A kind of polymethacrylimide airgel and preparation method thereof

A technology of polymethacrylimide and methacrylic acid, which is applied in the field of polymethacrylimide airgel and its preparation, can solve the problems of poor mechanical properties and achieve high mechanical properties, good mechanical properties and The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

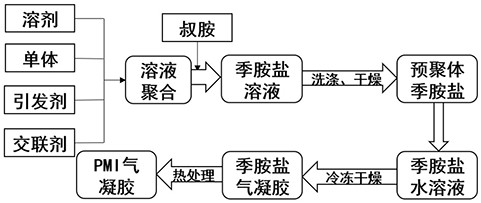

Method used

Image

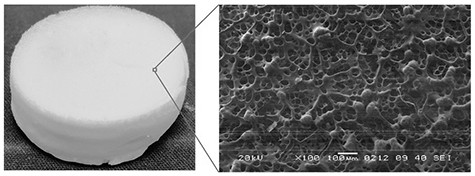

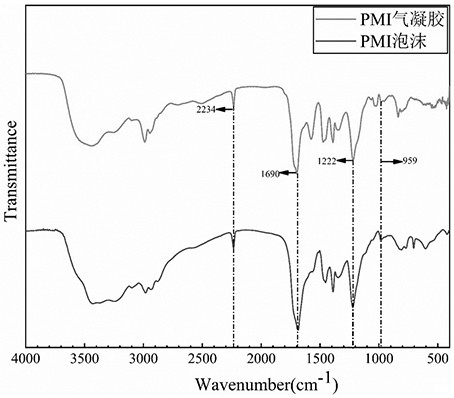

Examples

Embodiment 2

[0042] The difference from Example 1 is that Step 1: Mix 6 g of MAN, 9 g of MAA, 0.1 g of AM, 35 g of DMSO and 0.015 g of AIBN evenly. Under the condition of a constant temperature water bath at 60° C., the radical solution polymerization reaction was carried out for 96 hours to obtain a PMI prepolymer solution.

[0043] Step 2: Preparation of quaternary ammonium salt

[0044] Add 21.15 g of triethylamine to the PMI prepolymer solution in Step 1, stir vigorously until the solution is uniform, and then let it stand for 24 hours to react. After the reaction is completed, it becomes a PMI prepolymer quaternary ammonium salt solution.

[0045] When the obtained PMI prepolymer quaternary ammonium salt prepares an airgel with a solid content of 6 wt%, the airgel density is 0.1023g / cm, the compression modulus is 50.4MPa, and the thermal conductivity is 0.0620W / (m·K).

Embodiment 3

[0047]The difference from Example 1 is that Step 1: Mix 9 g of MAN, 6 g of MAA, 0.45 g of AM, 35 g of DMSO and 0.45 g of AIBN evenly. Under the condition of a constant temperature water bath at 60° C., the radical solution polymerization reaction was carried out for 96 hours to obtain a PMI prepolymer solution.

[0048] Step 2: Preparation of quaternary ammonium salt

[0049] Add 14.1 g of triethylamine to the PMI prepolymer solution in step 1, and keep stirring until the solution is uniform, and react for 24 hours. After the reaction is completed, it becomes a solution of uniform PMI prepolymer quaternary ammonium salt.

[0050] When the obtained quaternary ammonium salt is used to prepare an airgel with a solid content of 6 wt%, the obtained airgel has a density of 0.0923g / cm, a compressive modulus of 68.4MPa, and a thermal conductivity of 0.0617W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com