Spray device capable of meeting desulfurization towers under different working conditions of CFB (circulating fluidized bed) boiler

A technology of spraying device and desulfurization tower, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., which can solve the problem that the water from the nozzle cannot completely cover all the space in the tower, which affects the safe operation and service life of the desulfurization tower. Unscientific layer layout and other problems, to achieve the effects of strong adaptability to flue gas changes, convenient operation, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

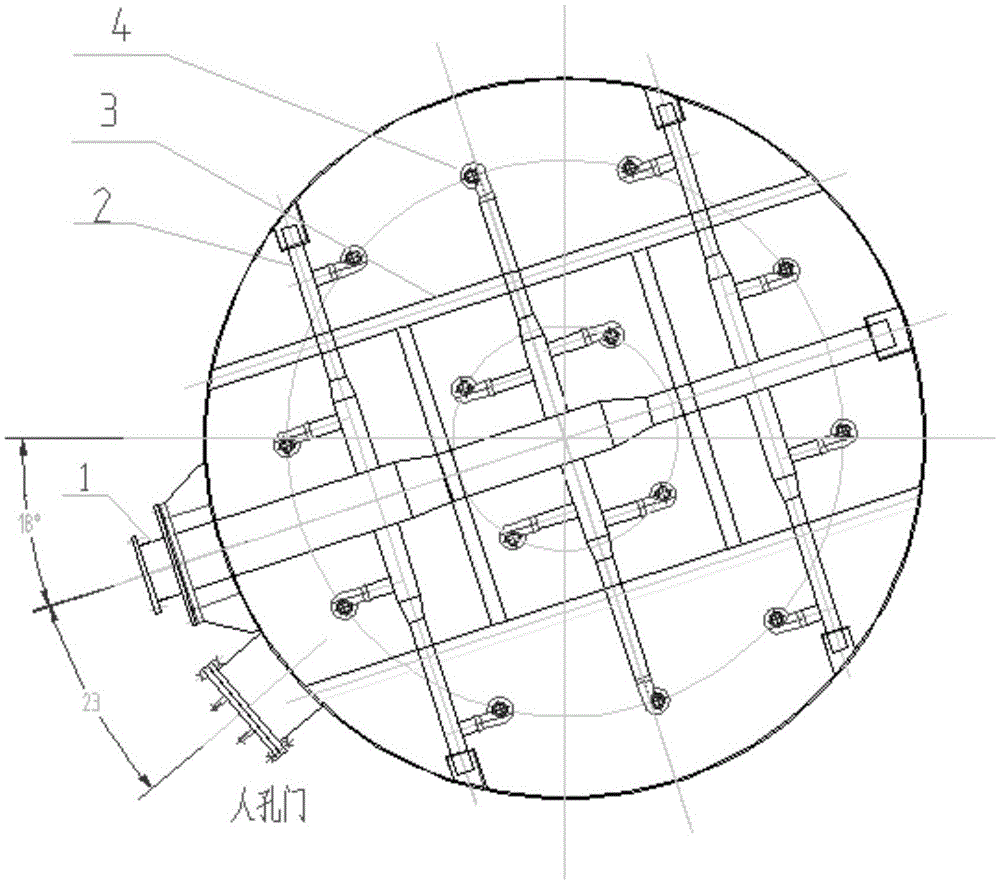

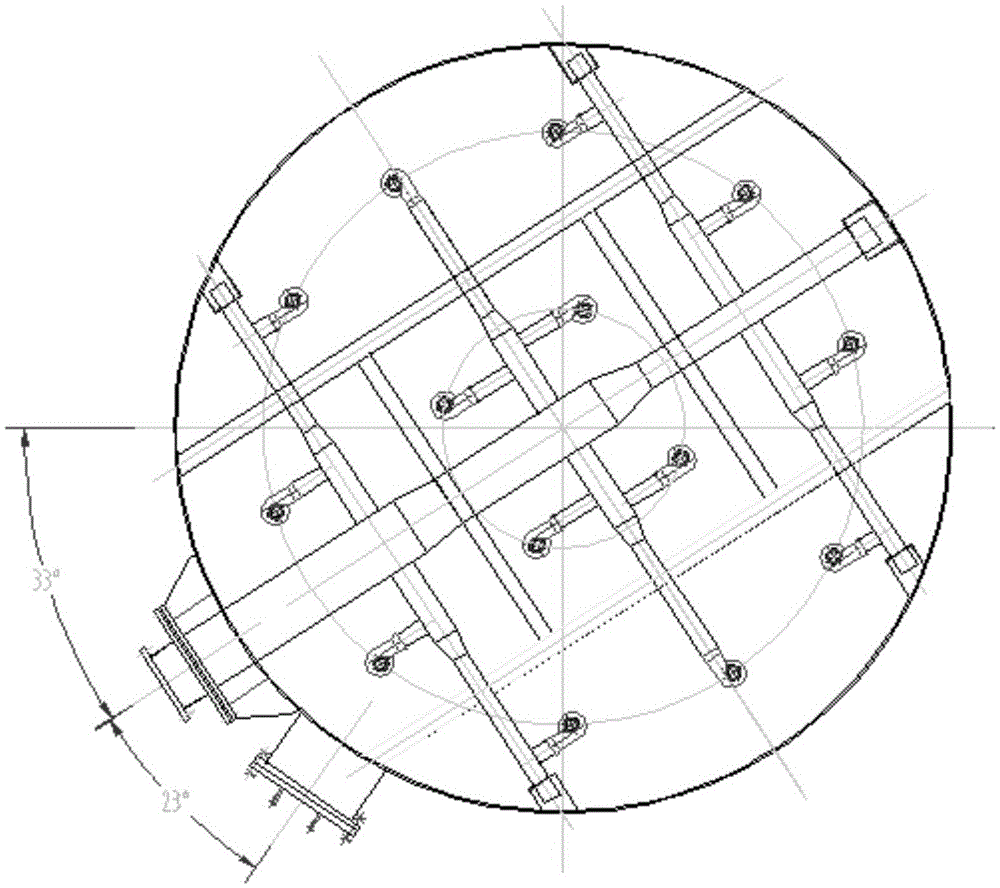

[0018] A spraying device that can satisfy the desulfurization tower under different working conditions of CFB boilers. The spray layer contains a main water inlet pipe, six branch pipes, and a load-bearing beam for fixing; the main water inlet pipe is a variable-diameter pipe, and is Pipelines that have undergone two diameter reductions; two branch pipes are set on each pipe with different diameters, and sprinklers are installed on the branch pipes; the sprinklers are symmetrically distributed with the main water inlet pipe as the center line; figure 1 As shown, the number of sprinklers is 14, which are divided into inner circle and outer circle and arranged symmetrically. There are 4 sprinkler heads in the inner circle and 10 sprinkler heads in the outer circle. The load-bearing beam is fixedly connected with the spray tower wall;

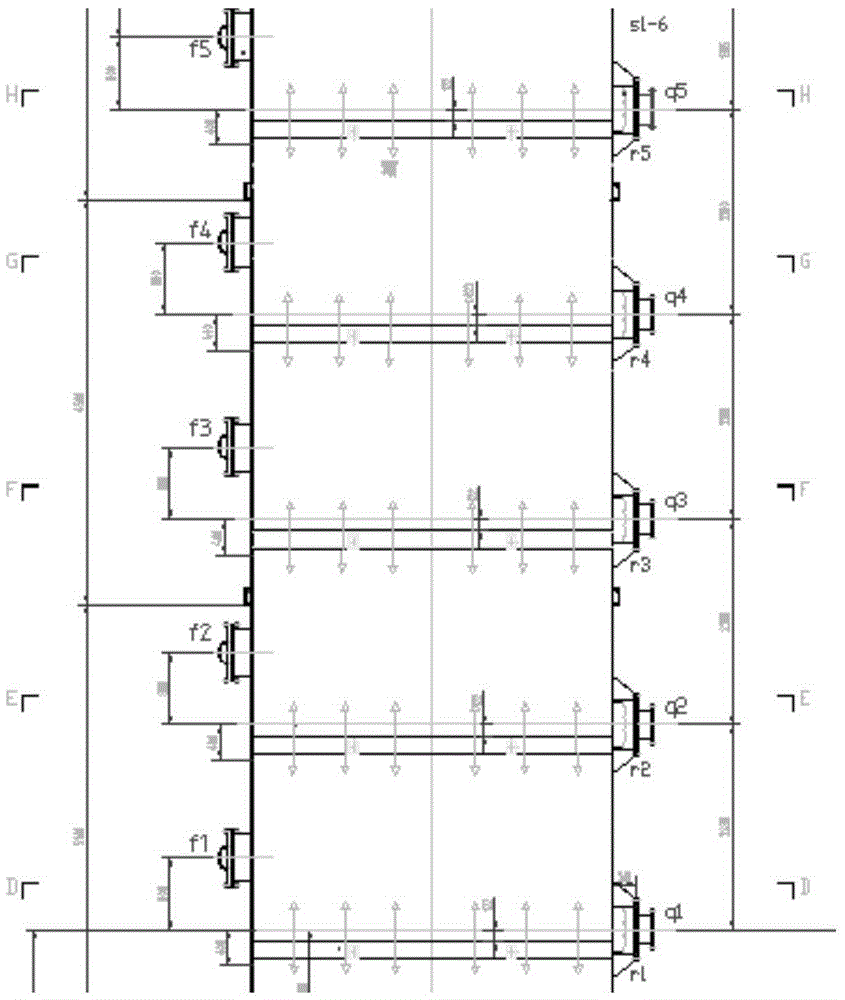

[0019] Such as figure 2 As shown, 5 spray layers are fixed in the spray tower, named respectively as the first spray layer, the second spray lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com