Defluorinating method of photovoltaic wastewater

A waste water and photovoltaic technology, applied in the direction of chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problem of insufficient removal effect, achieve non-fragmentation and anti-pollution, and low fluorine content in effluent , to reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

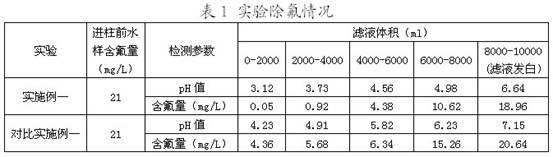

Examples

Embodiment 1

[0053] 1. Preparation of modified double resin ion exchanger:

[0054] H-type styrene resin is 001×4 strongly acidic styrene hydrogen ion exchange resin produced by Jiangsu Linhai Resin Company; H-type acrylic resin is D113 macroporous weakly acidic acrylic hydrogen ion exchange resin produced by Jiangsu Linhai Resin Company resin.

[0055] Prepare aluminum sulfate solutions with a mass percentage concentration of 8% and 4% by conventional methods.

[0056] Prepare the modified double resin ion exchanger as follows:

[0057] A. Preparation of gel strong acid Al-type ion exchange resin: Fill the exchange column with 50ml of 001×4 strong acidic styrene-based hydrogen ion exchange resin at normal temperature and pressure, and inject 300ml of sulfuric acid with a mass percentage concentration of 8%. Aluminum solution, soaked for 2h, then washed with deionized water to prepare 50.2ml gel strong acid Al-type ion exchange resin, for subsequent use;

[0058] B. Preparation of macr...

Embodiment 2

[0097] The raw materials for the preparation of the modified double resin ion exchanger are the same as those in Example 1.

[0098] The preparation method of the modified double resin ion exchanger is the same as that of Example 1, except that in step C, the gel strong acid type Al-type ion exchange resin prepared in step A and the macroporous weak acid type Al-type ion exchange resin prepared in step B are prepared. , according to the molar mass ratio of 1:8 mixed to prepare a modified double resin ion exchanger.

[0099] After testing, the obtained modified double resin ion exchanger has an average particle size of 0.6mm, a spherical rate of 96.5%, a water content of 51.6%, and a wet true density of 1.46g / ml.

[0100] The modified double resin ion exchanger of this example was used to carry out the ion exchange experiment of defluorination of photovoltaic wastewater.

[0101] Photovoltaic waste water flows into the regulating tank by itself, and is fully mixed and homogeni...

Embodiment 3

[0113] The raw materials for the preparation of the modified double resin ion exchanger are the same as those in Example 1.

[0114] The preparation method of the modified double resin ion exchanger is the same as that of Example 1, except that in step C, the gel strong acid type Al-type ion exchange resin prepared in step A and the macroporous weak acid type Al-type ion exchange resin prepared in step B are prepared. , according to the molar mass ratio of 3:1 mixed to prepare a modified double resin ion exchanger.

[0115] After testing, the obtained modified double resin ion exchanger has an average particle size of 0.68mm, a spherical rate of 94.8%, a water content of 53.5%, and a wet true density of 1.38g / ml.

[0116] The modified double resin ion exchanger of this example was used to carry out the ion exchange experiment of defluorination of photovoltaic wastewater.

[0117] Photovoltaic waste water flows into the regulating tank by itself, and is fully mixed and homogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com