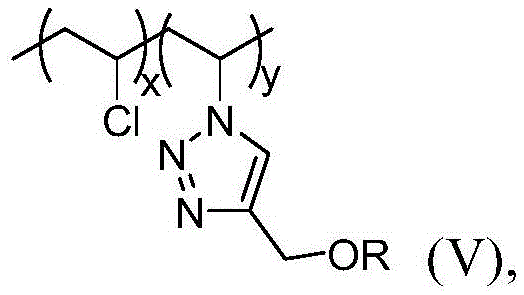

ActiveCN1860026ADoes not cause environmental problemsThe need to promote crystallizationSynthetic resin layered productsGlass transitionPolymer chemistry

It is an object to provide a biodegradable laminated sheet which is high in heat resistance, impact resistance and strength when subjected to loads at high temperature, does not develop wrinkles called 'bridges', which can be easily deep-drawn or formed into blister articles, which are typically complicated in shape. The biodegradable sheet is a laminated sheet comprising at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

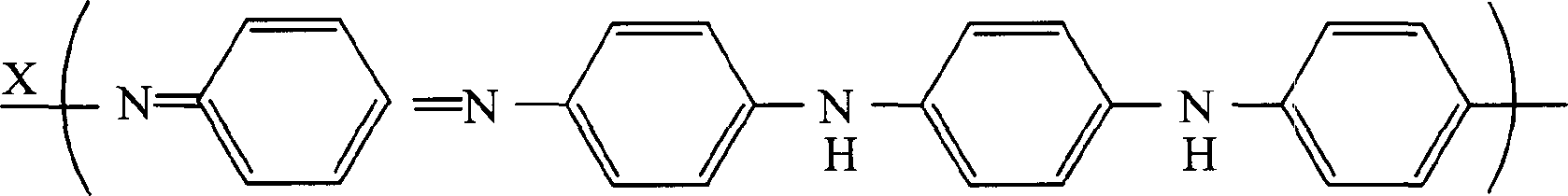

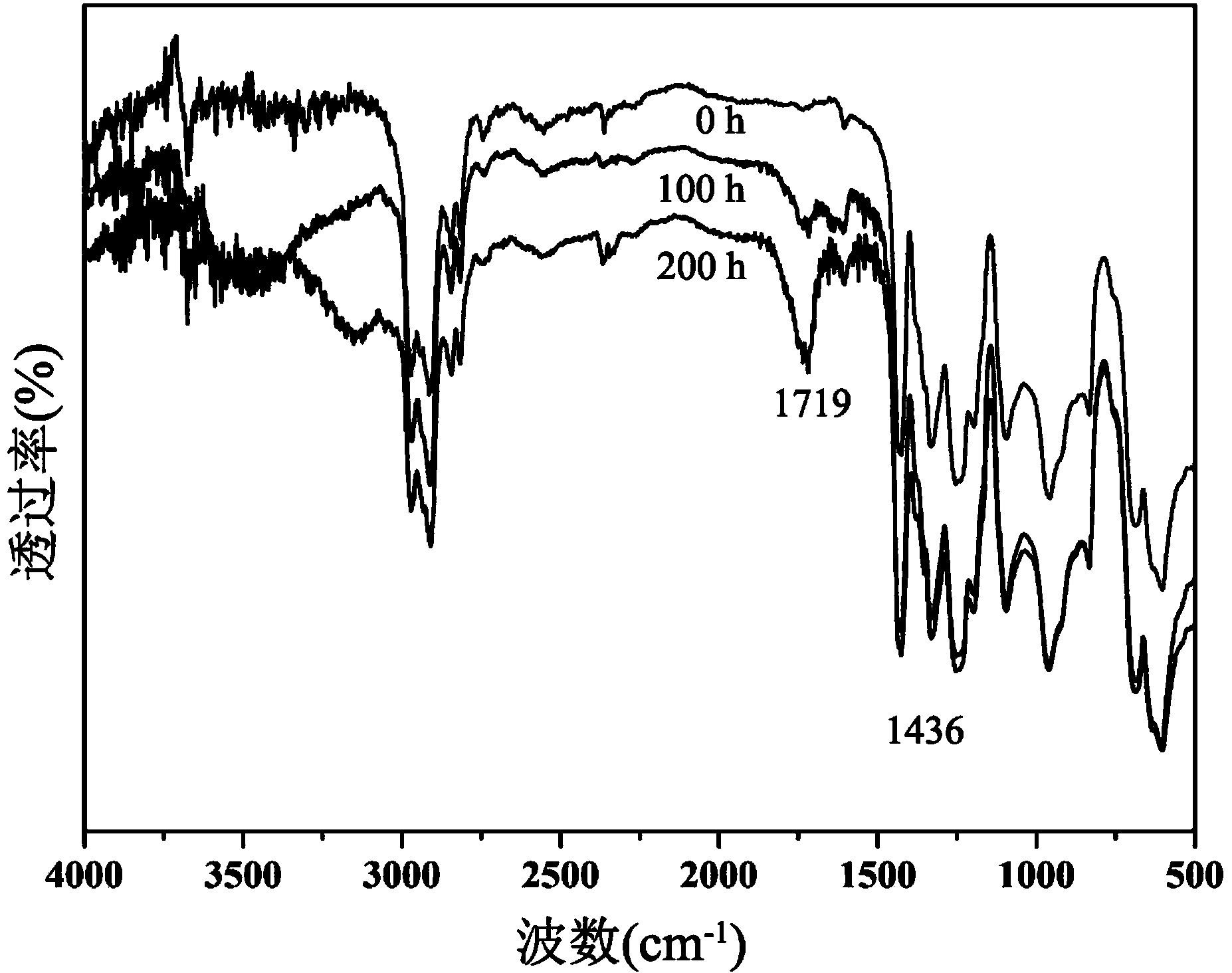

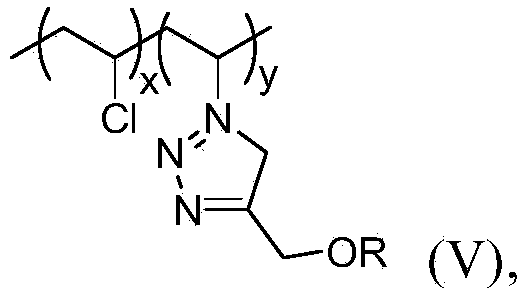

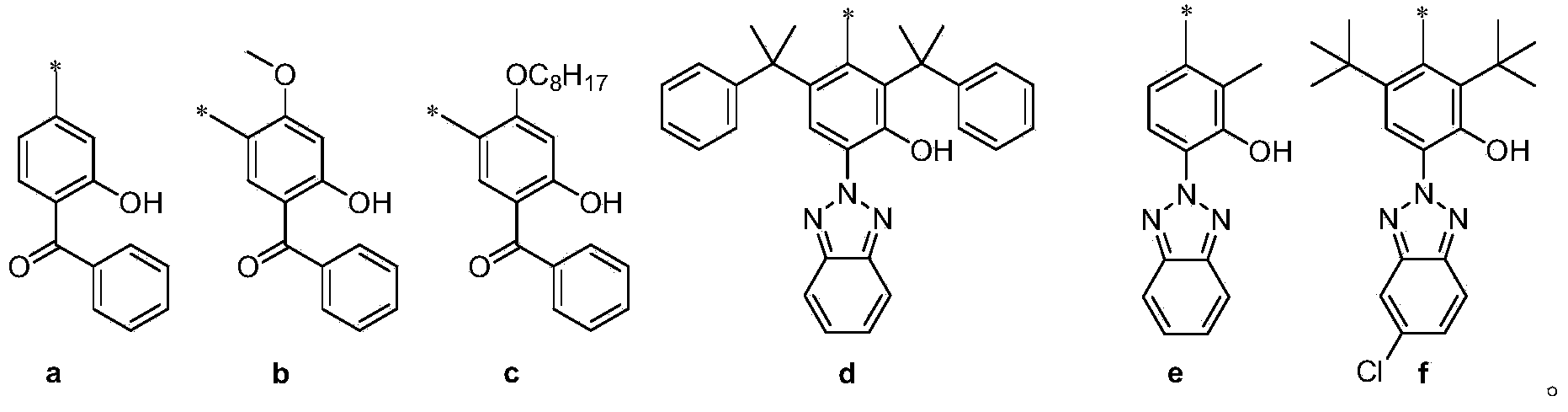

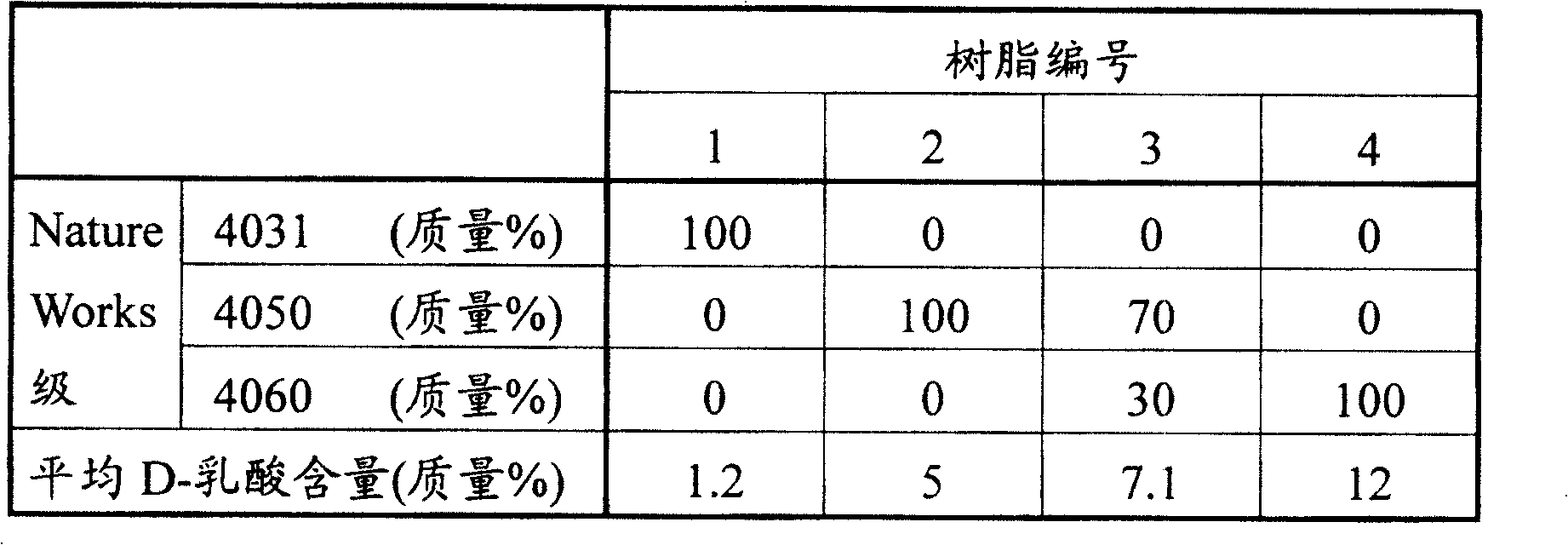

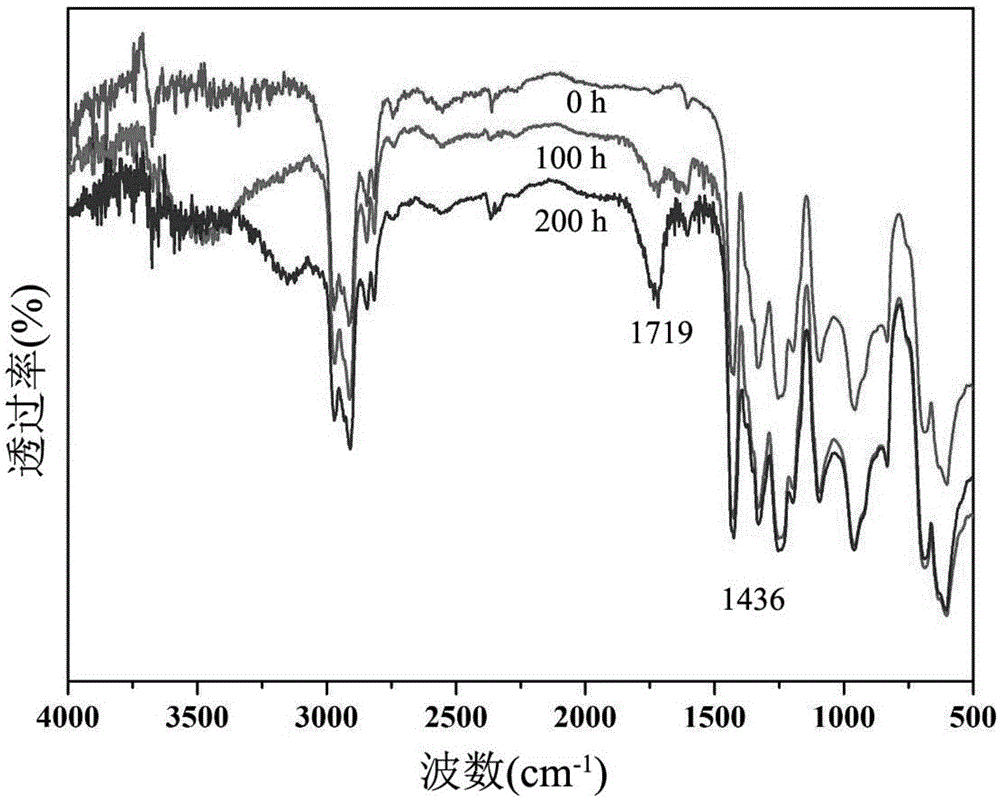

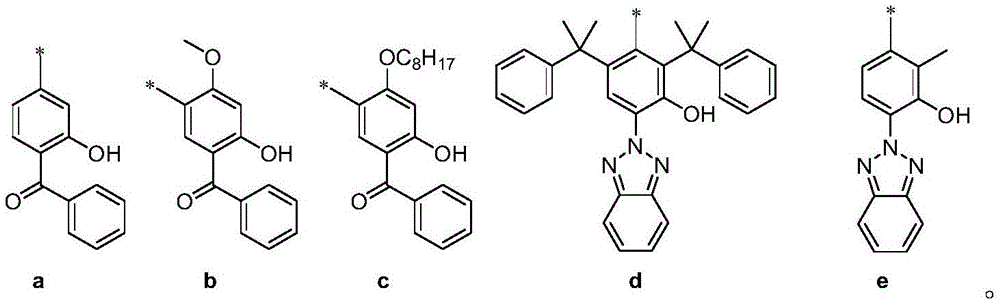

Ultraviolet light stabilizer based on polyvinyl chloride and preparation method thereof

The invention provides an ultraviolet light stabilizer based on polyvinyl chloride and a preparation method thereof. The structure of the ultraviolet light stabilizer is as shown in formula V, wherein R, x and y are defined according to the claims and the specification. The preparation method comprises steps of bringing in a nitrine functional group on the main chain of the polyvinyl chloride, and bringing in alkynyl on a small-molecular ultraviolet light stabilizer; and finally performing a 'click' reaction between nitrine and alkynyl to bond high-efficiency bonds of the ultraviolet light stabilizer on the main chain of the polyvinyl chloride. The preparation method is simple, and the content of the small-molecular ultraviolet light stabilizer is adjustable. A small-molecular ultraviolet light absorbent is bonded on the main chain of the polyvinyl chloride, so the problem of compatibility of the ultraviolet light absorbent in the polyvinyl chloride is avoided, and the environmental problem caused by precipitation of the small-molecular ultraviolet light stabilizer is avoided as well.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI +1

AB type aqueous fire extinguisher

ActiveCN106039627AFire effectiveReduce the temperatureFire rescueFire extinguisherHydrogen phosphateDiammonium phosphate

The invention relates to an AB type aqueous fire extinguisher which comprises a simple fire extinguishing container and an aqueous fire extinguishing agent packaged in the simple fire extinguishing container. The aqueous fire extinguishing agent comprises a component 1 and a component 2, the component 1 is water, and the component 2 is a main fire extinguishing agent body. The main fire extinguishing agent body is composed of, by weight, 8-20 parts of ammonium chloride, 5-15 parts of carbonate, 13-30 parts of diammonium hydrogen phosphate and 1-15 parts of bicarbonate. The aqueous fire extinguishing agent is packaged in the impact damage type container or the pressure storage type spraying container and made into manual casting type fire extinguishing liquid bombs or fire extinguishing mist spray, the fire extinguishing speed is high, and instant fire extinguishment can be achieved. The AB type aqueous fire extinguisher is small in size, low in weight, convenient to carry and low in cost, fire extinguishment can be achieved rapidly during a quite short period of time for A type fire disasters and B type disasters, reburning is avoided, the safety is high, an operation method is simple, and the AB type aqueous fire extinguisher is suitable for people of all ages to use and can serve as a simple standing fire extinguishing tool for homes, offices and the like.

Owner:洛阳实盾消防科技发展有限公司

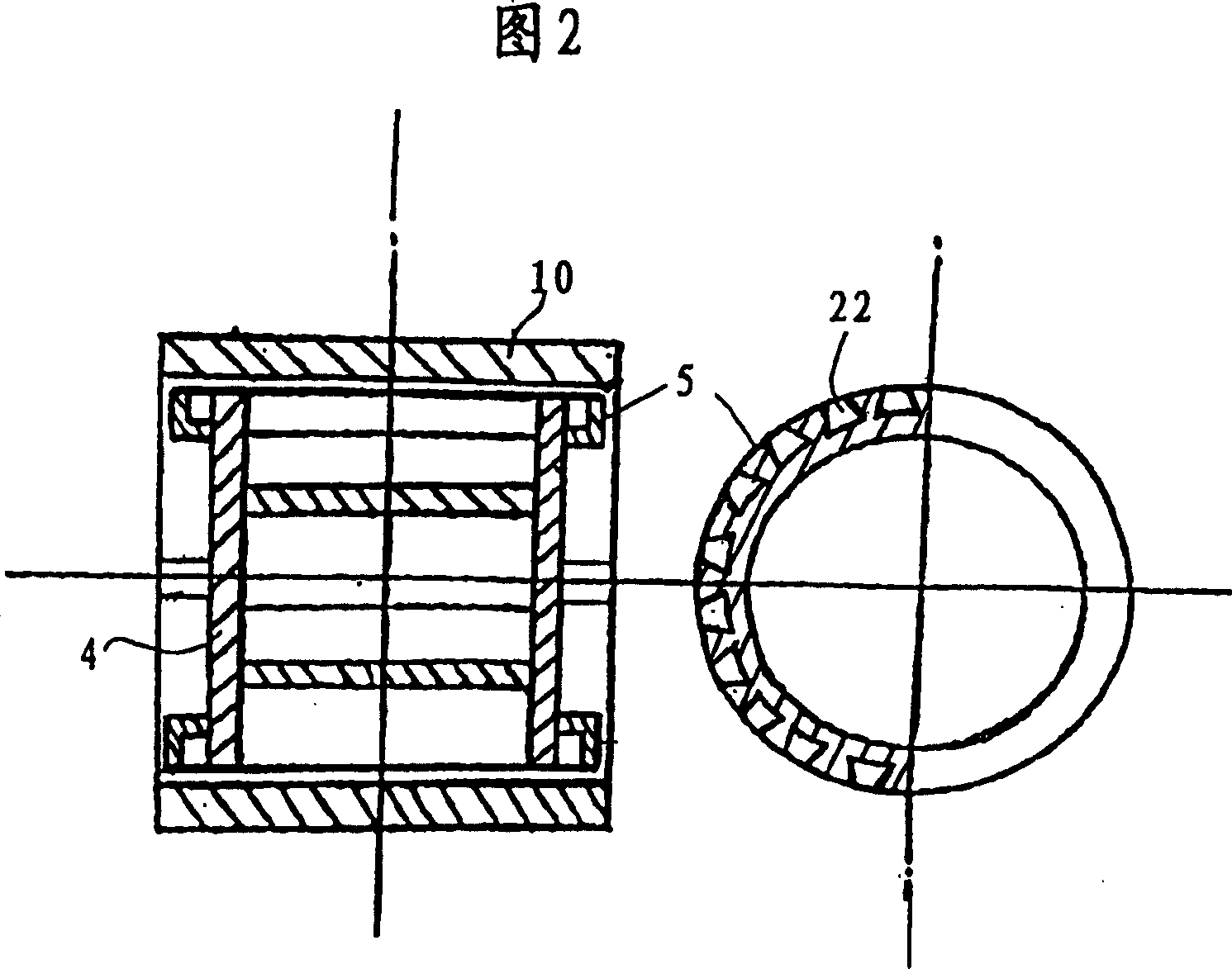

Blanking mould and manufacturing method thereof

InactiveCN1537708ACorrect punchingCorrectly and securely fastenedCleaning using gasesMetal working apparatusProduct gasEngineering

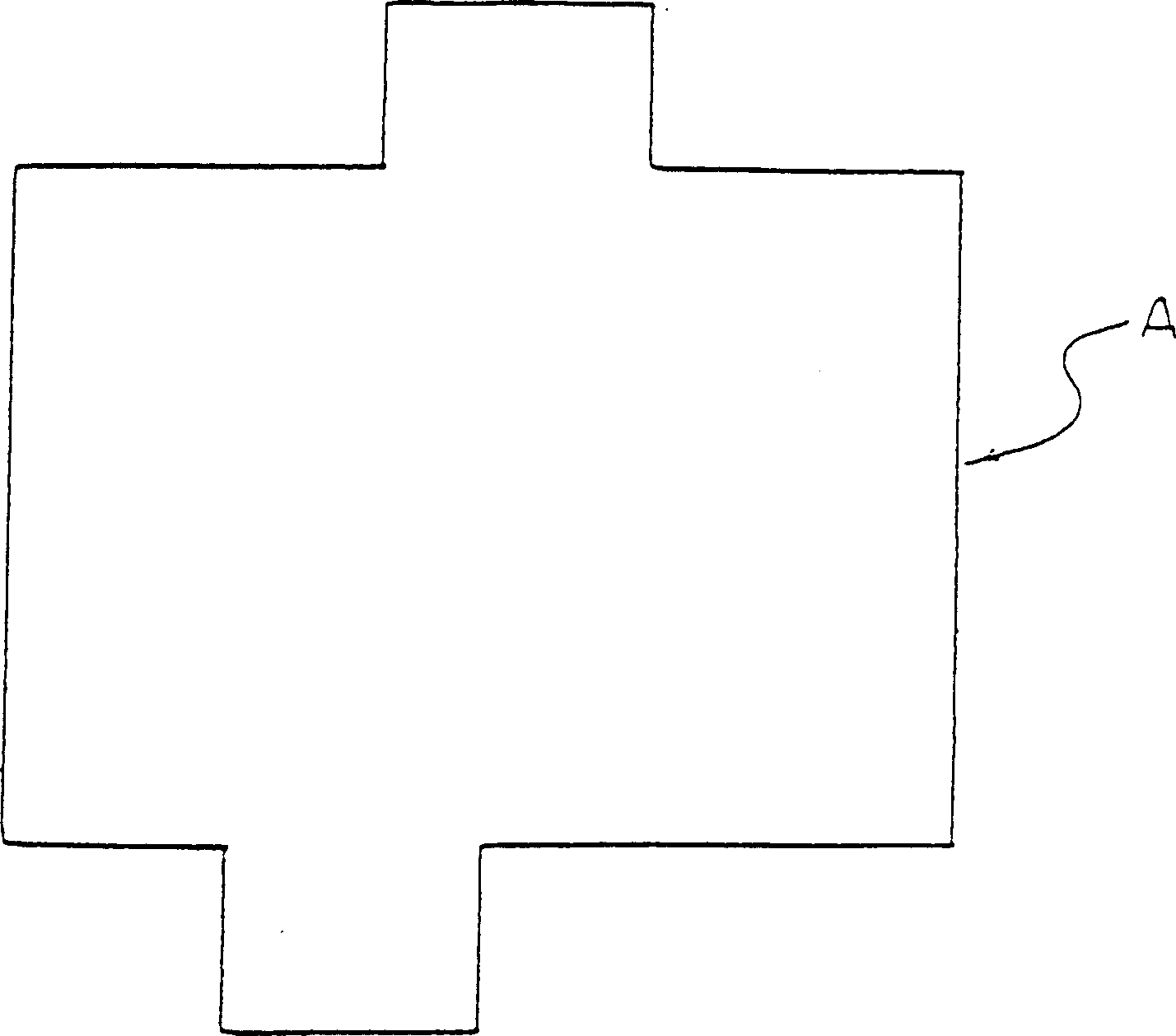

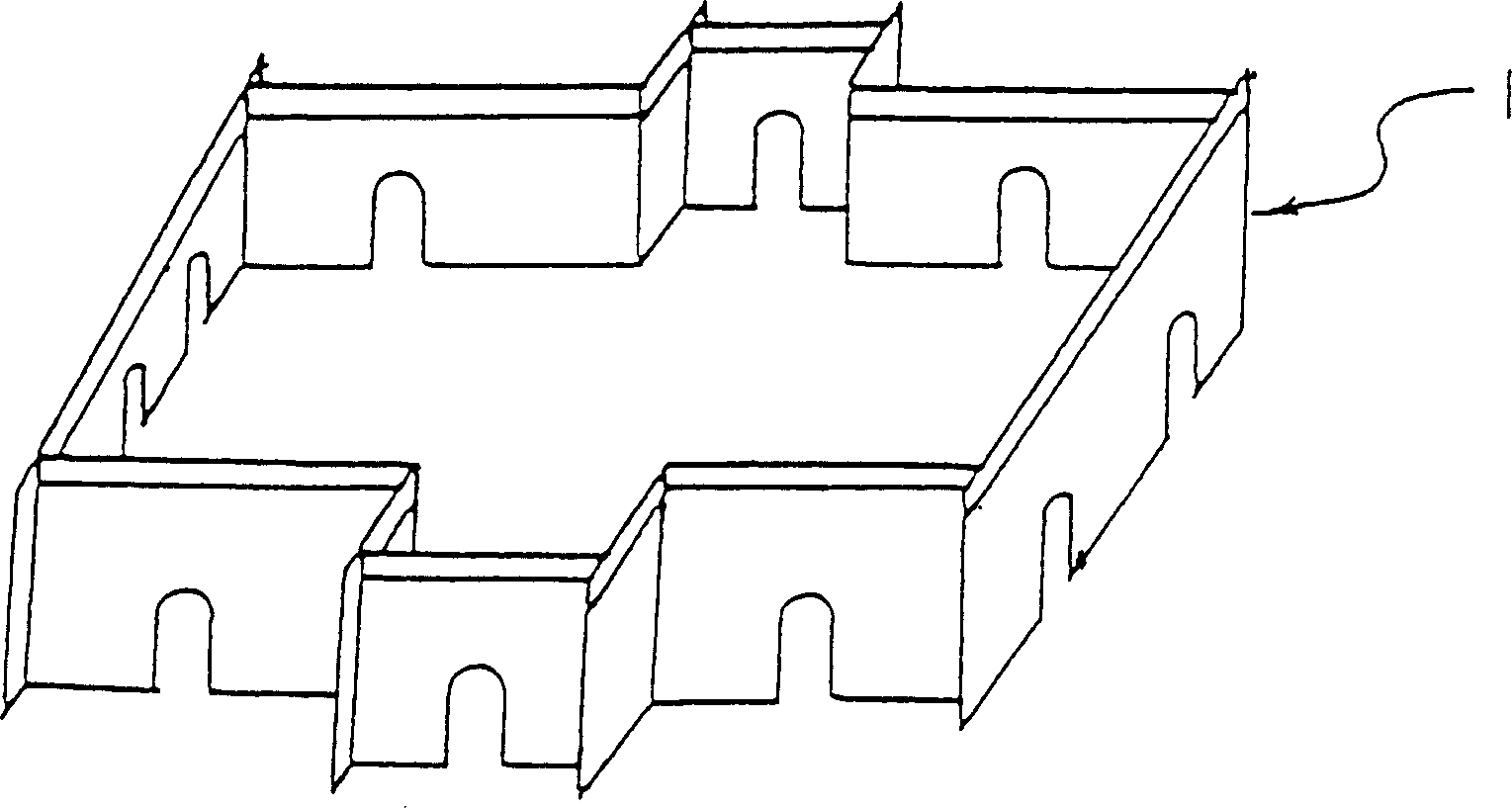

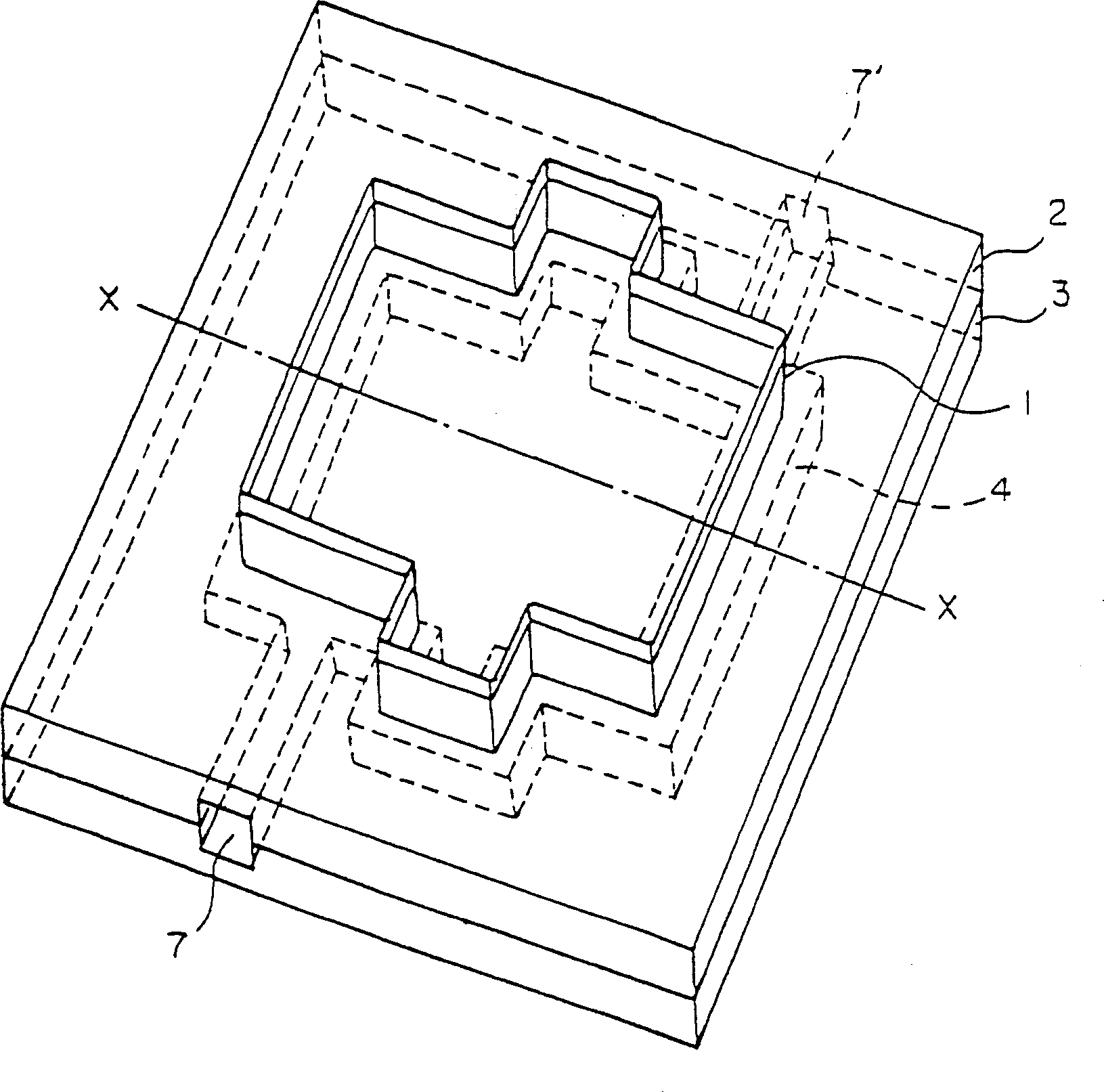

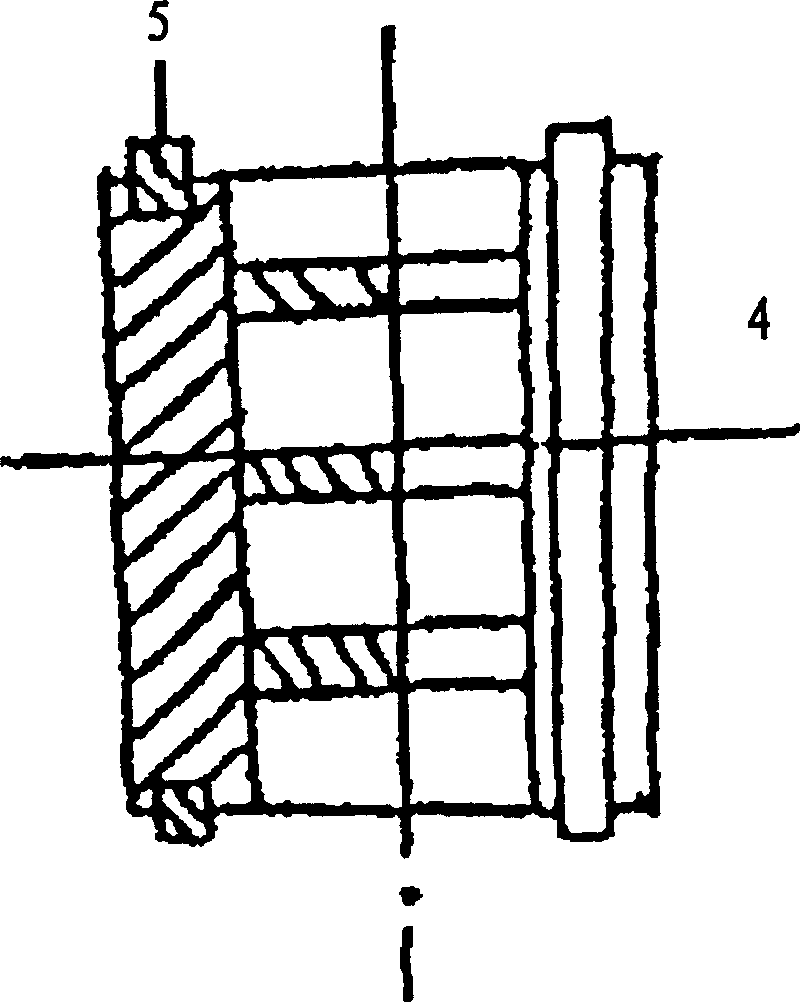

Provided is a blanking die which causes no slack of a fixed punch and carries out exact blanking even if a large number of sheetlike materials are blanked at a high speed, and also to provide a blanking die which easily separates products obtained by blanking the sheetlike materials from the scraps, and causes no pollution problems even if the disposal by incineration is carried out. Base materials 2, 3 of the blanking die have spaces 4 surrounding the punch 1. Resin is charged into the spaces and is solidified to fix the punch 1. Further, the spaces 4 are filled with gas, and the base material 2 is provided with a plurality of gas flowing-out holes. As a result, the products and the scraps are easily separated by flowing-out the gas through the gas flowing-out holes.

Owner:TAKAHASHI KEISEI

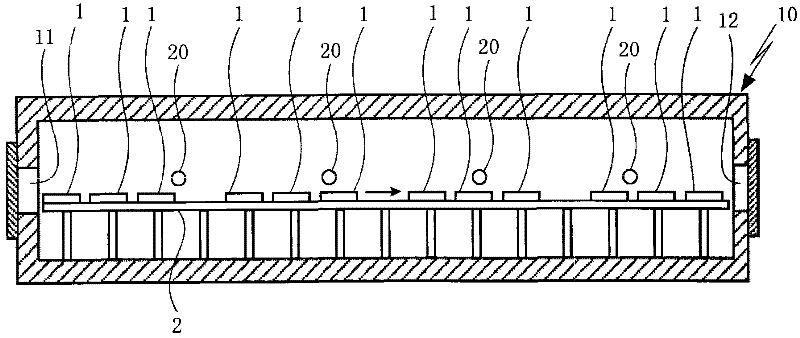

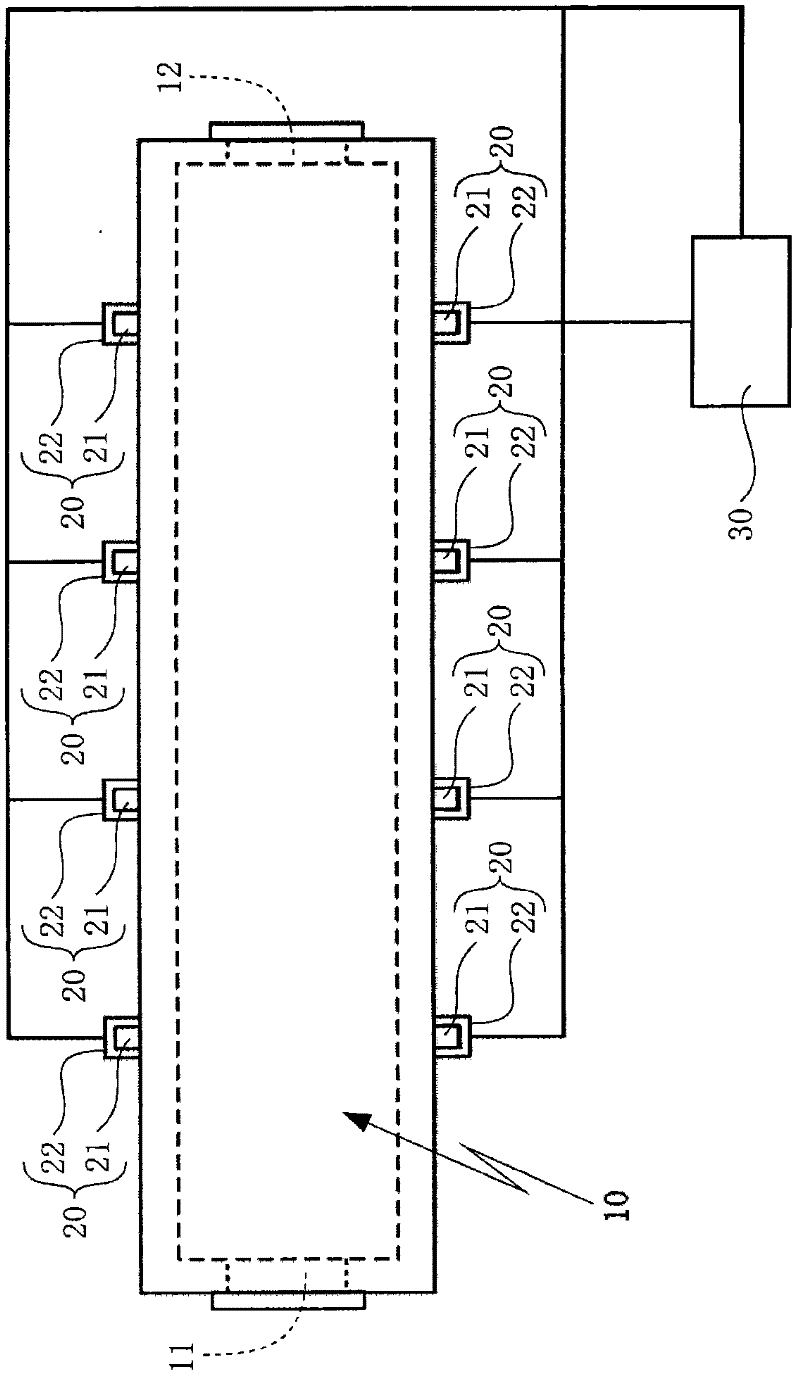

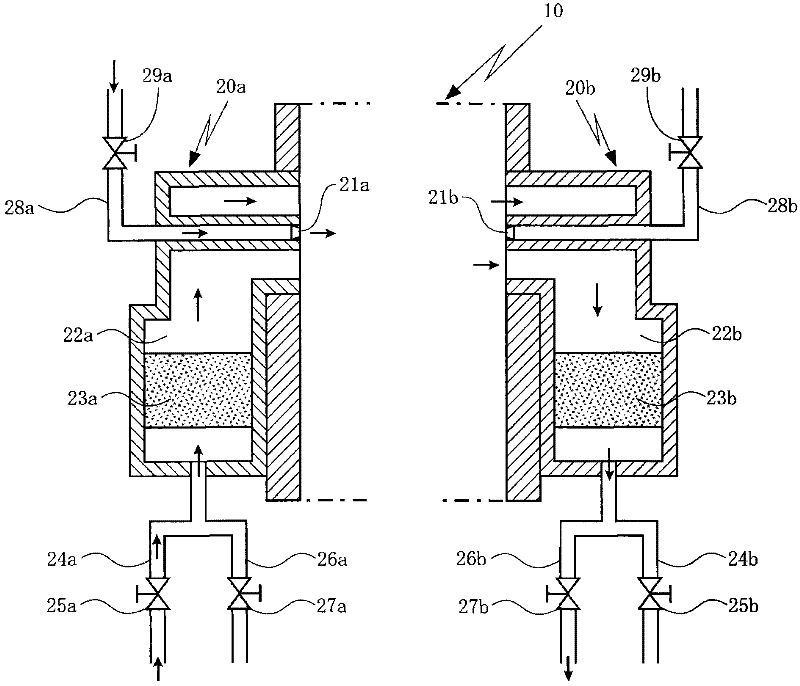

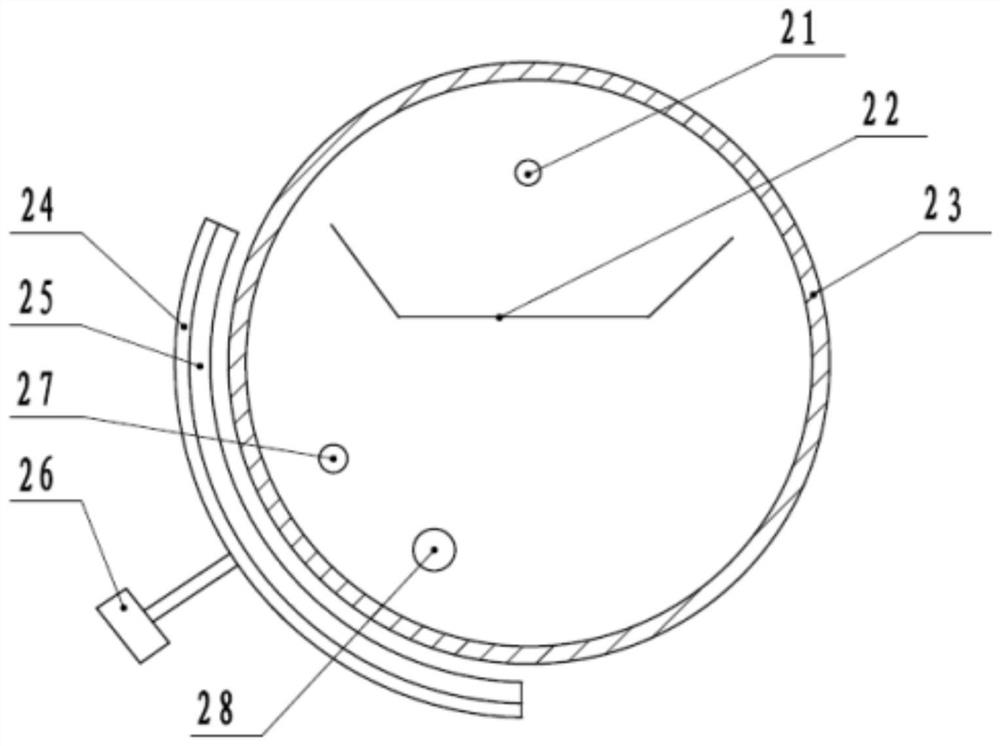

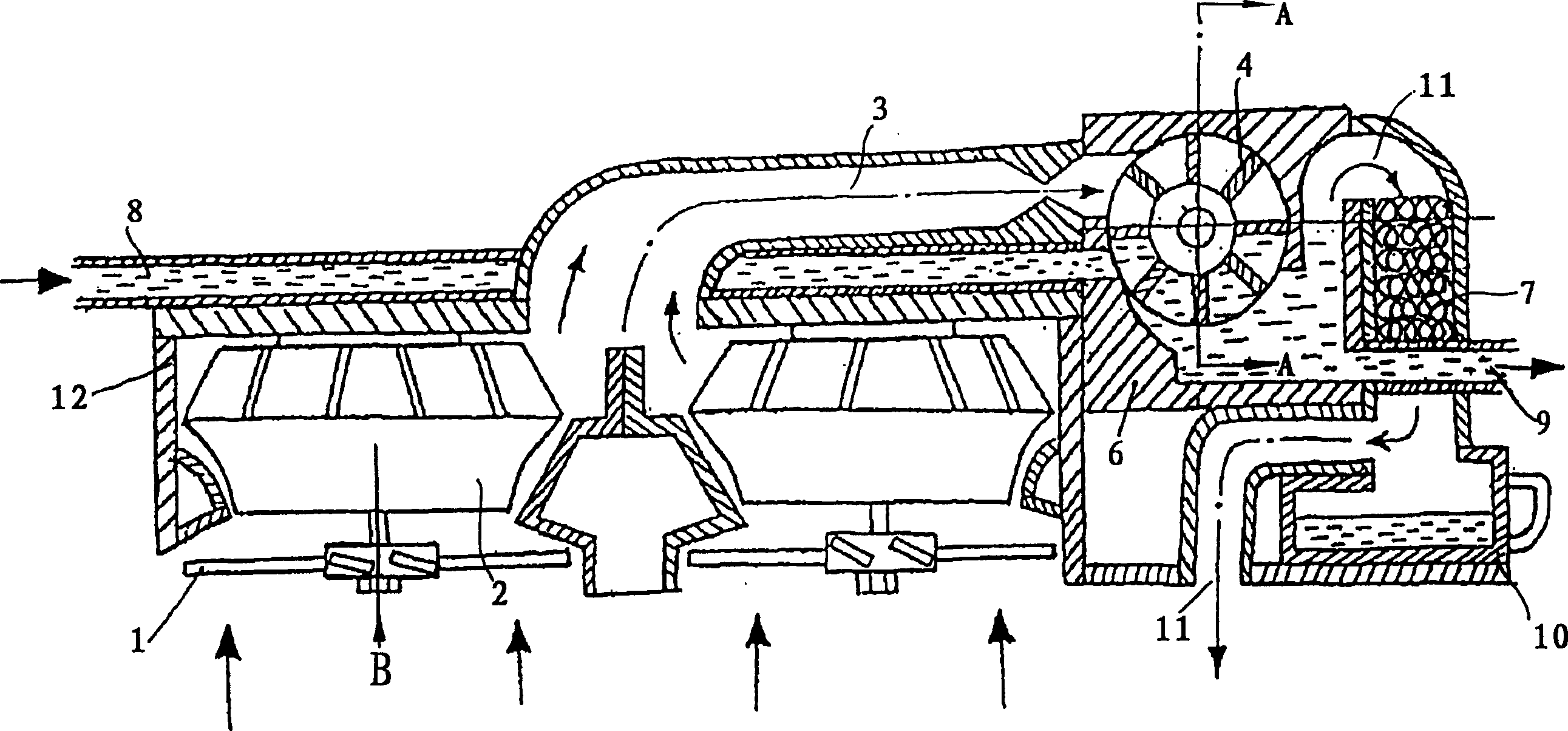

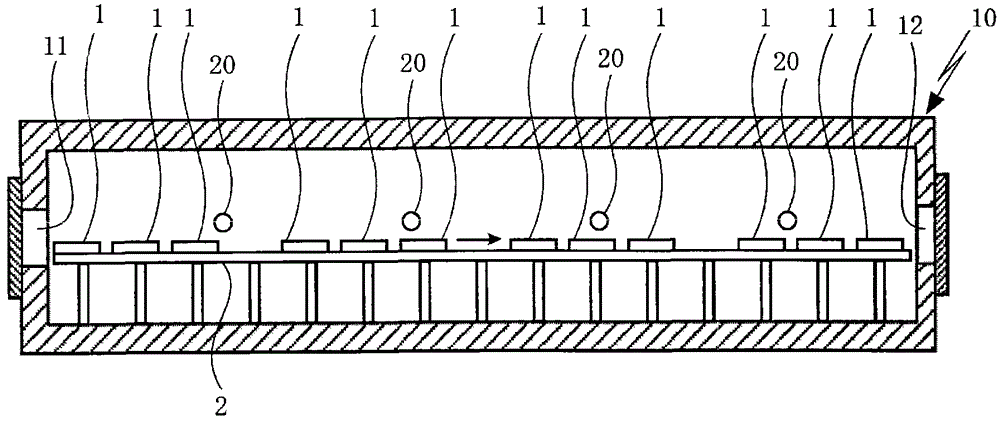

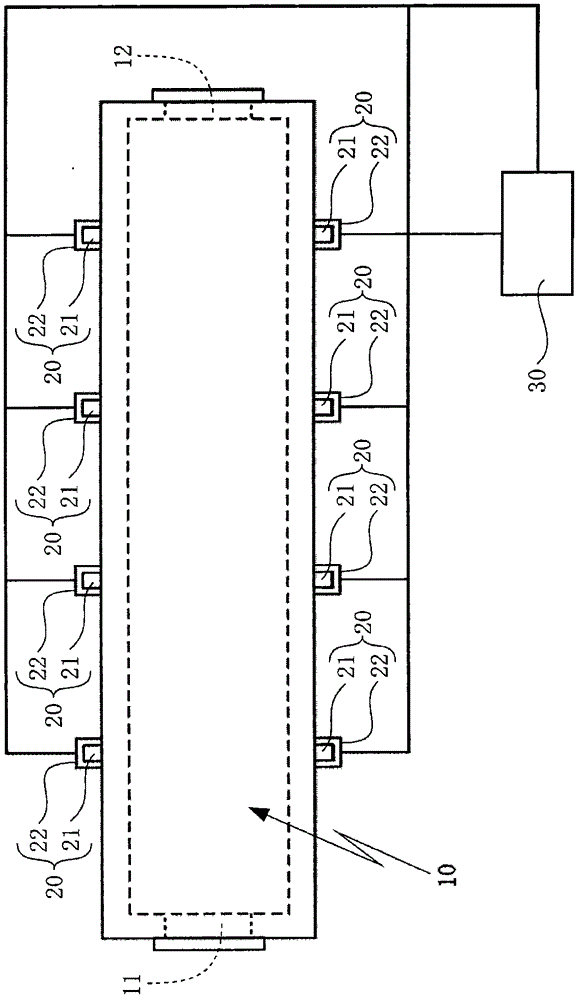

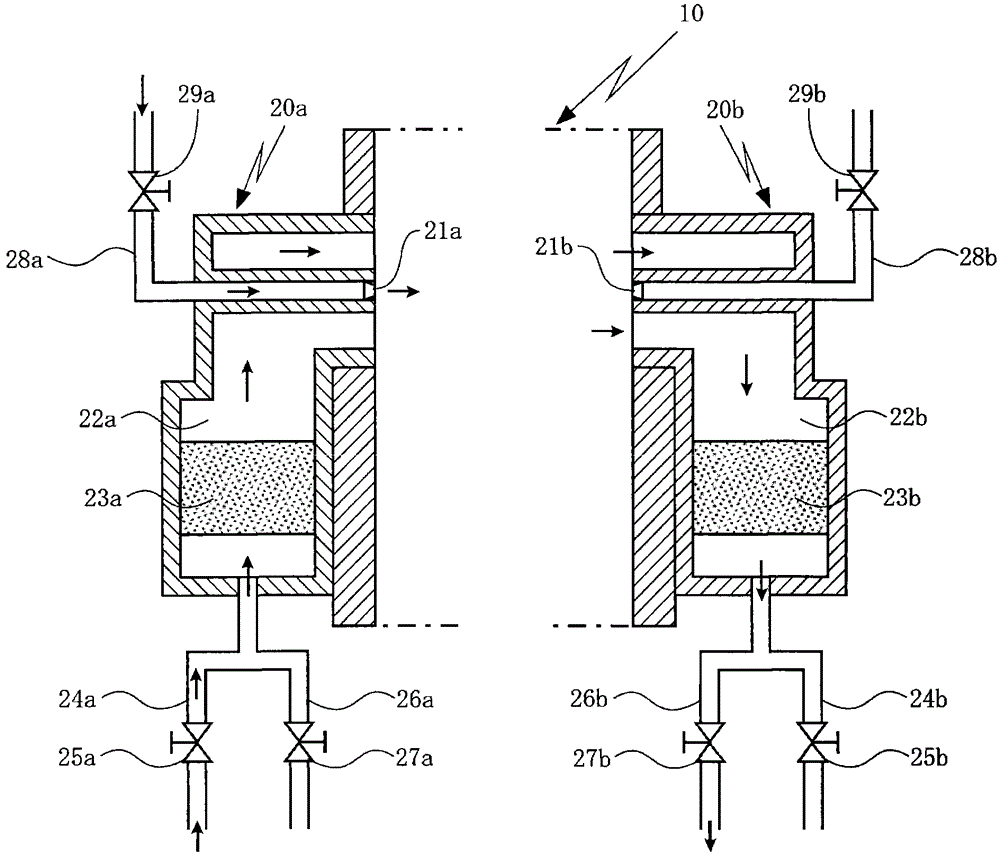

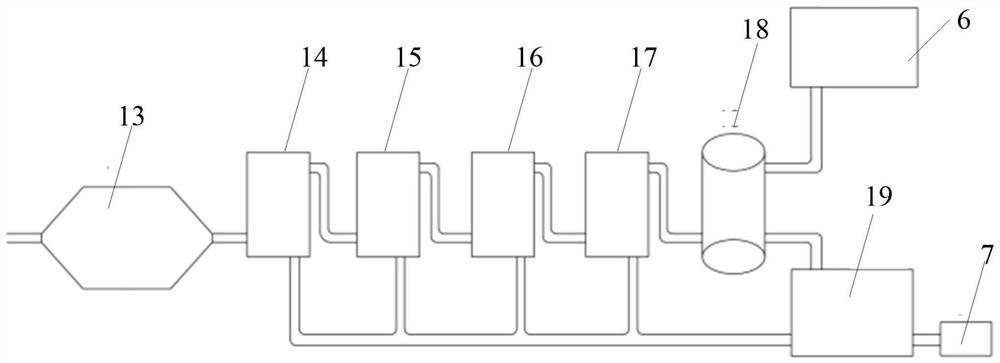

Combustion Control Method of Regenerative Combustion Heat Treatment Furnace

InactiveCN102269518ASuppresses changes in combustion stateStable combustionFuel supply regulationBurner control devicesCombustorProcess engineering

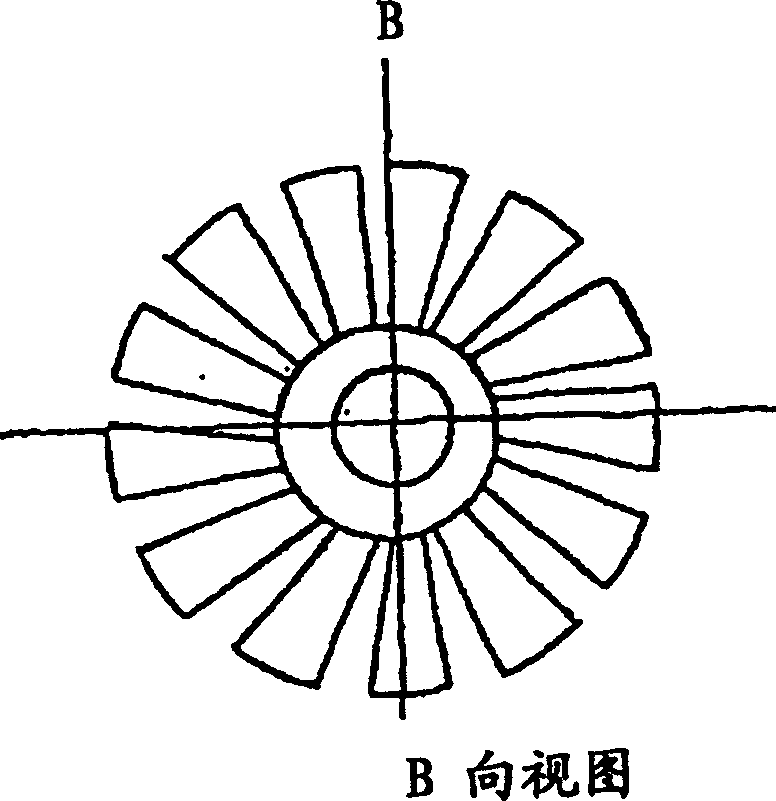

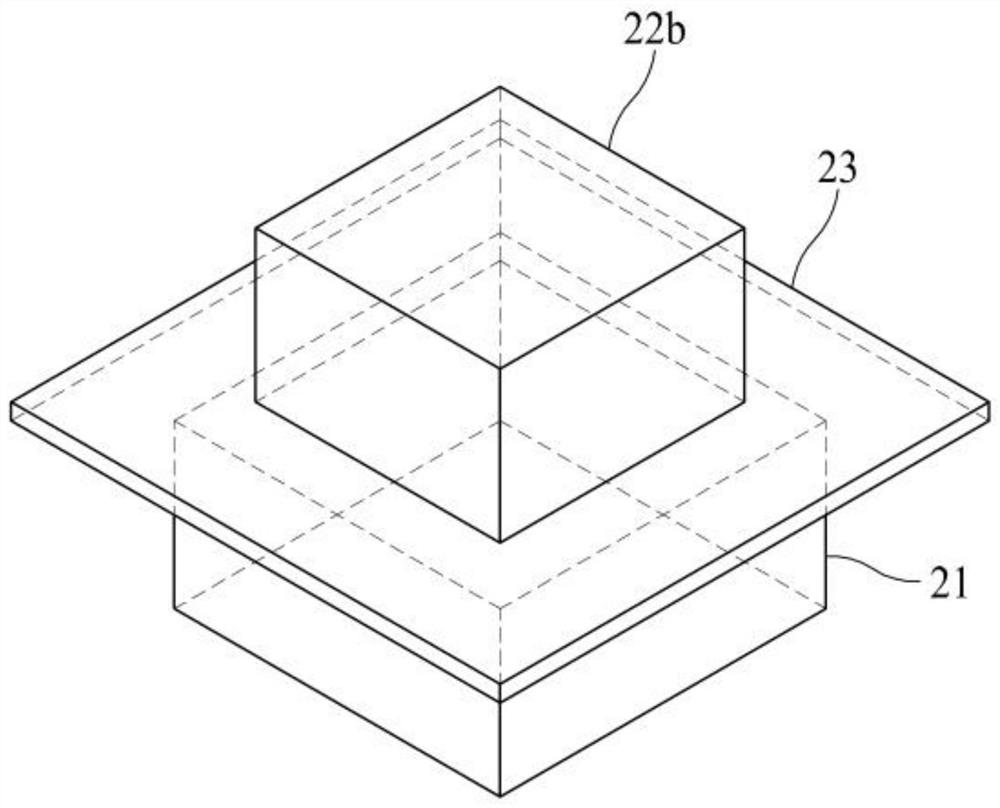

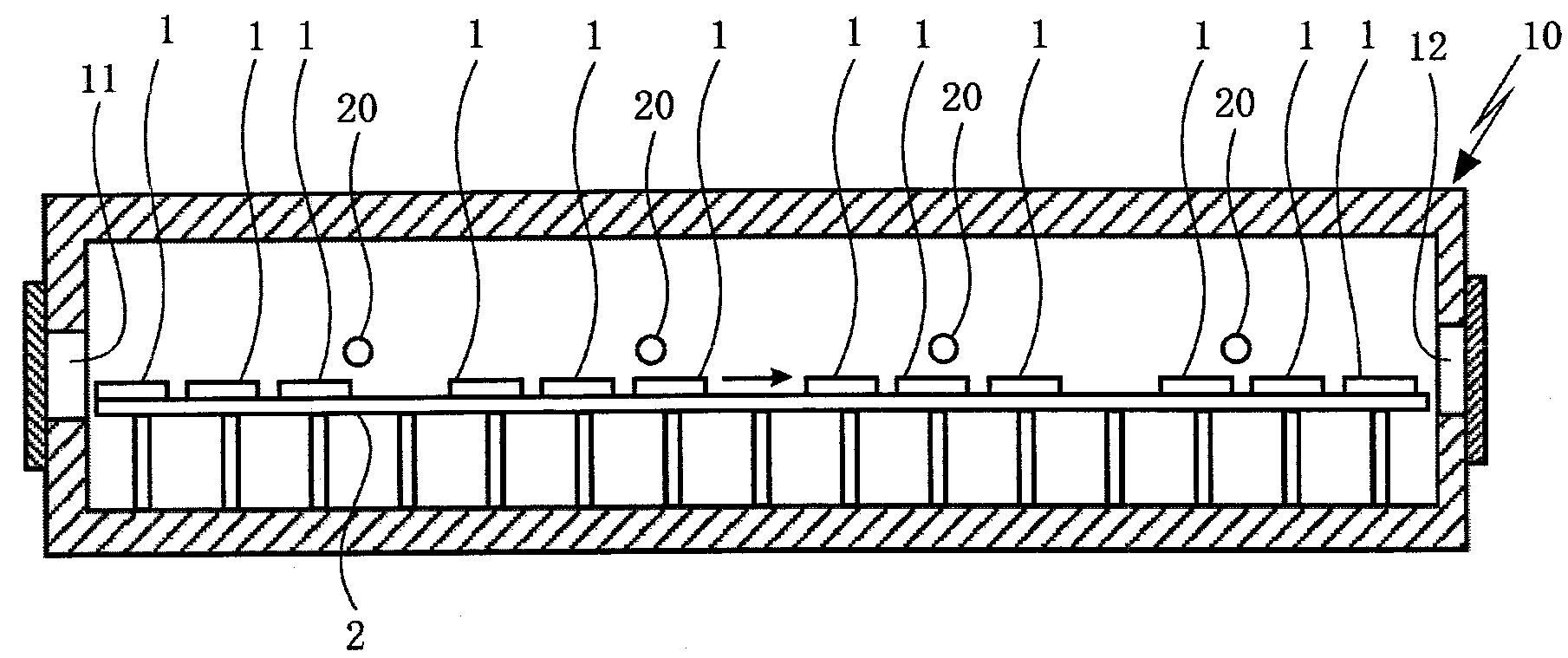

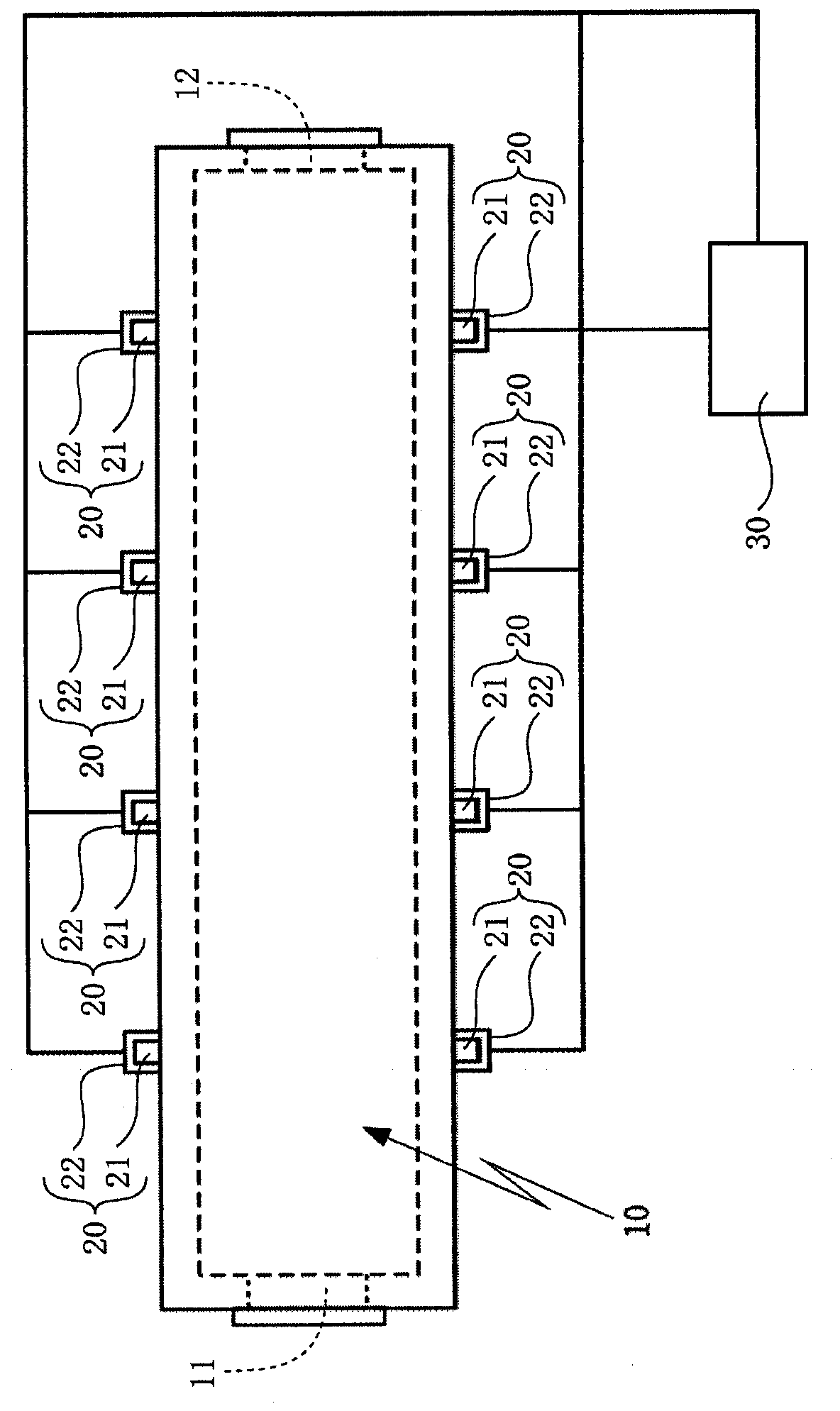

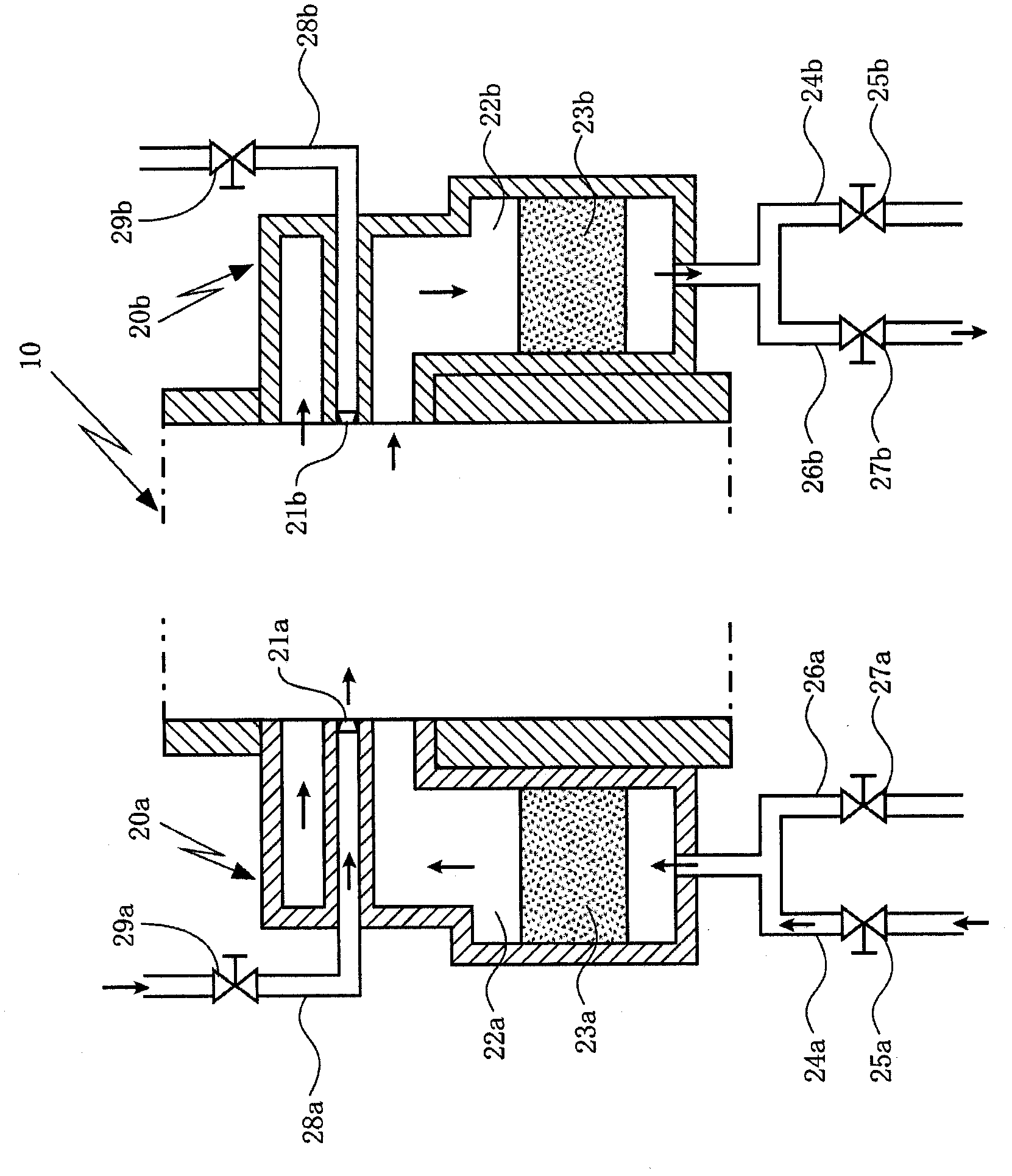

A combustion control method for a regenerative combustion type heat treatment furnace. When alternately switching the combustion operation and the heat storage operation in a pair of regenerative burners, the slave fuel gas supply pipe and the air supply pipe in each regenerative burner are The quantities of fuel gas and combustion air supplied from the tube are fixed, so that proper combustion can be performed stably. When switching between the combustion operation and the heat storage operation in a pair of regenerative burners (20), in the regenerative burner (20a) in combustion operation, the fuel gas supply pipe (28a) and the air supply The supply of fuel gas and combustion air supplied from the pipe (24a) decreases from the normal combustion state, and in the regenerative burner (20b) in the heat storage operation, the fuel gas supply pipe (28b) passes through the fuel gas supply pipe (28b) ) and air supply pipe (24b) to supply the fuel gas and combustion air supply from the stop state increased, and in a pair of regenerative burners, through the fuel gas supply pipe and the air supply pipe supplied from The supply of fuel gas and combustion air is fixed.

Owner:CHUGAI RO CO LTD

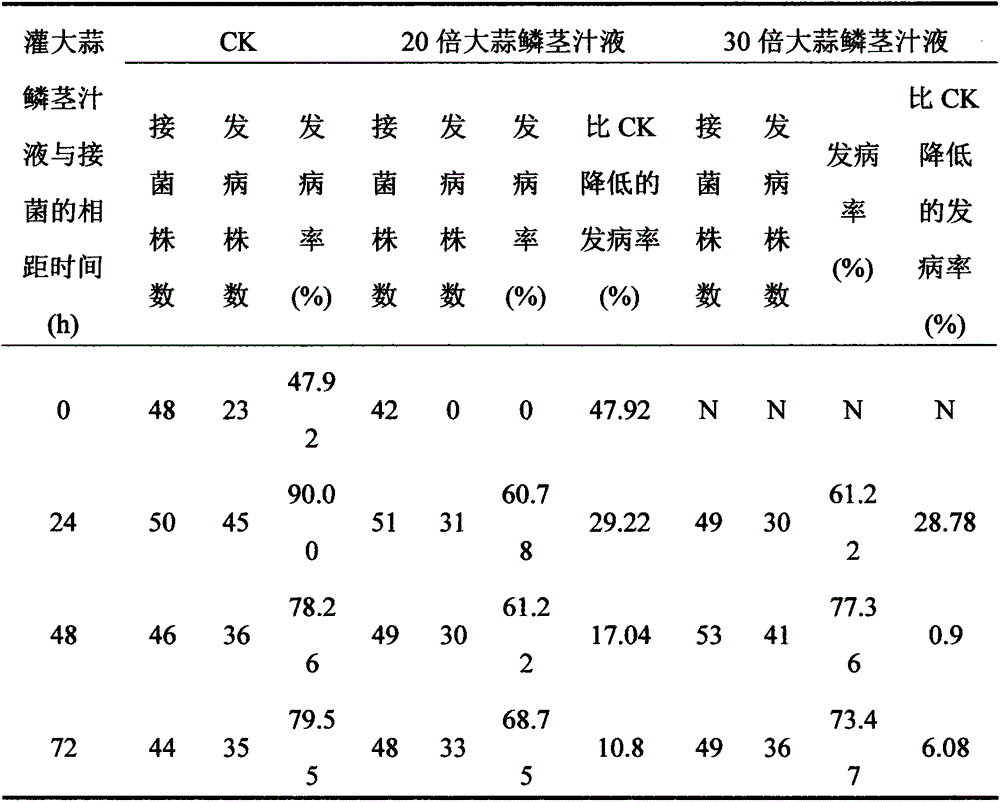

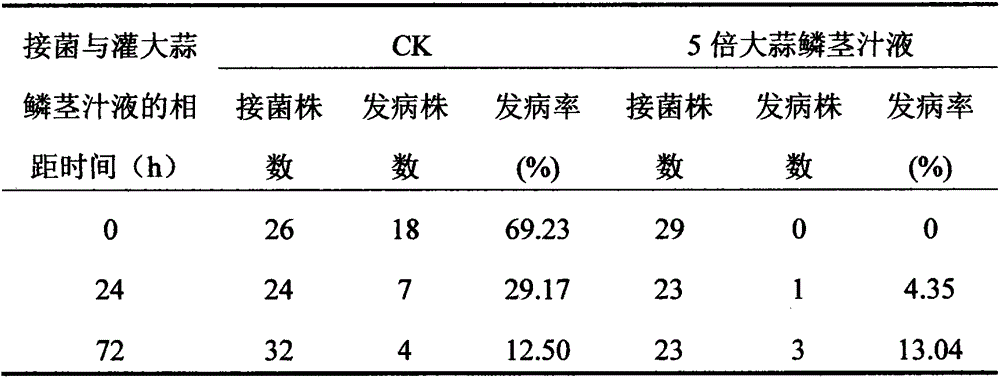

Application of garlic bulb juice in controlling pepper phytophthora blight

InactiveCN104920509AEffective preventionEffective therapeuticBiocideFungicidesPhytophthora sp.Capsicum annuum

The invention discloses an application of garlic bulb juice in controlling pepper phytophthora blight. According to the invention, garlic bulb is peeled and ground; the ground garlic bulb is mixed with sterile water, such that a dilute garlic bulb liquid is prepared; and the dilute garlic bulb liquid is used for irrigating pepper seedlings. According to the invention, the plant-sourced garlic bulb juice is used for controlling pepper phytophthora blight, and the pepper phytophthora blight can be effectively prevented and treated. The treatment method is simple, and does not cause environment problems. The method can be widely popularized.

Owner:甘肃省航天育种工程技术研究中心

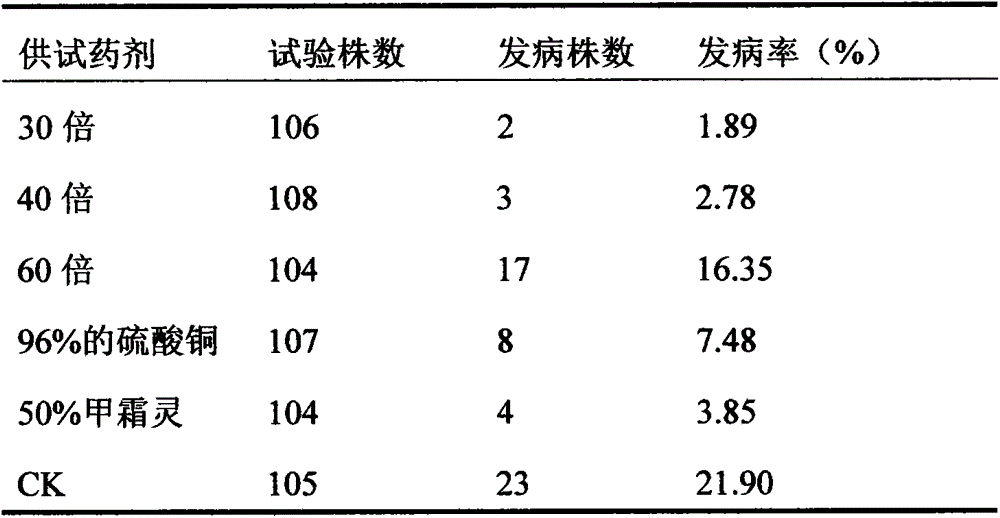

Method for producing tap water by using magnetic weighting agent coagulation magnetic separation technology

ActiveCN112520934AImprove turbidity reduction efficiencyImprove production turbidity reduction efficiencySpecific water treatment objectivesTreatment involving filtrationTap waterFiltration

The invention relates to a method for producing tap water by using a magnetic weighting agent coagulation magnetic separation technology, which comprises the following steps: adding a coagulant and amagnetic weighting agent into raw water to be treated for coagulation to obtain a coagulum, wherein the magnetic weighting agent is magnetic powder coated with polydopamine; carrying out solid-liquidmagnetic separation on the coagulum to obtain a precipitate and a clear liquid; carrying out solid-solid magnetic separation on the precipitate, and recycling to obtain a magnetic weighting agent; andcarrying out refined filtration and disinfection on the clarified liquid to obtain tap water. According to the method for producing tap water, a new magnetic loading coagulation magnetic separation technology is utilized, and the magnetic powder coated with polydopamine is further adopted as a magnetic weighting agent, so that the turbidity reduction efficiency of raw water production is greatlyimproved, the effluent quality is further ensured, the tap water production efficiency is improved, and the production cost is reduced. The magnetic weighting agent is added to produce tap water, so that the dosage of the coagulant is not additionally increased, secondary pollution to finished water is avoided, and the environmental problem is also avoided.

Owner:HNAC TECH

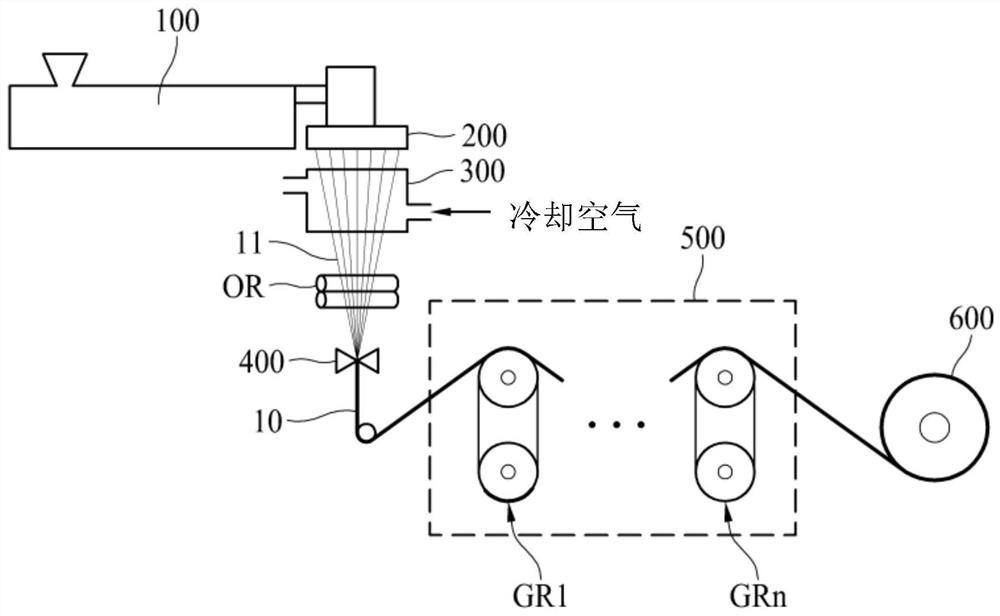

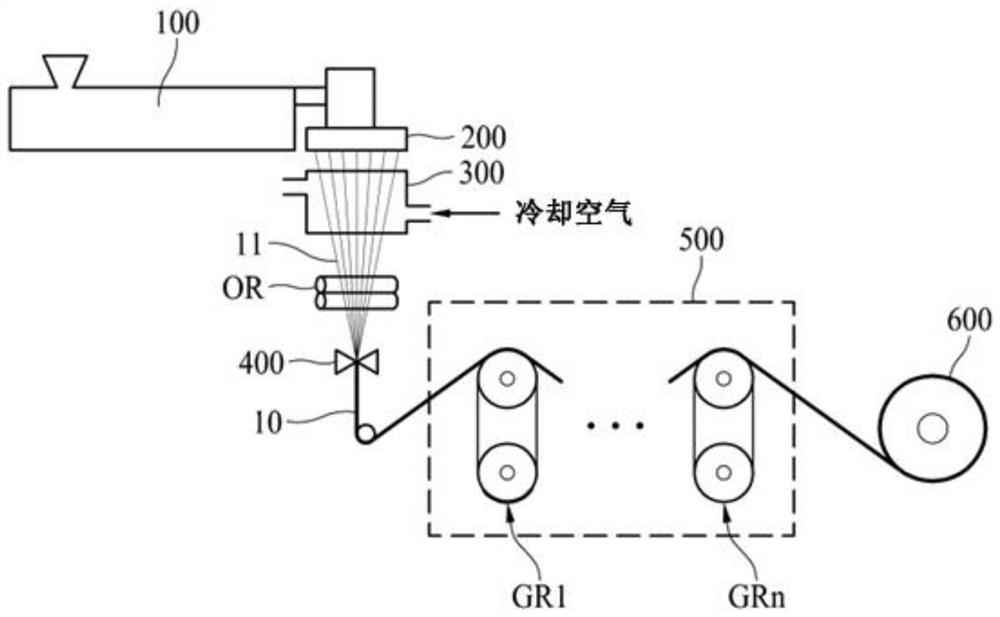

Polyethylene yarn, method for manufacturing the same, and skin cooling fabric comprising the same

ActiveCN114502784AHigh thermal conductivityImprove weavabilityProtective fabricsMelt spinning methodsYarnSkin cooling

The present disclosure relates to a polyethylene yarn capable of manufacturing a cool skin fabric having dimensional stability and improved weavability, and capable of manufacturing a cool skin fabric capable of providing a soft feel and a cool feel to a user; the present disclosure relates to a method of manufacturing the polyethylene yarn; and a skin cool fabric comprising the polyethylene yarn. The shrinkage stresses of the polyethylene yarn at 70 DEG C and 100 DEG C are respectively 0.005 g / d to 0.075 g / d. Further, the polyethylene yarn has a "dry heat shrinkage at 70 DEG C" of 0.1% to 0.5%, a "dry heat shrinkage at 100 DEG C" of 0.5% to 1.5%, and a "wet heat shrinkage at 100 DEG C" of 0.1% to 1%.

Owner:KOLON IND INC

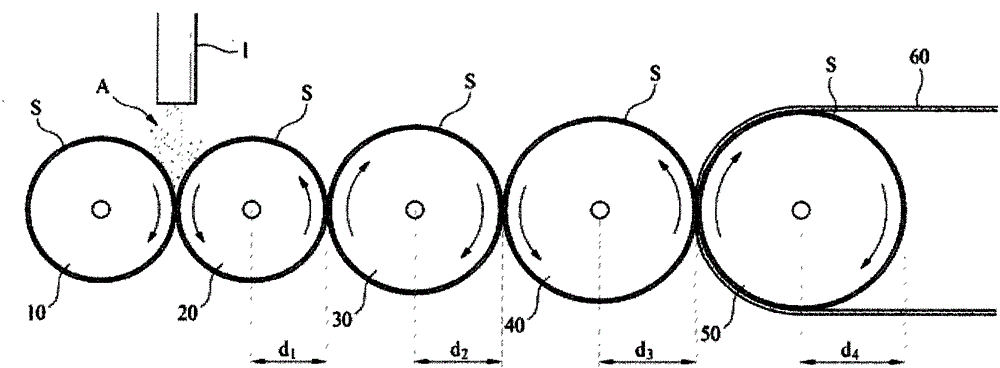

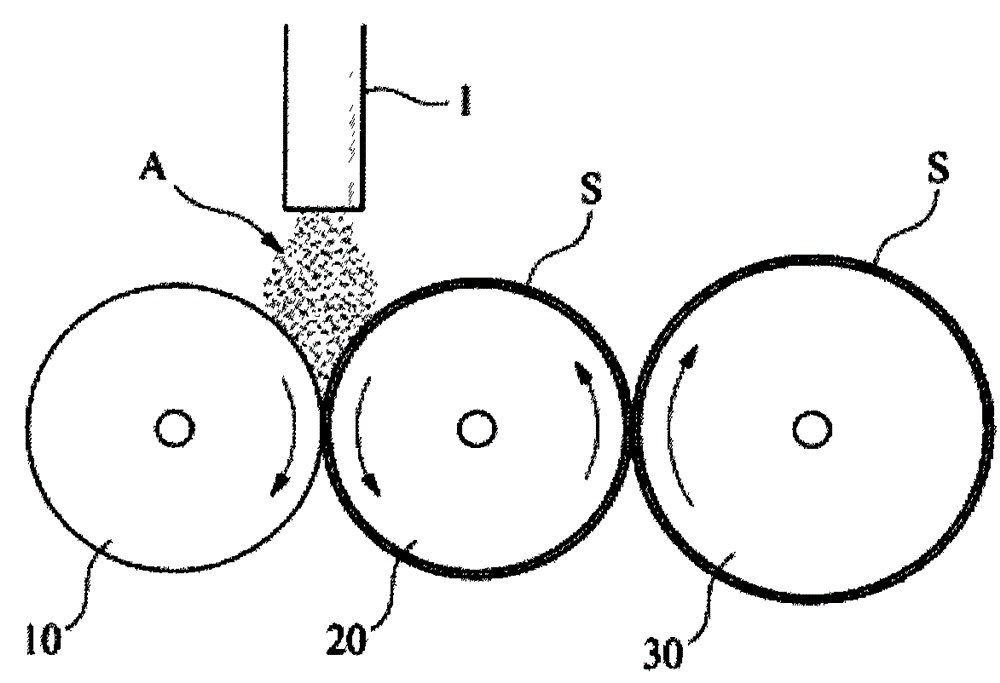

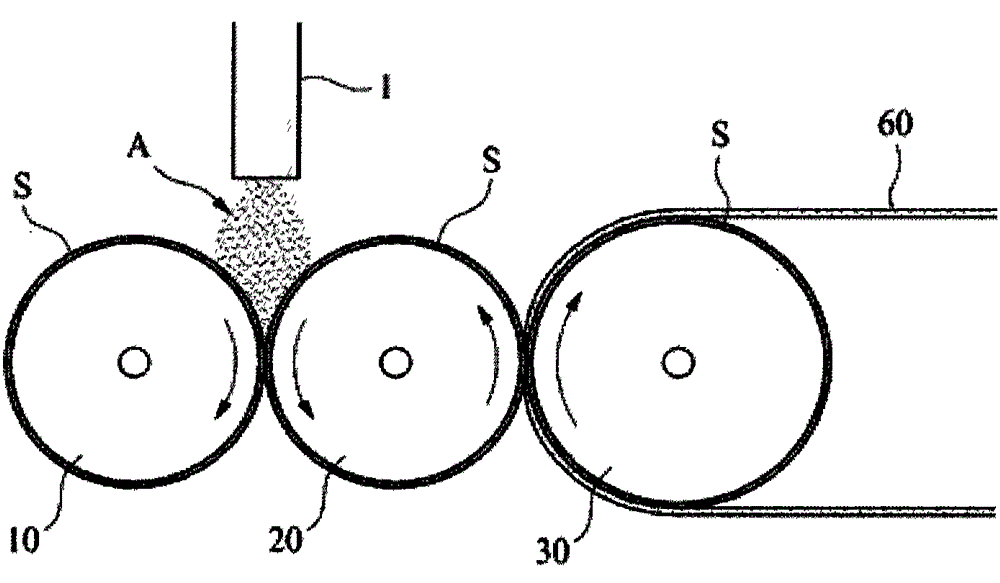

Graphene, and apparatus for manufacturing the same

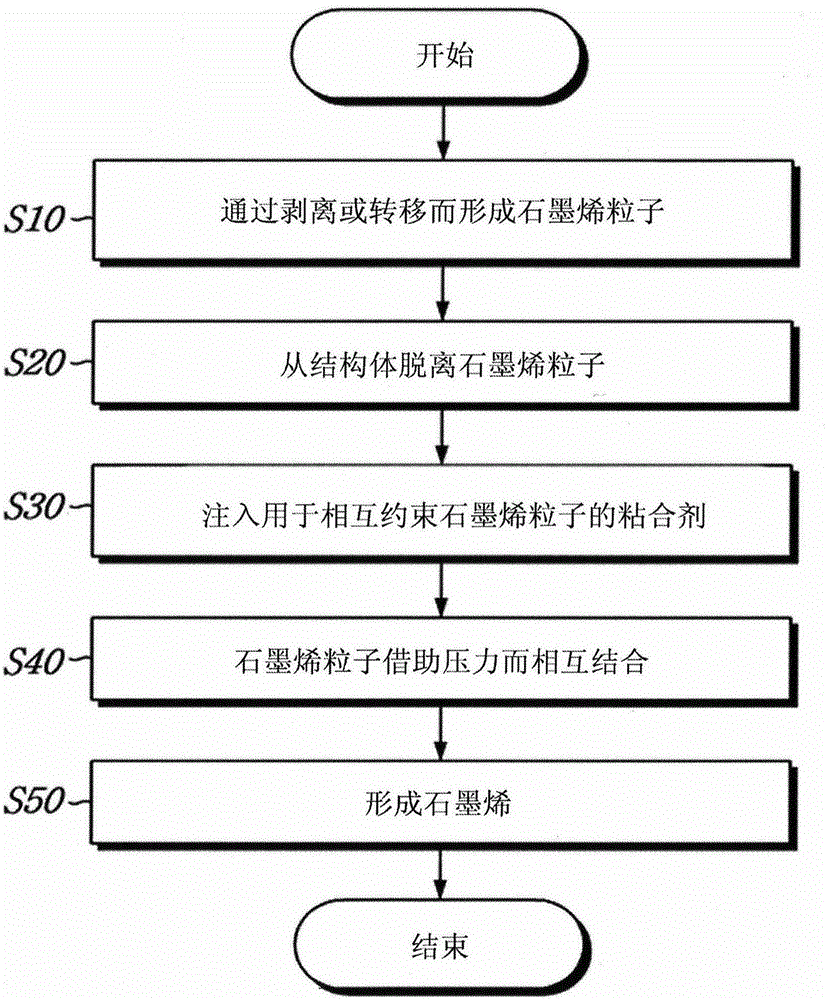

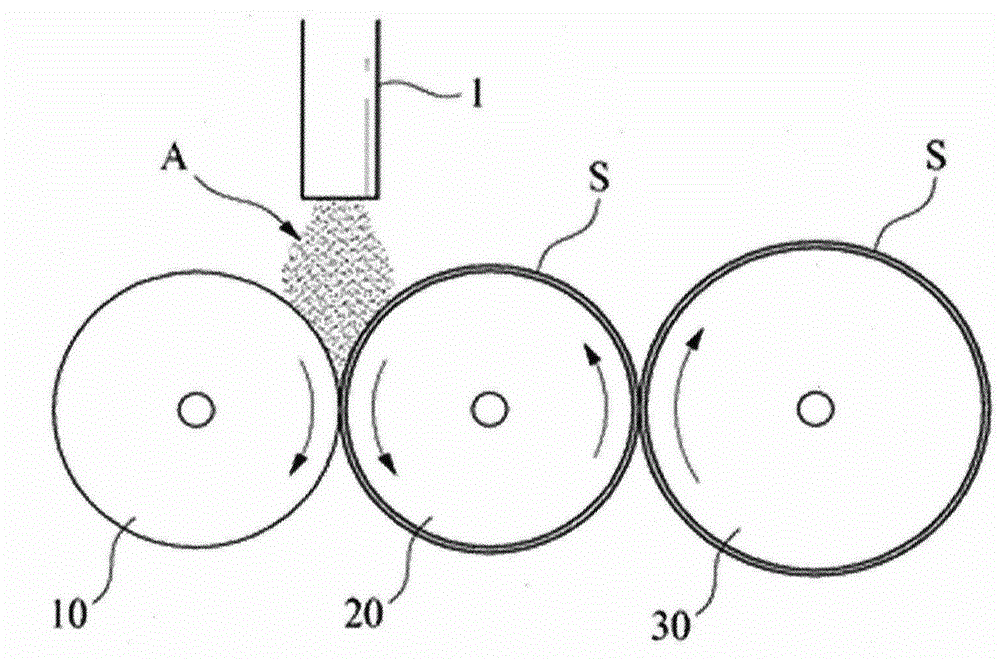

InactiveCN105000550AIncrease production capacityImprove conductivityGrapheneGraphiteTransfer mechanism

The present invention relates to technique for manufacturing graphene, more particularly, to graphene and an apparatus for manufacturing graphene which is manufactured massively using physical characteristic of graphite itself and exfoliating or transferring mechanism of various adhesive structures. The present invention also relates to graphene and an apparatus for manufacturing graphene generated by being seceded from at least one of the structures, after being exfoliated or transferred from a type of graphite material to at least one of structure, or generated by being seceded from at least one structure among a plurality of structures, after being continuously exfoliated or transferred from a type of graphite material to the plurality of structures.

Owner:朴得一

Exhaust gas filtering device

InactiveCN1565705AReliable filtrationDoes not cause environmental problemsCombination devicesExhaust fumesExhaust pipe

A waste gas filtering device comprises a double filtering device composed of an exhaust pipe connected with a waste gas generating device, a water tank filtering device and a filter which are connected with the other end of the exhaust pipe, and the filter is in the middle of an outlet pipe which connects said water tank and filter.

Owner:陈友年

Methods of manufacturing graphene and conductor

InactiveCN105314626AIncrease production capacityImprove conductivityGrapheneCarbon-silicon compound conductorsElectrical conductorGraphite

Owner:伊思幕有限公司

Photoresist stripper composition

ActiveCN103631103BExcellent peelabilityHarm reductionPhotosensitive material processingSolventPhotoresist

The present invention relates to a stripping liquid composition for removing photoresist, capable of replacing solvents such as NMP which is hazardous to human body, and which is excellent in stripping, thereby including N,N-dimethyl propionamide. The stripping liquid composition for removing photoresist includes: 10-85 % by weight of N,N-dimethyl propionamide, 1-30 % by weight of cyclic amines, 10-85 % by weight of amphiprotic polar solvent, and 0-50 % by weight of ultra-pure water.

Owner:DONGJIN SEMICHEM CO LTD

Combustion Control Method of Regenerative Combustion Heat Treatment Furnace

InactiveCN102269518BSuppresses changes in combustion stateStable combustionFuel supply regulationBurner control devicesCombustorProcess engineering

Owner:CHUGAI RO CO LTD

A type ab water system fire extinguisher

ActiveCN106039627BWidely used valueImprove fire extinguishing performanceFire rescueFire extinguisherHydrogen phosphateDiammonium phosphate

Owner:洛阳实盾消防科技发展有限公司

Biodegradable layered sheet

ActiveCN100439099CDoes not cause environmental problemsThe need to promote crystallizationSynthetic resin layered productsGlass transitionPolymer chemistry

It is an object to provide a biodegradable laminated sheet which is high in heat resistance, impact resistance and strength when subjected to loads at high temperature, does not develop wrinkles called 'bridges', which can be easily deep-drawn or formed into blister articles, which are typically complicated in shape. The biodegradable sheet is a laminated sheet comprising at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

A kind of ultraviolet light stabilizer based on polyvinyl chloride and preparation method thereof

ActiveCN103864966BGood compatibilityDoes not cause environmental problemsUltraviolet lightsPolyvinyl chloride

The invention provides an ultraviolet light stabilizer based on polyvinyl chloride and a preparation method thereof. The structure of the ultraviolet light stabilizer is as shown in formula V, wherein R, x and y are defined according to the claims and the specification. The preparation method comprises steps of bringing in a nitrine functional group on the main chain of the polyvinyl chloride, and bringing in alkynyl on a small-molecular ultraviolet light stabilizer; and finally performing a 'click' reaction between nitrine and alkynyl to bond high-efficiency bonds of the ultraviolet light stabilizer on the main chain of the polyvinyl chloride. The preparation method is simple, and the content of the small-molecular ultraviolet light stabilizer is adjustable. A small-molecular ultraviolet light absorbent is bonded on the main chain of the polyvinyl chloride, so the problem of compatibility of the ultraviolet light absorbent in the polyvinyl chloride is avoided, and the environmental problem caused by precipitation of the small-molecular ultraviolet light stabilizer is avoided as well.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI +1

Sulphur removal corrosion inhibitor and preparation method thereof

ActiveCN101955766BFast desulfurization reactionGuaranteed SolubilityDrilling compositionBorehole/well accessoriesGluconic acidStearic acid

The invention relates to a sulphur removal corrosion inhibitor, which is prepared from the following components in percentage by weight: 26% of calcium gluconate, 18% of ferrous sulfate, 10% of basic zinc carbonate, 9% of stearic amide and the balance of water. The sulphur removal corrosion inhibitor is insensitive to the pH value, has no effect on the rheological behavior of drilling fluid and simultaneously has good compatibility with other finishing agents in the drilling fluid. Ferrous ions in the sulphur removal corrosion inhibitor are easy to absorb by organic matters, a complex compound of the ferrous ions and organic acid is environment-friendly, and the discharge of drilling cuttings and the drilling fluid containing iron ion filtrate cannot cause environmental problems.

Owner:SICHUAN ZHENGRONG IND +1

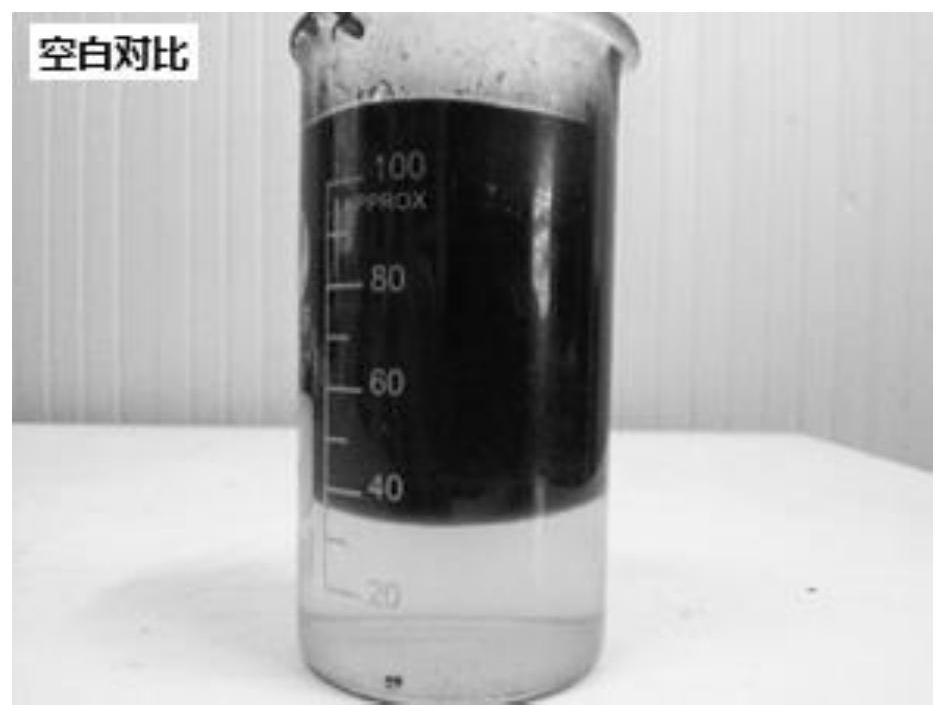

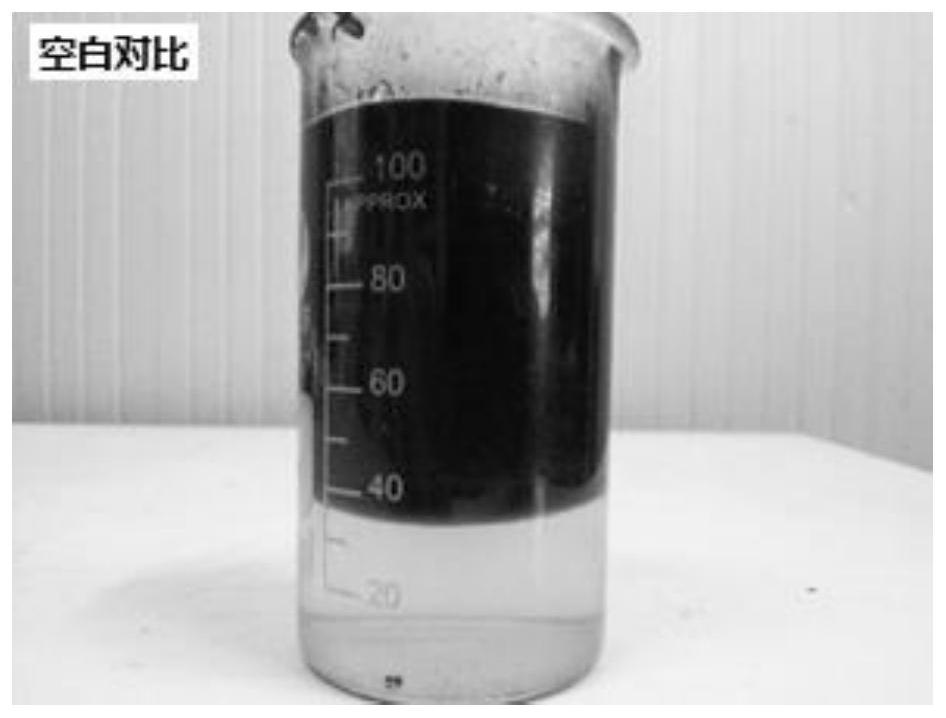

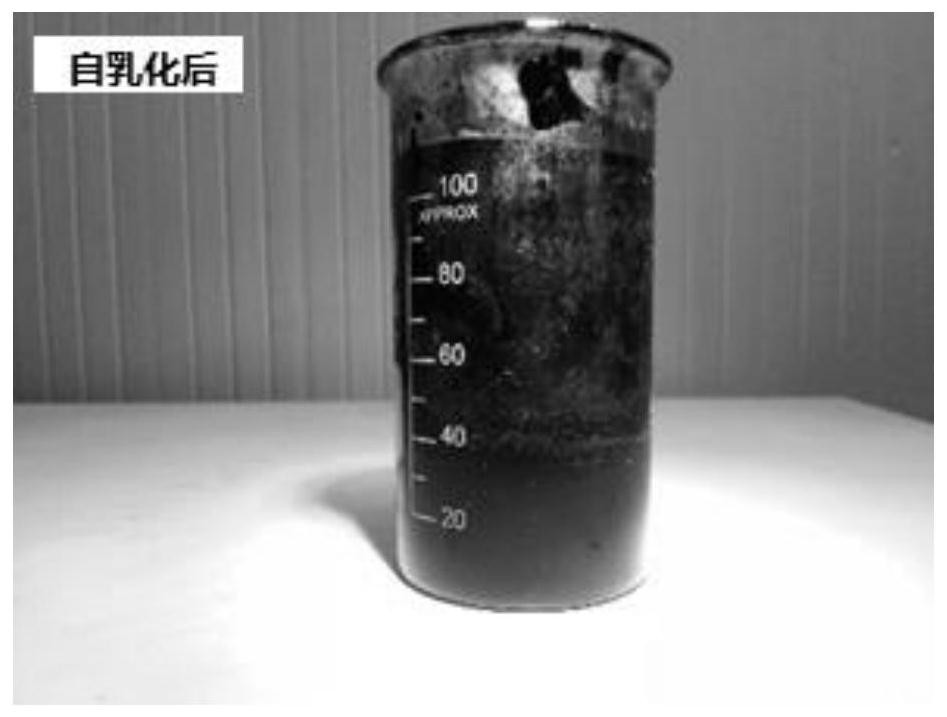

Preparation method of thick oil viscosity reduction and production increase agent, thick oil viscosity reduction and production increase agent and application of thick oil viscosity reduction and production increase agent

ActiveCN112500844AReduce manufacturing costDoes not cause environmental problemsFluid removalDrilling compositionEmulsionOil viscosity

The invention relates to the technical field of thickened oil production increase, and particularly discloses a preparation method of a thickened oil viscosity-reducing and production-increasing agentand the prepared thickened oil viscosity-reducing and production-increasing agent. The invention provides a method for producing a thickened oil self-emulsifying viscosity-reducing production-increasing agent by using lignin, which comprises the following steps: carrying out oxidative sulfonation modification on lignin, and reacting the modified lignin with aldehyde and phenol to modify; after the reaction is finished, performing neutralizing with alkali, adding amine for modification treatment, then adding a co-emulsifier, and performing stirring and uniform mixing to obtain the product. Thepreparation method is simple, raw materials are wide in source and low in price, and waste is avoided. Tests show that the thick oil viscosity reduction and production increase agent has good self-emulsifying performance on heavy oil, is stable in emulsion and good in high-temperature resistance, and is not obviously attenuated at 200 DEG C.

Owner:INST OF RESOURCES COMPREHENSIVE UTILIZATION GUANGDONG ACAD OF SCI

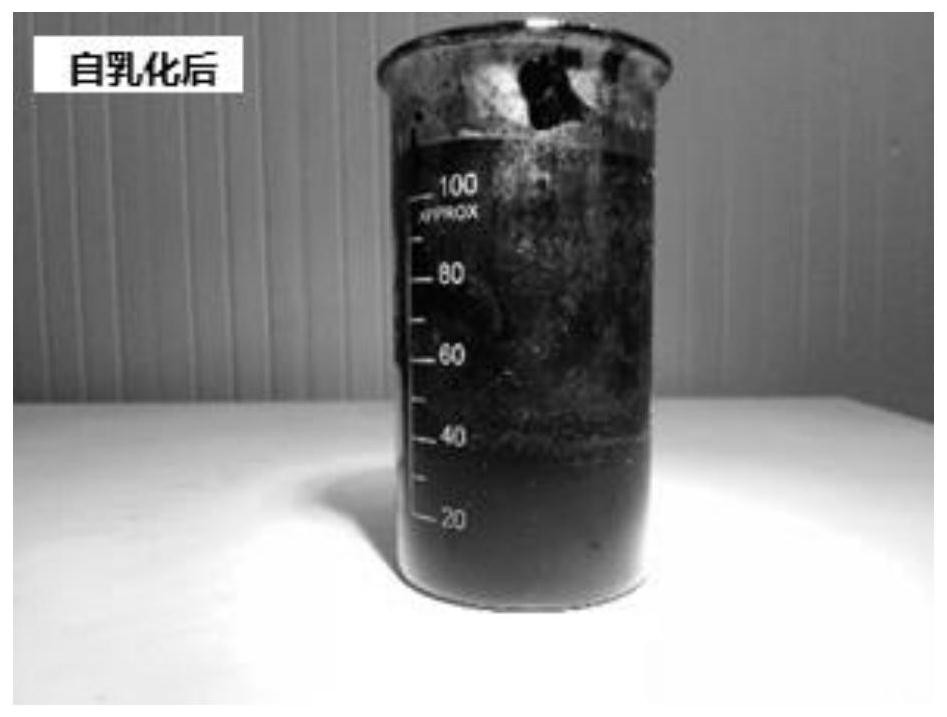

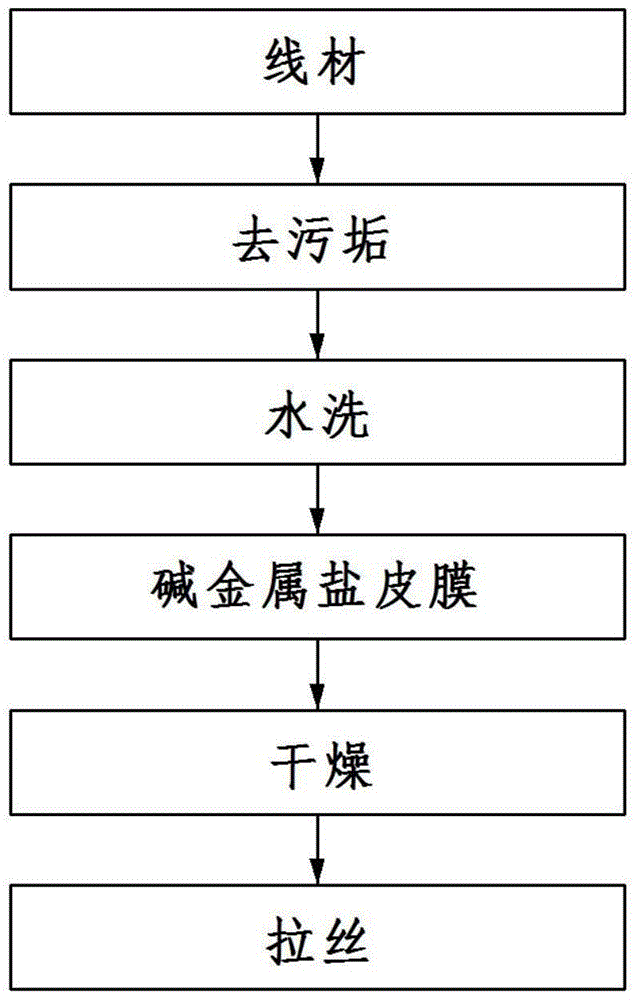

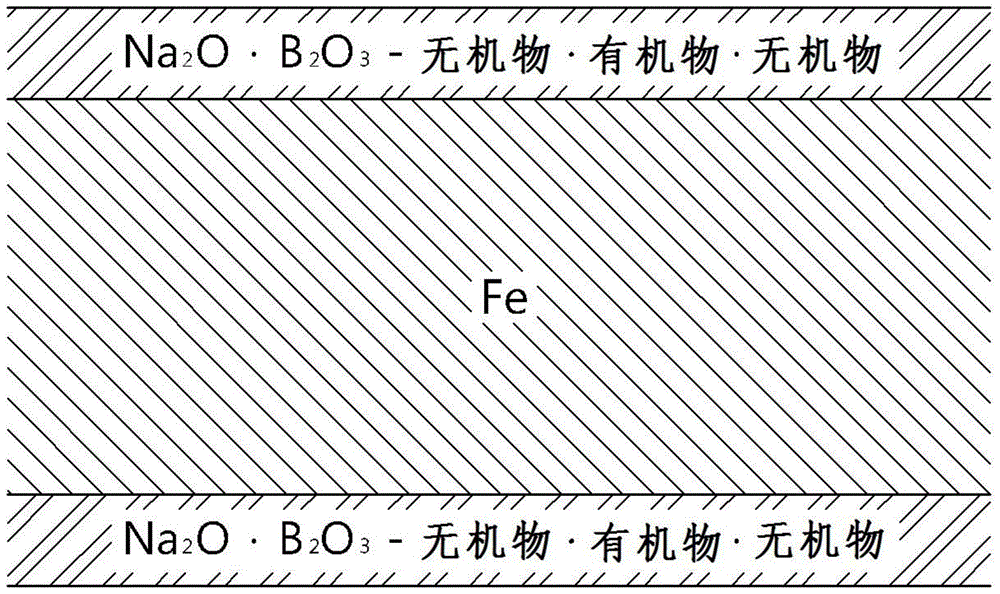

Metal surface treatment method and metal surface treatment agent

InactiveCN105316664BDoes not cause environmental problemsExtensibleMetallic material coating processesLubricationAlkali metal

The invention relates to a metal surface treatment method and a metal surface treatment agent. The method includes the steps of washing with water after removing the dirt of the metal material; after the washing, when the metal material is drawn through a wire drawing die, in order to improve the lubricating effect and protect the the surface of the metal material, the step of forming an alkali metal salt film on the surface of the metal material; and the drying step. The present invention does not cause environmental problems, and enables the surface of the wire to have extensibility, corrosion resistance, and wear resistance.

Owner:格林化学工业株式会社 +2

Preparation method of a cellulose nanofiber/silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material

InactiveCN107331865BWide variety of sourcesLow costHybrid capacitor electrodesCell electrodesCelluloseFreeze-drying

The invention relates to a method for preparing a cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material, which belongs to the technical field of carbon electrode materials. The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of the present invention comprises the following steps: uniformly mixing the cellulose nanofiber suspension with the silk fibroin solution to obtain a composite suspension; Treat in hydrochloric acid vapor for 1-12h to make cellulose nanofiber / silk fibroin composite hydrogel; freeze in liquid nitrogen for 5-60min and freeze-dry to make composite aerogel; under protective atmosphere, 700-1300 Carbonization at ℃ for 1‑8h, and then activated, that is. The cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material prepared by the method of the present invention has the characteristics of large size, good flexibility, and porosity, and also has the microstructure of 2D graphene morphology shape.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

A preparation method of a heavy oil viscosity-reducing and production-increasing agent, a heavy oil viscosity-reducing and production-increasing agent and its application

ActiveCN112500844BReduce manufacturing costDoes not cause environmental problemsFluid removalDrilling compositionEmulsionOil viscosity

The invention relates to the technical field of heavy oil production enhancement, and specifically discloses a preparation method of a heavy oil viscosity reduction and production enhancement agent and the prepared heavy oil viscosity reduction and production enhancement agent. The method provided by the present invention for producing heavy oil self-emulsifying viscosity reducing agent by using lignin firstly carries out oxidative sulfonation modification of lignin, and then reacts with aldehyde and phenol for modification; after the reaction is completed, it is neutralized with alkali, And add amine for modification treatment, then add co-emulsifier and stir to mix. The preparation method of the invention is simple, the source of raw materials is wide and cheap, and there is no waste. According to the test, it has good self-emulsifying performance and stable emulsion for heavy oil, and has good high temperature resistance performance, and there is no obvious attenuation at 200 °C.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Polyethylene yarn, method for manufacturing same, and cool-feeling fabric comprising same

ActiveCN113710836AFast heat conductionGood knitting performanceMelt spinning methodsWoven fabricsYarnPolymer science

Disclosed are polyethylene yarn, a method for manufacturing same, and a cool-feeling fabric comprising same, wherein the polyethylene yarn has improved weavability to enable the manufacturing of the cool-feeling fabric that can provide a user with soft tactile sensation as well as cooling sensation and has excellent pilling resistance, abrasion resistance, cuttability, and sewability. In a stress-strain curve of the polyethylene yarn, obtained from the measurement at room temperature, (i) the elongation is 0.5 to 3% at a stress of 1 g / d, (ii) the elongation is 5.5 to 10% at a stress of 3 g / d, and (iii) the difference between the elongation at a stress of 4 g / d and the elongation at the maximum stress is 5.5 to 25%, wherein the polyethylene yarn has a toughness of 55 to 120 J / m<3> at room temperature.

Owner:KOLON IND INC

Combustion control method of regenerative-combustion heat treatment furnace

InactiveCN102269519BAvoid it happening againSuppress incomplete combustionFuel supply regulationBurner control devicesCombustorFuel gas

Owner:CHUGAI RO CO LTD

Pyrolysis process wastewater treatment system and method based on dual-circulation fluidized bed boiler

PendingCN114110614AShort processReduce processing costsSpecial form destructive distillationElectrostatic separation detailsWater treatment systemProcess engineering

The invention provides a pyrolysis process wastewater treatment system and method based on a double-circulation fluidized bed boiler, and belongs to the field of wastewater treatment. A circulating fluidized bed pyrolyzing furnace, a waste water pool, a waste water pump, an atomizing spray gun capable of advancing and retreating, a compressed air tank, a first manual valve, a second manual valve and other components are additionally arranged on the basis of an existing power generation system, and the waste water treatment system based on the existing power generation system is provided. The composition structure of the pyrolysis process wastewater treatment system can be simplified, the pyrolysis process wastewater treatment process is shortened, the heat source circulating back to the circulating fluidized bed combustion furnace is fully utilized in the pyrolysis process wastewater treatment process, and the wastewater treatment cost can be saved. Besides, the pyrolysis process wastewater is incinerated in the circulating fluidized bed combustion furnace, so that organic matters in the pyrolysis process wastewater can be converted into harmless small molecules such as H2O and CO2 at high temperature, meanwhile, dioxin is prevented from being generated, and environmental problems cannot be caused.

Owner:山西平朔煤矸石发电有限责任公司 +1

An environmentally friendly cleaning agent

InactiveCN106811322ANon-toxicDoes not cause environmental problemsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsSODIUM XYLENESULFONATE

An environment-friendly cleaning agent, comprising the following components in parts by weight: 20-30 parts of absolute ethanol, 3-7 parts of sodium xylenesulfonate, 4-8 parts of sodium perborate, 5-10 parts of cyclohexane, alkane 3-8 parts of alcohol polyoxyethylene, 2-4 parts of sodium citrate, 1-3 parts of glycine, etc. The beneficial effect of the invention is that it will not cause environmental problems, basically has no poisonous effect on the human body, has fast volatilization speed, and has outstanding cleaning effect.

Owner:TIANCHANG EARTHQUAKE OFFICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com