Preparation method of cellulose nanofiber/silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material

A technology of nanofibers and silk fibroin, applied in the manufacture of hybrid/electric double layer capacitors, battery electrodes, nanotechnology, etc., can solve the problems of unfavorable material capacity, unfavorable size, etc., achieve low cost, improve cycle life, and facilitate scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

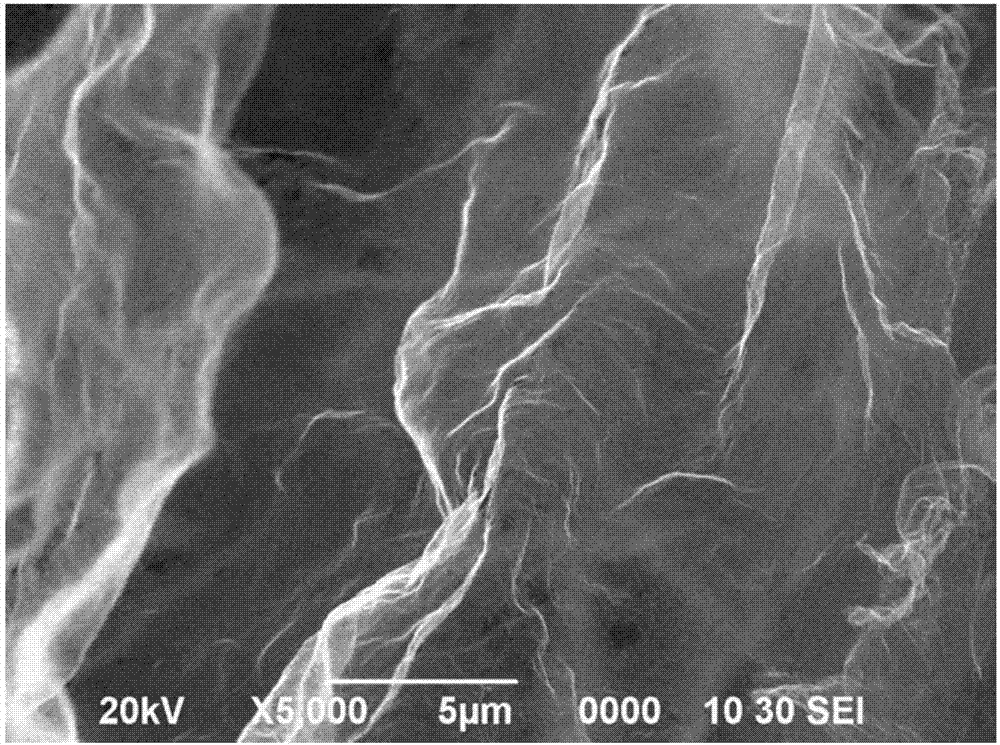

[0034] The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of this embodiment comprises the following steps:

[0035] 1) Preparation of cellulose nanofiber suspension and silk fibroin solution

[0036] The bamboo pulp was subjected to TEMPO catalytic oxidation reaction, then ultrasonically dispersed for 10 minutes, and then concentrated by vacuum rotation to obtain a suspension of cellulose nanofibers (CNFs), and the mass fraction of cellulose nanofibers (CNFs) in the suspension was 0.8%;

[0037] Dissolve the degummed cocoons into a LiBr solution with a concentration of 9.3 mol / L, and then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze for 3 days to obtain a silk fibroin solution. The mass fraction of silk fibroin in the silk fibroin solution is 7%;

[0038] 2) Preparation of cellulose nanofiber / silk fibroin composite suspension

[0039] The prepared silk fibroin solution wa...

Embodiment 2

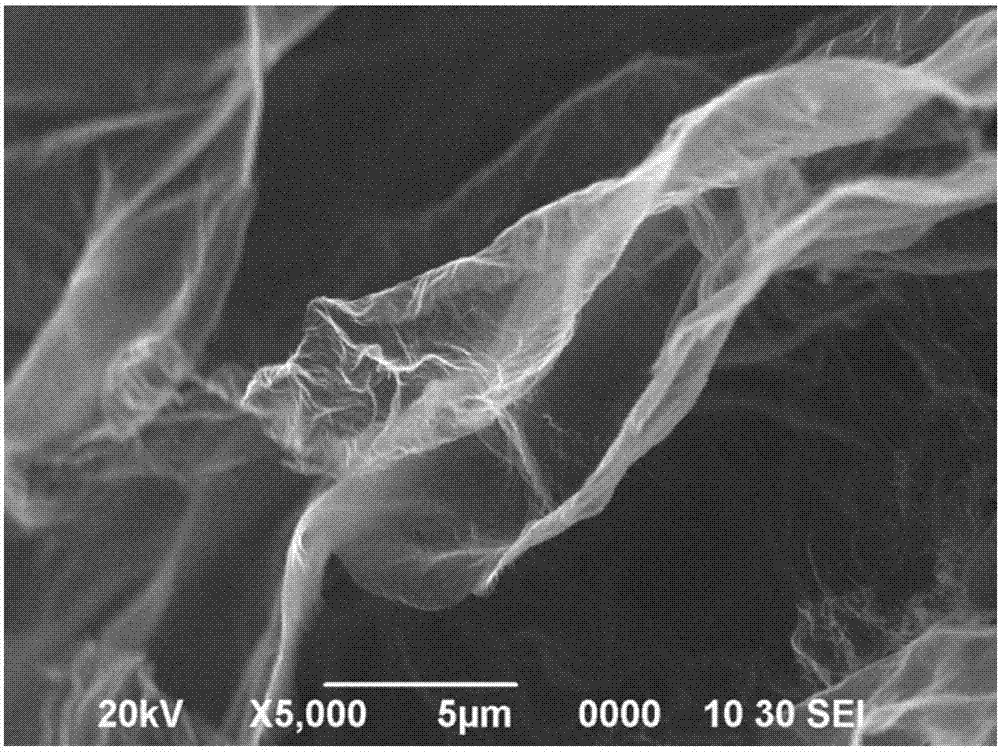

[0047] The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of this embodiment comprises the following steps:

[0048] 1) Preparation of cellulose nanofiber suspension and silk fibroin solution

[0049] The bamboo pulp was subjected to TEMPO catalytic oxidation reaction, then ultrasonically dispersed for 10 minutes, and then vacuum rotary concentration was carried out to obtain a suspension of cellulose nanofibers (CNFs), and the mass fraction of cellulose nanofibers (CNFs) in the suspension was 1.5%;

[0050] The degummed silkworm cocoons were dissolved in a LiBr solution with a concentration of 9.3mol / L, and then dialyzed for 3 days using a dialysis bag with a molecular weight cut-off of 3500 to obtain a silk fibroin solution. The mass fraction of silk fibroin in the silk fibroin solution was 8%;

[0051] 2) Preparation of cellulose nanofiber / silk fibroin composite suspension

[0052] The prepared...

Embodiment 3

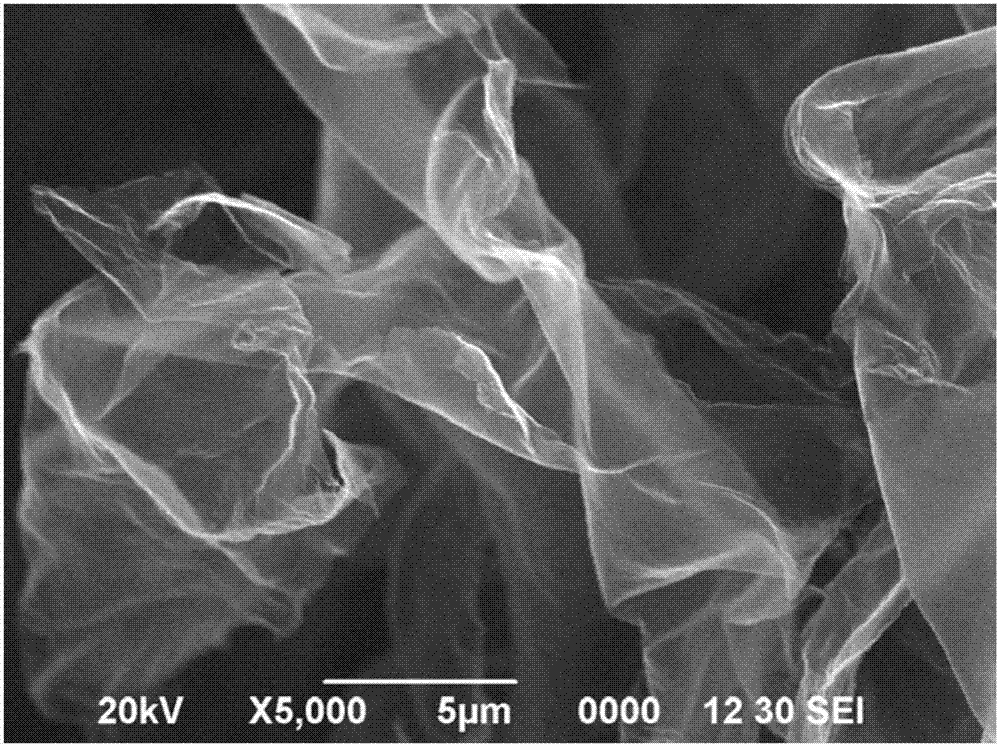

[0060] The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of this embodiment comprises the following steps:

[0061] 1) Preparation of cellulose nanofiber suspension and silk fibroin solution

[0062] The bamboo pulp was subjected to TEMPO catalytic oxidation reaction, then ultrasonically dispersed for 10 minutes, and then vacuum rotary concentration was carried out to obtain a suspension of cellulose nanofibers (CNFs). The mass fraction of cellulose nanofibers (CNFs) in the suspension was 1 %;

[0063] The degummed silkworm cocoons were dissolved in a LiBr solution with a concentration of 9.3mol / L, and then dialyzed for 3 days using a dialysis bag with a molecular weight cut-off of 3500 to obtain a silk fibroin solution. The mass fraction of silk fibroin in the silk fibroin solution was 5%;

[0064] 2) Preparation of cellulose nanofiber / silk fibroin composite suspension

[0065] The prepared silk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com