Pyrolysis process wastewater treatment system and method based on dual-circulation fluidized bed boiler

A wastewater treatment system and circulating fluidized bed technology, applied in the direction of incinerators, combustion methods, coke ovens, etc., can solve the problems of large area of the system, long process, high cost, etc., to save costs, simplify the composition structure, shorten The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

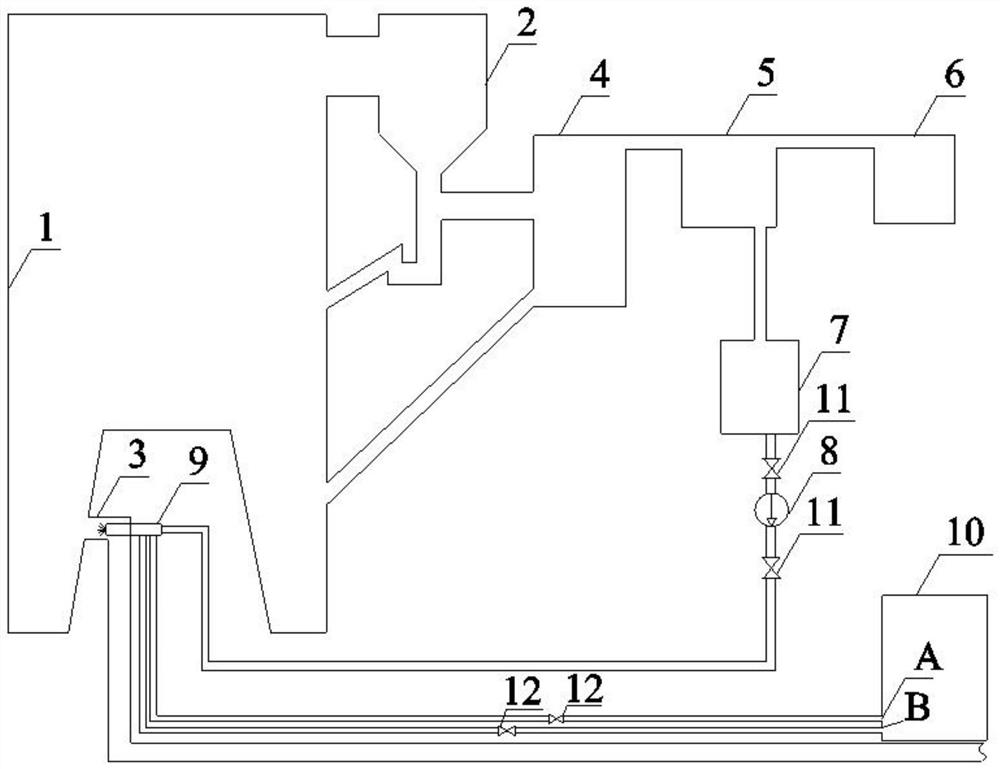

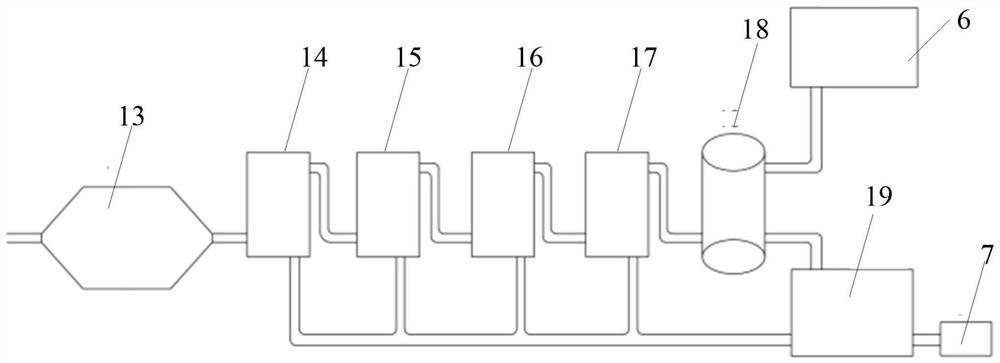

[0033] Such as figure 1 As shown, the pyrolysis process wastewater treatment system based on double circulating fluidized bed boiler in this embodiment includes circulating fluidized bed combustion furnace 1, cyclone separator 2, secondary air pipe 3, circulating fluidized bed pyrolysis Furnace 4, gas purification and cooling device 5, gas storage tank 6, waste water pool 7, waste water pump 8, advance and retreat atomizing spray gun 9, compressed air tank 10, two first manual valves 11 and two second manual valves 12 , wherein, the secondary air duct 3 is inserted inside the underpants legs of the circulating fluidized bed combustion furnace 1, and the inlet of the secondary air duct is connected with the fan; the flue gas outlet of the circulating fluidized bed combustion furnace 1 passes through the flue and The flue gas inlet of the cyclone separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com