Exhaust gas filtering device

A technology of waste gas filtration and filtration device, which is applied in the direction of combination device, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of polluted atmosphere, high cost, unsuitable indoor air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

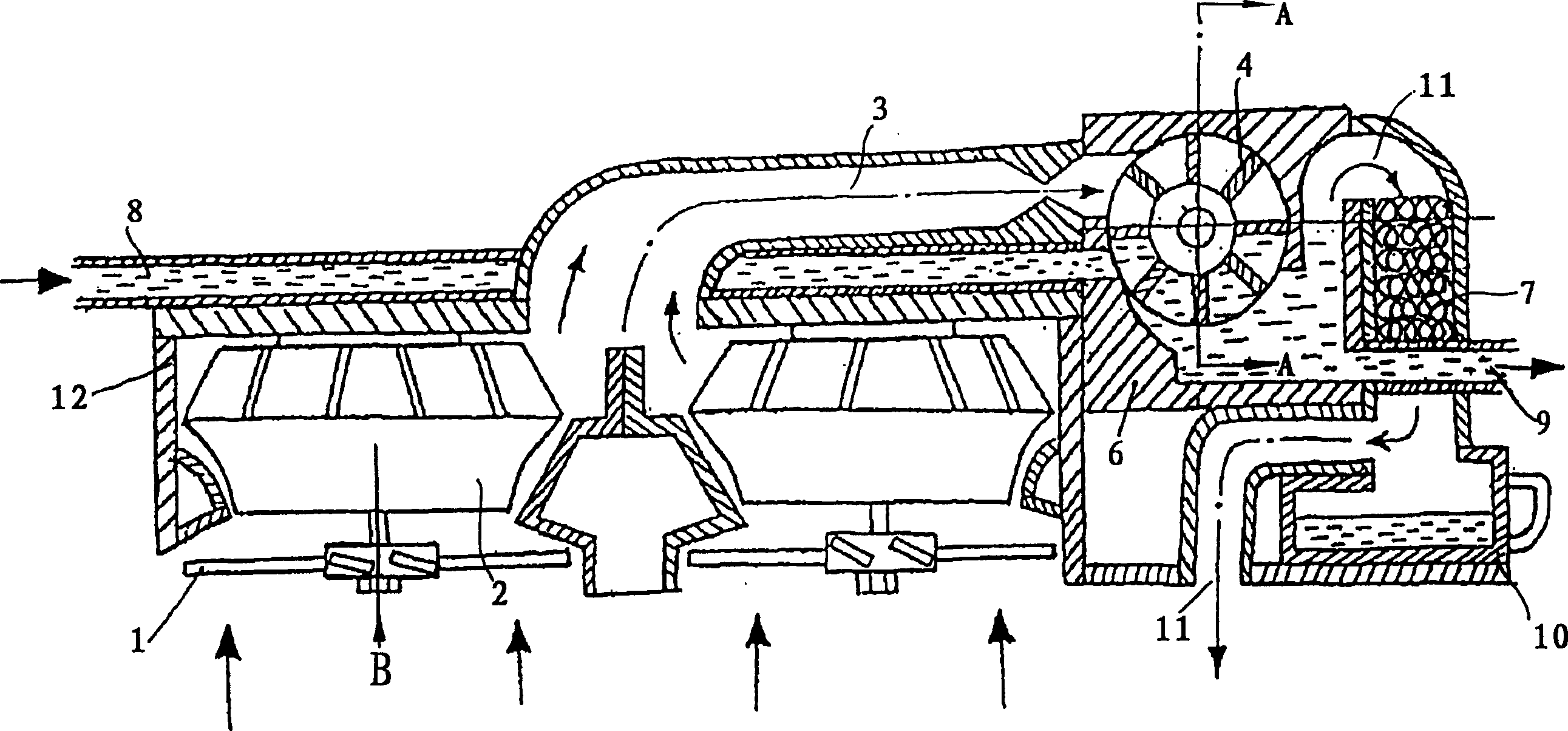

[0013] figure 1 Shown is a range hood without pollution (or called a range hood), wherein a double filtering device is installed at the rear of the exhaust pipe of the range hood.

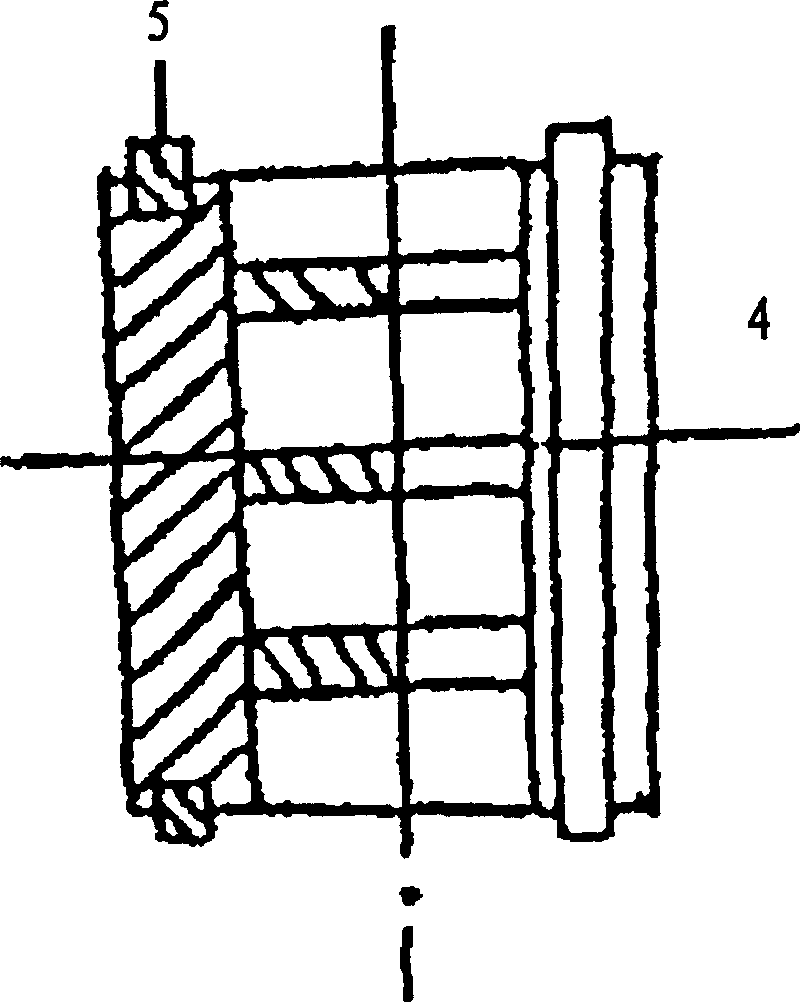

[0014] like figure 1 As shown, using the strong high-speed wind force produced by the fans 1 and 2 installed in the range hood cover 12, that is, using the waste heat sucked by the range hood, blowing a water turbine 4 to rotate after passing through the exhaust pipe 3, using The blades in the water turbine 4 press the hot gas and oil fumes into the water together for cooling and primary filtration, and the hot gases such as oil fumes and steam will be converted into sewage and discharged. After the gas in the airflow is ejected from the water, it will pass through a filter 7 for secondary filtration, and the fine oil particles and water droplets contained in the filtered gas will become athermal and clean gas and be discharged back into the room.

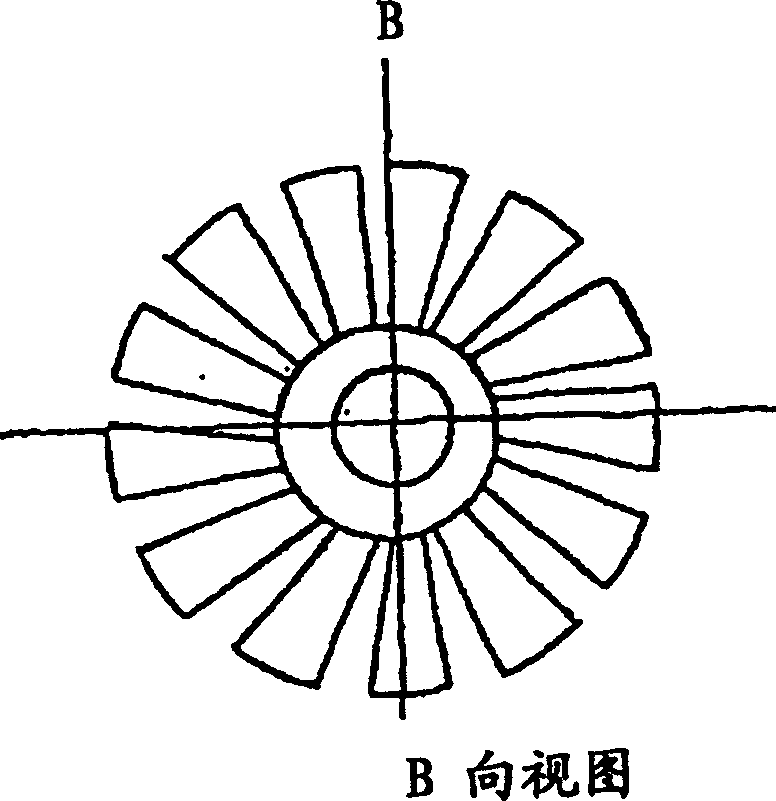

[0015] Fan 2 is a centrifugal turbofan, and fan...

Embodiment 2

[0020] Fig. 4 shows Embodiment 2 of the present invention, which relates to an exhaust emission system suitable for use by vehicles and ships, wherein components with the same structure as Embodiment 1 are represented by the same symbols.

[0021] As shown in Figure 4, the waste gas blowdown system is connected to the internal combustion engine case 13 of the vehicle or ship. When the internal combustion engine is working, the exhaust gas produced flows into the exhaust pipe 3, and the exhaust gas is compressed and expanded due to the narrowing and gradual expansion of the pipeline. The rapid expansion pushes the water turbine 4 to rotate, and the waste gas is compressed into the water loaded in the water tank 6. Simultaneously, the cooling water pumped out from the internal combustion engine is pumped into the water tank 6 through the water pipe 15 after passing through the cooler 14 . Since the outlet of the water pipe 15 is aligned with the rotor body of the water turbine 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com