Device for preparing hydrogen through hydrolysis

A technology of hydrolysis hydrogen production and hydrolysis reactor, applied in the direction of hydrogen production, etc., can solve the problems of difficult regeneration and recycling of reaction by-products, poor stability of hydrogen storage fuel solution, short service life of catalysts, etc., and achieve fast and convenient hydrogen production The effect of promotion application and controllable rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

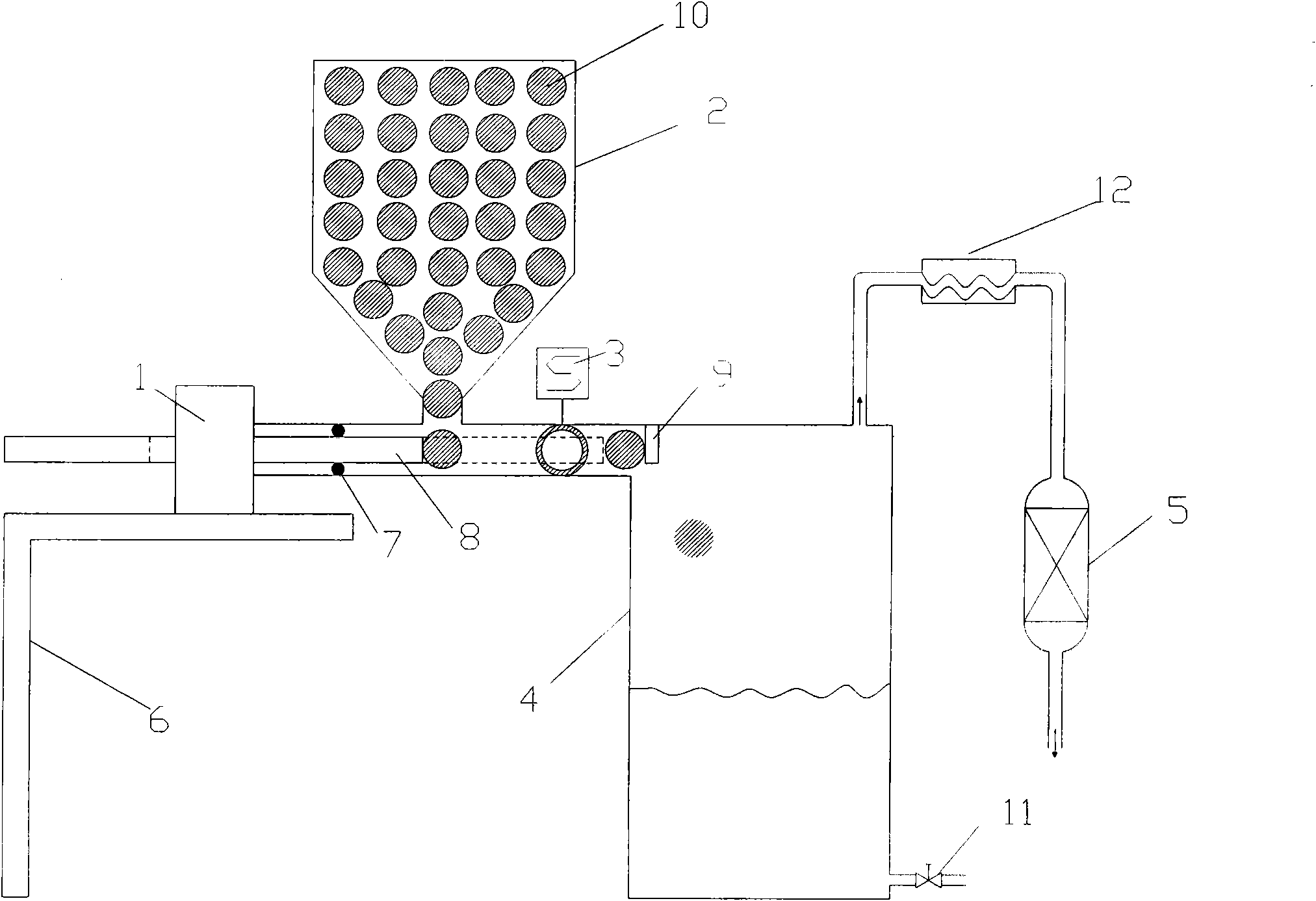

[0025] See attached figure 1 .

[0026] A hydrolysis hydrogen production device, which is composed of a storage tank 2, a reactor 4, a condenser 12 and a dryer 5, and is characterized in that the storage tank 2 stores solid reaction materials, and the storage tank 2 is connected with a driving mechanism 1, which drives Mechanism 1 communicates with hydrolysis reactor 4 . The storage tank 2 stores the solid reaction material as containing LiBH 4 , NaBH 4 and NH 3 BH 3 Capsules of three mixtures of 10. The driving mechanism 1 is fixed on the bracket 6, and the driving mechanism 1 is a cylinder piston, and a sealing O-ring 7 is installed at the front end of the push rod 8 of the cylinder piston. The driving mechanism pushes the solid reaction material capsule 10 into the hydrolysis reactor to produce hydrogen.

[0027] The upper part of the hydrolysis reactor 4 is located at the drive mechanism connected to the reactor inlet and is equipped with a solid reaction material c...

Embodiment 2

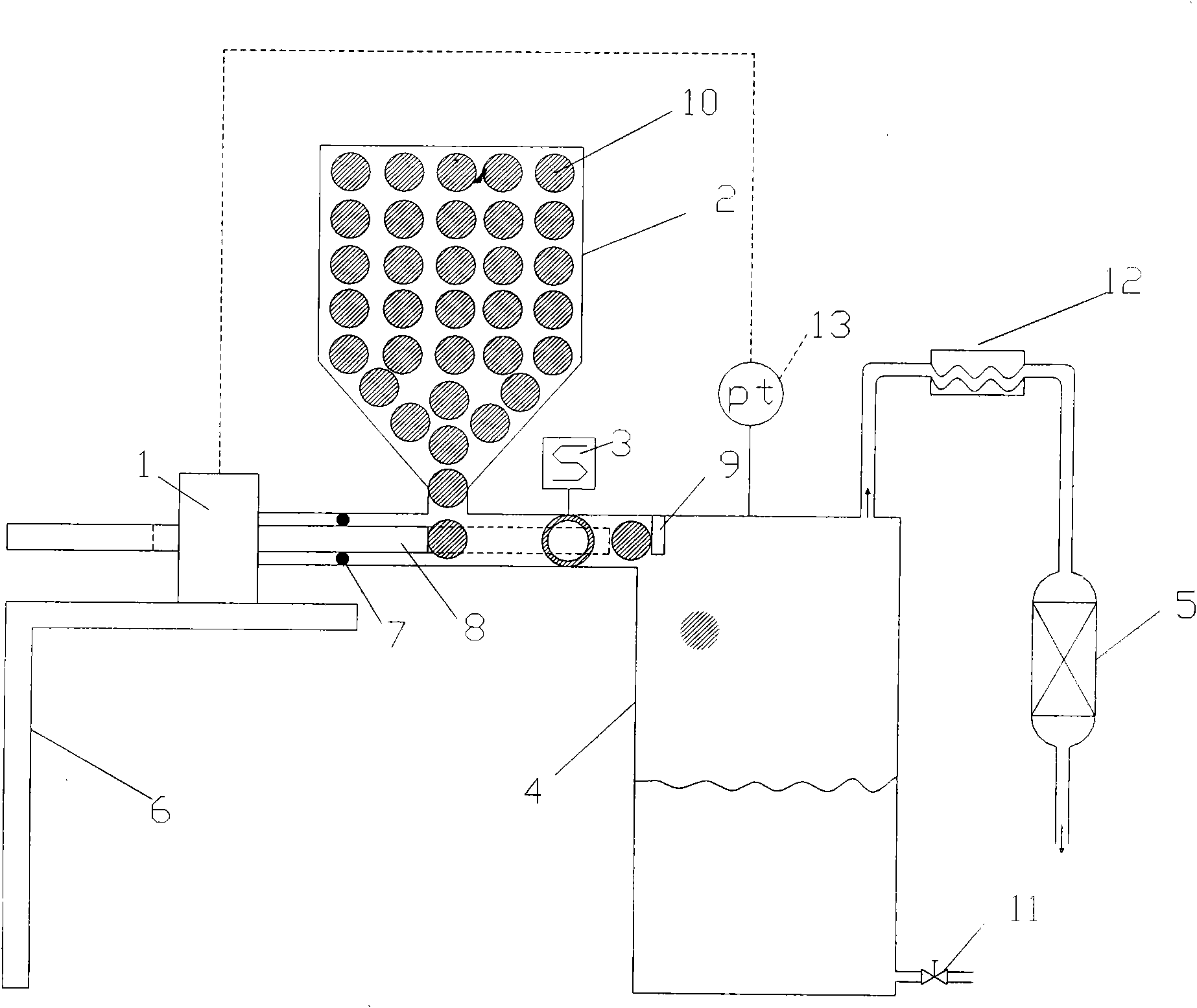

[0029] See attached figure 2 .

[0030] A hydrolysis hydrogen production device, which is composed of a storage tank 2, a reactor 4, a condenser 12 and a dryer 5, and is characterized in that the storage tank 2 stores solid reaction materials, and the storage tank 2 is connected with a driving mechanism 1, which drives Mechanism 1 communicates with hydrolysis reactor 4 . The storage tank 2 stores the solid reaction material as containing LiBH 4 , NaBH 4 and NH 3 BH 3 Three blends of 10 capsules. The driving mechanism 1 is fixed on the bracket 6, and the driving mechanism 1 is a cylinder piston, and a sealing O-ring 7 is installed at the front end of the push rod 8 of the cylinder piston. The driving mechanism pushes the solid reaction material capsule 10 into the hydrolysis reactor to produce hydrogen. The hydrolysis reactor 4, the cold cooler 12 and the drier 5 are equivalent to embodiment 1.

[0031] The characteristic of this embodiment is that the driving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com