Modified Y type molecular sieve and preparation method thereof

A molecular sieve and modification technology, used in molecular sieve catalysts, chemical instruments and methods, hydrocarbon oil cracking, etc., can solve the problems of large damage to molecular sieve channel structure and skeleton structure, complicated processing process, etc., to improve the modification effect, The effect of improving the reaction environment and simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

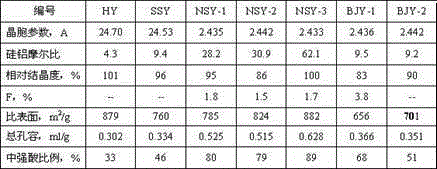

Examples

preparation example Construction

[0029] The preparation method of modified Y molecular sieve of the present invention specifically comprises the following steps:

[0030] (1) Preparation of fluorine-containing silicon solution such as ammonium fluorosilicate aqueous solution: take ammonium fluorosilicate and gradually add it to stirred distilled water at a temperature of 30-60°C until the crystals are completely dissolved. After filtration, a clear, transparent and stable solution is prepared. ammonium fluorosilicate solution.

[0031] (2) Take the industrial SSY molecular sieve, put it into the spray immersion tank, and spray the measured mixed solution of fluorine-containing and silicon-containing compounds onto the surface of the molecular sieve; after the spray immersion, it will undergo 30-240 minutes of health preservation, so that the solution can overcome the capillary phenomenon and surface tension are uniformly dispersed on the surface of the molecular sieve; then drying treatment is carried out at ...

Embodiment 1

[0036] (1) Prepare ammonium fluorosilicate aqueous solution, the temperature of the aqueous solution is 35°C, the mass concentration of ammonium fluorosilicate in the aqueous solution is 0.3%, and the molar ratio of fluorine to silicon is 1:3;

[0037] (2) Take the industrially produced SSY molecular sieve, spray and dip the ammonium fluorosilicate aqueous solution prepared in step (1), the spray dipping amount is 200% of the mass of the treated molecular sieve, after 50 minutes of health preservation, dry at a temperature of 150 °C, the drying time For 200min, the dried Y molecular sieve is subjected to hydrothermal treatment, the treatment temperature is 450°C, the water vapor pressure is 0.8MPa, and the hydrothermal treatment time is 50min;

[0038] (3) After the hydrothermal treatment, the molecular sieve was treated in a dilute acid solution with a concentration of 0.5mol / L for 50 minutes, and after solid-liquid separation, the filter cake was washed to neutrality, and the...

Embodiment 2

[0040] (1) Prepare an aqueous solution of ethyl orthosilicate and ammonium fluoroborate, the temperature of the aqueous solution is 55°C, the mass concentration of ammonium fluoroborate in the aqueous solution is 3.6%, and the molar ratio of fluorine to silicon is 3:1;

[0041] (2) Take the industrially produced HY molecular sieve, spray and dip the aqueous solution containing fluorine and silicon prepared in step (1), the spray dipping amount is 40%, after 200 minutes of health preservation, dry at a temperature of 80°C for 40 minutes, The dried Y molecular sieve is subjected to hydrothermal treatment, the treatment temperature is 600°C, the water vapor pressure is 0.1MPa, and the hydrothermal treatment time is 200min;

[0042] (3) After the hydrothermal treatment, the molecular sieve was treated in a dilute acid solution with a concentration of 1.5mol / L for 200 minutes, and after solid-liquid separation, the filter cake was washed to neutrality, and the filter cake was dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com