Device for culturing biological flocculating constituent by use of solid waste of aquaculture

A solid waste and aquaculture technology, applied in the fields of application, food science, feed, etc., can solve the problems of consumption, oxygen consumption, and high turbidity of aquaculture water, so as to improve the reaction environment, improve the quality of culture, and solve the problem of suspension mixing. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

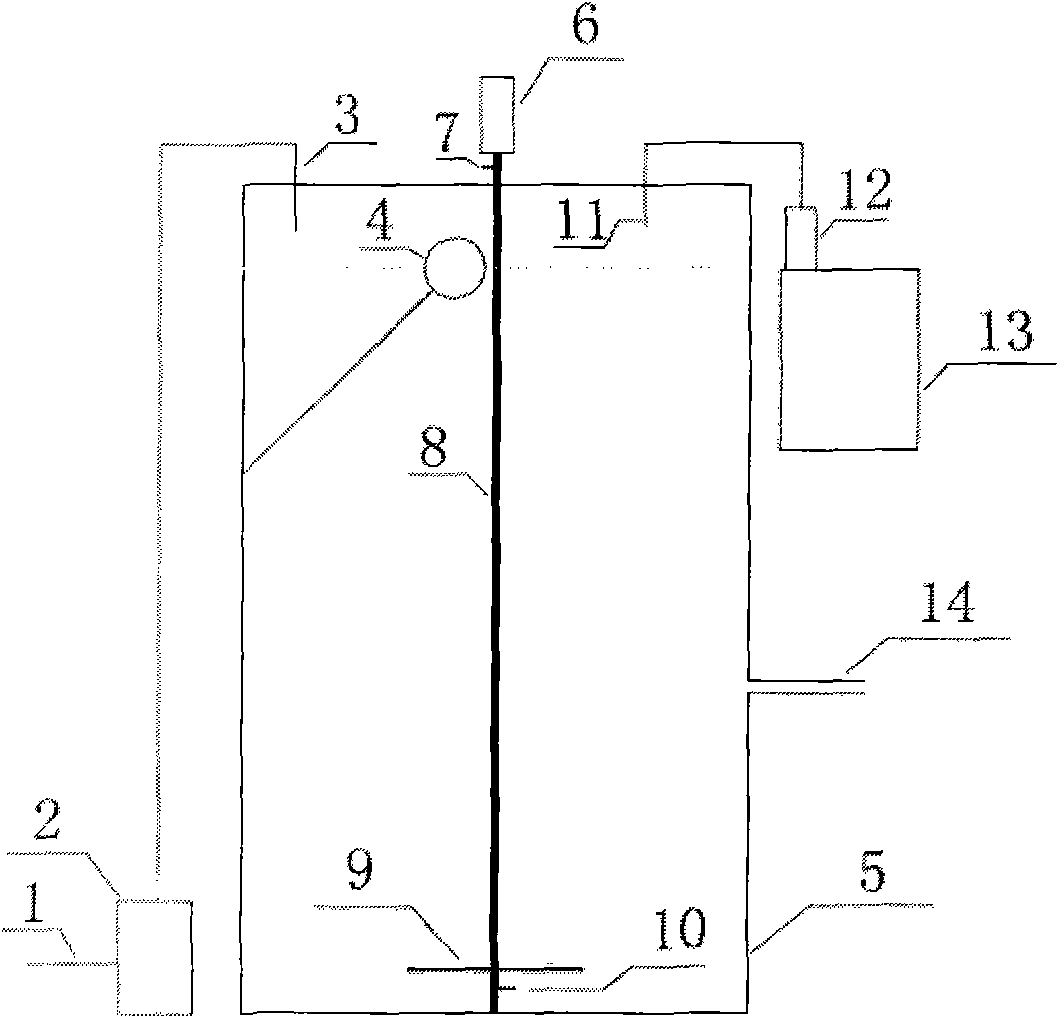

[0010] The present invention (referring to accompanying drawing) is made up of culture tank 5, feeding pump 2, float level switch 4, mixer 6, dosing pump 12, and described culture tank preferably adopts the circular shape of diameter 1.2m, high 2.0m. For glass fiber reinforced plastic tanks or tanks made of other materials with similar dimensions and specifications, a feed port 3 and a dosing port 11 are arranged on the top of the circular glass steel tank, the feed port is connected to the feed pump, and the dosing port is connected to the dosing pump; A discharge port 14 is set at a depth of 0.8m on the side wall of the circular fiberglass water tank; a mixer is installed on the top of the circular fiberglass water tank, and the axis of the mixer coincides with the central axis of the culture tank; the filling depth of organic solid waste in the circular fiberglass water tank is 1.8m;

[0011] The feed pump 2 is a general-purpose submersible sludge pump, and the feed pump sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com