Anti-corrosion paint for steel with polyaniline

A technology of anti-corrosion coatings and polyaniline, which is applied in the direction of anti-corrosion coatings, polyurea/polyurethane coatings, epoxy resin coatings, etc., can solve the problems of unsustainable anti-corrosion effects, application restrictions, environmental pollution, etc., and achieve excellent anti-corrosion effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

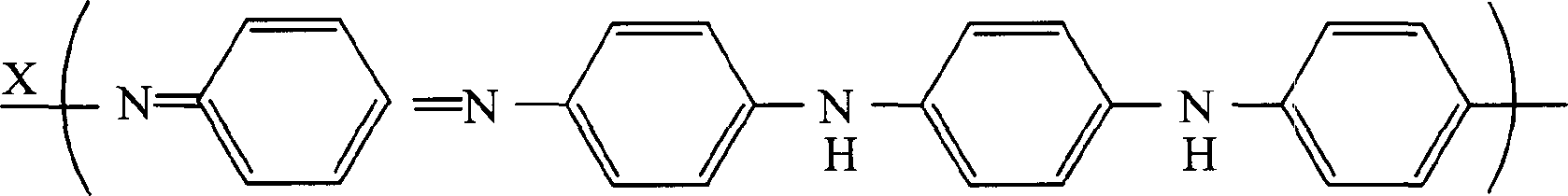

Image

Examples

Embodiment 1

[0047] 1-1. Preparation of paint for primer coating

[0048] 60wt% of thermoplastic polyurethane resin (solid content 50%), 7wt% of reduced polyaniline (ES), 0.5wt% of Bentone#34 (RHEOX Co.), 0.5wt% of Anti-Terra-U (BYK Chemi ) and 21 wt% of a mixed solvent containing cellosolve acetate, methyl ethyl ketone and ethyl cellosolve, stirred for 30 minutes and ground with an attritor to make the particle size exceed 5NS (North standard grade) units. Subsequently, 0.5wt% BYK-006 (BYK Chemie) and BYK-410 (BYK Chemie) and 10wt% mixed solvent were added to the above mixture and stirred for 30 minutes to obtain the primer anticorrosion coating of the present invention.

[0049] 1-2. Preparation of paint for surface coating

[0050] The urethane acrylate resin (solid content 50%) of 55wt%, the TiO of 20wt% 2 R-902 (Dupont.Co), 0.3wt% of Benton#34 (RHEOX Co.) and 0.2wt% of Anti-Terra-U (BYK Chemie) were mixed, stirred for 30 minutes and ground with an attritor to achieve a particle siz...

Embodiment 2

[0061] The reduced polyaniline was replaced with oxidized polyaniline, and 10 wt% of the solvent was replaced with talc as a filler. In addition, the anti-corrosion coating was prepared according to the method in Example 1. The physical properties of the resulting coatings were evaluated and the results are shown in Tables 1 and 2.

Embodiment 3

[0063] With 25wt% base resin containing cellulose acetate-propionate and epoxy resin (mixing ratio 4:1), 7wt% reduced polyaniline (ES), 0.3wt% Bentone#34 (RHEOX Co.), 0.2 wt% of Anti-Terra-U (BYK Chemi) and 67.5 wt% of a mixed solvent containing methyl ethyl ketone, ethyl cellosolve and butyl acetate were used to prepare anti-corrosion coatings for primer coating. Prepare the coating that is used for top coat and test sample with the method for embodiment 1, and the test result of physical characteristic is shown in table 1 and table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com