A preparation method of a heavy oil viscosity-reducing and production-increasing agent, a heavy oil viscosity-reducing and production-increasing agent and its application

A technology for reducing viscosity and heavy oil, applied in chemical instruments and methods, production fluids, earthwork drilling, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The viscosity-reducing and recovery-increasing agent for heavy oil provided by the present embodiment is obtained through the following steps:

[0042] In the reactor, add 20kg of water, then add 10kg of lignin, and stir to obtain an aqueous lignin solution;

[0043] Add 0.5 kg of 95 mass % sulfuric acid and 0.5 kg of 60 mass % nitric acid to the above lignin aqueous solution, and stir and react at 100° C. for 2 h;

[0044] Then add 1kg of diol and 1kg of acetaldehyde, and continue to react for 2h under stirring at 100°C;

[0045] Then continue to add 1kg of sodium hydroxide and 0.5kg of sodium carbonate, stir evenly, then add 1kg of ethylenediamine, and continue to react at 100°C for 2h;

[0046] Cool to 60°C, continue to add 1 kg of fatty alcohol polyoxyethylene alcohol sodium sulfate, 0.5 kg of fatty alcohol polyoxyethylene ether and 0.5 kg of fatty acid potassium, and continue stirring for 2 hours.

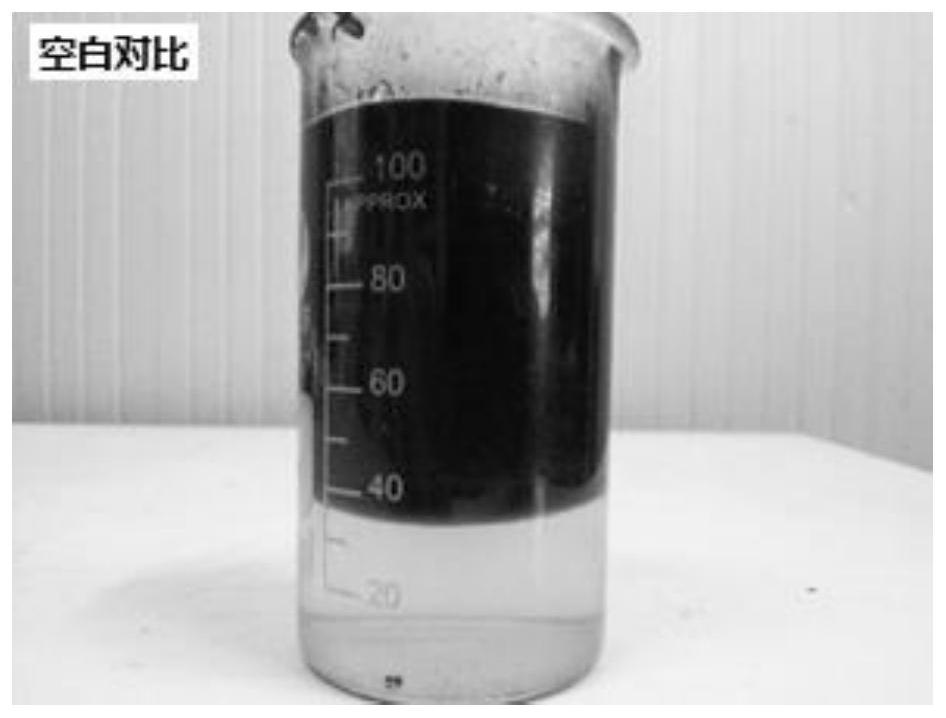

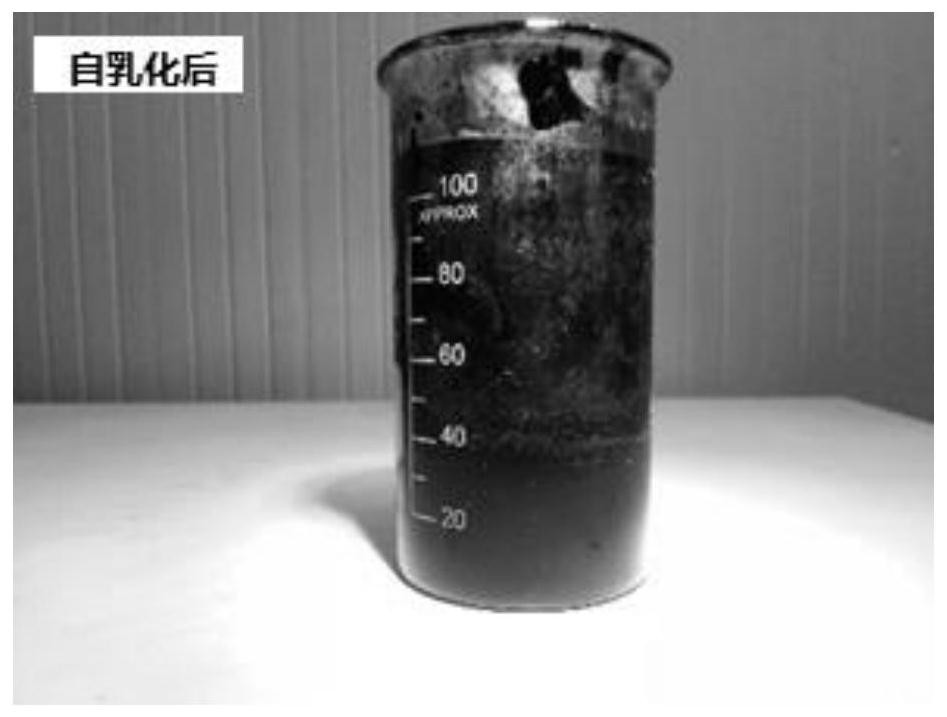

[0047] The obtained self-emulsifying viscosity-reducing and reco...

Embodiment 2

[0050] The viscosity-reducing and recovery-increasing agent for heavy oil provided by the present embodiment is obtained through the following steps:

[0051] In the reactor, add 20kg of water, then add 10kg of lignin, and stir to obtain an aqueous lignin solution;

[0052] To the above lignin aqueous solution, 0.5 kg of 95 mass % sulfuric acid and 0.5 kg of 60 mass % nitric acid were added, and the reaction was stirred at 100° C. for 2 h;

[0053] Then add 1kg of diol and 1kg of acetaldehyde, and continue to react for 2h under stirring at 100°C;

[0054] Then continue to add 1kg sodium hydroxide and 0.5kg sodium carbonate, stir evenly;

[0055] Cool to 60°C, continue to add 1 kg of fatty alcohol polyoxyethylene alcohol sodium sulfate, 0.5 kg of fatty alcohol polyoxyethylene ether and 0.5 kg of fatty acid potassium, continue to stir for 2 hours, and after cooling, the heavy oil self-emulsifying viscosity reducing and recovery enhancing agent is obtained.

[0056] The obtaine...

Embodiment 3

[0058] The viscosity-reducing and recovery-increasing agent for heavy oil provided by the present embodiment is obtained through the following steps:

[0059] In the reactor, add 20kg of water, then add 10kg of lignin, and stir to obtain an aqueous lignin solution;

[0060] To the above lignin aqueous solution, 0.5 kg of 95 mass % sulfuric acid and 0.5 kg of 60 mass % nitric acid were added, and the reaction was stirred at 100° C. for 2 h;

[0061] Then continue to add 1kg of sodium hydroxide and 0.5kg of sodium carbonate, stir evenly, then add 1kg of ethylenediamine, and continue to react at 100°C for 2h;

[0062] Cool to 60°C, continue to add 1 kg of fatty alcohol polyoxyethylene alcohol sodium sulfate, 0.5 kg of fatty alcohol polyoxyethylene ether and 0.5 kg of fatty acid potassium, continue to stir for 2 hours, and after cooling, the heavy oil self-emulsifying viscosity reducing and recovery enhancing agent is obtained.

[0063] The obtained self-emulsifying viscosity-red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com