Metal surface treatment method and metal surface treatment agent

A metal surface treatment and metal material technology, applied in the direction of metal material coating process, etc., can solve the problem of heat source consumption, and achieve the effect of cost saving, process reduction, heat source and basic unit reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in detail below.

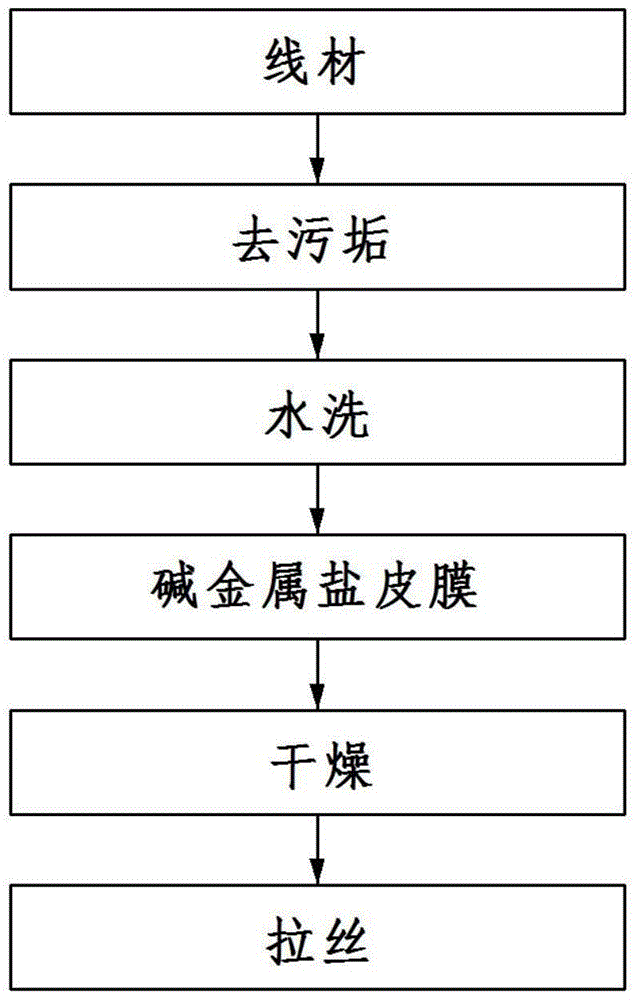

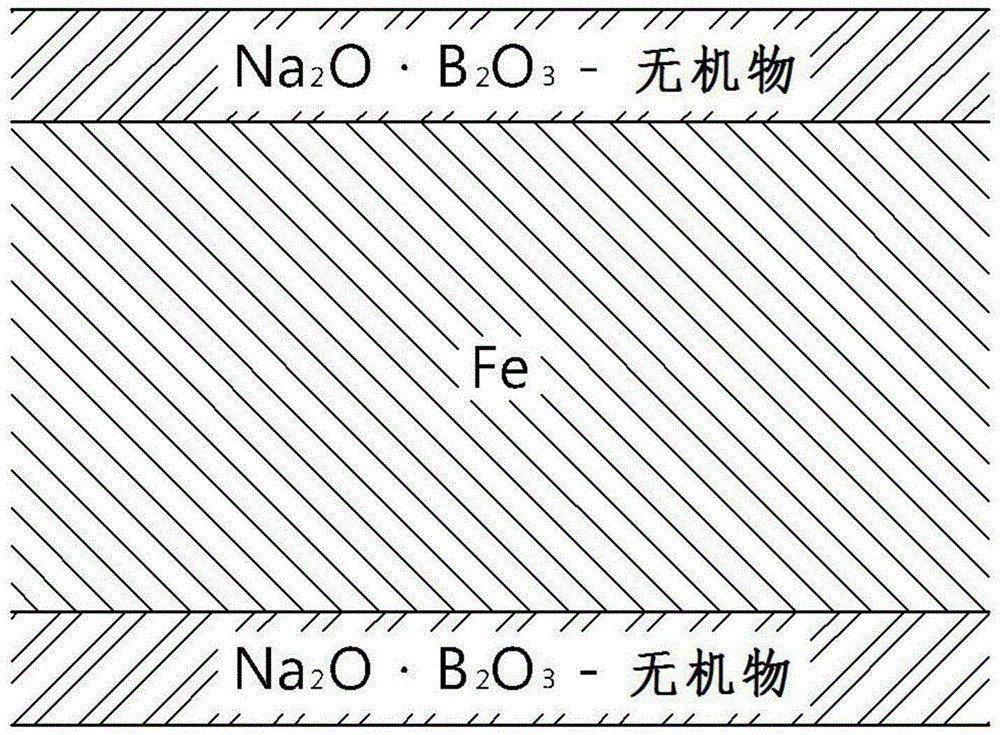

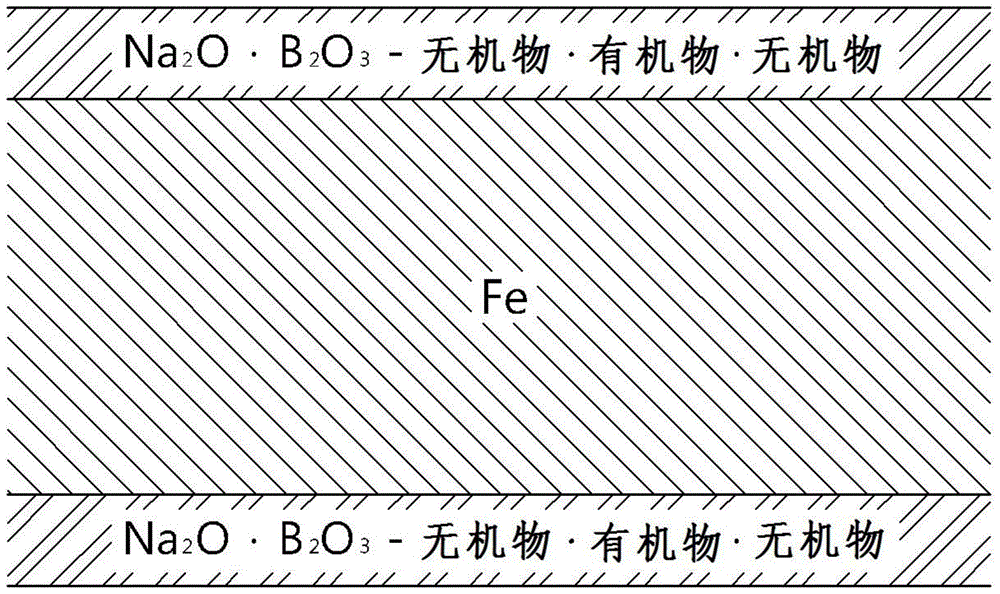

[0039] Such as figure 1 As shown, the metal surface treatment method of the present invention includes: the step of washing with water after removing the dirt of the metal material; after washing, when the metal material is drawn through a wire drawing die, in order to improve the lubrication effect, protect the surface of the metal material and A step of carrying (carrier (pick-up)) various lubricants to form an alkali metal salt pretreatment film (hereinafter referred to as "alkali metal salt film") on the surface of the metal material; and a drying step.

[0040] The metal material is made of wire. Wire rod refers to a wire rod (Wire Rod) that is used to manufacture various wires through wire drawing. The wire rod is manufactured by hot rolling to have a diameter of 5.5mm-32mm, and is manufactured as steel wire, iron wire, piano wire by drawing through the hole of the wire drawing d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com