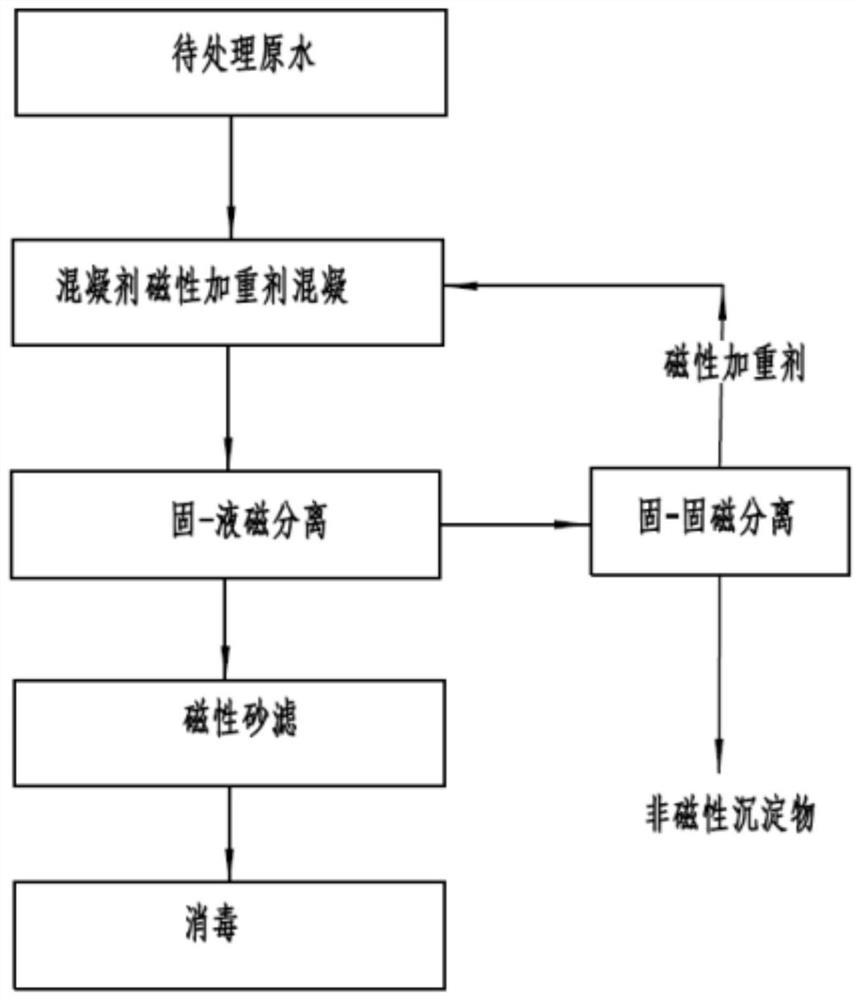

Method for producing tap water by using magnetic weighting agent coagulation magnetic separation technology

A technology of weighting agent and magnetic separation, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, magnetic field/electric field water/sewage treatment, etc. Problems such as large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

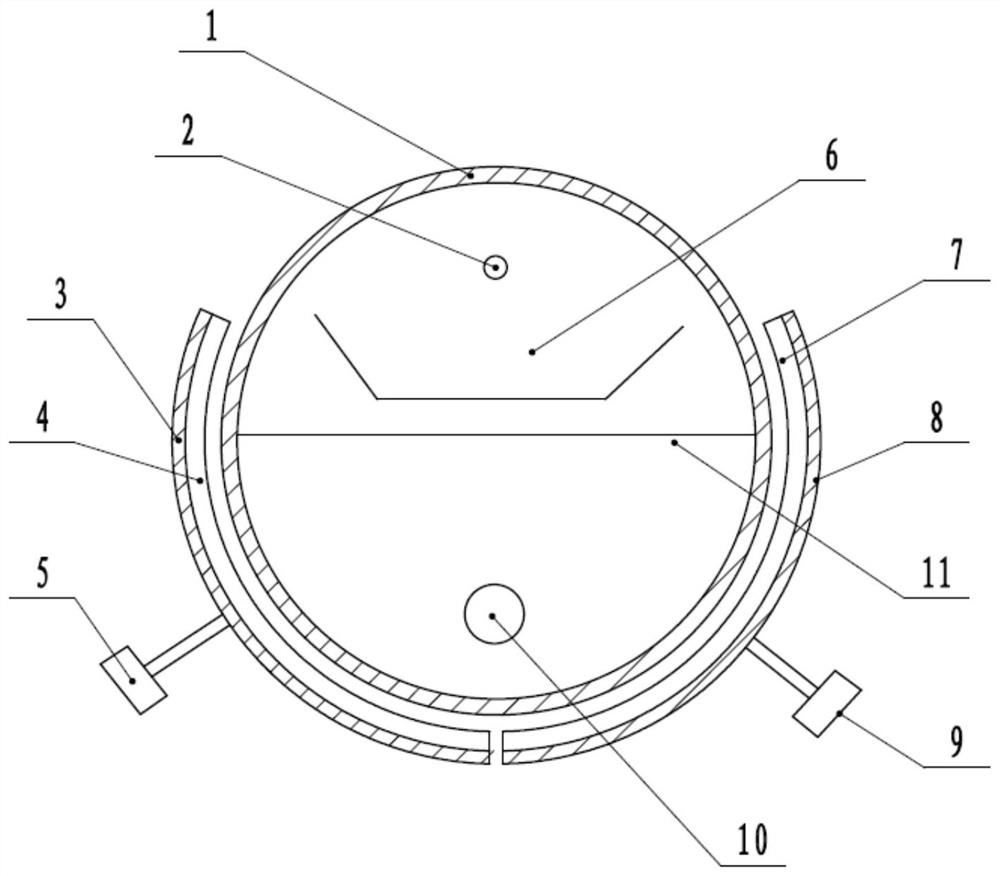

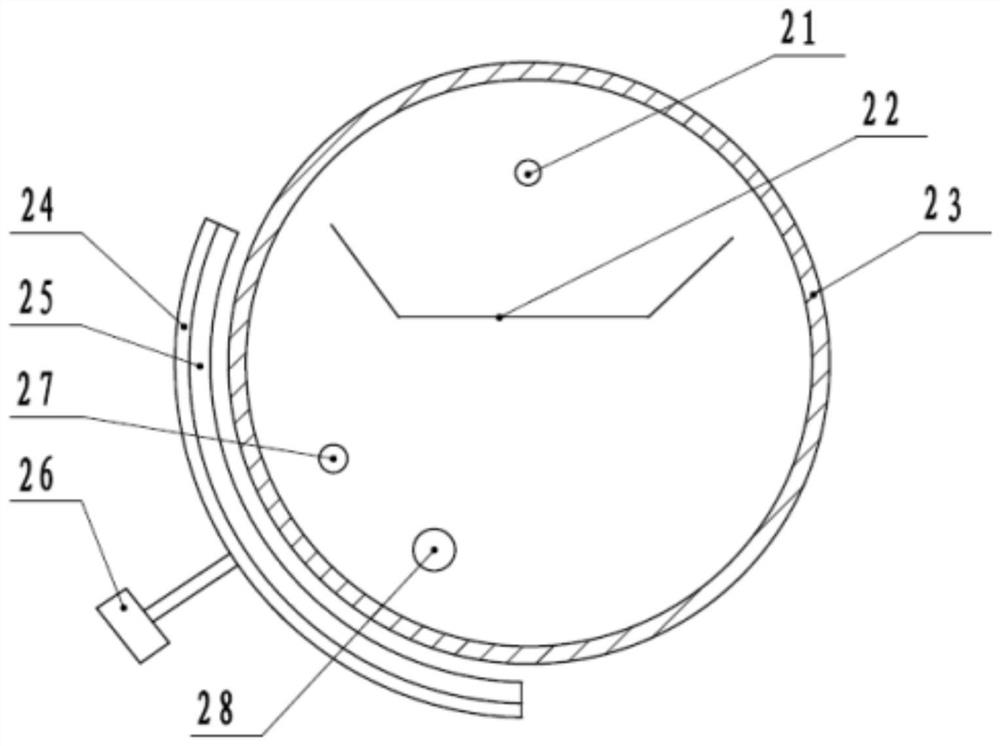

Image

Examples

preparation example Construction

[0060] 1. Preparation of magnetic weighting agent and magnetic filter sand

[0061] Select the igneous rock-shaped single magnetite raw ore, and the distribution rate of the raw ore magnetite is more than 60%, preferably more than 90%.

[0062] After crushing (crushing ratio 3~4), coarse grinding (rod mill crushing ratio 70~100), ultrafine grinding (stirring mill crushing ratio 9000~10000), screening (6~8 mesh), classification (400 mesh ), magnetic separation (0.04 ~ 0.12mT), reverse flotation (float quartz), filtration (press filtration) and drying (80 ~ 115 ℃) to produce a pure natural and does not contain other harmful trace elements, density close to 5.2, The coercive force is not greater than 0.05 Gauss, and micron (37 ~ 5μm) ferroferric oxide magnetic powder.

[0063] Wherein, in the above-mentioned sieving step, the millimeter-scale sand particles (with a particle size of 1 to 3 mm) sieved through the 6-mesh and 8-mesh sieves are used as sand for fine filtration, that ...

Embodiment 1

[0076] Raw water sample turbidity reduction test with 100 turbidity: the test instrument is ZR4-6 coagulation test mixer; the test container is 1000mL.

[0077] Add polyaluminium chloride and magnetic weighting agent to the raw water sample with 100 turbidity to test the sedimentation effect. The addition amount of polyaluminum chloride is 0.03g / L (ie 30mg / L); the addition amount of magnetic weighting agent is respectively: 0g / L, 0.1g / L, 0.2, 0.5, 1.0 and 1.5g / L.

[0078] Samples were taken at 5, 10, 15, and 20 minutes of settling time, and the turbidity test was carried out; the experimental results are shown in Figure 4 .

Embodiment 2

[0080] Raw water sample turbidity reduction test with 80 turbidity: the test instrument is ZR4-6 coagulation test mixer; the test container is 1000mL.

[0081] Add polyaluminium chloride and magnetic weighting agent to the raw water sample with 80 turbidity to test the sedimentation effect. The addition amount of polyaluminum chloride is 0.025g / L; the addition amount of magnetic weighting agent is respectively: 0g / L, 0.1g / L, 0.2g / L, 0.5g / L, 1.0g / L and 1.5g / L.

[0082] At the settling time: 5, 10, 15 and 20 minutes, samples were taken for turbidity test; the experimental results are shown in Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com