Polyethylene yarn, method for manufacturing the same, and skin cooling fabric comprising the same

A polyethylene and yarn technology, applied in the field of polyethylene yarn, can solve the problems of not being suitable for making fabrics with a cool feeling on the skin, low elongation at break, poor weavability, etc., and achieve excellent weavability and high thermal conductivity Sexy, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

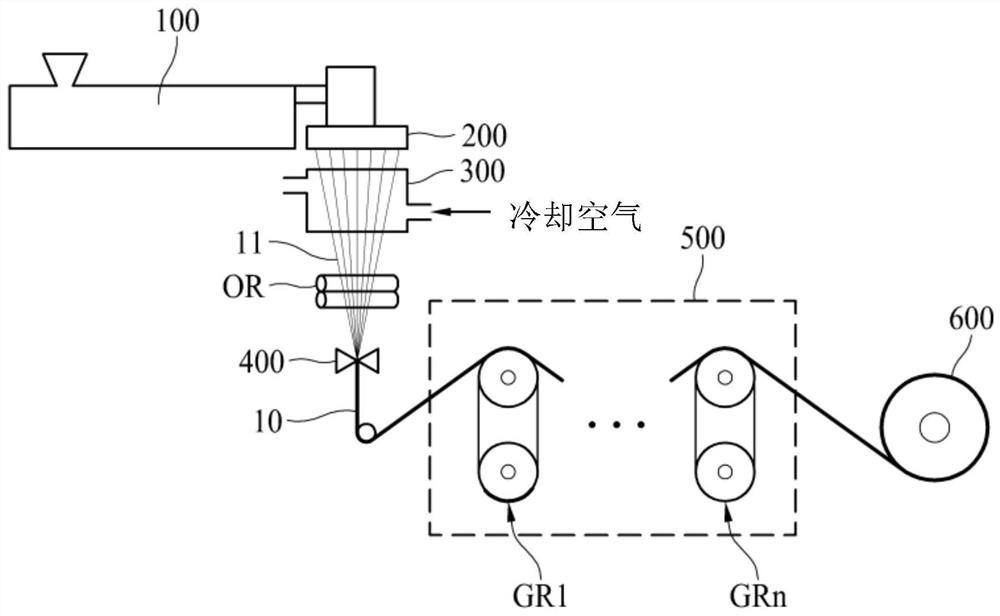

[0144] use figure 1 The apparatus shown in produces polyethylene yarn comprising 200 filaments and having a total fineness of 400 denier. Specifically, the density is 0.961g / cm 3 , weight average molecular weight (Mw) is 87,660g / mol, polydispersity index (PDI) [ratio of weight average molecular weight (Mw) to number average molecular weight (Mn) (Mw / Mn)] is 6.4 and melt index (at 190°C Polyethylene chips with a MI) of 11.9 g / 10 min were injected into the extruder 100 and melted. The molten polyethylene was extruded through a spinneret 200 having 200 holes. L / D is the ratio of the hole length L to the hole diameter D of the spinneret 200, and is 5.0. The spinneret temperature was 270°C.

[0145] The filaments 11 formed when discharged from the spinneret 200 are finally cooled to 25° C. in the quench zone 300 by cooling air with a wind speed of 0.5 m / s, and converged into multifilaments 10 by the convergence unit 400 and moved to the multi-stage drawing Extension part 500. ...

Embodiment 2

[0149] In addition to using a density of 0.958g / cm 3 , a polyethylene chip with a weight average molecular weight (Mw) of 98,290 g / mol, a polydispersity index (PDI) of 8.4 and a melt index (MI at 190°C) of 6.1 g / 10min, with a spinneret temperature of 275°C and A polyethylene yarn was obtained in the same manner as in Example 1 except that the overfeed ratio was 7.5%.

Embodiment 3

[0151] In addition to using a density of 0.948g / cm 3 , a polyethylene chip with a weight average molecular weight (Mw) of 78,620 g / mol, a polydispersity index (PDI) of 8.2 and a melt index (MI at 190°C) of 15.5 g / 10min, with a spinneret temperature of 260°C and A polyethylene yarn was obtained in the same manner as in Example 1 except that the total draw ratio was 7.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com