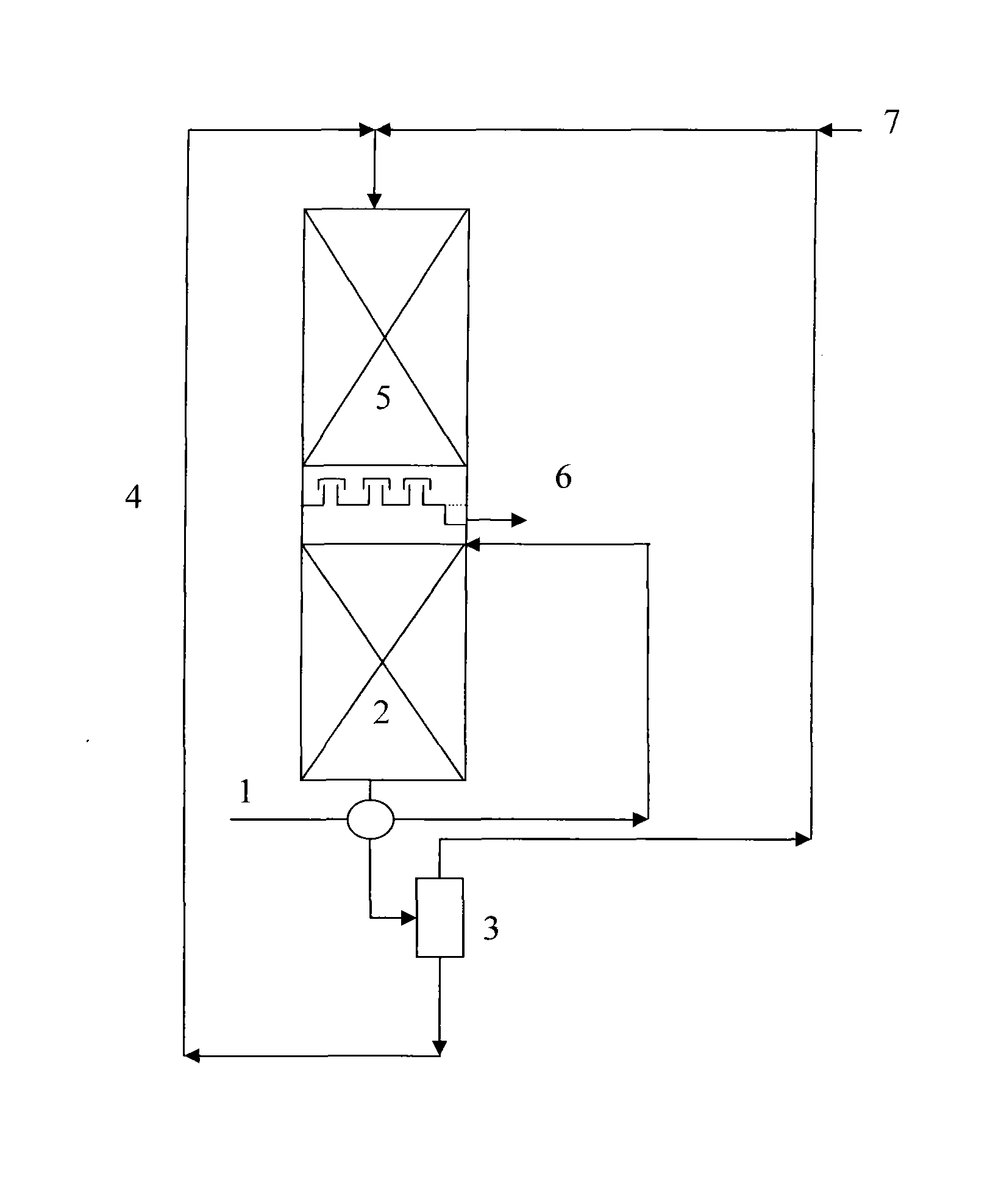

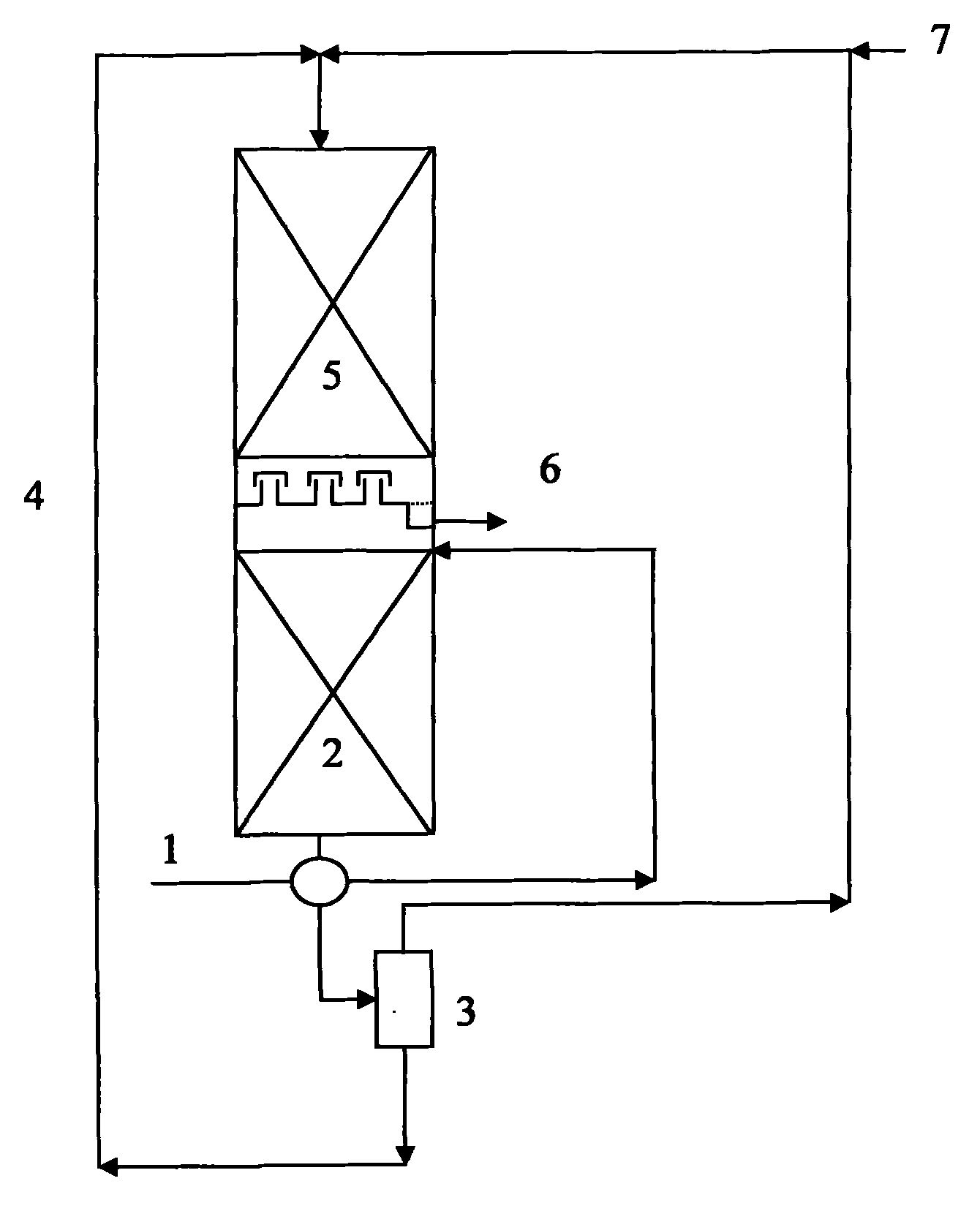

Diesel hydrogenation process method

A process method and diesel technology, which can be used in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of unreasonable temperature distribution of the catalyst bed, unfavorable long-term stable operation of the catalyst, large hydrogenation heat release, etc. Achieve the effect of reducing energy consumption, increasing service life and improving response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

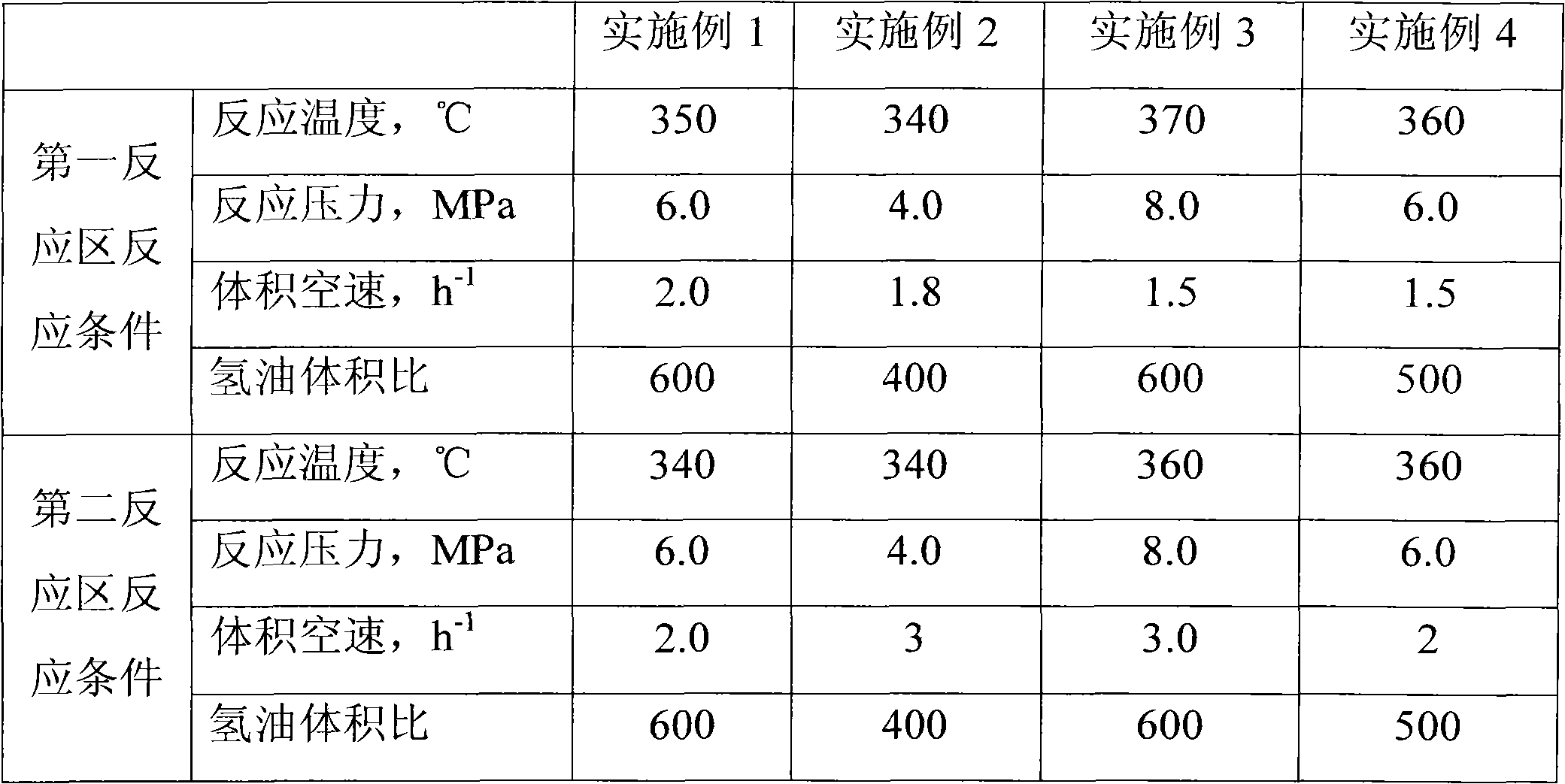

Examples

Embodiment Construction

[0015] In the diesel hydrogenation process of the present invention, the catalyst in the first reaction zone and the second reaction zone refers to a non-precious metal hydrogenation catalyst with functions such as hydrodesulfurization, hydrodenitrogenation, aromatics saturation, hydrogenation and upgrading, and the function of the catalyst Can focus on certain aspects. The non-precious metal catalyst generally exists in an oxidized state before use, and needs to be presulfurized so that the non-precious metal oxide can be converted into a sulfide to be reactive. Therefore, the non-precious metal catalyst should remain in a sulfide state during use. The hydrogenation catalyst used in the present invention can adopt conventional diesel oil hydrofinishing catalysts or hydrogenation upgrading catalysts, etc., generally with VIB group and / or Group VIII metals as active components, with alumina or silicon-containing alumina as a carrier, Molecular sieves and other components may al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com