Method for extracting refined gold from palladium-silver-containing anode mud

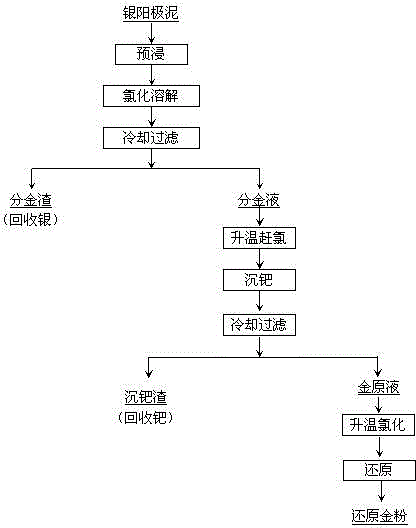

An anode slime and palladium-silver technology is applied in the field of purifying gold from high-palladium-silver anode slime, which can solve the problems of increased material return, low gold direct yield, and reduced gold reduction rate, and achieves short process structure and fast reaction. Efficient and responsive environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) First put 200kg of palladium-containing 4% silver anode slime into a 1000L glass-lined reactor for hydrochloric acid pre-soaking to remove impurities. The liquid-solid ratio is 3:1, the concentration of hydrochloric acid is 2.5mol / L, the temperature is 75°C, and the reaction time is 3h , filter after completion of the reaction, the filtrate is discharged, and the filter cake is prepreg, weighing 180kg.

[0020] (2) Dissolve the prepreg slag in aqueous solution by chlorination, the liquid-solid ratio is 5:1, the concentration of hydrochloric acid is 2.8mol / L, the temperature is 85°C, the dissolution time is 8h, after the reaction is completed, filter, and the filtrate contains 8.2g / L palladium The gold separation solution, the filter cake is silver chloride slag, and the silver chloride slag is reduced by iron powder and returned to the previous process for processing.

[0021] (3) Raise the temperature of the gold separation solution to 80°C to catch chlorine, react...

Embodiment 2

[0025] (1) First put 250kg of palladium-containing 4.2% silver anode slime into a 1000L glass-lined reactor for hydrochloric acid pre-soaking to remove impurities. The liquid-solid ratio is 3:1, the concentration of hydrochloric acid is 2.5mol / L, the temperature is 75°C, and the reaction time is 4h , filter after completion of the reaction, the filtrate is discharged, and the filter cake is prepreg, weighing 220kg.

[0026] (2) Dissolve the prepreg slag in an aqueous solution with a liquid-to-solid ratio of 4:1, a hydrochloric acid concentration of 2.9mol / L, a temperature of 85°C, and a dissolution time of 10 hours. After the reaction is completed, filter and the filtrate contains palladium at a rate of 10.6g / L. The gold separation solution, the filter cake is silver chloride slag, and the silver chloride slag is reduced by iron powder and returned to the previous process for processing.

[0027] (3) Raise the temperature of the gold separation solution to 85°C to catch chlori...

Embodiment 3

[0031] (1) First put 150kg of palladium-containing 3.5% silver anode sludge into a 1000L glass-lined reactor for hydrochloric acid pre-soaking to remove impurities. The liquid-solid ratio is 4:1, the concentration of hydrochloric acid is 2mol / L, the temperature is 80°C, and the reaction time is 5h. After the reaction is completed, filter, and the filtrate is discharged, and the filter cake is prepreg, weighing 130kg.

[0032] (2) Dissolve the prepreg slag in an aqueous solution with a liquid-solid ratio of 6:1, a hydrochloric acid concentration of 2.9mol / L, a temperature of 90°C, and a dissolution time of 10 hours. After the reaction is completed, filter and the filtrate contains 6.6g / L of palladium. Gold separation liquid, the filter cake is silver chloride slag, and the silver chloride slag is reduced by iron powder and returned to the previous process for processing.

[0033] (3) Warm up the gold separation solution to 90°C for chlorine removal, react for 1 hour, then add d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com