Microwave plasma reactor used for manufacturing monocrystal diamond and diffusion device thereof

A technology of diffusion device and plasma, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as unfavorable manufacture of high-quality single crystal diamond, damage to the distribution of the equipotential surface of electric field, and influence on the growth environment of seed crystals, etc. , to achieve the effect of improving the adequacy of the reaction, improving the quality, and improving the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

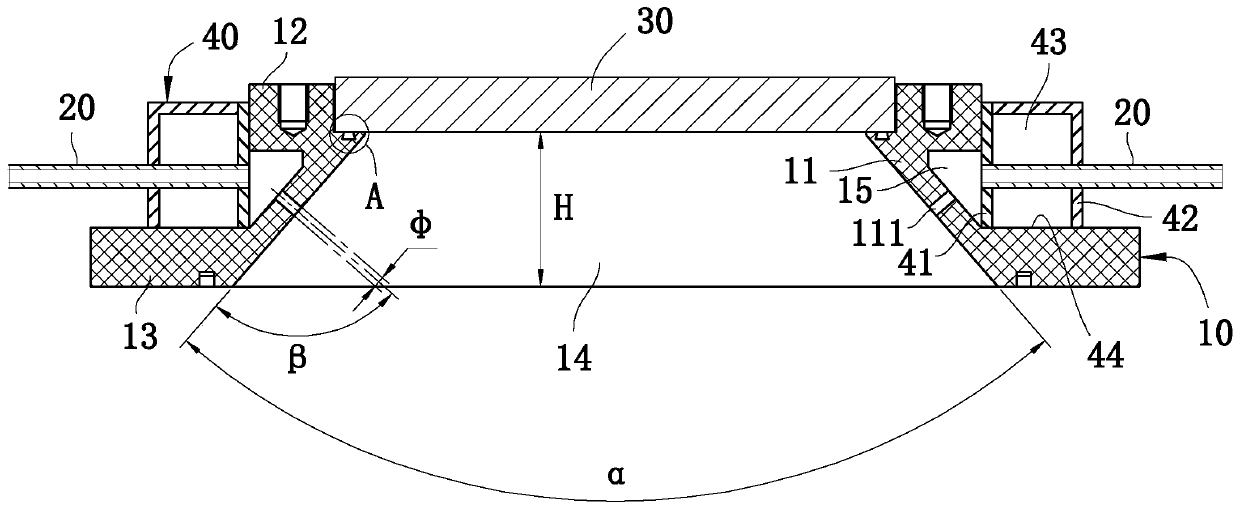

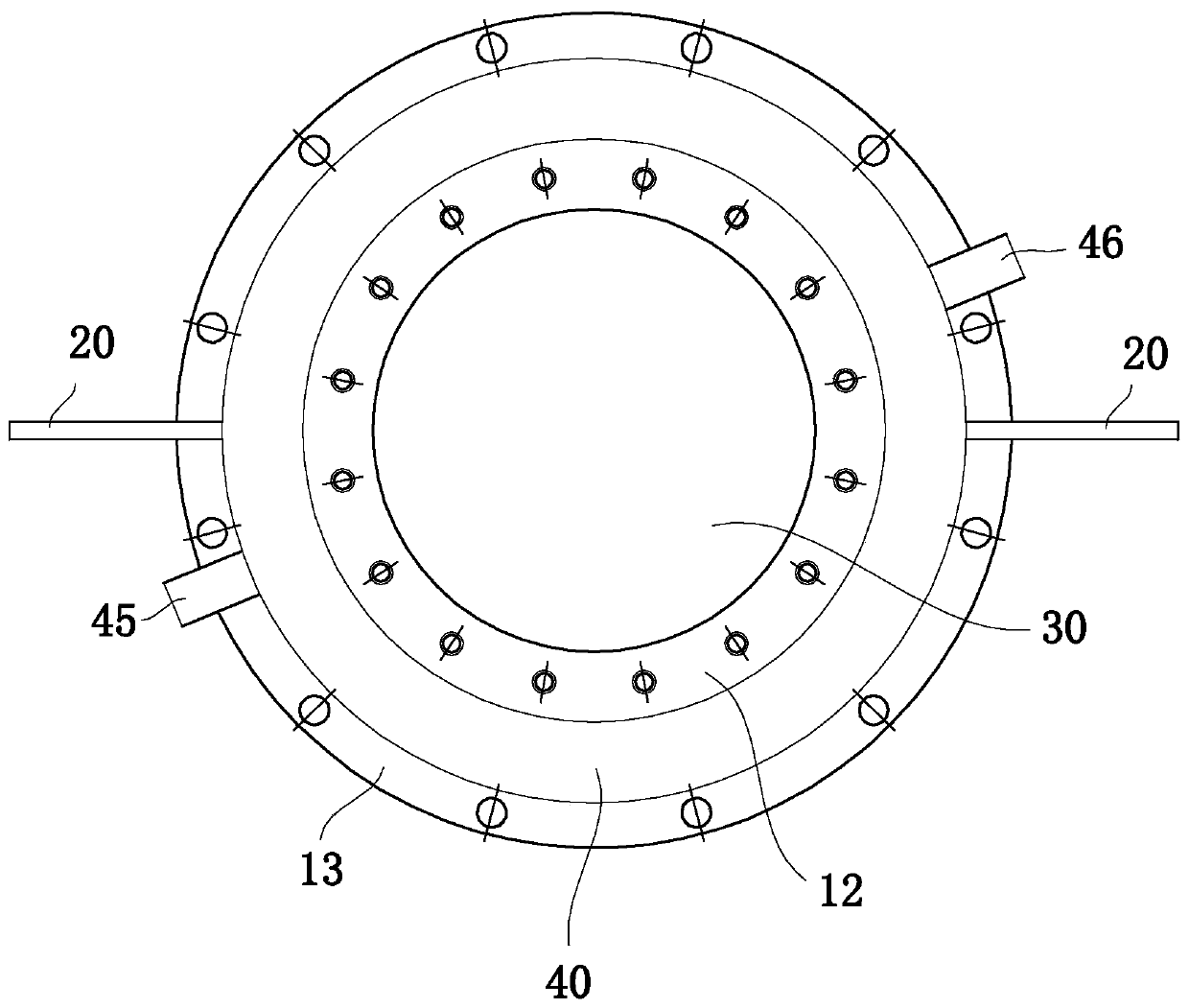

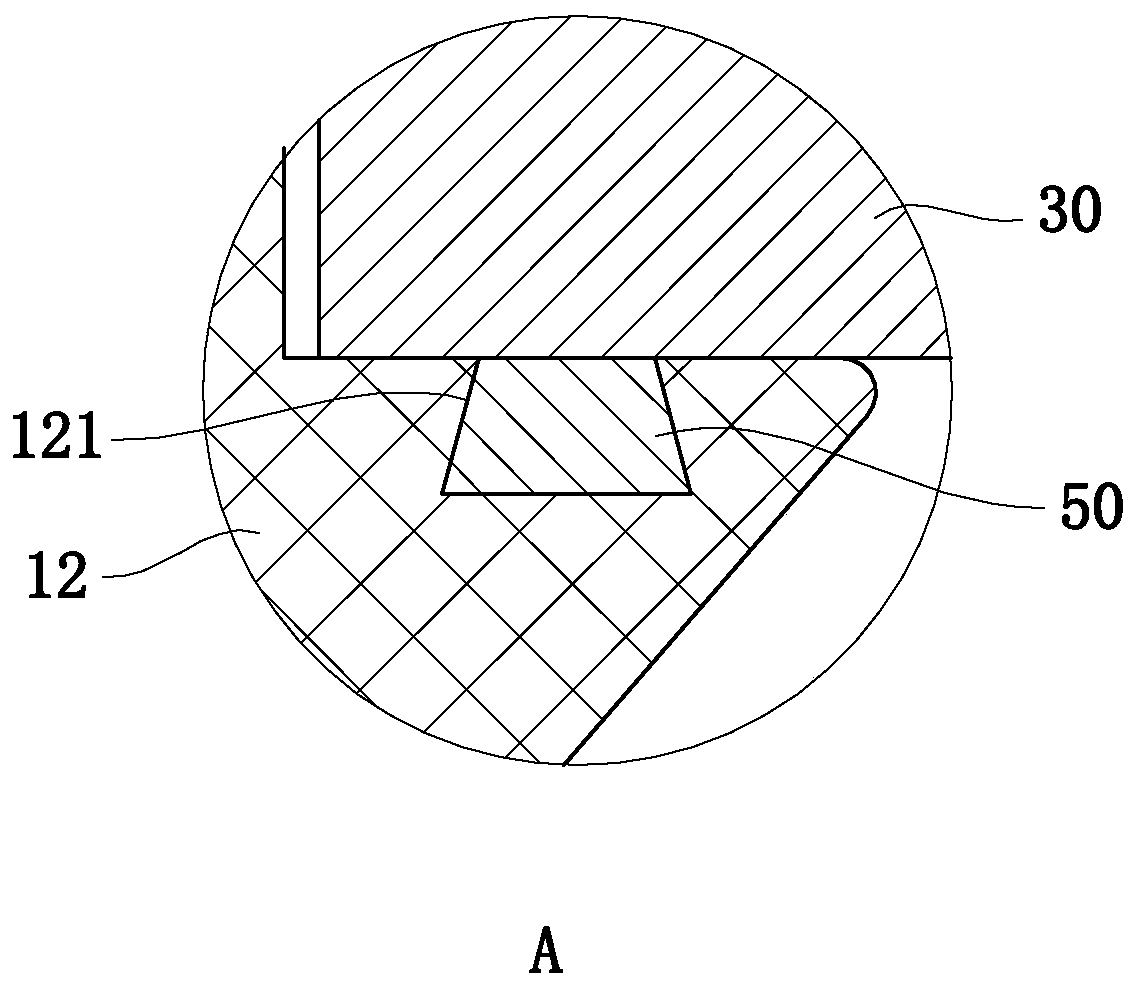

[0049] refer to figure 1 , shows a structure of a diffusion device, including a diffusion base 10 , a dielectric glass 30 mounted on the diffusion base 10 and a jacket 40 . The diffusion base 10 includes a tapered wall body 11, a first flange 12 connected to the upper edge of the wall body 11 and a second flange 13 connected to the lower edge of the wall body 11, the first flange 12 and The second flange 13 is arranged in parallel, and the diameter of the first flange 12 is smaller than the diameter of the second flange 13, so that the two form a stepped distribution.

[0050] The wall body 11 encloses a diffusion port 14 in its interior. The cross-sectional area of the diffusion port 14 increases uniformly from one side of the first flange 12 toward the second flange 13. The entire diffusion port 14 has a Taper, taper α is between 130°~140°, preferably 135°.

[0051] A plurality of air holes 111 are also provided on the wall body 11, and one end of the air holes 111 commu...

Embodiment 2

[0063] refer to Figure 4 , a microwave plasma reactor for producing single crystal diamond, comprising the diffusion device of Embodiment 1 and a plasma chamber 60 connected to the diffusion device. The diffusion device is connected to the plasma chamber 60 through the second flange 13 , and the entire diffusion device is above the plasma chamber 60 .

[0064] There is a resonant cavity 61 inside the plasma chamber 60 , the diffusion port 14 communicates with the resonant cavity 61 , a base 62 is provided at the bottom of the resonant cavity 61 , and the seed crystal is placed on the base 62 . Wherein, the resonant cavity 61 is cylindrical, and the base 62 is located at the center of the resonant cavity 61 and at the axis of the diffusion port 14 . The bottom of the resonant cavity 61 is also connected with a plurality of gas outlet pipes 63 for circulating and exhausting the mixed gas.

[0065] During work, the air cavity 15 is filled with mixed gas through the intake pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com