Method for improving hydrogen recovery rate

A recovery rate and hydrogen technology, applied in hydrogen separation, using solid contact hydrogen separation, etc., can solve the problems of large investment and high energy consumption in cryogenic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw gas composition

[0036] FCC dry gas

[0037] composition

H 2

CH 4

C 2

C 3

C 4

CO

CO 2

O 2

N 2

V%

45.00

15.50

14.33

1.40

0.25

1.29

3.38

0.45

18.4

[0038] The feed gas is firstly dewatered by the gas-liquid separator under the pressure of ~1.5MPa, and then enters a membrane separation device.

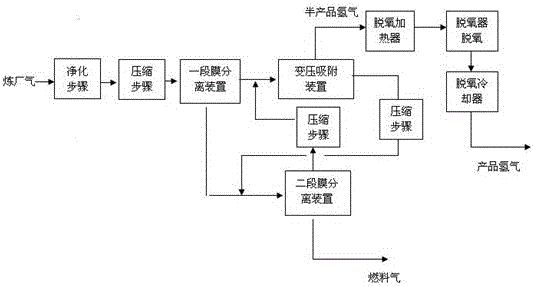

[0039] One-stage membrane separation device: hydrogen gas passes through the membrane to form permeate gas (hydrogen-containing gas), and the hydrogen-containing gas enters the pressure swing adsorption device for pressure swing adsorption hydrogen separation. The retentate gas that fails to pass through the membrane directly enters the second-stage membrane separation system.

[0040] The permeated gas after membrane separation enters the pressure swing adsorption device at a pressure of ~0.6MPa and a temperature of ≤40°C. In the pressure swing adsorption system, there is a ...

Embodiment 2

[0046] Raw gas composition

[0047] Refinery Gas 1

[0048] composition

H 2

CH 4

C 2 h 6

C 2 h 4

C 3 h 8

C 3 h 6

iC 4

CO 2

O 2

N 2

V%

45.00

14.38

9.63

13.21

1.73

0.21

0.03

0.04

0.29

15.48

[0049] Refinery Gas 2

[0050] composition

H 2

CH 4

C 2 h 6

C 2 h 4

C 3 h 8

C 3 h 6

iC 4

c 4

C 5

CO 2

O 2

N 2

h 2 o

V%

83.65

10.61

1.75

0.00

1.66

0.00

1.09

0.41

0.37

0.00

0.00

0.11

0.35

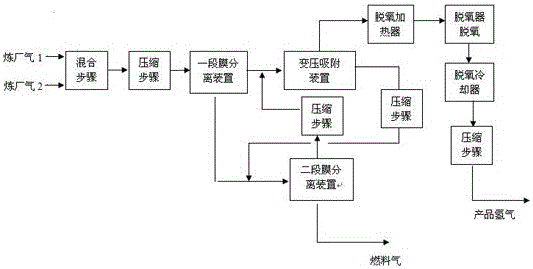

[0051] The mixed purified dry gas after desulfurization catalytic dry gas and low-separation gas enters the first-stage membrane separation device at ~2.0MPa.

[0052] One-stage membrane separation device: After hydrogen passes through the membrane, permeate gas (hydrogen-containing gas) is formed, and the hydrogen-containing gas e...

Embodiment 3

[0058] Raw gas composition

[0059] catalytic dry gas

[0060] composition

H 2

CH 4

C 2 h 6

C 2 h 4

C 3 h 8

C 3 h 6

iC 4

CO 2

O 2

h 2 S

C 5

N 2

V%

26.27

28.33

14.39

14.56

0.18

0.67

0.16

1.42

0.37

≤20ppm

0.04

13.61

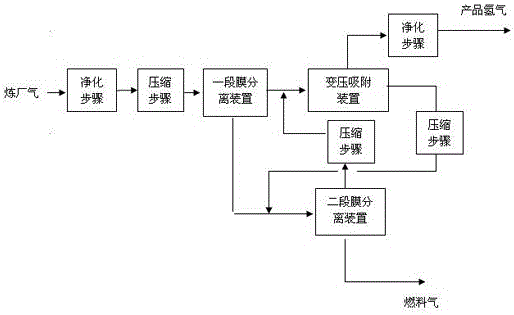

[0061] The raw material gas passes through the gas-liquid separator to remove liquid substances under the pressure of ~2.0MPa, and then enters a membrane separation device.

[0062] One-stage membrane separation device: After hydrogen passes through the membrane, permeate gas (hydrogen-containing gas) is formed, and the hydrogen-containing gas enters the pressure swing adsorption system for pressure swing adsorption hydrogen separation. The gas that fails to pass through the membrane forms the retentate gas and directly enters the second-stage membrane separation system.

[0063] The permeate gas after a stage of membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com