Preparation method of a cellulose nanofiber/silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material

A nanofiber, silk fibroin technology, applied in the manufacture of hybrid/electric double layer capacitors, battery electrodes, nanotechnology, etc., can solve problems such as unfavorable material capacity and unfavorable size, achieve low cost, improve cycle life, and facilitate scale the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

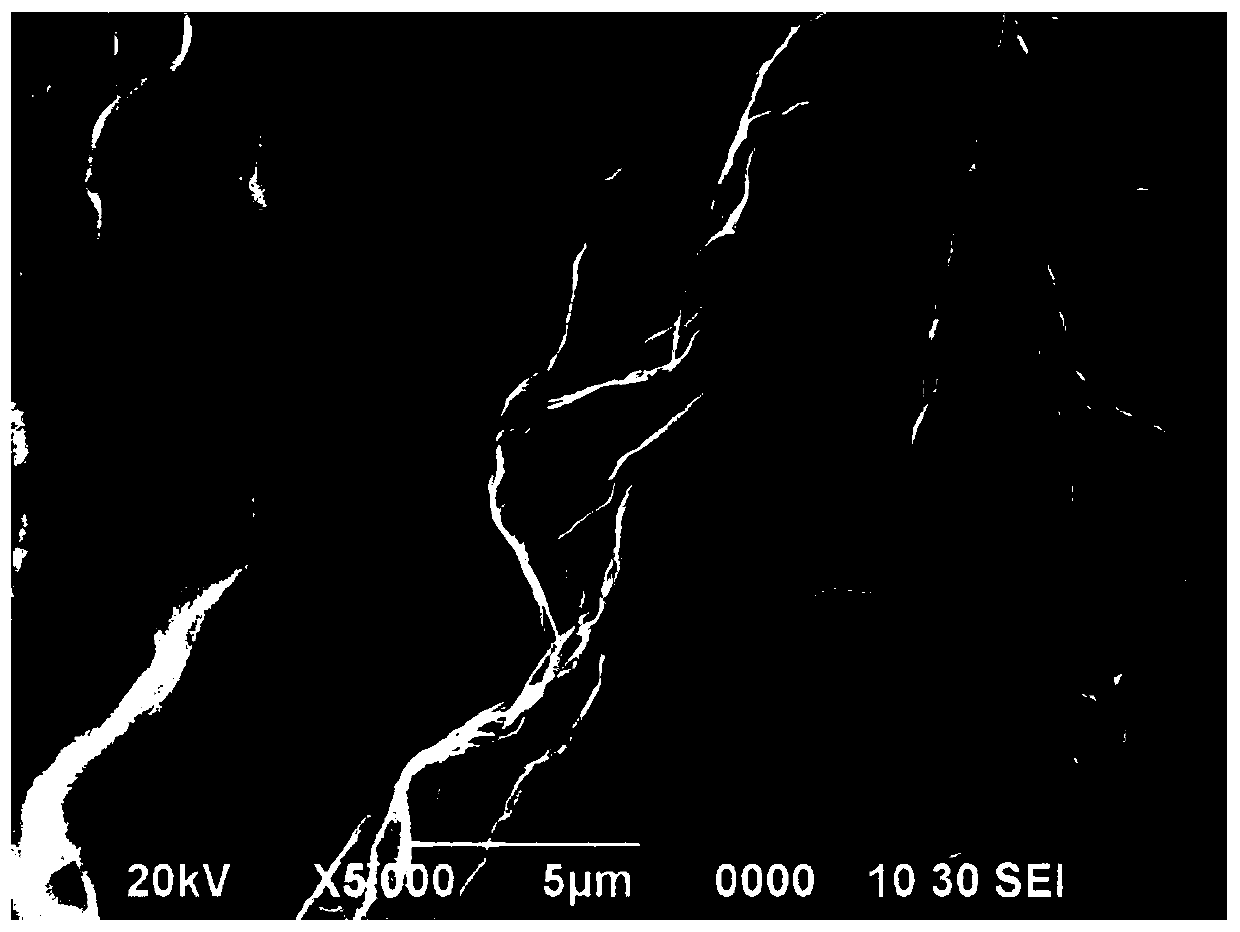

Embodiment 1

[0034] The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of this embodiment comprises the following steps:

[0035] 1) Preparation of cellulose nanofiber suspension and silk fibroin solution

[0036] The bamboo pulp was subjected to TEMPO catalytic oxidation reaction, then ultrasonically dispersed for 10 minutes, and then vacuum rotary concentration was carried out to obtain a suspension of cellulose nanofibers (CNFs), and the mass fraction of cellulose nanofibers (CNFs) in the suspension was 0.8%;

[0037] The degummed silkworm cocoons were dissolved in a LiBr solution with a concentration of 9.3mol / L, and then dialyzed for 3 days using a dialysis bag with a molecular weight cut-off of 3500 to obtain a silk fibroin solution. The mass fraction of silk fibroin in the silk fibroin solution was 7%;

[0038] 2) Preparation of cellulose nanofiber / silk fibroin composite suspension

[0039] The prepared...

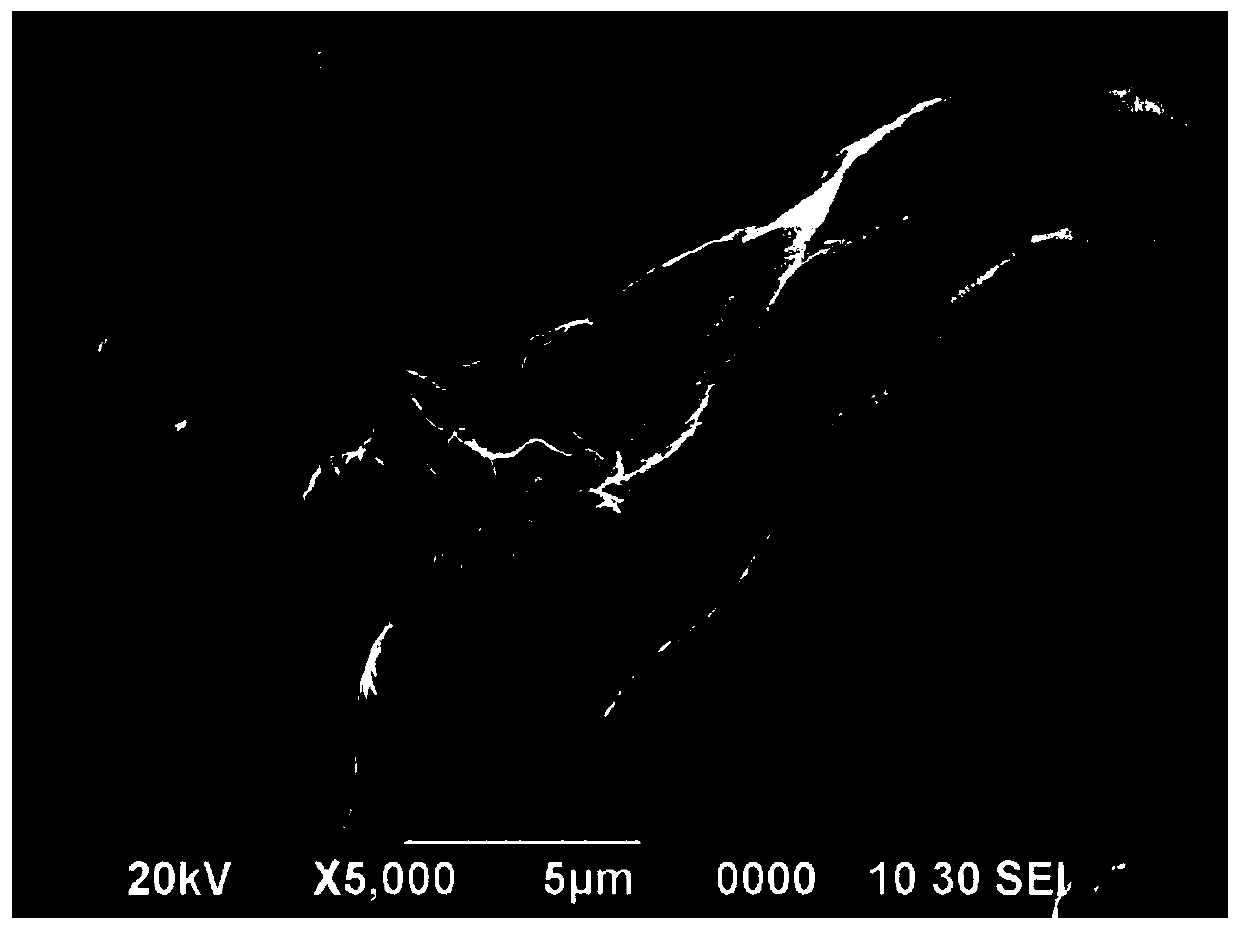

Embodiment 2

[0047] The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of this embodiment comprises the following steps:

[0048] 1) Preparation of cellulose nanofiber suspension and silk fibroin solution

[0049] The bamboo pulp was subjected to TEMPO catalytic oxidation reaction, then ultrasonically dispersed for 10 minutes, and then vacuum rotary concentration was carried out to obtain a suspension of cellulose nanofibers (CNFs), and the mass fraction of cellulose nanofibers (CNFs) in the suspension was 1.5%;

[0050] The degummed silkworm cocoons were dissolved in a LiBr solution with a concentration of 9.3mol / L, and then dialyzed for 3 days using a dialysis bag with a molecular weight cut-off of 3500 to obtain a silk fibroin solution. The mass fraction of silk fibroin in the silk fibroin solution was 8%;

[0051] 2) Preparation of cellulose nanofiber / silk fibroin composite suspension

[0052] The prepared...

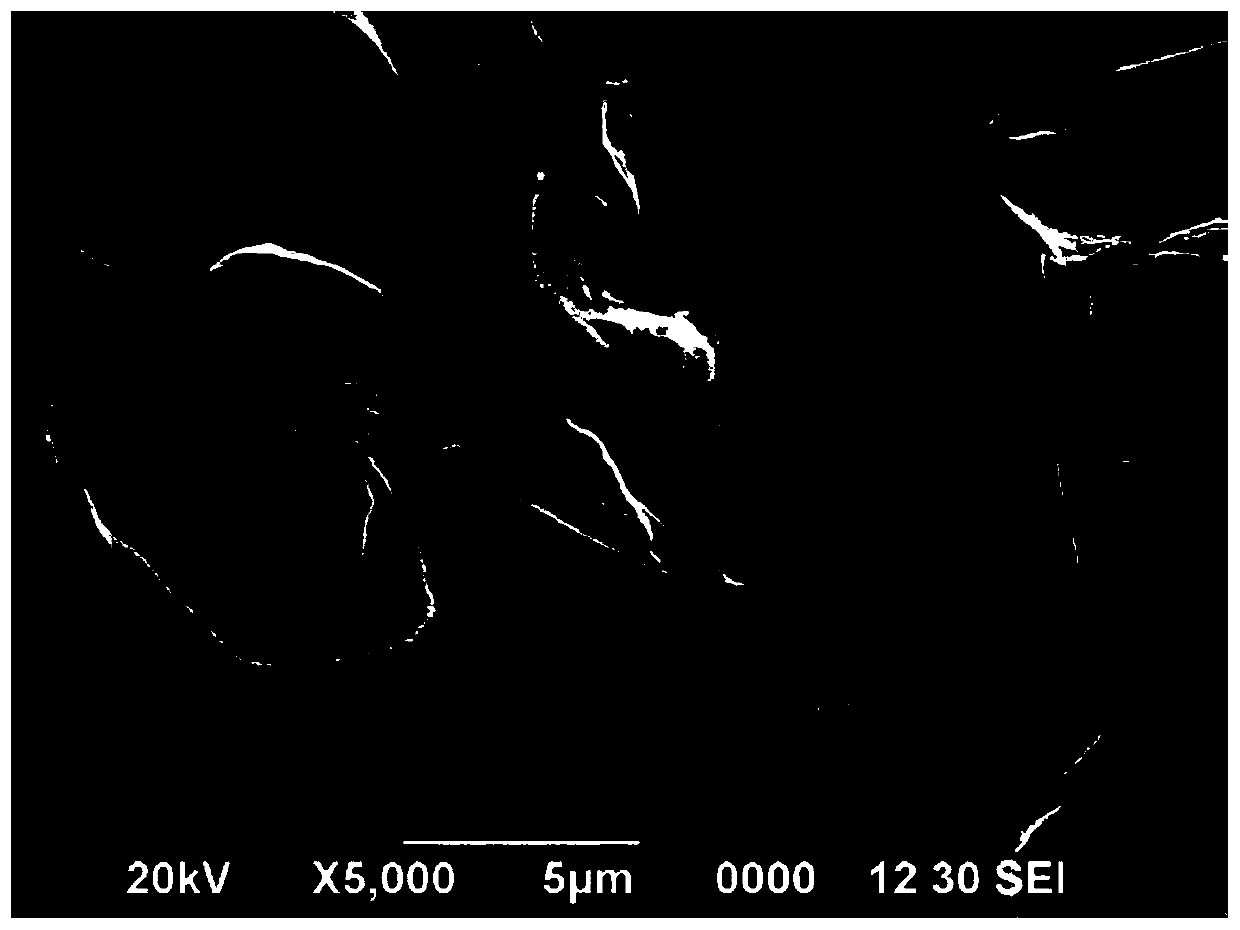

Embodiment 3

[0060] The preparation method of the cellulose nanofiber / silk fibroin-based porous nitrogen-doped 2D carbon nanosheet electrode material of this embodiment comprises the following steps:

[0061] 1) Preparation of cellulose nanofiber suspension and silk fibroin solution

[0062] The bamboo pulp was subjected to TEMPO catalytic oxidation reaction, then ultrasonically dispersed for 10 minutes, and then vacuum rotary concentration was carried out to obtain a suspension of cellulose nanofibers (CNFs). The mass fraction of cellulose nanofibers (CNFs) in the suspension was 1 %;

[0063] The degummed silkworm cocoons were dissolved in a LiBr solution with a concentration of 9.3mol / L, and then dialyzed for 3 days using a dialysis bag with a molecular weight cut-off of 3500 to obtain a silk fibroin solution. The mass fraction of silk fibroin in the silk fibroin solution was 5%;

[0064] 2) Preparation of cellulose nanofiber / silk fibroin composite suspension

[0065] The prepared silk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com