Preparation method of thick oil viscosity reduction and production increase agent, thick oil viscosity reduction and production increase agent and application of thick oil viscosity reduction and production increase agent

A heavy oil and viscosity-reducing technology, which is applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve the problems of reducing economic benefits, increasing oil production costs, and high production costs, so as to improve economic benefits, reduce production costs, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The heavy oil viscosity reducing and increasing recovery agent provided in this example is prepared through the following steps:

[0042] Add 20kg of water to the reaction kettle, then add 10kg of lignin, and stir to obtain an aqueous solution of lignin;

[0043] Add 0.5 kg of 95% by mass sulfuric acid and 0.5 kg of 60% by mass nitric acid to the above lignin aqueous solution, and stir and react at 100° C. for 2 h;

[0044] Then add 1kg hydroquinone and 1kg acetaldehyde, and stir at 100°C to continue the reaction for 2h;

[0045] Then continue to add 1kg of sodium hydroxide and 0.5kg of sodium carbonate, stir evenly, then add 1kg of ethylenediamine, and stir at 100°C to continue the reaction for 2h;

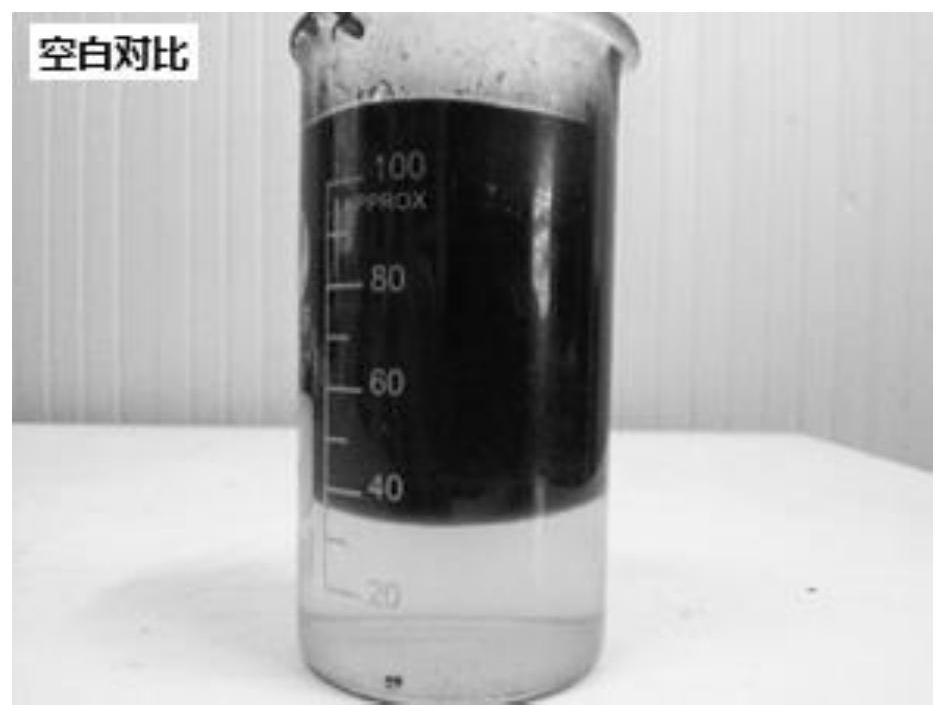

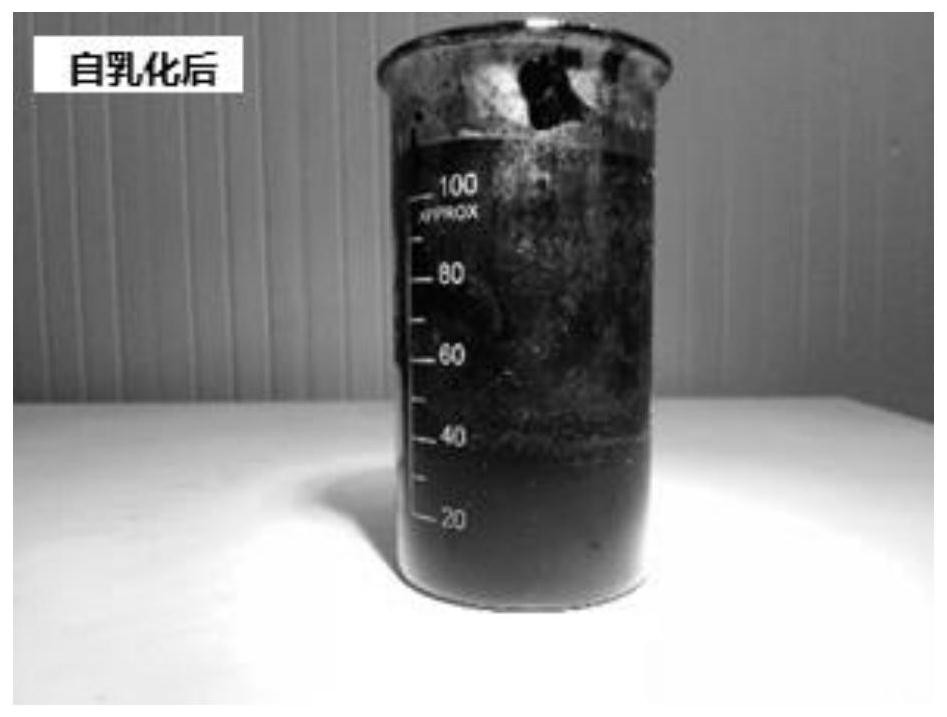

[0046] Cool down to 60°C, continue to add 1 kg of fatty alcohol polyoxyethylene alcohol sodium sulfate, 0.5 kg of fatty alcohol polyoxyethylene ether and 0.5 kg of fatty acid potassium, continue stirring for 2 hours, and after cooling, a viscous oil self-emulsifying visco...

Embodiment 2

[0050] The heavy oil viscosity reducing and increasing recovery agent provided in this example is prepared through the following steps:

[0051] Add 20kg of water to the reaction kettle, then add 10kg of lignin, and stir to obtain an aqueous solution of lignin;

[0052] Add 0.5 kg of 95% by mass sulfuric acid and 0.5 kg of 60% by mass nitric acid to the above lignin aqueous solution, and stir and react at 100° C. for 2 h;

[0053] Then add 1kg hydroquinone and 1kg acetaldehyde, and stir at 100°C to continue the reaction for 2h;

[0054] Then continue to add 1kg sodium hydroxide and 0.5kg sodium carbonate, stir;

[0055] Cool down to 60°C, continue to add 1 kg of fatty alcohol polyoxyethylene alcohol sodium sulfate, 0.5 kg of fatty alcohol polyoxyethylene ether and 0.5 kg of fatty acid potassium, continue stirring for 2 hours, and after cooling, a viscous oil self-emulsifying viscosity reducing agent is obtained.

[0056] Take the obtained thick oil self-emulsifying viscosity...

Embodiment 3

[0058] The heavy oil viscosity reducing and increasing recovery agent provided in this example is prepared through the following steps:

[0059] Add 20kg of water to the reaction kettle, then add 10kg of lignin, and stir to obtain an aqueous solution of lignin;

[0060] Add 0.5 kg of 95% by mass sulfuric acid and 0.5 kg of 60% by mass nitric acid to the above lignin aqueous solution, and stir and react at 100° C. for 2 h;

[0061] Then continue to add 1kg of sodium hydroxide and 0.5kg of sodium carbonate, stir evenly, then add 1kg of ethylenediamine, and stir at 100°C to continue the reaction for 2h;

[0062] Cool down to 60°C, continue to add 1 kg of fatty alcohol polyoxyethylene alcohol sodium sulfate, 0.5 kg of fatty alcohol polyoxyethylene ether and 0.5 kg of fatty acid potassium, continue stirring for 2 hours, and after cooling, a viscous oil self-emulsifying viscosity reducing agent is obtained.

[0063] Take the obtained thick oil self-emulsifying viscosity-reducing vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com