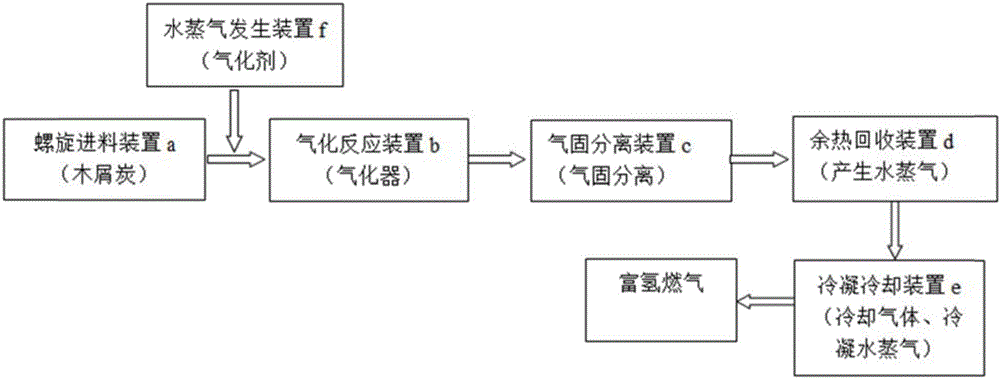

Method and device for preparing hydrogen-enriched fuel gas through sawdust charcoal gasification by high-temperature water vapor

A technology of high-temperature water vapor and water vapor, applied in the field of biomass gasification, to achieve the effect of saving hydrogen production costs and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

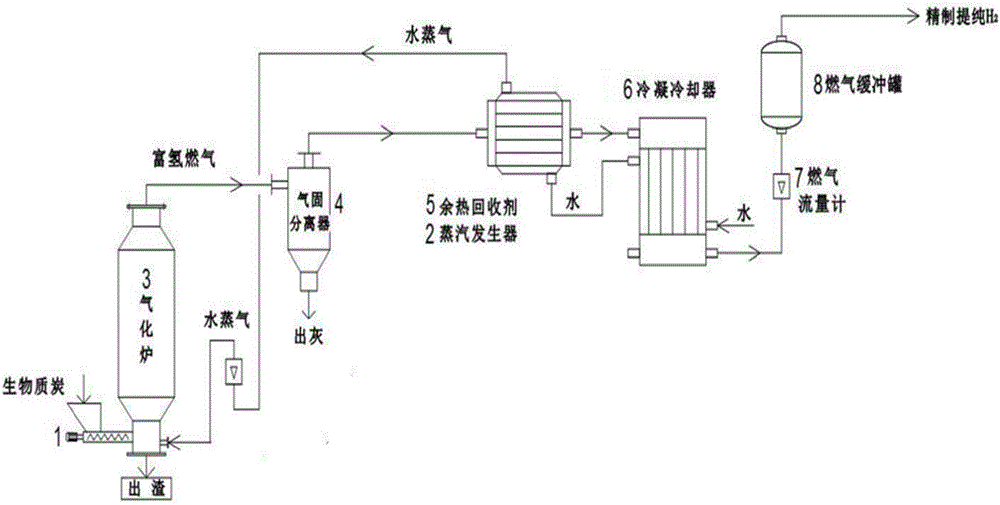

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Using sawdust charcoal less than 0.56 mm in size as the raw material, check the system connection before starting the experiment, and check the air tightness of the system by purging with nitrogen. At the beginning of the experiment, first set a heating rate of 10°C / min to raise the temperature of the gasifier to 850°C, turn on the steam generator, and output the required flow rate of reaction steam stably. After the system is stable, the screw feeding device will be turned on to transport the sawdust charcoal to the gasifier. The gasification reaction will be stable and the steam generator will be turned off, and the waste heat recovery device will provide the water vapor required for the reaction.

[0024] The main reactions that take place in the gasifier furnace are as follows:

[0025] C+H 2 O→CO+H 2

[0026] CO+H 2 O→CO 2 +H 2

[0027] C+CO 2 →2CO

[0028] The three reactions are all endothermic reactions, and the H 2 output.

[0029] After t...

Embodiment 2

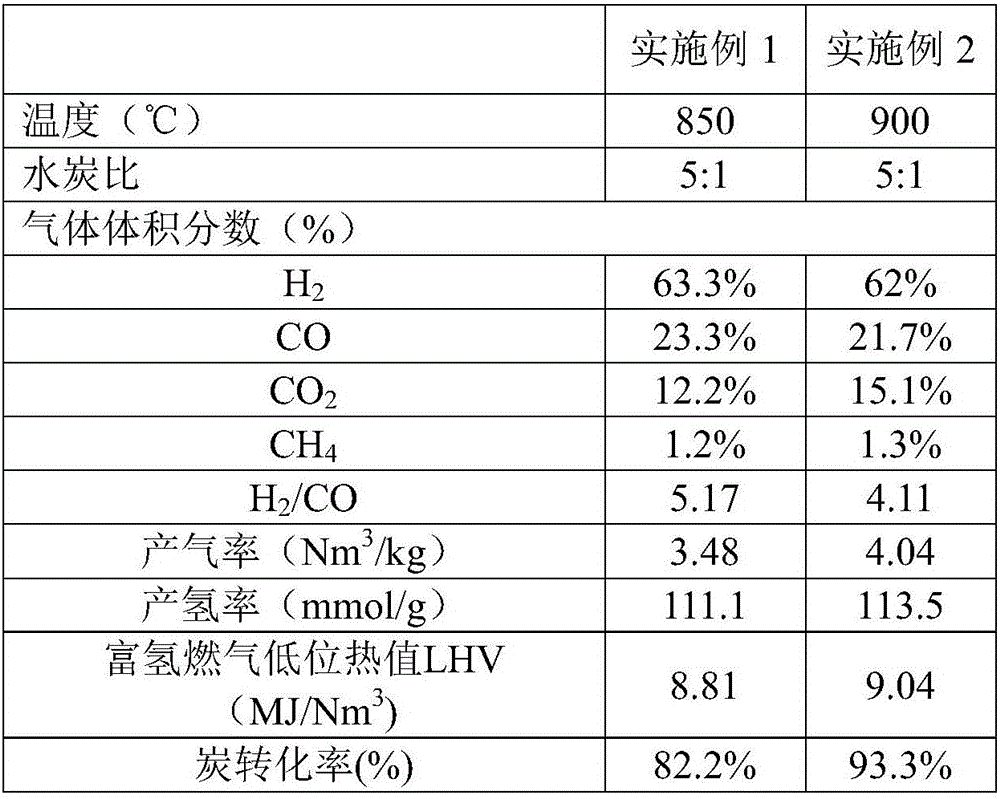

[0030] Example 2: The gasification reaction temperature is 900° C., the implementation process is the same as in Example 1, and the experimental results are shown in Table 1.

[0031] Table 1 Water vapor gasification results of sawdust charcoal at 850°C and 900°C

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com