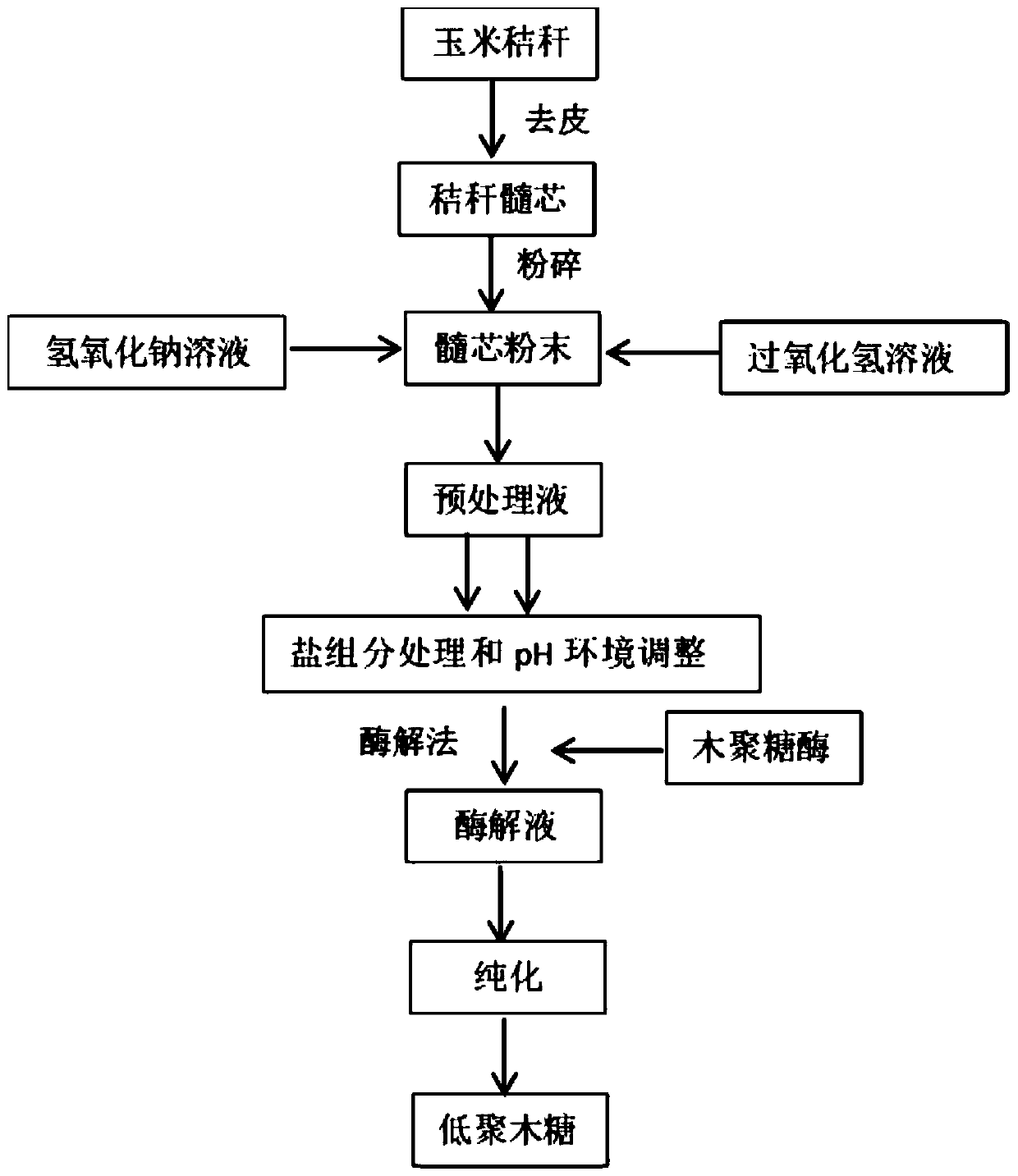

Method for preparing xylooligosaccharide by using corn straw cores

A corn stover and xylo-oligosaccharide technology, which is applied in the field of xylo-oligosaccharides, can solve the problems of high equipment requirements, cumbersome processes, and reduce the yield of xylo-oligosaccharides, and achieves that the equipment requirements are not strict, the operation process is simple and convenient. The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Selecting dry, mold-free corn stalks for dehulling and peeling to obtain corn stalk pith, cutting the pith into small pieces and pulverizing into powder with a grinder for later use.

[0032] 2) Take the crushed corn stalk pith core powder, add 0.5% hydrogen peroxide solution with a mass fraction of 0.5% sodium hydroxide solution according to the solid-liquid ratio of 1:10 (g / mL), and adjust the pH value to 11. The reaction temperature is 60°C, and the reaction time is 2 hours. Suction filtration was carried out after the reaction, and the filtrate was collected to obtain a pretreatment liquid.

[0033] 3) Desalting and pH adjustment of the pretreatment solution in step 2): use 732 type cation exchange resin and D301-FD type anion exchange resin in series, the volume ratio of anion and cation resins is 2:1, and the operating temperature is 50 °C, the pH is 6.0, and the time is 60 minutes.

[0034] 4) Evaporate the solution to one-third of the original volume with a...

Embodiment 2

[0039] 1) Selecting dry, mold-free corn stalks for dehulling and peeling to obtain corn stalk pith, cutting the pith into small pieces and pulverizing into powder with a grinder for later use.

[0040] 2) Take the pulverized corn stalk core powder, add 1.5% hydrogen peroxide solution with a mass fraction of 1.5% sodium hydroxide solution according to the solid-liquid ratio of 1:20 (g / mL), and adjust the pH value to 11.6, the reaction temperature is 70°C, and the reaction time is 4h. Suction filtration was carried out after the reaction, and the filtrate was collected to obtain a pretreatment liquid.

[0041] 3) Desalting and pH adjustment of the pretreatment solution in step 2): use 732 type cation exchange resin and D301-FD type anion exchange resin in series, the volume ratio of anion and cation resins is 2:1, and the operating temperature is 50 °C, the pH is 6.0, and the time is 60 minutes.

[0042] 4) Rotate the solution in step 2) with a rotary evaporator, evaporate the...

Embodiment 3

[0047] 1) Selecting dry, mold-free corn stalks for dehulling and peeling to obtain corn stalk pith, cutting the pith into small pieces and pulverizing into powder with a grinder for later use.

[0048] 2) Take the pulverized corn stalk pith core powder, add a 2% hydrogen peroxide solution with a mass fraction of 2% according to the solid-liquid ratio of 1:25, adjust the pH value to 11.6 with a 2% sodium hydroxide solution, and react The temperature is 75°C and the reaction time is 4h. Suction filtration was carried out after the reaction, and the filtrate was collected to obtain a pretreatment liquid.

[0049]3) Desalting and pH adjustment of the pretreatment solution in step 2): use 732 type cation exchange resin and D301-FD type anion exchange resin in series, the volume ratio of anion and cation resins is 2:1, and the operating temperature is 50 °C, the pH is 6.0, and the time is 60 minutes.

[0050] 4) Rotate the solution in step 3) with a rotary evaporator, evaporate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com